Ultrafine talcum powder and polypropylene filling color masterbatch and preparation method thereof

A technology of ultra-fine talc and polypropylene, which is applied in the field of plastic filling masterbatch, can solve the problems of normal discharge of high-speed mixer, difficult temperature control of high-speed mixer, agglomeration and agglomeration, etc., so that the production process is easy to control. , The effect of increasing the bulk density of particles and not easy to dust phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

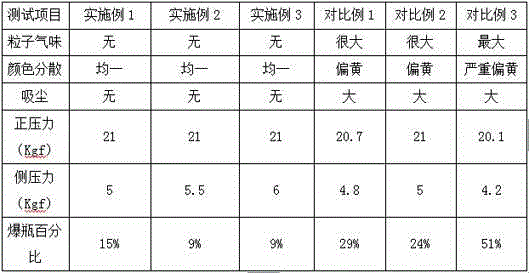

Examples

Embodiment 1

[0033] Put 50% of 3000 mesh superfine talc powder, 4% of titanium dioxide, and 6% of monoglyceride oleate into the mixer and mix at high speed for 3 minutes, then add 38% of homopolypropylene powder and 2% of porous zeolite powder into the mixer Internal high-speed mixing for 2 minutes; put the mixed material into the twin-screw extrusion granulator whose model is SET-100 (the diameter of the twin-screw extrusion granulator of this model is 100mm), and extrude at normal temperature; The raw material is directly fed into the screw barrel of the preheated twin-screw extruder (temperature setting 200°C), extruded, cooled, dried, and granulated to prepare superfine talc powder filled polypropylene masterbatch.

Embodiment 2

[0035] Put 80% of 1500 mesh superfine talc powder, 0.1% of phthalocyanine green, 2% of monoglyceride oleate, 5% of caprylic glyceride into the mixer and mix at high speed for 2 minutes, then add 12% of copolymerized polypropylene powder, porous inorganic silicon Put 0.9% into the mixer and mix at high speed for 2 minutes; put the mixed material into the twin-screw extruder granulator whose model is SET-100 (the diameter of the twin-screw extruder granulator of this model is 100mm), at room temperature Extrusion; feed the extruded material directly into the screw barrel of the preheated twin-screw extruder (temperature setting 220°C), extrude, cool, dry, and granulate to prepare superfine talcum powder filled with polypropylene Masterbatch.

Embodiment 3

[0037]Put 60% of 5000 mesh superfine talc powder, 0.1% of pigment violet, 1% of monoglyceride oleate, and 9% of glyceryl monocaprate into the mixer for 2 minutes at high speed, then add 20% of copolymerized polypropylene powder, Put 8% of homopolypropylene powder and 1.9% of porous ceramic powder into the mixer and mix at high speed for 2 minutes; put the mixed material into the model SET-140 (the diameter of the twin-screw extruder granulator of this model is 140mm) extruded at room temperature; the extruded material is directly fed into the screw barrel of the preheated twin-screw extruder (temperature setting 220°C), extruded, cooled, dried, Granulation to prepare superfine talc powder filled polypropylene masterbatch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com