Modified hydrotalcite and preparation method thereof, PVC heat stabilizer and application

A heat stabilizer and modified water technology, applied in the field of modified hydrotalcite and its preparation, PVC heat stabilizer, can solve the problem of "zinc salt" failure, etc., achieve simple operation, easy industrialization, excellent initial whiteness and long-term thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

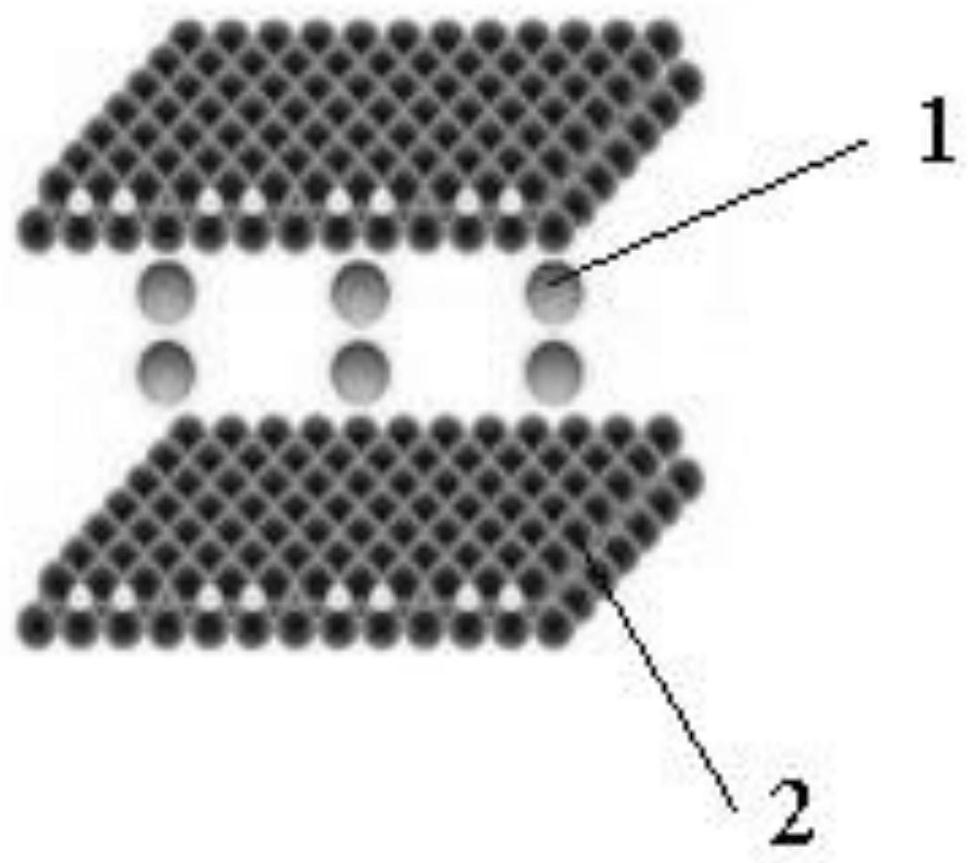

Image

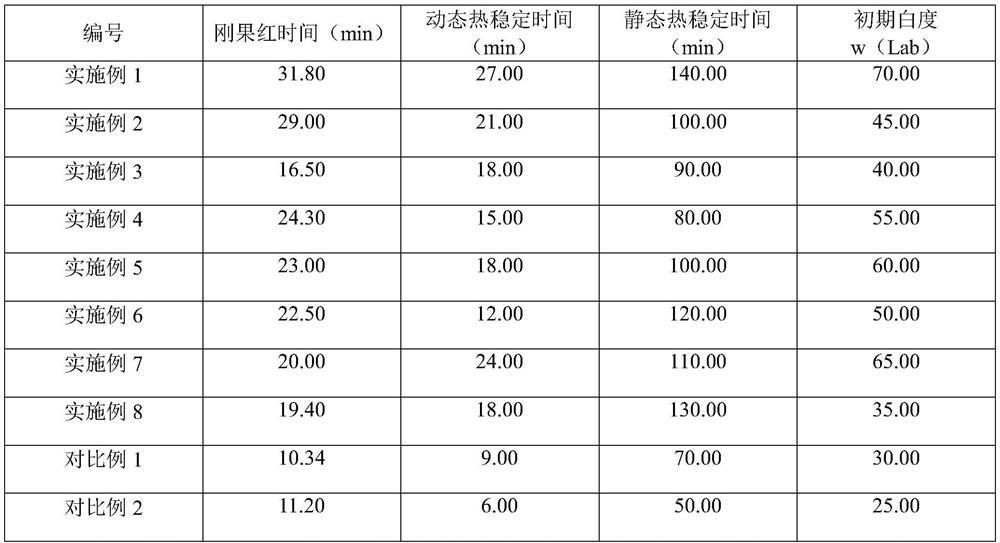

Examples

Embodiment 1

[0060] 1. Preparation steps of uracil epoxy acid group intercalated hydrotalcite (T-LDHs):

[0061] (1) Dissolve 4-thiouracil in acetic acid in a three-necked round-bottom flask, and dissolve for 0.5 h in a water bath at 60° C. under the conditions of 200 r / min magnetic stirring and heating to obtain a 1.75 mol / L 4-thiouracil solution.

[0062] (2) Nitrogen gas was passed into the three-neck round bottom flask, glycidic acid was slowly added dropwise into the flask at a rate of 2 mL / min, and the molar ratio of glycidic acid to 4-thiouracil was 1:1.5. After reacting for 10 hours, filter with suction, wash and dry in an oven at 50°C for 5 hours to obtain 4-thiouracil glycidic acid.

[0063] (3) Titrate the NaOH solution with a concentration of 1.0 mol / L into the 4-thiouracil glycidic acid solution until the pH value is 8.0 to obtain the 4-thiouracil glycidic acid base solution.

[0064] (4) Pour the 4-thiouracil glycidic acid base solution into a three-necked round-bottomed fla...

Embodiment 2

[0071] 1. Preparation steps of uracil epoxy acid group intercalated hydrotalcite (T-LDHs):

[0072] (1) Dissolve 2-thiouracil in chloroform in a three-necked round-bottomed flask, and dissolve it in a water bath at 40°C with 400r / min magnetic stirring and heating for 0.5h to obtain 1.30mol / L 2-thiouracil solution.

