Superhydrophobic polyvinylidene fluoride (PVDF) aerogel material and preparation method thereof

A polyvinylidene fluoride and aerogel technology, which is applied in the field of super-hydrophobic polyvinylidene fluoride (PVDF) aerogel material and its preparation, can solve the problem of removing powder and slag, detrimental to the health of environmental protection construction personnel, and destroying aerogel insulation materials. Pore structure and other problems, to achieve the effect of good flexibility, good hydrophobicity and thermal insulation performance, and safe preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] At 70°C, add sodium chloride with a mass fraction of 1% and PVDF powder with a mass fraction of 5% into N-N dimethylformamide, and stir for 20 minutes to obtain a clear PVDF solution. Deionized water with a mass fraction of 20% was added to the PVDF solution to obtain PVDF sol; PVDF sol was placed at 10°C for sol-gel reaction to obtain PVDF gel; PVDF gel was immersed in deionized water at 20°C for solvent replacement for 8 times (each replacement time is 6 hours) to obtain a hydrogel, and the hydrogel is freeze-dried to obtain a superhydrophobic PVDF airgel material. PVDF airgel sample density 0.075 / g / cm 3 , porosity 95.8%, specific surface area 306m 2 / g, the water contact angle is 153°, the thermal conductivity is 0.04463W / (m·K), the nanopores are distributed in the range of 3-100nm, and the micropores are distributed in the range of 0.5-5μm.

example 2

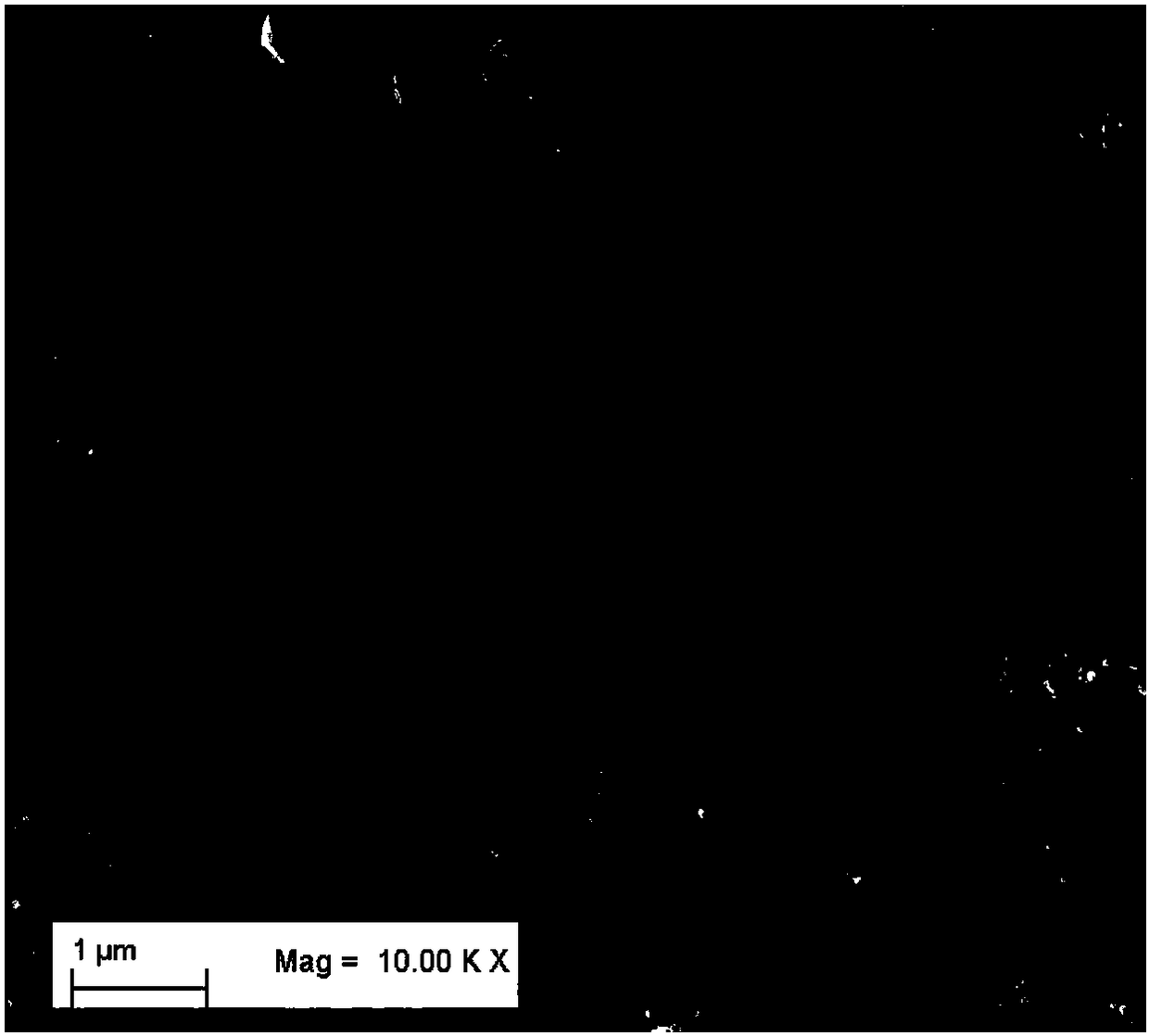

[0027] At 80°C, add lithium chloride with a mass fraction of 2% and PVDF powder with a mass fraction of 10% into N-N dimethylacetamide, and stir for 40 minutes to obtain a clear PVDF solution. Deionized water with a mass fraction of 15% was added to the PVDF solution to obtain a PVDF sol; the PVDF sol was placed at 20°C for a sol-gel reaction to obtain a PVDF gel; the PVDF gel was immersed in ethanol at 25°C for 6 times of solvent replacement ( Each replacement time is 8 hours) to obtain an alcohol gel, and the alcohol gel is subjected to CO 2 The superhydrophobic PVDF airgel material was obtained by supercritical drying. PVDF airgel sample density 0.143g / cm 3 , porosity 92%, specific surface area 343m 2 / g, water contact angle of 158°, thermal conductivity of 0.03531W / (m·K), nanopores distributed in the range of 5-80nm, and micropores distributed in the range of 0.5-3μm.

[0028] See attached picture, figure 1 Photo of the PVDF airgel made in Example 2. It can be seen th...

example 3

[0031] At 90°C, add polyvinylpyrrolidone with a mass fraction of 3% and PVDF powder with a mass fraction of 15% into dimethyl sulfoxide, and stir for 60 minutes to obtain a clear PVDF solution. 10% deionized water was added to the solution to obtain PVDF sol; the PVDF sol was placed at 10°C for sol-gel reaction to obtain PVDF gel; the PVDF gel was immersed in methanol at 30°C for 4 solvent replacements (each replacement The time is 12 hours) to obtain the alcohol gel, and the alcohol gel is subjected to CO 2 The superhydrophobic PVDF airgel material was obtained by supercritical drying. PVDF airgel sample density 0.198g / cm 3 , porosity 89%, specific surface area 256m 2 / g, the water contact angle is 154°, the thermal conductivity is 0.04152W / (m·K), the nanopores are distributed in the range of 3-100nm, and the micropores are distributed in the range of 0.8-5μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com