PCTFE modified filling composite material and production method thereof

A PCTFE and composite material technology, applied in the field of PCTFE modified filled composite material and its production, can solve the problems of poor plasticization of difficult products, narrow molding temperature range, large melt viscosity, etc., and meet the requirements of processing temperature and holding time. Strict, wide molding temperature range, low melt viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In the first embodiment of the present invention, the percentage by weight of each component of PCTFE modified filled composite material is:

[0020] PCTFE polymer 85%--95%

[0021] Carbon fiber 4.2%--14.2%

[0022] Coupling agent 0.3%--0.8%

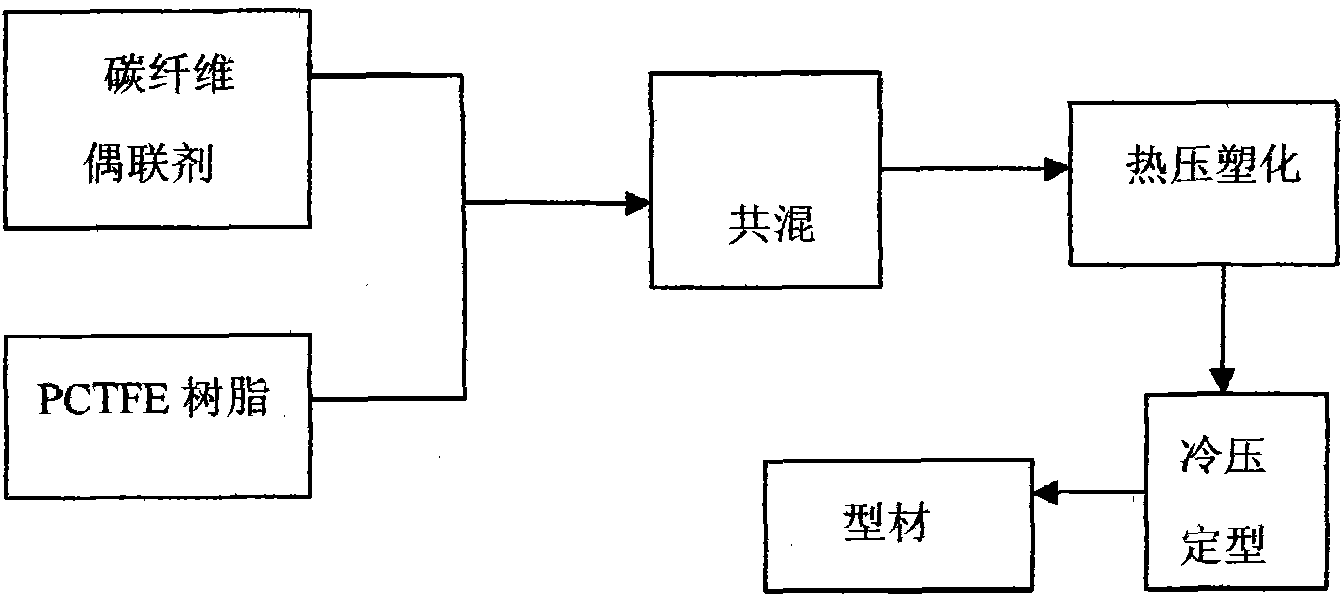

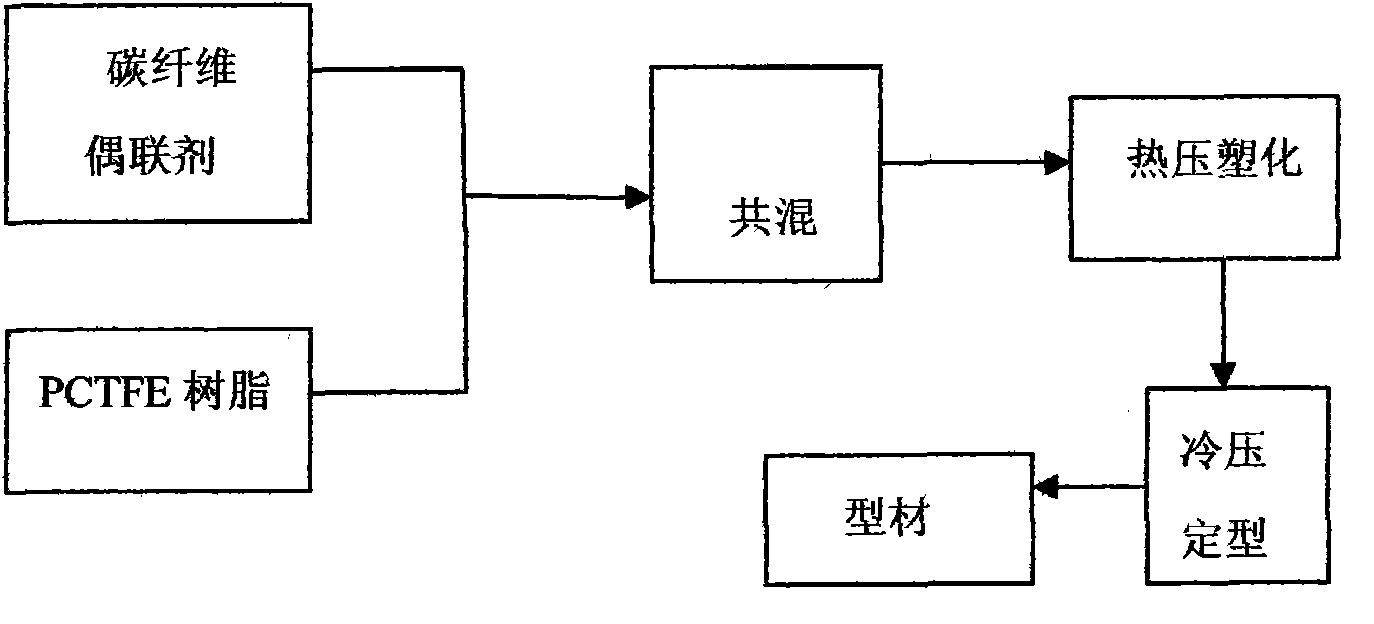

[0023] Referring to accompanying drawing, the production method of the PCTFE modified filling composite material of the first embodiment of the present invention comprises the steps:

[0024] 1. Raw material mixing: mix and stir each component in proportion;

[0025] 2. Extrusion and blending: Extrude with a twin-screw extruder, the screw test diameter ratio is 20:1 or 22:1, and the blending temperature is controlled at: barrel temperature 125°C-140°C, head temperature 145°C- 150°C;

[0026] 3. Heating and plasticizing: Select the corresponding mold according to the profile specifications, weigh the blended raw materials and add them to the prepared mold, and then put the mold into the heating equipment for hot pressing and pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com