Adhesive sheet

A technology of adhesive sheets and adhesive layers, applied in the direction of adhesives, adhesive types, heat-activated films/sheets, etc., can solve the problem of reduced bonding strength, reduced heat-resistant bonding strength, and filling of concave-convex adherends Poor thermal conductivity and other problems, to achieve the effect of balanced characteristics and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

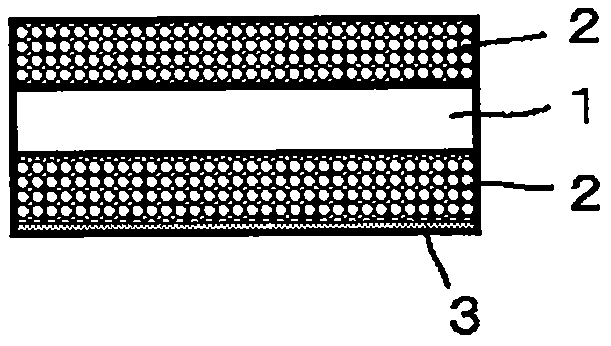

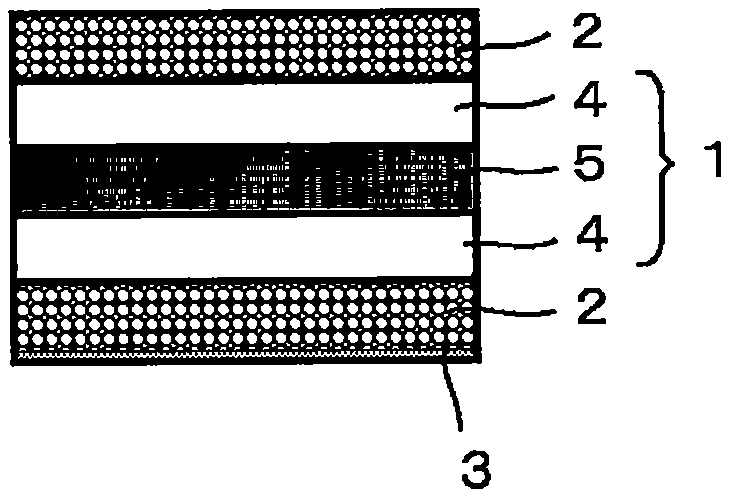

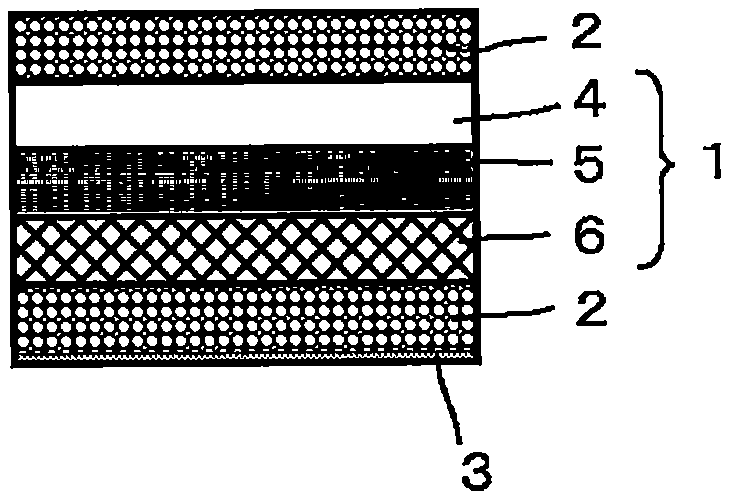

Method used

Image

Examples

Embodiment 1~10

[0165]

[0166] On one side of the substrates K1a to K10, apply an expansive adhesive (mixtures 2 to 3 and 6 to 7) After that, the solvent was removed by drying at 90° C. for 5 minutes to form an expandable adhesive layer. A polyester film with a thickness of 38 μm, one side of which had been subjected to silicone mold release treatment, was pressed on the surface of the expandable adhesive layer with a hot roller heated to 100° C. to obtain a product in the first step. On the other side of the base material of the first process product, apply the same type of expandable adhesive combination so that the thickness after drying is about 35 μm (about 25 μm in Example 8, and about 30 μm in Examples 9 and 10). After that, the solvent was removed by drying at 90° C. for 5 minutes to form an expandable adhesive layer. A polyester film with a thickness of 38 μm, one surface of which was subjected to a silicone release treatment, was pressed on the surface of the expandable adhesive...

Embodiment 11

[0168] Apply an expansive adhesive (combination 8) on one side of a 38 μm silicone heavy release / release treated polyester film so that the thickness after drying is 25 μm, and then dry at 90°C for 5 minutes to remove the solvent and form Expandable adhesive layer. On the surface of the expandable adhesive layer, one side of a silicone light release / release treated polyester film of 38 μm was bonded and wound up to obtain an adhesive sheet of Example 11. When this adhesive sheet is used, the release-treated polyester film on both sides is peeled off, and it is used as a substrate-less adhesive sheet composed only of an expandable adhesive layer.

[0169] The adhesive sheets of Examples 1 to 11, Reference Examples 1 to 3, and Comparative Examples 1 to 2 above were evaluated by the following methods. The results are shown in Tables 3-5.

[0170] [Thickness of adhesive sheet]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| breakdown voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com