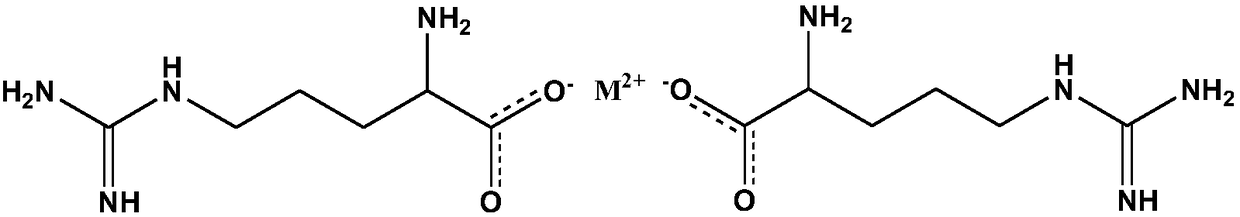

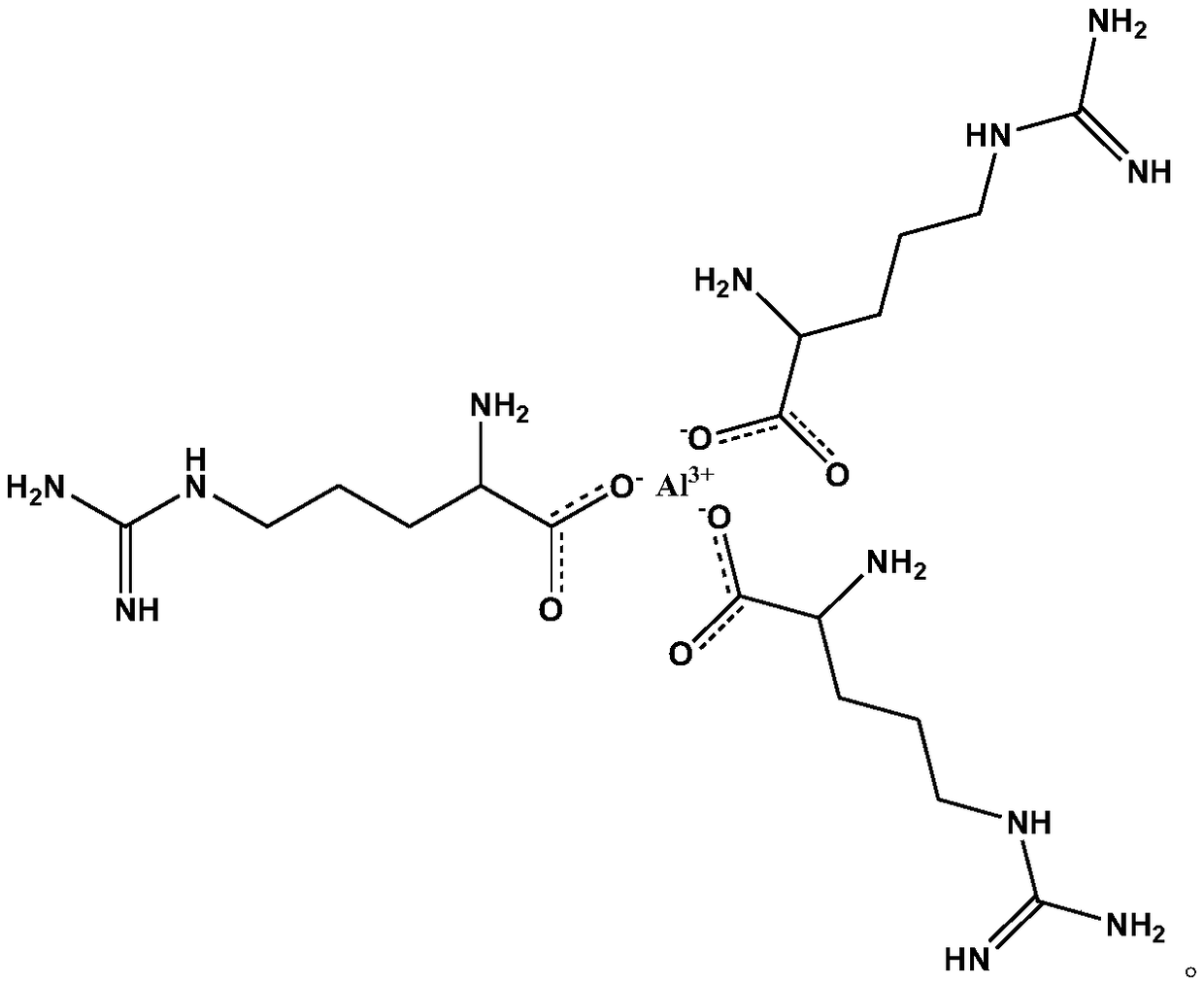

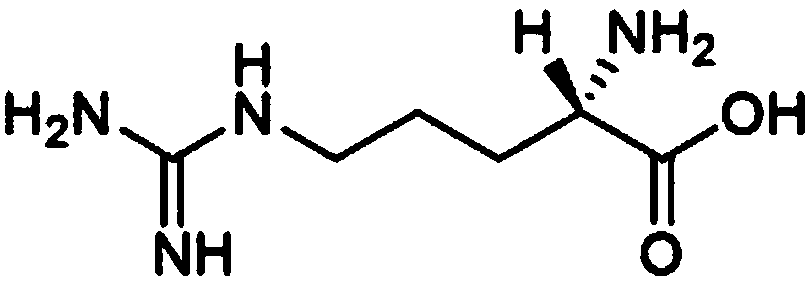

Arginine metal complex, compound heat stabilizer and application thereof

A technology of metal complexes and heat stabilizers, which is applied in the field of complex heat stabilizers and arginine metal complexes, and can solve the problem that calcium-zinc heat stabilizers cannot have both excellent initial whiteness and long-term stability and other problems, to achieve excellent thermal stability, improve mechanical properties and apparent quality, good initial whiteness and long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Weigh 0.4mol of arginine, add 200mL of water, then add 0.2mol of zinc chloride, mix well, add 100mL of lye containing 0.4mol of sodium hydroxide, react at 90°C for 2h, place in 50 Evaporate water for 48 hours under blast conditions at ℃, wash with hot water, and then dry under blast conditions at 50°C for 48 hours to obtain zinc arginine;

[0043] (2) mix and compound according to the following formula raw materials: 2phr zinc arginine, 0.3phr arginine, 0.6phr epoxy soybean oil, 0.4phr polyethylene wax, 0.4phr antioxidant 1010, make compound type heat stabilizer;

[0044] (3) Preparing PVC products: After weighing 100phr of PVC powder, 2phr of compound heat stabilizer prepared in step (2), and 50phr of plasticizer dibutyl phthalate, mix them evenly, and then use a double-roller mixer at 150°C. Mix for 3 minutes at the roller speed of 9rad / min and 11rad / min in the mill; the obtained PVC mixture is pressed into a PVC sheet with a thickness of 1mm on a press at 160°C....

Embodiment 2

[0046](1) Weigh 0.6mol arginine, add 300mL water, then add 0.3mol calcium chloride, mix well, add 150mL lye containing 0.5mol sodium hydroxide, react at 75°C for 2h, place at 75°C Evaporate water for 24 hours under blast conditions at ℃, wash with hot water, and then dry under blast conditions at 75°C for 24 hours to obtain calcium arginine;

