Chinese medicine residue reinforced reprocessed plastic composite material, and preparation method thereof

A technology of recycled plastics and composite materials, applied in the field of composite materials, it can solve the problems of oxidation, cracks in wood-plastic products, mildew, etc., and achieve the effect of increasing the interface area, increasing the content and improving the performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

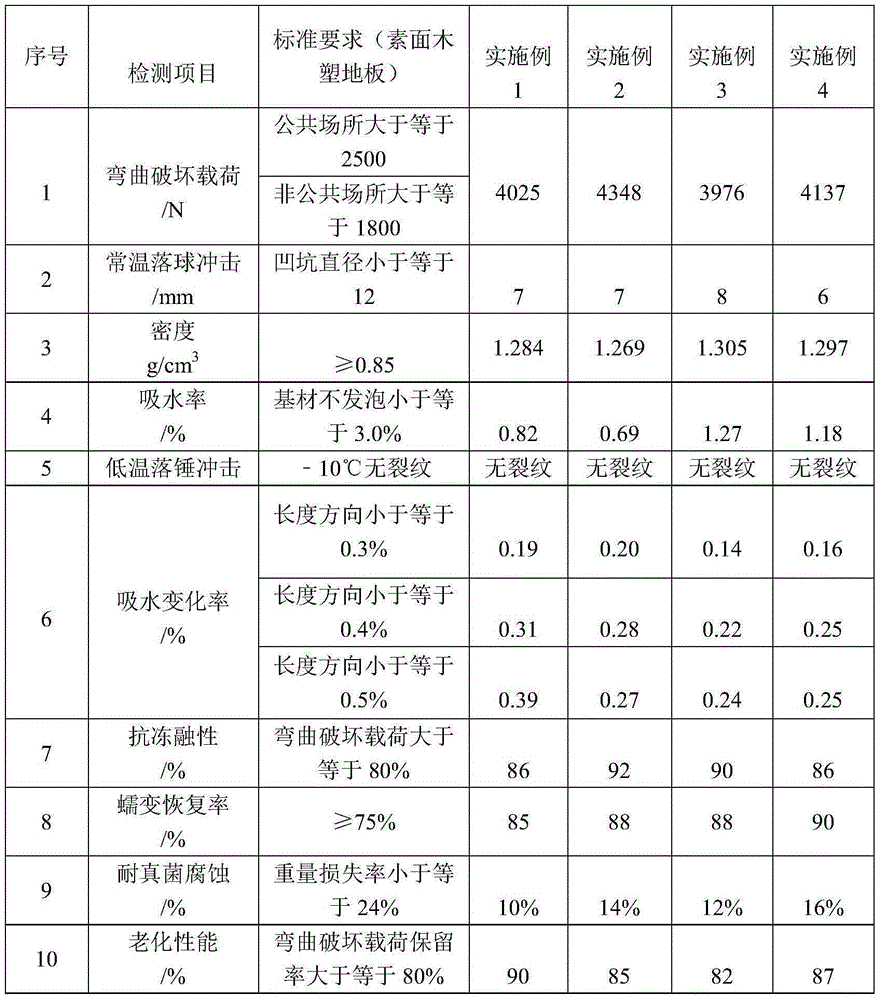

Examples

Embodiment 1

[0038] A kind of licorice dregs reinforced recycled polyethylene composite material is prepared according to the following steps:

[0039] (1) Pretreatment of licorice residue

[0040] The licorice residue was pretreated by steam explosion method. First, pick the licorice dregs, remove impurities, put them into a crusher and crush them into coarsely broken licorice dregs; secondly, soak the above broken licorice dregs in 0.5 mol / L sodium hydroxide aqueous solution for 24 hours Wash to be neutral and dry; then, place the above-mentioned dried licorice residue in a steam blaster, feed steam, stabilize the pressure for 2 minutes at a preset steam pressure of 2.0 MPa, and release the pressure instantly for explosion; finally, collect The blasted traditional Chinese medicine dregs were put into a constant temperature drying box, dried for 24 hours, and then pulverized. After pretreatment, the moisture content of the licorice dregs was 2.38%.

[0041] (2) Modified recycled polyeth...

Embodiment 2

[0052] A kind of Shichangpu medicinal dregs reinforced recycled polypropylene composite material is prepared according to the following steps:

[0053] (1) Pretreatment of Shichangpu medicine dregs

[0054] The medicinal dregs of Acorus calamus were pretreated by steam explosion method. Firstly, pick and remove impurities from Acorus shichangpu, put them into a crusher for crushing, and crush them into coarsely crushed Acorus shichangpu medicine residues; secondly, mix the above crushed shichangpu medicine residues with 1.0 mol / L sodium hydroxide aqueous solution After soaking for 24 hours, it was washed to be neutral and dried; then, the above-mentioned dried Acorus herb residues were placed in a steam blaster, and steam was introduced to stabilize the pressure for 4 minutes at the preset steam pressure of 1.0 MPa, and then the pressure was released and exploded instantly. ; Finally, collect the blasted traditional Chinese medicine dregs, put them into a constant temperature...

Embodiment 3

[0066] A kind of honeysuckle, sophora flavescens, licorice root, notoginseng mixed medicine dregs reinforced recycled polyethylene composite material, prepared according to the following steps:

[0067] (1) Pretreatment of mixed medicinal residues

[0068] The mixed medicinal residues were pretreated by steam explosion method. First, pick the mixed medicinal residues, remove impurities, put them into a crusher and crush them into coarse mixed medicinal residues; secondly, soak the above crushed mixed medicinal residues in 1.0mol / L sodium hydroxide aqueous solution for 24h Wash to be neutral and dry; then, put the above-mentioned dried mixed medicinal residues in a steam blaster, inject steam, and after stabilizing the pressure at the preset steam pressure of 4.0MPa for 10 minutes, release the pressure and explode instantly; finally, collect The blasted traditional Chinese medicine dregs were put into a constant temperature drying box, dried for 24 hours, and then pulverized. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com