High polymer ester calcium and synthesis method thereof

A technology of polymer ester-based calcium and a synthesis method, which is applied in the field of polymer ester-based calcium and its synthesis, can solve the problems of difficult to fully exert thermal stability, difficult to integrate PVC resin, and limited to be widely used, and achieve system compatibility. Excellent performance, simple preparation method and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

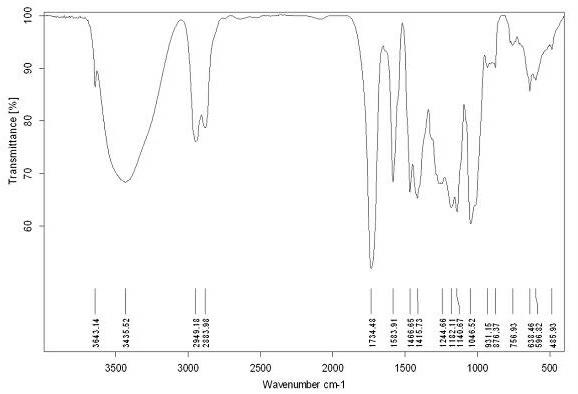

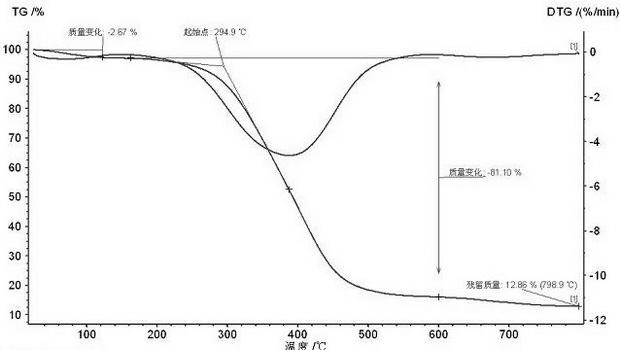

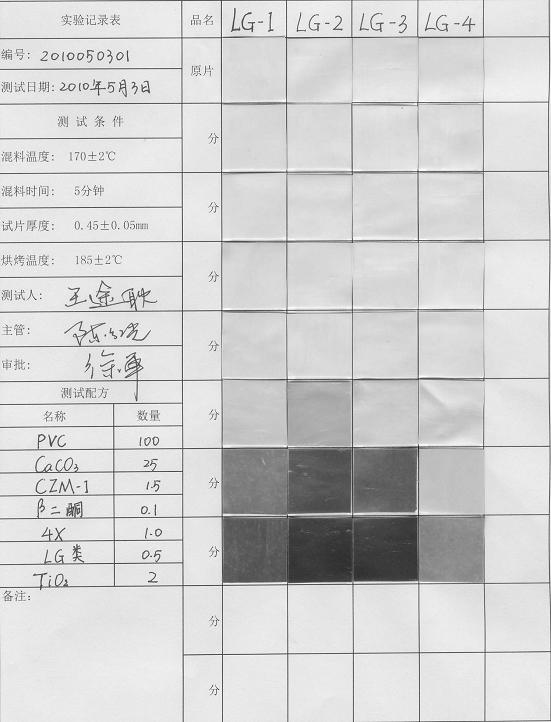

[0023] Example 1 Adopt the synthesis method of the present invention, prepare polymeric ester-based calcium according to the following steps and analyze the obtained polymeric ester-based calcium product, wherein, the synthetic adopted catalyst of polymeric ester-based calcium is SO 4 2- / Oxide-type solid superacid, specifically a kind of SO prepared by Chinese patent ZL 200610035325.9 (patent name: a preparation method of solid superacid) 4 2- / TiO 2 -SiO 2 Solid super acid.

[0024] 1. Synthesis of polymeric ester-based calcium: premix 212 Kg of adipic acid and 232 Kg of pentaerythritol and put them into the reaction kettle evenly. When the reaction temperature reaches 145°C, add 0.8 KgSO 4 2- / TiO 2 -SiO 2 Solid super acid, collect the water released from the reaction; as the reaction temperature rises slowly, keep the reaction temperature at 200°C, when the collected water released from the reaction is 38Kg, slowly add 49Kg of calcium oxide, keep the reaction for...

Embodiment 2

[0039] Example 2 Adopt synthetic method described in the present invention, prepare macromolecular ester-based calcium according to the following steps: 182Kg of adipic acid and 218 Kg of pentaerythritol are premixed and evenly put into reactor, when reaction temperature reaches 140 ℃, add 0.9 Kg catalyst, collect reaction released moisture; along with the temperature of reaction rising slowly, the reaction temperature was maintained at 198°C, and when the moisture discharged from the collected reaction was 30Kg, 28 Kg of calcium oxide was slowly added, and the feed was kept for 1.3 hours to obtain high Molecular ester calcium.

[0040] The catalyst used in this example is SO 4 2- / Oxide-type solid superacid, specifically a kind of SO prepared by Chinese patent ZL 200610035325.9 (patent name: a preparation method of solid superacid) 4 2- / SnO 2 -SiO 2 Solid super acid.

Embodiment 3

[0041] Example 3 Adopt synthetic method described in the present invention, prepare polymeric ester-based calcium according to the following steps: 201Kg of adipic acid and 228 Kg of pentaerythritol are premixed and evenly put into reactor, when reaction temperature reaches 150 DEG C, add 1.0 Kg catalyst, collect reaction Released moisture; as the reaction temperature rises slowly, the reaction temperature is maintained at 202°C, and when the collected and released moisture is 30Kg, slowly add 32 Kg of calcium hydroxide, keep the reaction for 1.4 hours, and discharge the material to obtain High molecular weight calcium ester.

[0042] The catalyst used in this example is SO 4 2- / Oxide-type solid superacid, specifically a kind of SO prepared by Chinese patent ZL 200610035325.9 (patent name: a preparation method of solid superacid) 4 2- / ZrO 2 -SiO 2 Solid super acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com