Magnesium-aluminum-zinc environment-friendly stabilizer special for U-PVC calendered sheet

An environmentally friendly stabilizer and stabilizer technology, applied in the field of PVC stabilizers, can solve the problems of poor thermal stability, large environmental impact, and rising prices, and achieve the effects of good stabilization effect, good colorability and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

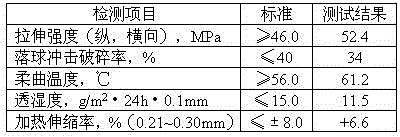

Image

Examples

Embodiment 1

[0017] Embodiment 1 adopts following formula to prepare a kind of special environment-friendly stabilizer for U-PVC calendered sheet: Magnesium-aluminum-zinc composition 285kg, zinc stearate 60kg, antioxidant 1010 16kg, calcium acetylacetonate 55kg, three (2-hydroxyethyl base) isocyanurate 100kg, oxidized polyethylene wax 60kg, polyethylene wax 80kg.

[0018] The preparation method is as follows:

[0019] (1) The magnesium-aluminum-zinc composition was prepared using the method described in patent ZL200810110606.3: in a 1.5 cubic stainless steel reaction kettle equipped with a stirrer, a thermometer and a heating jacket, add pentaerythritol tristearate (PETS-3) 180Kg, stearic acid (Hst) 520Kg, adipic acid 178Kg, stir slowly when heated to 80-120°C, add 5Kg of glacial acetic acid (or hydrogen peroxide), stir well, and pour into the reaction kettle at 100°C-120°C Add ZnO44Kg, Mg(OH)2 48Kg and Al2O327Kg with a purity of more than 98%, continue to heat up to 140°C, and keep the r...

Embodiment 2

[0021] Embodiment 2 adopts the following formula to prepare a kind of special environment-friendly stabilizer for U-PVC calendered sheet: embodiment 1 makes magnesium-aluminum-zinc composition 260kg, zinc stearate 150kg, antioxidant 1010 18kg, calcium acetylacetonate 68kg, three (2-hydroxyethyl) isocyanurate 110kg, oxidized polyethylene wax 180kg, polyethylene wax 60kg.

Embodiment 3

[0022] Embodiment 3 adopts following formula to prepare a kind of special environment-friendly stabilizer for U-PVC calendered sheet: Embodiment 1 makes magnesium-aluminum-zinc composition 275kg, zinc stearate 50kg, antioxidant 1010 15kg, calcium acetylacetonate 46kg, three (2-hydroxyethyl) isocyanurate 1300kg, oxidized polyethylene wax 180kg, polyethylene wax 60kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com