Dedicated Mg-Al-Zn modified non-toxic compound stabilizer for PVC (Poly Vinyl Chloride) pipes

A composite stabilizer and PVC pipe technology, applied in the field of PVC stabilizers, can solve the problems that cannot ignore the production quality requirements, and achieve the effects of improving processing stability and long-term stability, good internal and external lubrication performance, and strengthening initial whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

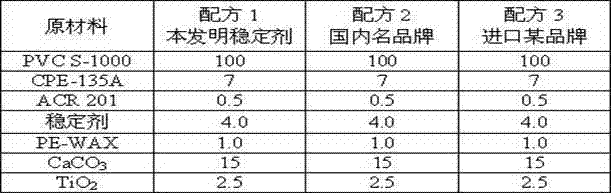

Examples

Embodiment 1

[0018] Example 1 The following raw materials and steps are used to prepare the special magnesium-aluminum-zinc modified non-toxic composite stabilizer for PVC pipes of the present invention:

[0019] 1. Preparation of fatty acid calcium zinc composition: put 1500Kg of stearic acid and 230Kg of 12-hydroxystearic acid into the reactor and heat; Slowly add 50Kg of calcium hydroxide to the kettle, then slowly add 275Kg of zinc oxide to complete the feeding; after the completion of feeding, keep the reaction at 170°C for 1.5 hours; after the reaction is completed, add 56Kg of 16-18 alcohol to the reaction kettle, stir Evenly, then discharge, cool and grind to obtain the fatty acid calcium zinc composition;

[0020] 2. Preparation of polymeric ester-based calcium: pre-mix 212 Kg of adipic acid and 232 Kg of pentaerythritol and put them into the reactor evenly. When the reaction temperature reaches 145°C, add 0.8 KgSO 4 2- / TiO 2 -SiO 2 Solid super acid, collect the water relea...

Embodiment 2

[0024] Example 2 The following raw materials and steps are used to prepare the special magnesium-aluminum-zinc modified non-toxic composite stabilizer for PVC pipes of the present invention:

[0025] 1. Preparation of fatty acid calcium zinc composition: put 1700Kg of lauric acid and 400Kg of 12-hydroxystearic acid into the reactor and heat; Slowly add 35Kg of calcium hydroxide, and then slowly add 230Kg of zinc oxide to complete the feeding; after the completion of feeding, keep the reaction at 170°C for 1.5 hours; after the reaction is completed, add 40Kg of 16-18 alcohol into the reaction kettle, and stir , then discharging, cooling and grinding to obtain the fatty acid calcium zinc composition;

[0026] 2. Preparation of polymeric ester-based calcium: the polymeric ester-based calcium prepared in Example 1;

[0027] 3. Preparation of stabilizer:

[0028] (1) Weigh each raw material according to the formula: fatty acid calcium zinc composition 120Kg, calcium stearate 2...

Embodiment 3

[0030] Example 3 The following raw materials and steps are used to prepare the special magnesium-aluminum-zinc modified non-toxic composite stabilizer for PVC pipes of the present invention:

[0031] 1. Preparation of fatty acid calcium zinc composition: put 1000Kg of stearic acid and 500Kg of 12-hydroxystearic acid into the reactor and heat; Slowly add 25Kg of calcium oxide into the kettle, and then slowly add 210Kg of zinc oxide to complete the feeding; after the completion of feeding, keep the reaction at 170°C for 1.5 hours; after the reaction is completed, add 80Kg of 16-18 alcohol into the reaction kettle, and stir , then discharging, cooling and grinding to obtain the fatty acid calcium zinc composition;

[0032] 2. Preparation of polymeric ester-based calcium: the polymeric ester-based calcium prepared in Example 1;

[0033] 3. Preparation of stabilizer:

[0034](1) Weigh the following raw materials according to the formula: fatty acid calcium zinc composition 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com