Flame-retardant reinforced high-temperature-resistant nylon composite material

A nylon composite material and high-temperature-resistant technology, which is applied in the field of flame-retardant reinforced high-temperature-resistant nylon composite materials, can solve problems affecting the appearance of the product, precipitation, mold pollution, etc., achieve excellent visual effects, improve initial whiteness, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

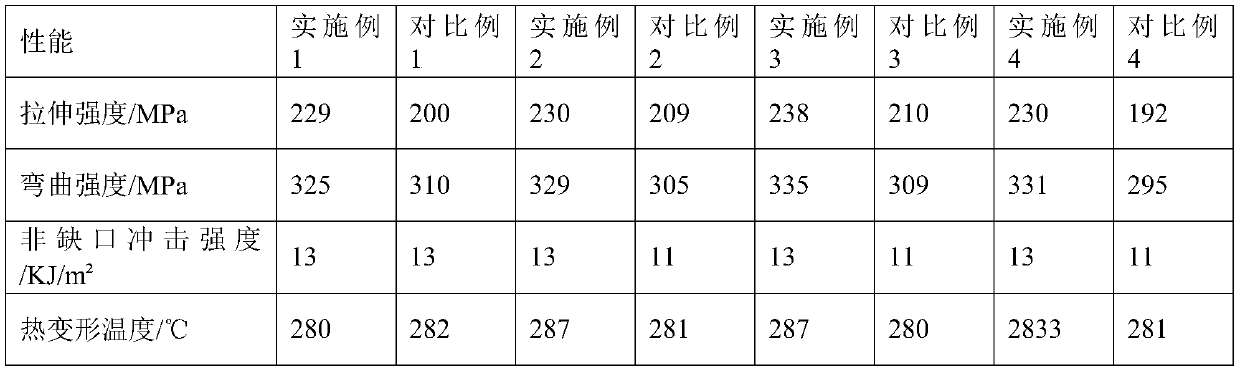

Examples

Embodiment 1

[0022] Weigh each by weight ratio of 30kg nylon 46, 30kg short glass fiber (single filament diameter 6 μm, length 3mm), 10kg flame retardant (brominated polystyrene), 3kg antimony trioxide, 0.1kg polyvinylpyrrolidone After the components are mixed, the other components except the glass fiber are mixed uniformly to obtain the premix; then the obtained premix is put into the twin-screw extruder, and the glass fiber is put into the side feeding process, melted and kneaded, extruded The flame-retardant reinforced high-temperature-resistant nylon composite material is obtained by pelletizing. The process parameters of the twin-screw extruder are: the temperature of the feeding section is 290°C, the temperature of the melting and plasticizing section is 280°C, the temperature of the mixing and homogenizing section is 250°C, and the temperature of the melting section is 250°C. The temperature of the conveying section of the body is 260°C, the temperature of the head is 290°C, and th...

Embodiment 2

[0026] According to 34kg nylon 6T / 66, 50kg short glass fiber (single filament diameter 12μm, length 4mm), 12kg flame retardant (brominated polystyrene), 4kg antimony trioxide, 0.5kg polyvinylpyrrolidone, 0.5kg ethylene acrylic acid The weight ratio of the copolymer After weighing each component, first mix the other components except glass fiber evenly to obtain a premix; then put the obtained premix into a twin-screw extruder, and adopt the side feeding process Put in glass fiber, melt and knead, extrude and granulate to obtain a flame-retardant reinforced high-temperature-resistant nylon composite material. The process parameters of the twin-screw extruder are: the temperature of the feeding section is 300°C, the temperature of the melting and plasticizing section is 310°C, and the mixing The temperature of the homogenization section is 255°C, the temperature of the melt conveying section is 270°C, the temperature of the head is 300°C, and the speed of the host of the twin-scr...

Embodiment 3

[0030] According to 45kg nylon 6T / 6I, 55kg short glass fiber (monofilament diameter 13μm, length 5mm), 20kg flame retardant (polybrominated styrene), 6kg anhydrous zinc borate, 1kg polyvinylpyrrolidone, 0.5kg ethylene acrylic acid copolymer After weighing each component, mix other components except glass fiber evenly to obtain a premix; then put the obtained premix into a twin-screw extruder, and use the side feeding process to input Glass fiber, melted and kneaded, extruded and granulated to obtain a flame-retardant reinforced high-temperature-resistant nylon composite material. The process parameters of the twin-screw extruder are: the temperature of the feeding section is 320 ° C, the temperature of the melting and plasticizing section is 330 ° C, and the mixing is uniform. The temperature of the melting section is 260°C, the temperature of the melt delivery section is 290°C, the temperature of the head is 330°C, and the speed of the main engine of the twin-screw extruder is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com