Positive electrode piece of lithium-ion power battery and preparation method thereof

A power battery and positive electrode technology, which is applied in the field of lithium ion power battery positive electrode and its preparation, can solve the problems of large internal resistance of the electrode and poor bonding between the positive electrode material and the current collector, etc. Tightly integrated, precisely controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

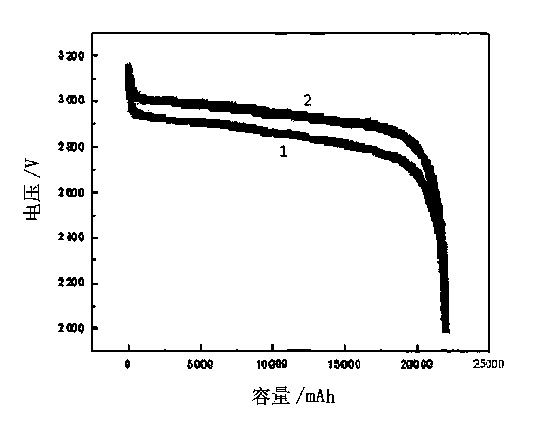

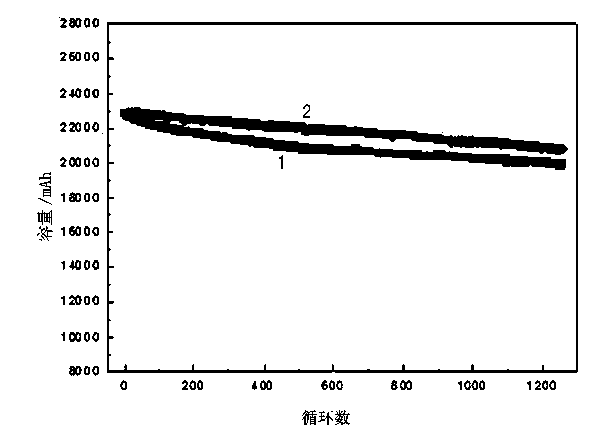

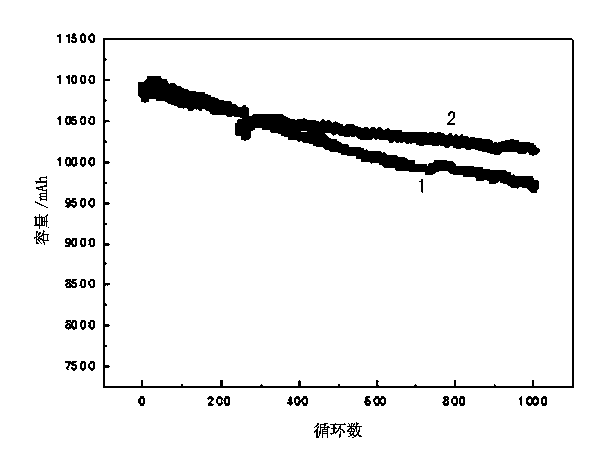

Image

Examples

Embodiment 1

[0030] (1) Preparation of carbon layer: Put 20 μm aluminum foil current collector into magnetron sputtering equipment, use 99.995% graphite target as carbon source, and vacuumize to 5×10 -3 Below Pa, pass O 2 Ar+O with volume percentage of 10% 2 Mix gas, keep the gas flow rate at 0.2Pa, adjust the sputtering current to 0.45A, bias voltage -50V, and sputter for 2000s to form a 1μm carbon layer.

[0031] (2) Preparation of cathode material slurry: 65 parts by weight of LiFePO 4 , 20 parts by weight of LiNiPO 4 , 8 parts by weight of superconducting carbon and 2 parts by weight of carbon nanotubes were baked at 100°C for 16 hours for later use, and 5 parts by weight of polyvinylidene fluoride was added to 80-100 parts by weight of N-methylpyrrolidone, and stirred After 12 hours, add 8 parts by weight of superconducting carbon and 2 parts by weight of carbon nanotubes, stir for 2 hours, and then add a total of 65 parts by weight of LiFePO in two equal amounts. 4 and 20 part...

Embodiment 2

[0047] (1) Preparation of the carbon layer: Put a 30 μm aluminum foil current collector into the magnetron sputtering equipment, use 99.995% graphite target as the carbon source, and evacuate to 5×10 -3 Below Pa, pass O 2 Ar+O with volume percentage of 10% 2 Mix gas, keep the gas flow at 0.2Pa, adjust the sputtering current to 0.6A, bias -50V, sputter for 6000s, and form a 3μm carbon layer;

[0048] (2) Preparation of cathode material slurry: 10 parts by weight of LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 , 10 parts by weight LiMn 2 o 4 , 36 parts by weight LiCoPO 4 , 20 parts by weight LiNiPO 4 , 20 parts by weight LiMnPO 4 , 2 parts by weight of conductive graphite, and 1 part by weight of conductive carbon black were baked at 120°C for 8 hours for later use, then 1 part by weight of polyvinylidene fluoride was added to 80-100 parts by weight of N-methylpyrrolidone, and stirred for 1 hour Then add 2 parts by weight of conductive graphite, 1 part by weight of conductive car...

Embodiment 3

[0062] (1) Preparation of the carbon layer: Put a 15 μm aluminum foil current collector into the magnetron sputtering equipment, use 99.995% graphite target as the carbon source, and evacuate to 5×10 -3 Below Pa, pass O 2 Ar+O with volume percentage of 10% 2 Mix gas, keep the gas flow at 0.2Pa, adjust the sputtering current to 0.2A, bias -50V, sputter for 200s, and form a 10nm carbon layer;

[0063] (2) Preparation of cathode material slurry: first, 5 parts by weight of LiAlO 2 , 10 parts by weight LiMgO 2 , 10 parts by weight of LiFe 1 / 3 co 1 / 3 mn 1 / 3 PO 4 , 5 parts by weight Li 2 AlO 3 , 5 parts by weight Li 2 NiO 3 , 5 parts by weight Li 2 MgO 3 , 5 parts by weight Li 2 CoO 3 , 25 parts by weight 0.4Li 2 MnO 3 0.6LiMnO 2 , 10 parts by weight of conductive carbon black and 10 parts by weight of flake graphite were baked at 80°C for 24 hours for later use, and 10 parts by weight of polyvinylidene fluoride was added to 80-100 parts by weight of N-met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com