Heatproof flame-retardant locomotive cable

A locomotive cable, heat-resistant technology, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve the problems of poor heat resistance and flame retardancy, poor heat resistance and flame retardancy, etc., to achieve Improvement of strength and heat resistance, improvement of heat resistance, effect of improvement of heat resistance and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

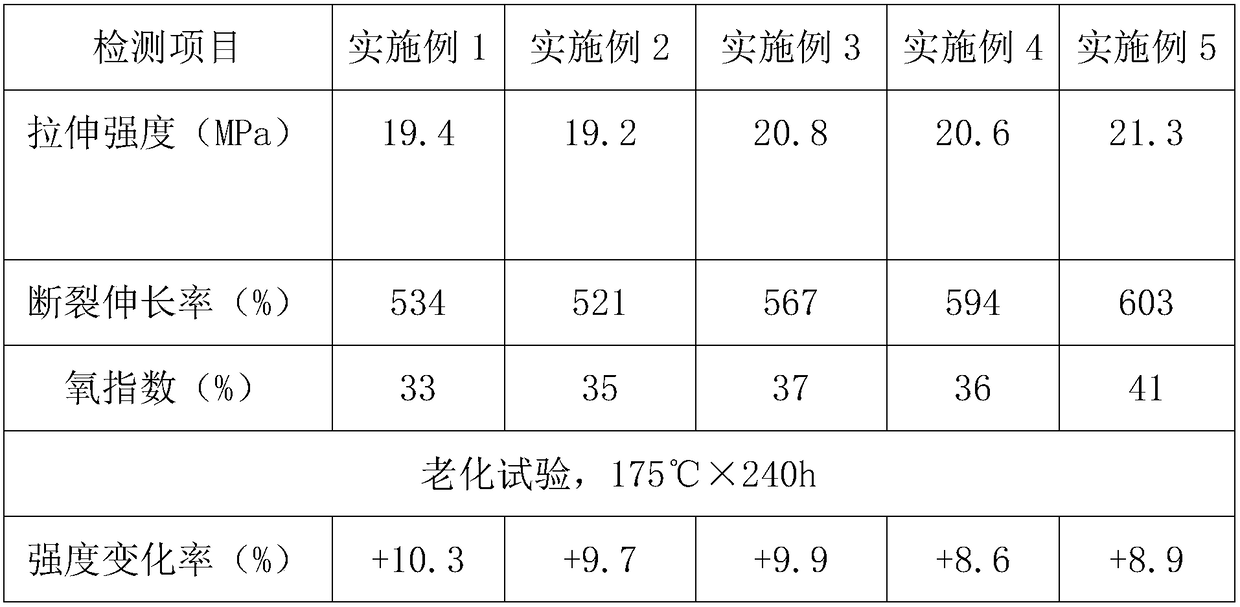

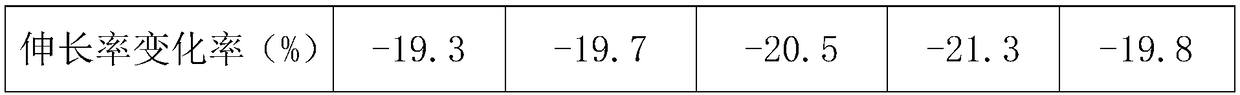

Examples

Embodiment 1

[0014] A heat-resistant and flame-retardant locomotive cable proposed by the present invention includes a cable core and a sheath layer coated on the outside of the cable core; the raw materials of the sheath layer include by weight: 150 parts of polyvinyl chloride, 30 parts of nitrile rubber 25 parts of polyester thermoplastic polyurethane elastomer, 3 parts of polyamic acid, 7 parts of zinc oxide, 0.3 parts of stearic acid, 2 parts of sulfur, 6 parts of pentaerythritol, 15 parts of ammonium polyphosphate, 10 parts of melamine, 5 parts of titanium dioxide , 2 parts of magnesium hydroxide coated with zinc hydroxystannate, 12 parts of nano-silicon dioxide, 3 parts of nano-calcium carbonate, 5 parts of ammonium octamolybdate, 2 parts of zinc naphthenate, 4 parts of calcium stearate, 1-benzene Base-3-methyl-5-pyrazolone 2 parts, sorbitol 7 parts.

Embodiment 2

[0016] A heat-resistant and flame-retardant locomotive cable proposed by the present invention includes a cable core and a sheath layer coated on the outside of the cable core; the raw materials of the sheath layer include by weight: 100 parts of polyvinyl chloride, 60 parts of nitrile rubber 5 parts, polyester thermoplastic polyurethane elastomer 5 parts, polyamic acid 15 parts, zinc oxide 3 parts, stearic acid 1.2 parts, sulfur 0.9 parts, pentaerythritol 15 parts, ammonium polyphosphate 5 parts, melamine 15 parts, titanium dioxide 20 parts , 10 parts of magnesium hydroxide coated with zinc hydroxystannate, 3 parts of nano-silicon dioxide, 15 parts of nano-calcium carbonate, 1 part of ammonium octamolybdate, 5 parts of zinc naphthenate, 1 part of calcium stearate, 1-benzene Base-3-methyl-5-pyrazolone 5 parts, sorbitol 2 parts.

Embodiment 3

[0018] A heat-resistant and flame-retardant locomotive cable proposed by the present invention includes a cable core and a sheath layer coated on the outside of the cable core; the raw materials of the sheath layer include by weight: 110 parts of polyvinyl chloride, 55 parts of nitrile rubber 9 parts of polyester thermoplastic polyurethane elastomer, 13 parts of polyamic acid, 4 parts of zinc oxide, 1 part of stearic acid, 1.2 parts of sulfur, 13 parts of pentaerythritol, 14 parts of ammonium polyphosphate, 14 parts of melamine, 9 parts of titanium dioxide , 8 parts of magnesium hydroxide coated with zinc hydroxystannate, 6 parts of nano-silicon dioxide, 13 parts of nano-calcium carbonate, 2 parts of ammonium octamolybdate, 4.3 parts of zinc naphthenate, 2 parts of calcium stearate, 1-benzene 4.2 parts of base-3-methyl-5-pyrazolone, 3 parts of sorbitol;

[0019] Wherein, the nano-calcium carbonate is modified nano-calcium carbonate; the modified nano-calcium carbonate is prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com