Firework powder automatic screening and device

An automatic sieving and drug technology, which is applied in filtration, chemical instruments and methods, solid separation, etc., can solve problems such as heat generation and safety hazards, and achieve the effects of small possibility, improved production efficiency, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

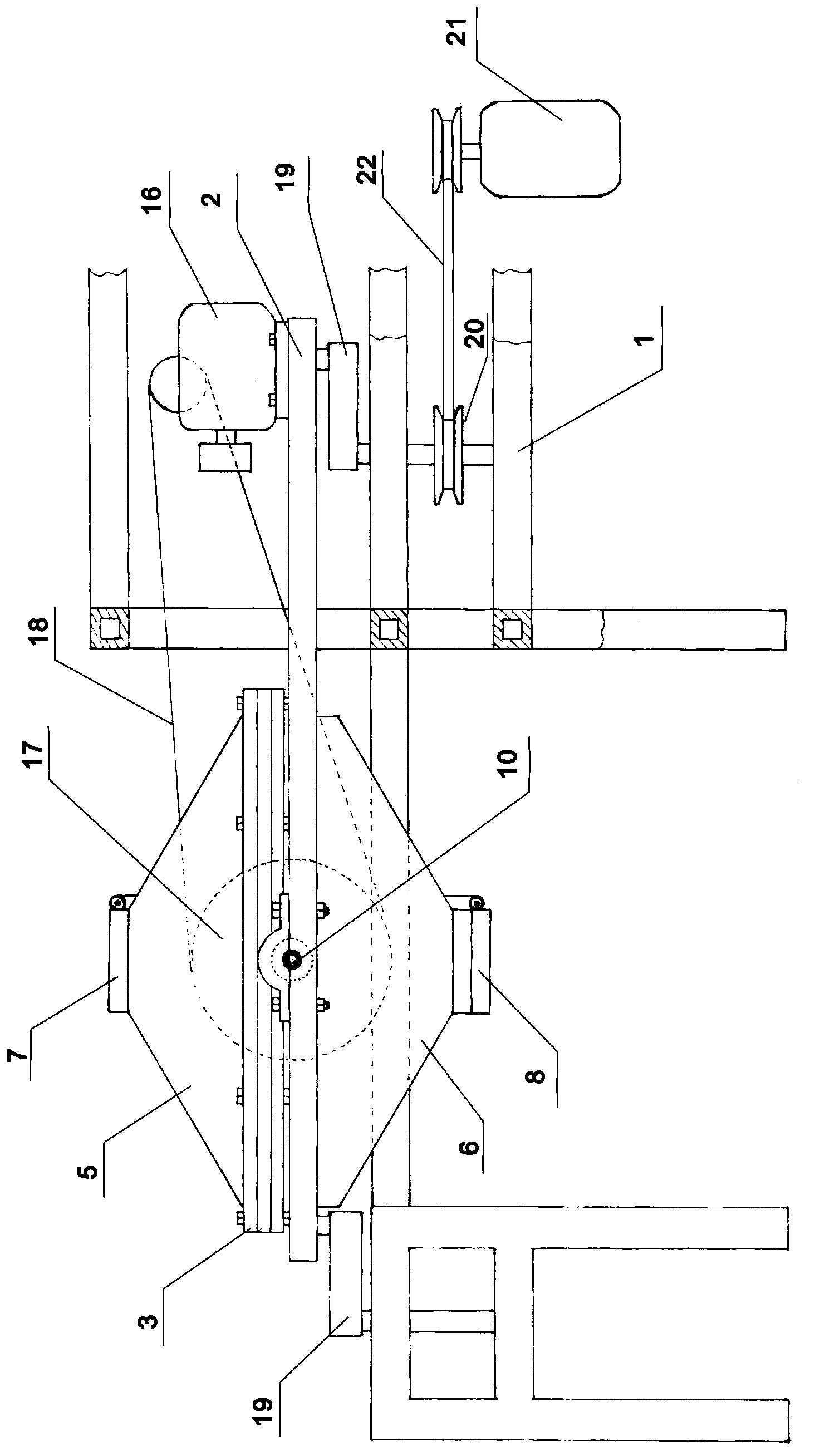

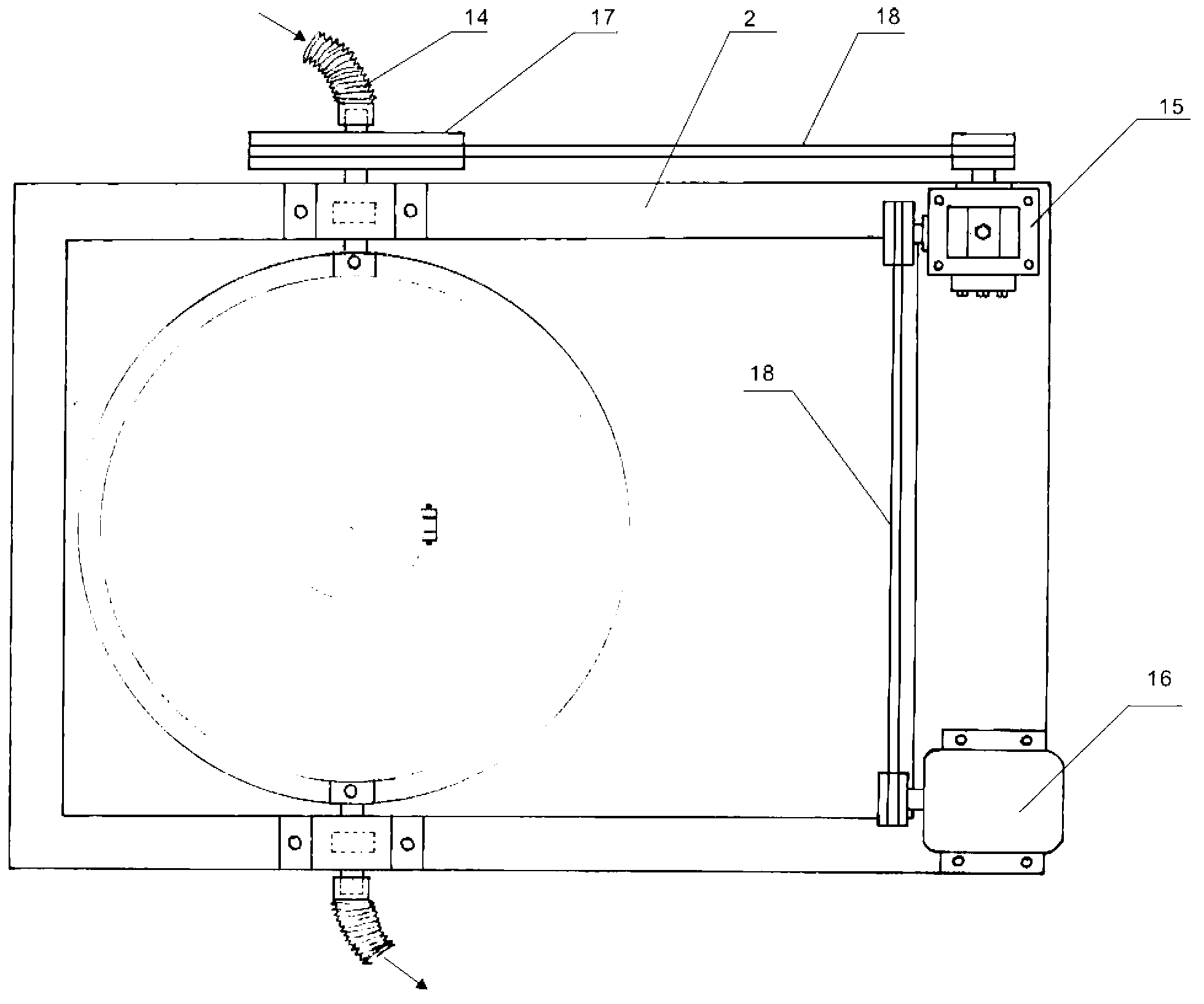

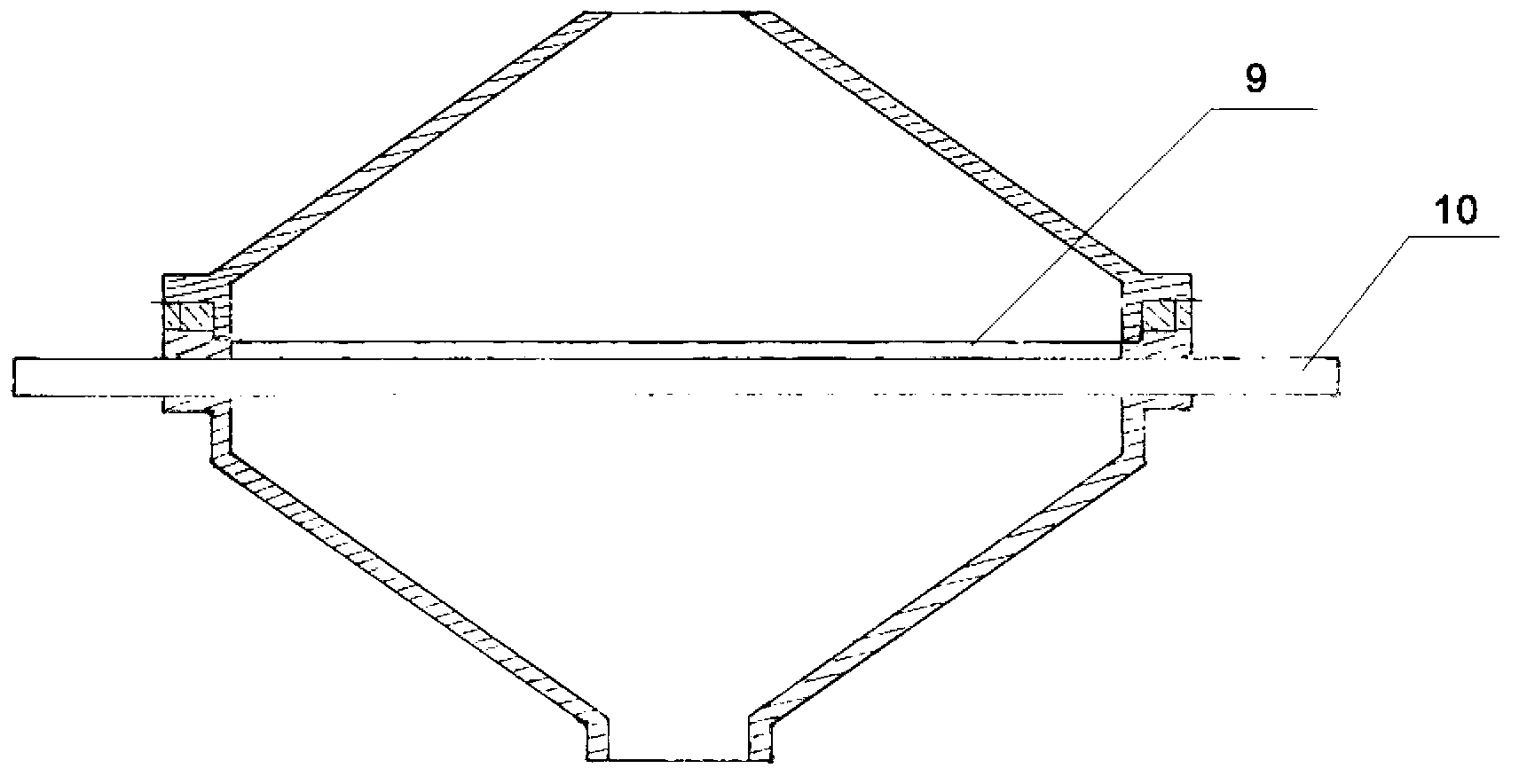

[0018] Referring to the drawings, which reflect a specific structure of the present invention, the pyrotechnic drug automatic sieve and device includes a main frame 1 and a hermetic medicine container 3, and the inner cavity of the medicine container 3 is divided into upper and lower parts by a screen 9 The medicine cavity 5 and the lower and the medicine cavity 6, the upper and the medicine cavity 5 are provided with a loading door 7, and the lower and the medicine cavity 6 is provided with a discharging door 8. As a preference, the upper and lower medicine chambers 5 and the lower and medicine chambers 6 are both set in the shape of a truncated cone, the larger bottom surfaces of the two truncated cones are connected and sealed together, and the smaller bottom surfaces of the two truncated cones are equipped with the feeding gate 7 or the discharging The door 8 and the frame of the screen 9 are arranged between the larger bottom surfaces of the two round tables.

[0019] The me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com