Preparation method of binderless ZSM-5 molecular sieve

A ZSM-5, binder-free technology, applied in the direction of crystalline aluminosilicate zeolite, borane silicone crystalline aluminosilicate zeolite, etc., can solve the problem of pollution environment, no binder ZSM-5 molecular sieve preparation The process is complicated and other problems, so as to achieve the effect of reducing production cost, simple and environmentally friendly preparation process, and good technical effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0020] Add 30 milliliters of deionized water to the reaction kettle in advance, place 10 grams of sample A in Comparative Example 1 above the porous stainless steel mesh in the reaction kettle and seal it, and then treat it at 180°C for 24 hours, 48 hours, 72 hours, and 96 hours , 120 hours. The sample numbers are respectively marked as A-24-water, A-48-water, A-72-water, A-96-water, A-120-water.

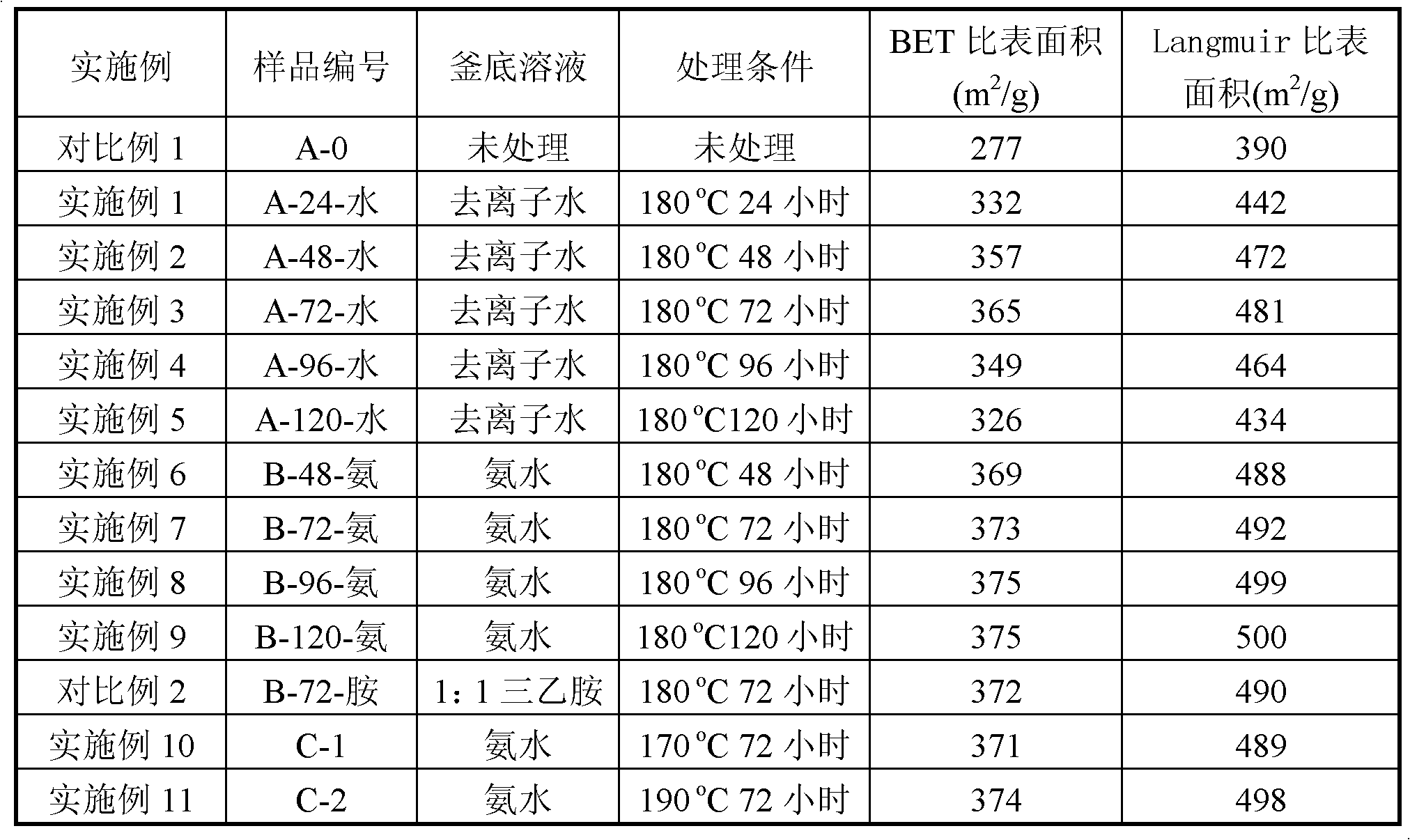

[0021] The product was first dried at 110°C, and then calcined in a muffle furnace at 550°C for more than 4 hours. The calcined product was characterized by X-ray powder diffraction (XRD) and nitrogen adsorption. The results are shown in Table 1 and Table 2. The XRD pattern of the product treated for 24 hours shows that the relative crystallinity and specific surface area of the sample have increased, indicating that part of the amorphous silica binder has been transformed into a ZSM-5 molecular sieve. After 72 hours of treatment, the relative crystallinity of the product is al...

Embodiment 6~9

[0023] Take by weighing 40 grams of ZSM-5 molecular sieves (silicon-aluminum ratio 600, template agent tetrapropyl ammonium bromide content 11.5% in the channel), add 31 grams of 40% (weight) silica sol and mix evenly, extrude into strips, Dry at 110°C to obtain sample B.

[0024] 30 milliliters of ammonia water was added to the reaction kettle in advance, and 10 grams of sample B was placed in the reaction kettle above the porous stainless steel mesh and sealed, and then treated at 180°C for 48 hours, 72 hours, 96 hours, and 120 hours. The sample numbers are marked as B-48-Ammonia, B-72-Ammonia, B-96-Ammonia, B-120-Ammonia.

[0025] The product was first dried at 110°C, and then calcined in a muffle furnace at 550°C for 4 hours. The calcined product was characterized by X-ray powder diffraction (XRD) and nitrogen adsorption, and the results are shown in Table 1 and Table 2. The XRD pattern of the product treated for 24 hours shows that the relative crystallinity and specifi...

Embodiment 10~11

[0029] Take by weighing 20 grams of ZSM-5 molecular sieves (silicon-aluminum ratio 300, template agent tetrapropylammonium bromide content 11% in the channel), add 15 grams of 40% (weight) silica sol and mix evenly, extrude into strips, Dry at 110°C to obtain sample C.

[0030] Add 30 ml of ammonia water to the reaction kettle in advance, place 10 grams of sample B in the reaction kettle above the porous stainless steel mesh and seal it, and then treat it at 170 and 190°C for 72 hours, and the sample numbers are marked as C-1 and C-2 .

[0031] The product was first dried at 110°C, and then calcined in a muffle furnace at 550°C for 4 hours. The calcined products were characterized by X-ray powder diffraction (XRD) and nitrogen gas adsorption. The results are shown in Table 1 and Table 2. The samples treated at 170°C and 190°C all have higher relative crystallinity and specific surface area.

[0032] Table 1

[0033]

[0034] Table 2

[0035] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com