[0047] (2) carry out mixing and compounding according to following formula raw material: 2phr calcium arginine, 0.3phr arginine, 0.6phr epoxy soybean oil, 0.4phr polyethylene wax, 0.4phr antioxidant 1010, make compound type heat stabilizer;

[0048] (3) Preparing PVC products: After weighing 100phr of PVC powder, 2phr of compound heat stabilizer prepared in step (2), and 50phr of plasticizer dibutyl phthalate, mix them evenly, and then use a double-roller mixer at 150°C. Mix for 3 minutes at the roller speed of 9rad / min and 11rad / min in the mill; the obtained PVC mixture is pressed into a PVC sheet with a thickness of 1mm on a press at ...

Embodiment 3

[0050] (1) Weigh 0.8mol of arginine, add 400mL of water, then add 0.8mol of magnesium chloride, mix well, add 200mL of lye containing 0.6mol of sodium hydroxide, react at 90°C for 2h, and place in a drum at 100°C Evaporate water for 12 hours under wind conditions, wash with hot water, and then dry at 100°C for 12 hours under blast conditions to obtain magnesium arginate;

[0051] (2) mix and compound according to the following formula raw materials: 2phr magnesium arginate, 0.3phr arginine, 0.6phr epoxy soybean oil, 0.4phr polyethylene wax, 0.4phr antioxidant 168, make compound type heat stabilizer;

[0052] (3) Preparing PVC products: After weighing 100phr of PVC powder, 2phr of compound heat stabilizer prepared in step (2), and 50phr of plasticizer dibutyl phthalate, mix them evenly, and then use a double-roller mixer at 150°C. Mix for 3 minutes at the roller speed of 9rad / min and 11rad / min in the mill; the obtained PVC mixture is pressed into a PVC sheet with a thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com