Electric wire and cable material and preparation method of same

A technology for wire and cable materials and raw materials, applied in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of insufficient flame retardancy, mechanical strength, toughness and aging resistance, and achieve insulating chemical inactivity. Good high temperature resistance and good aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

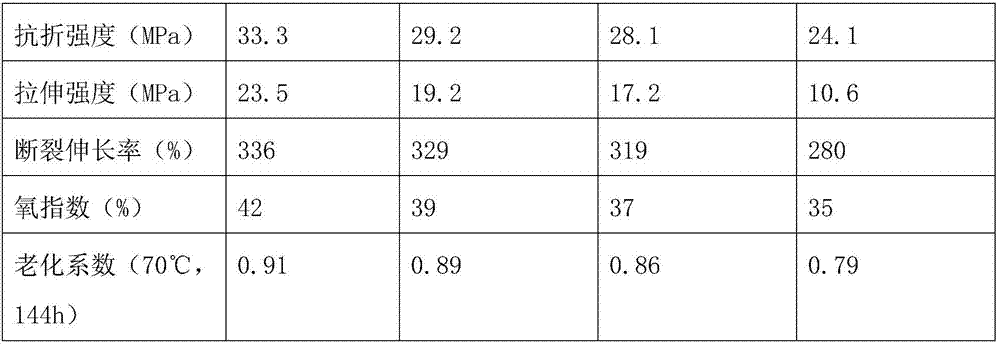

Embodiment 1

[0042] A wire and cable material, comprising the following raw materials in parts by weight: 100 parts of vinyl chloride resin, 30 parts of methyl vinyl silicone rubber, 21 parts of ethylene-vinyl acetate copolymer, 35 parts of nano-active calcium carbonate, 0.9 parts of toner, poly 7 parts of vinyl wax, 11 parts of talcum powder, 18 parts of ceramic fiber, 11 parts of floating beads, 7 parts of brown corundum, 1.1 parts of plasticizer, 0.6 parts of compatibilizer, 0.7 parts of flame retardant, 0.6 parts of antioxidant, light 0.3 parts of stabilizer and 0.5 parts of heat stabilizer.

[0043] Methyl vinyl silicone rubber is added to the raw material. Methyl vinyl silicone rubber has the advantages of good high and low temperature resistance, good electrical insulation and good aging resistance.

[0044] Ethylene-vinyl acetate copolymer is added to the raw material, and the ethylene-vinyl acetate copolymer has the advantages of good corrosion resistance, good toughness and good ...

Embodiment 2

[0062] A wire and cable material, comprising the following raw materials in parts by weight: 90 parts of polyvinyl chloride resin, 20 parts of methyl vinyl silicone rubber, 18 parts of ethylene-vinyl acetate copolymer, 32 parts of nano-active calcium carbonate, 0.7 parts of toner, 4 parts of polyethylene wax, 8 parts of talcum powder, 15 parts of ceramic fiber, 9 parts of floating beads, 6 parts of brown corundum, 0.7 parts of plasticizer, 0.3 parts of compatibilizer, 0.5 parts of flame retardant, 0.4 parts of antioxidant, 0.1 part of light stabilizer and 0.2 part of heat stabilizer.

[0063] Methyl vinyl silicone rubber is added to the raw material. Methyl vinyl silicone rubber has the advantages of good high and low temperature resistance, good electrical insulation and good aging resistance.

[0064] Ethylene-vinyl acetate copolymer is added to the raw material, and the ethylene-vinyl acetate copolymer has the advantages of good corrosion resistance, good toughness and good...

Embodiment 3

[0082] A wire and cable material, comprising the following raw materials in parts by weight: 110 parts of polyvinyl chloride resin, 40 parts of methyl vinyl silicone rubber, 24 parts of ethylene-vinyl acetate copolymer, 38 parts of nano-active calcium carbonate, 1.1 parts of toner, 10 parts of polyethylene wax, 14 parts of talcum powder, 21 parts of ceramic fiber, 13 parts of floating beads, 8 parts of brown corundum, 1.5 parts of plasticizer, 0.9 parts of compatibilizer, 0.9 parts of flame retardant, 0.8 parts of antioxidant, 0.5 parts of light stabilizer and 0.8 parts of heat stabilizer.

[0083] Methyl vinyl silicone rubber is added to the raw material. Methyl vinyl silicone rubber has the advantages of good high and low temperature resistance, good electrical insulation and good aging resistance.

[0084] Ethylene-vinyl acetate copolymer is added to the raw material, and the ethylene-vinyl acetate copolymer has the advantages of good corrosion resistance, good toughness an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com