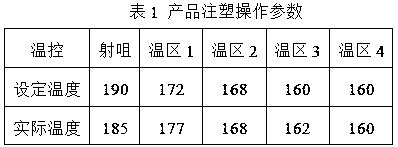

Magnesium-aluminum-zinc modified non-toxic composite environment-friendly stabilizer for U-PVC transparent injection molded part product

An environmentally friendly stabilizer, magnesium-aluminum-zinc technology, applied in the field of stabilizers, can solve the problems of poor injection molding process, excessive PVC material, affecting plasticizing performance, etc., to improve compatibility, balance internal and external lubrication, and improve environmental protection performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1 The following raw materials and steps were used to prepare the magnesium-aluminum-zinc modified non-toxic and environment-friendly composite stabilizer for PVC transparent injection molded parts according to the present invention:

[0020] (1) Preparation of polymer calcium ester base: 182Kg of adipic acid and 218Kg of pentaerythritol were pre-mixed and put into the reaction kettle. When the reaction temperature reached 140°C, 0.9 Kg of SO was added. 4 2- / SnO 2 -SiO 2 Solid super acid, collect the water released by the reaction; with the reaction temperature rising slowly, keep the reaction temperature at 198 ° C, when the collected water released by the reaction is 30Kg, slowly add calcium oxide 28Kg, keep the reaction after 1.3 hours Unwinding to obtain polymer calcium ester base;

[0021] (2) Preparation of stabilizer: Weigh the following raw materials according to the formula: fatty acid calcium zinc composition 382Kg, magnesium aluminum zinc compositi...

Embodiment 2

[0022] Example 2 The following raw materials and steps were used to prepare the magnesium-aluminum-zinc modified non-toxic composite environmental stabilizer for PVC transparent injection molded parts according to the present invention:

[0023] (1) Preparation of polymer: the polymer ester calcium prepared in Example 1 was used;

[0024] (2) Preparation of stabilizer: Weigh the following raw materials according to the formula: fatty acid calcium zinc composition 275Kg, antioxidant 107675Kg, magnesium aluminum zinc composition 428Kg, hydrotalcite 135Kg, sodium dehydroacetate 28Kg, stearoyl benzoyl Acyl methane 49Kg, polymer ester calcium 330Kg, the raw materials are mixed, sieved and packaged to obtain a stabilizer.

Embodiment 3

[0025] Example 3 The following raw materials and steps were used to prepare the magnesium-aluminum-zinc modified non-toxic composite environmental stabilizer for PVC transparent injection molded parts according to the present invention:

[0026] (1) Preparation of high-molecular-weight calcium ester-based calcium: Example 1 was used to prepare high-molecular-weight calcium ester-based calcium;

[0027] (2) Preparation of stabilizer: Weigh the following raw materials according to the formula: fatty acid calcium zinc composition 420Kg, magnesium aluminum zinc composition 210Kg, antioxidant 1076 27Kg, sodium dehydroacetate 40Kg, stearoyl benzoyl methane 37Kg, The polymer ester calcium is 445Kg. The raw materials are mixed, sieved and packaged to obtain a stabilizer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com