Composite material used for PVC heat stabilizers, and preparation method thereof

A composite material and heat stabilizer technology, applied in the field of PVC heat stabilizer, can solve the problems of affecting the dispersibility of organic matter matrix, large surface energy, serious coloring, etc., to achieve excellent thermal stability, reduce surface energy, and improve compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

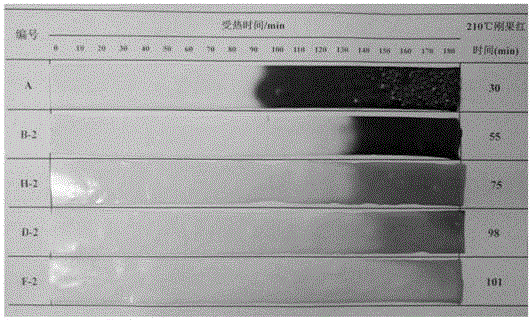

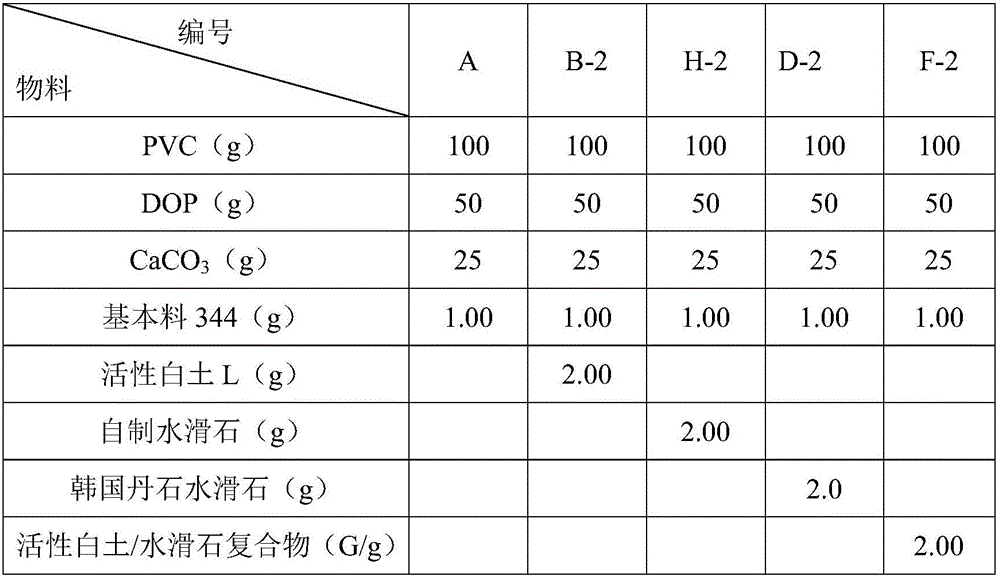

Examples

Embodiment 1

[0027] Example 1: Hang Jin 2 # Preparation of soil / hydrotalcite composites

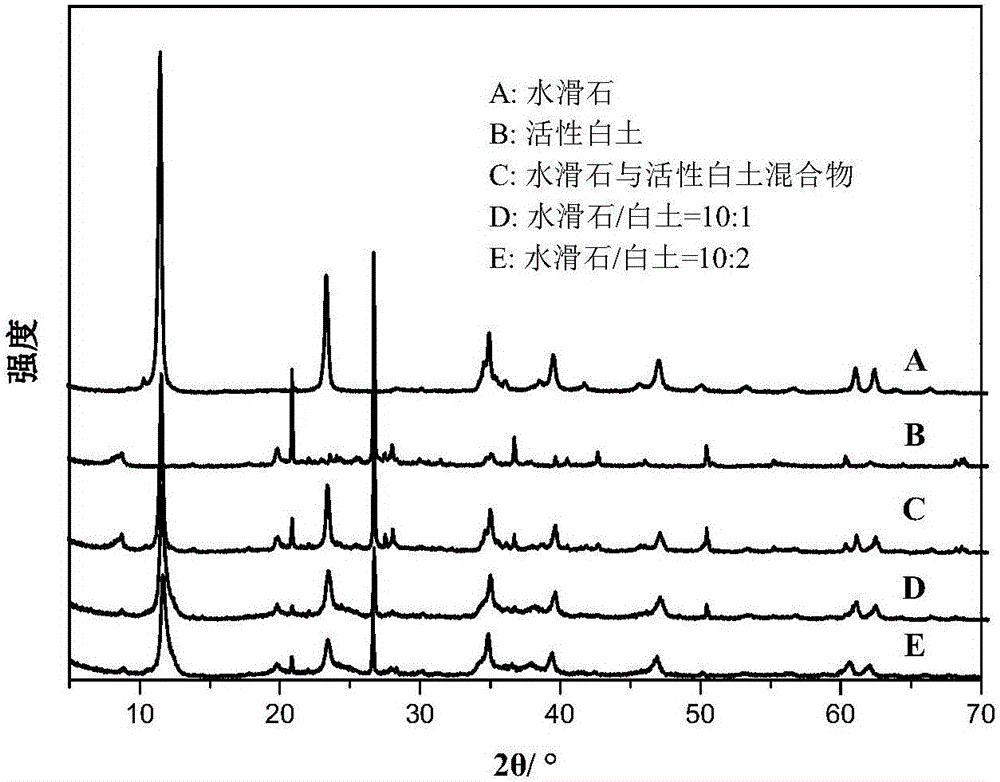

[0028] Weigh 200g Hang Jin 2 # Soil, add 800ml of hydrochloric acid with a mass fraction of 15%, reflux and stir at 80°C for 2 hours, cool, filter, wash the filter cake until neutral, dry and pulverize to obtain activated clay L1. The XRD figure of the activated clay of gained sees figure 1 .

[0029] Weigh 5.0g activated clay L1, add 50ml deionized water, 0.050g Span-60, reflux and stir at 90°C for 3 hours, then slowly add 0.25g dimethyldiethoxysilane, and reflux and stir for 4 hours, Slurry M1 was prepared.

[0030] Weigh 50.0 g of hydrotalcite, add 375 ml of deionized water, reflux and stir at 90° C. for 1 hour, then slowly add 2.5 g of dimethyldimethoxysilane, and reflux and stir for 3 hours to obtain slurry N1.

[0031] Mix slurry M1 and slurry N1, adjust the pH of the mixed slurry to 10 with sodium hydroxide, stir at 150°C for 3 hours, cool, wash, dry and pulverize the filter cake to obtain...

Embodiment 2

[0032] Example 2: Hang Jin 2 # Preparation of soil / hydrotalcite composites

[0033] Weigh 100g Hang Jin 2 # Soil, add 400ml of sulfuric acid with a mass fraction of 20%, reflux and stir at 95°C for 4 hours, cool, filter, wash the filter cake until neutral, dry and pulverize to obtain activated clay L2.

