Antibacterial heat-resistant polyvinyl chloride wall-protecting plate

A technology of polyvinyl chloride and siding, which is applied in the field of panels, can solve the problems of siding with bacteria, poor stability, loss of use value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

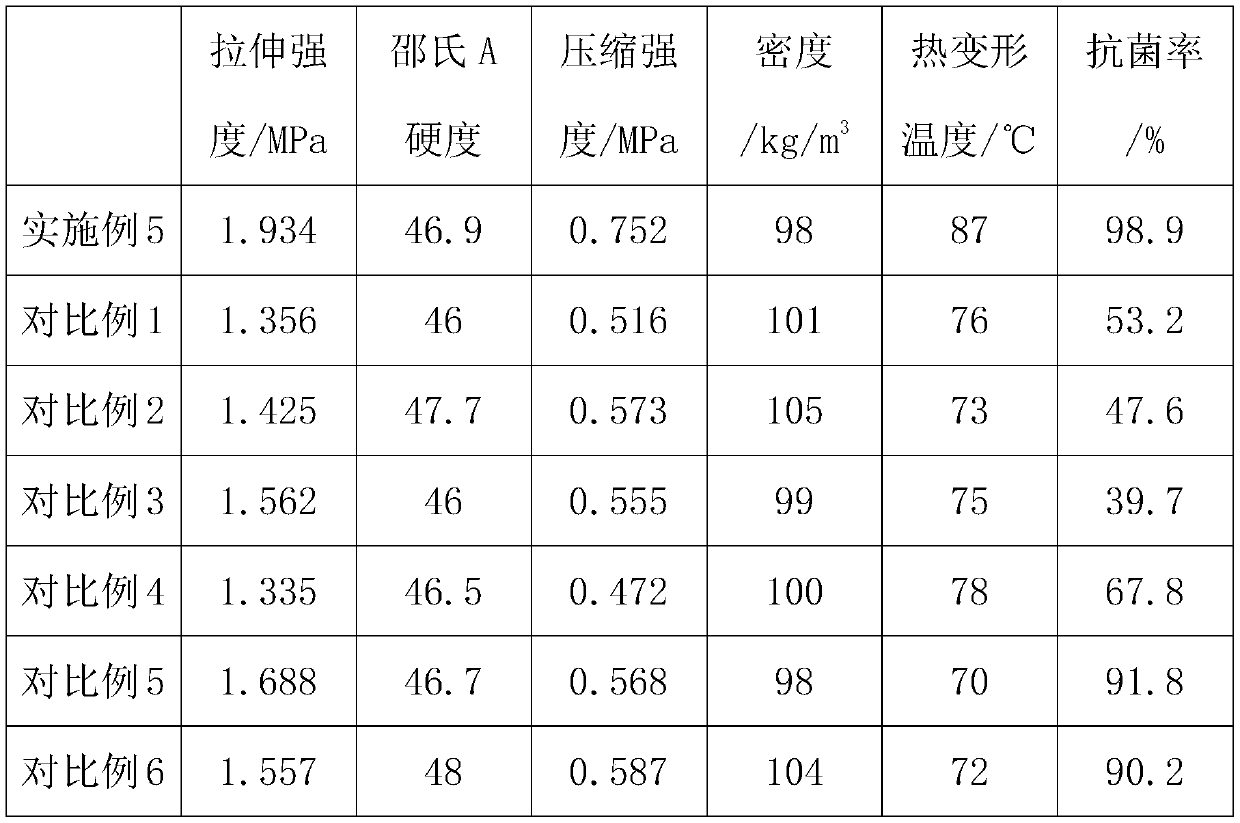

Examples

Embodiment 1

[0016] An antibacterial and heat-resistant polyvinyl chloride wall panel proposed by the present invention, its raw materials include: 80 parts of polyvinyl chloride, 11 parts of vinyl chloride resin, 13 parts of polypropylene, 3 parts of chlorinated polyethylene, nano-titanium dioxide composite 6 parts of active clay, 0.3 parts of activated clay, 2 parts of hydrotalcite, 0.5 parts of nano-montmorillonite, 3 parts of composite foaming agent, 0.2 parts of 1-phenyl-3-methyl-5-pyrazolone, stearic acid 2 parts of zinc, 1 part of calcium adipate, 0.25 parts of sorbitol, 0.53 parts of cinnamaldehyde barbituric acid, 0.3 parts of lubricant, 0.1 part of methyl silicone oil, 3 parts of dibutyl phthalate.

Embodiment 2

[0018] An antibacterial heat-resistant polyvinyl chloride wall panel proposed by the present invention, its raw materials include: 55 parts of polyvinyl chloride, 23 parts of vinyl chloride resin, 5 parts of polypropylene, 8 parts of chlorinated polyethylene, nano-titanium dioxide composite 3 parts of active clay, 1.5 parts of activated clay, 1 part of hydrotalcite, 2 parts of nano-montmorillonite, 2 parts of composite foaming agent, 1.1 parts of 1-phenyl-3-methyl-5-pyrazolone, stearic acid 1 part of zinc, 2 parts of calcium adipate, 0.1 part of sorbitol, 2.7 parts of cinnamaldehyde barbituric acid, 0.1 part of lubricant, 0.32 part of methyl silicone oil, 1 part of dibutyl phthalate.

Embodiment 3

[0020] An antibacterial heat-resistant polyvinyl chloride wall panel proposed by the present invention, its raw materials include: 76 parts of polyvinyl chloride, 13 parts of vinyl chloride resin, 12 parts of polypropylene, 4 parts of chlorinated polyethylene, nano-titanium dioxide composite 5.5 parts of active clay, 0.4 parts of activated clay, 1.8 parts of hydrotalcite, 0.7 parts of nano-montmorillonite, 2.8 parts of composite foaming agent, 0.6 parts of 1-phenyl-3-methyl-5-pyrazolone, stearic acid 1.8 parts of zinc, 1.2 parts of calcium adipate, 0.22 parts of sorbitol, 0.7 parts of cinnamaldehyde barbituric acid, 0.26 parts of lubricant, 0.17 parts of methyl silicone oil, 2.7 parts of dibutyl phthalate;

[0021] Wherein, the massfraction of vinyl acetate in the vinyl acetate resin is 8wt%;

[0022] In the chlorinated polyethylene, the content of chlorine is 40wt%;

[0023] The nano-titanium dioxide composite is prepared according to the following process: immerse polyether...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com