[0073] (2) Nitrogen was passed into the three-necked round bottom flask, and epoxycaproic acid was slowly added dropwise into the flask at a rate of 1 mL / min. The molar ratio of epoxycaproic acid to 2-thiouracil was 1:1.1. After reacting for 6 hours, filter with suction, wash and dry in an oven at 40°C for 8 hours to obtain 2-thiouracil epoxycaproic acid.

[0074] (3) Titrate the NaOH solution with a concentration of 1.2 mol / L into the 2-thiouracil epoxycaproic acid solution until the pH value is 9.0 to obtain the 2-thiouracil epoxycaproic acid base solution.

[0075] (4) Pour the 2-thiouracil epoxy caproic acid base solution into a three-necked round bottom flas...

Embodiment 3

[0082] 1. Preparation steps of uracil epoxy acid group intercalated hydrotalcite (T-LDHs):

[0083] (1) Dissolve 1,3-dimethyl-6-aminouracil in acetic acid in a three-necked round-bottomed flask, and dissolve it in a 70°C water bath and 100r / min magnetic stirring for 0.5h to obtain 2.33mol / min L uracil solution.

[0084] (2) Pass argon into the three-neck round bottom flask, slowly drop methylglycidic acid into the flask at a rate of 2mL / min, methylglycidic acid 1,3-dimethyl-6 - The molar ratio of aminouracil is 1:2. After reacting for 12 hours, filter with suction, wash and dry in an oven at 60°C for 4 hours to obtain 1,3-dimethyl-6-aminouracil methylglycidic acid.

[0085] (3) NaOH solution with a concentration of 1.5mol / L is titrated into 1,3-dimethyl-6-aminouracil glycidic acid solution until the pH value is 7.5 to obtain 1,3-dimethyl- 6-aminouracil methyl glycidic acid primer.

[0086] (4) Pour the 1,3-dimethyl-6-aminouracil methyl glycidic acid base solution into a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com