Screw rotor end face profile pair and construction method thereof

A rotor end and profile technology, applied in the volume field, can solve the problems of less structural variables, reduced structural flexibility of the profile pair, and insufficient parameterization from an open perspective.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

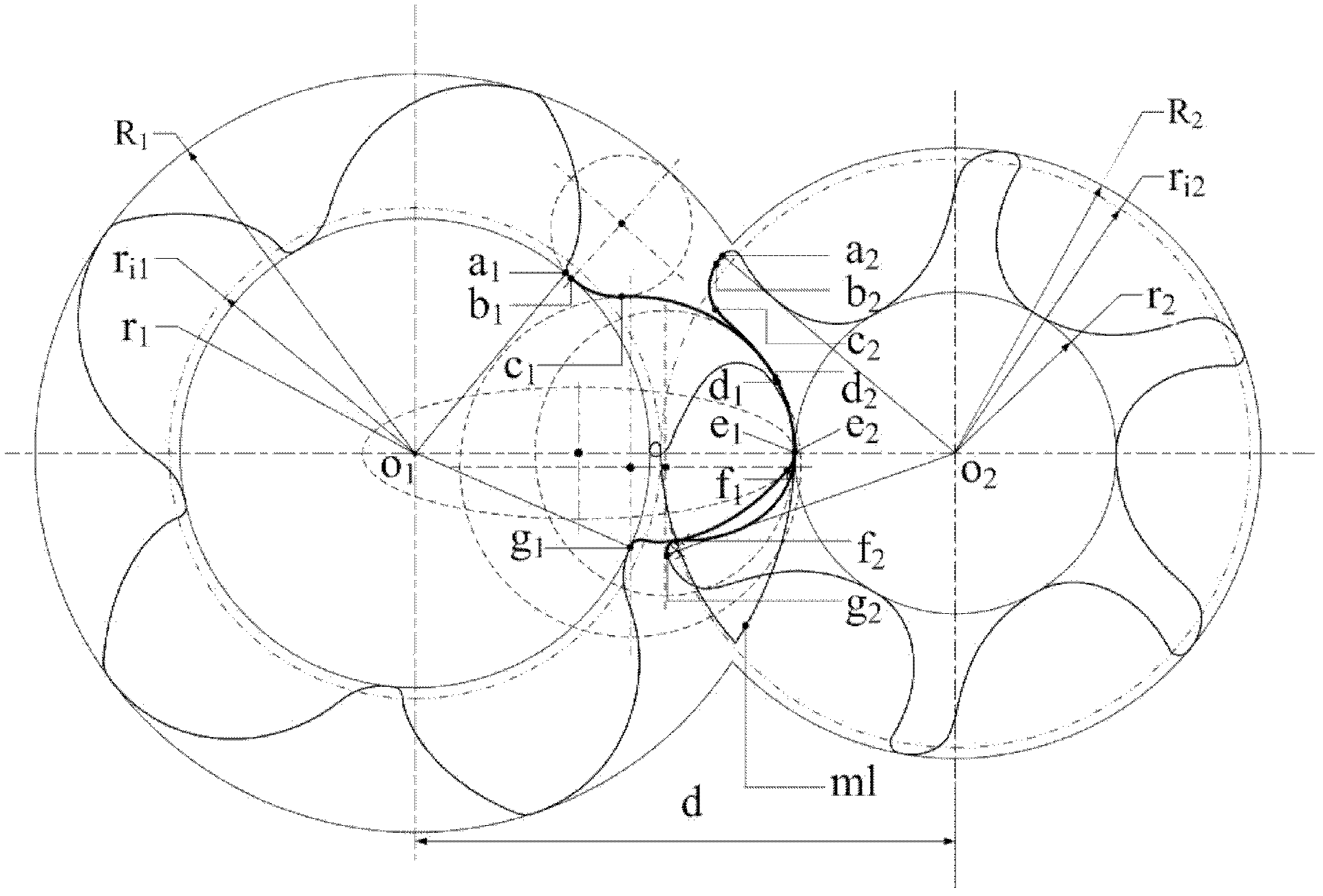

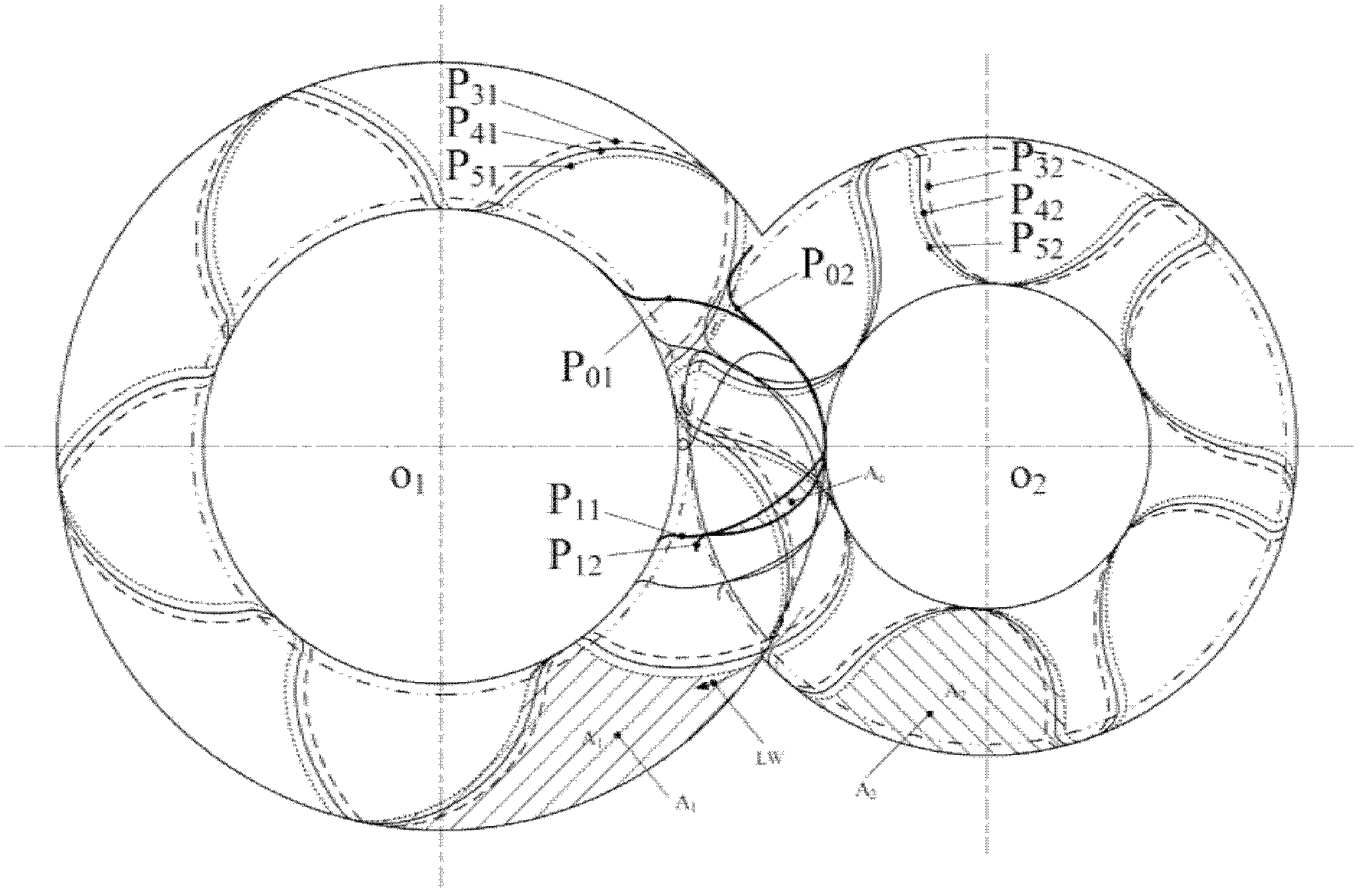

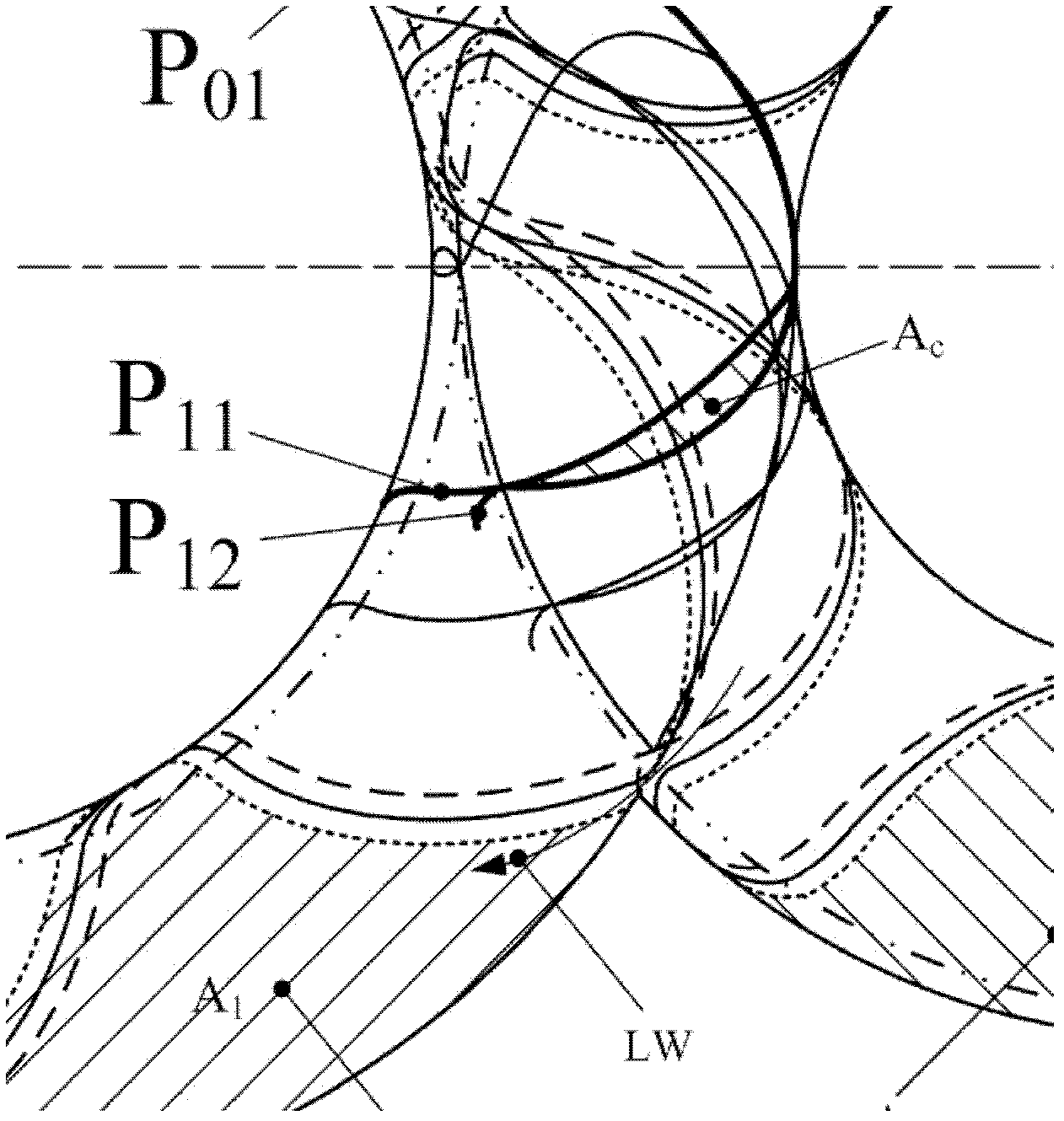

[0088] Attached below figure 1 to the attached Figure 16 The present invention will be described in detail with specific embodiments.

[0089] The main parameters of the selected screw rotor pair: the center distance d; the number of teeth of the male rotor z 1 The value range is a natural number greater than or equal to 1, the number of female rotor teeth z 2 The range of values satisfies z 2 -z 1 =0, 1, 2; the range of tooth height H is: 0 The formula for calculating the characteristic circle parameters of the rotor end profile pair is as follows:

[0090] Male rotor pitch circle radius:

[0091] Male rotor root circle radius: r 1 =r i1 -h;

[0092] External radius of male rotor: R 1 =r i1 +H;

[0093] Female rotor pitch circle radius:

[0094] Female rotor root circle radius: r 2 =d-R 1 ;

[0095] Outer radius of female rotor: R 2 =d-r 1 ;

[0096] The default geometric requirements in the construction process of each rotor profile are that the consti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com