Lattice structure and a device and method for producing same

A grid structure and grid technology, applied in the direction of structural elements, wire nets, building components, etc., can solve problems such as huge manufacturing costs, structural changes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

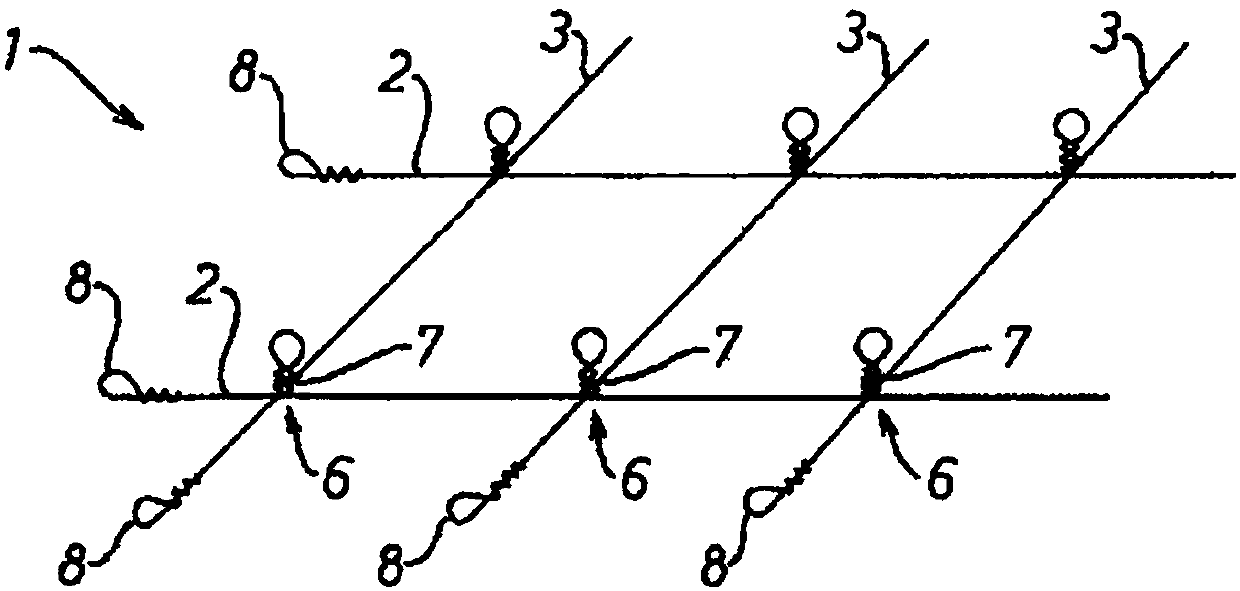

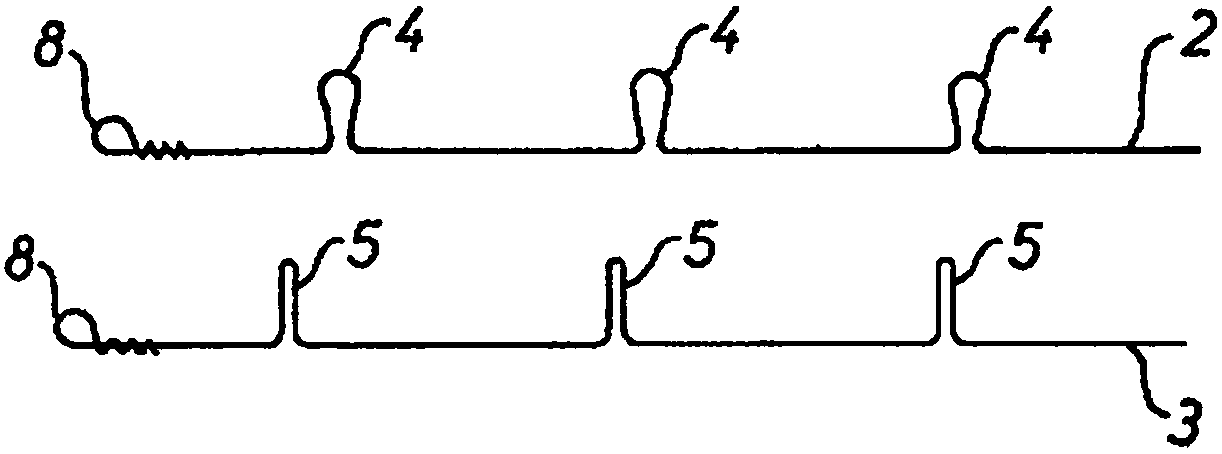

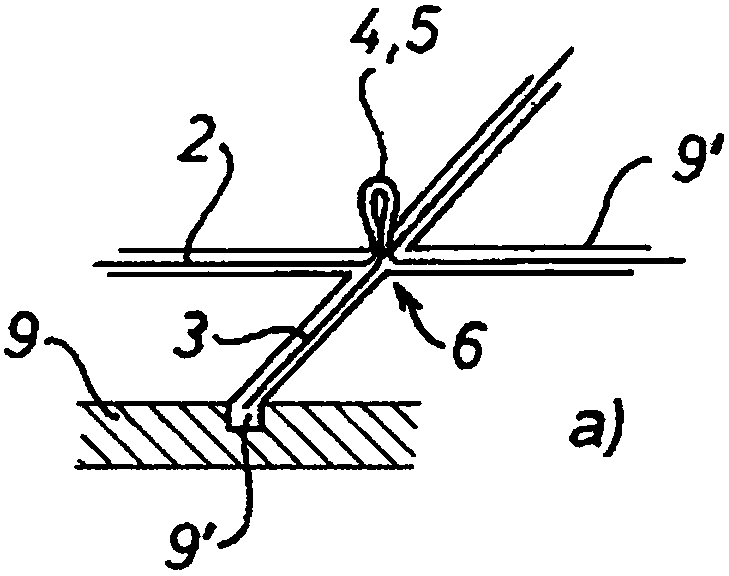

[0026] according to figure 1 The grid structure 1 to FIG. 3 consists of longitudinal elements 2 and transverse elements 3 , preferably made of steel, provided with vertically standing rings 4 and 5 . In particular, these longitudinal and transverse elements are wires, strands, ropes, rods or profiles. However, it can also be a composite product comprising steel and synthetic material and / or synthetic product and also a sandwich element thereof.

[0027] Furthermore, the transverse elements may have different dimensions and may be made of different materials and / or have different properties, eg different strength, than the longitudinal elements.

[0028] Such a grid structure 1 is suitable for various applications in the fields of reinforcement, protection and / or immobilization. Such grid structures could be embedded and / or used in concrete or asphalt for reinforcement, for example, in mining or similar applications for armor.

[0029] However, it may also be suitable for ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com