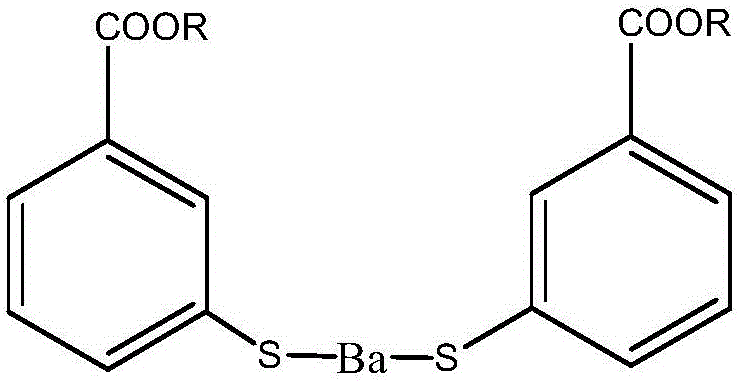

Thiosalicylic acid fatty alcohol ester barium and preparation method, composition and application thereof

A technology of barium mercaptobenzoic acid and alcohol ester, which is applied in the field of barium mercaptobenzoic acid fatty alcohol ester and its preparation, composition and application, can solve the problems affecting the coloring and precipitation of PVC film, poor stability of barium salt, unfavorable Stabilizer dispersion and other issues, to achieve good static and dynamic thermal stability, improve component compatibility, and save the amount of stabilizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

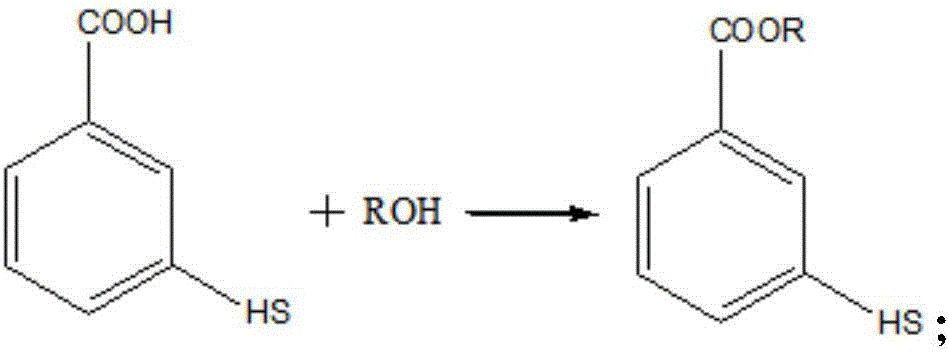

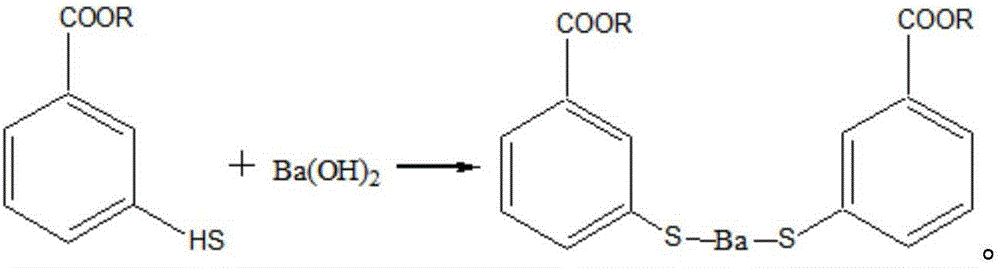

Method used

Image

Examples

Embodiment 1

[0037] Put 155g of 2-mercaptobenzoic acid, 130g of isooctyl alcohol, and 1.6g of concentrated sulfuric acid into the reactor, stir, raise the temperature to 105°C, and continue the reaction for 3.5 hours at a vacuum of -0.06MPa, remove the generated water, and then wash with water to remove the concentrated Sulfuric acid, dehydration to obtain isooctyl mercaptobenzoate; mix the intermediate product of the above reaction with 165g butanediol methyl ether at 60-65°C for 30 minutes, then add 95g of barium hydroxide, heat up to 105°C, and react for 3.5 hour, dehydrated, filtered to obtain barium isooctyl mercaptobenzoate, and the content of barium was 13.50% after determination.

Embodiment 2

[0039] Put 155g of 2-mercaptobenzoic acid, 330g of behenyl alcohol (C22 alcohol), and 2.0g of concentrated sulfuric acid into the reactor, stir, heat up to 115°C, and continue the reaction for 2.5 hours at a vacuum of -0.09MPa to remove the generated water. Then wash with water to remove concentrated sulfuric acid, and dehydrate to obtain behenyl mercaptobenzoate; mix the intermediate product of the above reaction with 50g of butanediol methyl ether at 60-65°C for 40 minutes, then add 97g of barium hydroxide, and heat up to 115 ℃, reacted for 2.5 hours, dehydrated, and filtered to obtain barium behenyl mercaptobenzoate, and the content of barium was 11.86% after determination.

Embodiment 3

[0041] Put 155g of 2-mercaptobenzoic acid, 130g of high-carbon fatty alcohol (C12-14 alcohol), and 2.4g of concentrated sulfuric acid into the reactor, stir, heat up to 110°C, and continue the reaction for 3.0 hours at a vacuum of -0.075MPa, remove The generated water is then washed with water to remove concentrated sulfuric acid, and dehydrated to obtain a high-carbon fatty alcohol ester of mercaptobenzoic acid; the intermediate product of the above reaction is mixed with 100 g of butanediol methyl ether at 60-65 ° C for 40 minutes, and then put into hydrogen oxidation 97g of barium was heated up to 105° C., reacted for 3.5 hours, dehydrated, and filtered to obtain barium mercaptobenzoic acid high-carbon fatty alcohol ester. After measuring, the barium content was 13.18%.

[0042] Two, preparation of barium salt composition of fatty alcohol mercaptobenzoate

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com