[0034] Weigh 10.0g activated clay L2, add 60ml deionized water, 0.050g sodium stearate benzenesulfonate, reflux and stir at 80°C for 3 hours, then slowly add 1.0g octyltrimethoxysilane, and reflux and stir for 3 hours , to prepare slurry M2.

[0035] Weigh 50.0 g of hydrotalcite, add 350 ml of deionized water, reflux and stir at 80° C. for 1 hour, then slowly add 1.50 g of octyltrimethoxysilane, and reflux and stir for 3 hours to obtain slurry N2.

[0036] Mix slurry M2 and slurry N2, adjust the pH of the mixed slurry to 11 with sodium hydroxide, stir at 120°C for 4 hours, cool, wash, dry and pulverize the filter cake to obtain Hangjin 2 # Soil / hydrotalcite composite G2. ...

Embodiment 3

[0037] Example 3: Hang Jin 2 # Preparation of soil / hydrotalcite composites

[0038] Weigh 150g Hang Jin 2 # Add 600ml of pyrophosphoric acid with a mass fraction of 12%, reflux and stir at 105°C for 1.5 hours, cool, filter, wash the filter cake until neutral, dry and pulverize to obtain activated clay L3.

[0039]Weigh 7.0g activated clay L3, add 40ml deionized water, 0.14g glyceryl monostearate, reflux and stir at 100°C for 3 hours, then slowly add 0.49g diethyldimethoxysilane, and reflux and stir for 2.5 hours, slurry M3 was prepared.

[0040] Weigh 50g of hydrotalcite, add 350ml of deionized water, reflux and stir at 100°C for 1 hour, then slowly add 3.5g of diethyldimethoxysilane, and reflux and stir for 2.5 hours to obtain slurry N3.

[0041] Mix slurry M3 and slurry N3, adjust the pH of the mixed slurry to 9 with sodium hydroxide, stir at 140°C for 3.5 hours, cool, wash, dry and pulverize the filter cake to obtain Hangjin 2 # Soil / hydrotalcite composite G3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com