A kind of triazole-based composite heat stabilizer for pvc

A technology of composite heat stabilizer and auxiliary heat stabilizer, which is applied in the application field of triazole-based composite heat stabilizer in the field of polyvinyl chloride processing, and achieves the effects of high-efficiency stable function, long-term stability improvement, and high-efficiency expansion of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

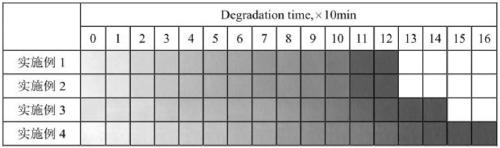

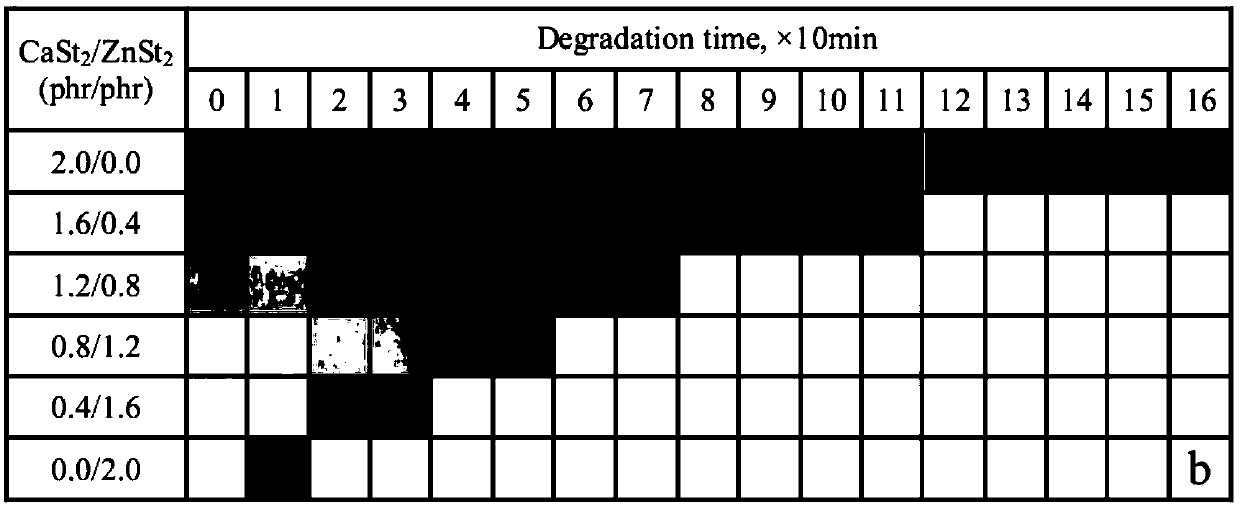

Embodiment 1~4

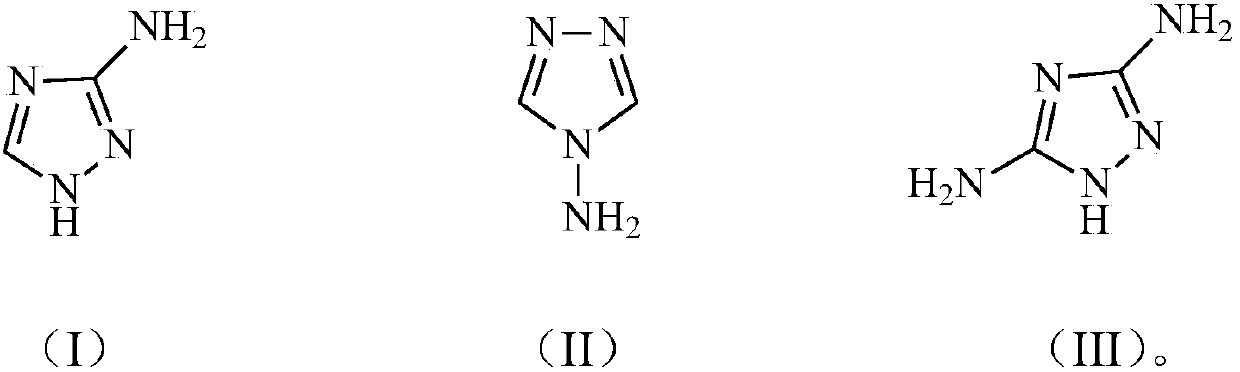

[0029] 100.00g of PVC powder, 2.00g of 3-amino-1,2,4-triazole / zinc composite heat stabilizer (Example 1, 2), 10.00g of dioctyl phthalate, 3.00g of stearic acid, Calcium carbonate 20.00g. Plasticize into PVC sheets on a double-roller plastic mixer with a roller temperature of 180°C and a roller distance of 1mm.

[0030] 100.00g of PVC powder, 4.00g of 4-amino-1,2,4-triazole / zinc composite heat stabilizer (example 3), 10.00g of dioctyl phthalate, 3.00g of stearic acid, calcium carbonate 20.00g. Plasticize into PVC sheets on a double-roller plastic mixer with a roller temperature of 180°C and a roller distance of 1mm.

[0031] With PVC powder 100.00g, 3,5-diamino-1,2,4-triazole / zinc composite heat stabilizer (example 4) 4.00g, dioctyl phthalate 10.00g, stearic acid 3.00g , calcium carbonate 20.00g. Plasticize into PVC sheets on a double-roller plastic mixer with a roller temperature of 180°C and a roller distance of 1mm.

[0032] The specific formula of the raw material dosa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com