Jack connector assembly

A technology of connectors and contacts, which is applied to the parts, connections, electrical components of connecting devices, etc., can solve the problems of difficulty in adjusting the size of the plugging force, increased stress relaxation of materials, and high heat generation of contacts, so as to reduce the heat. , the effect of enhancing electrical conductivity and improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

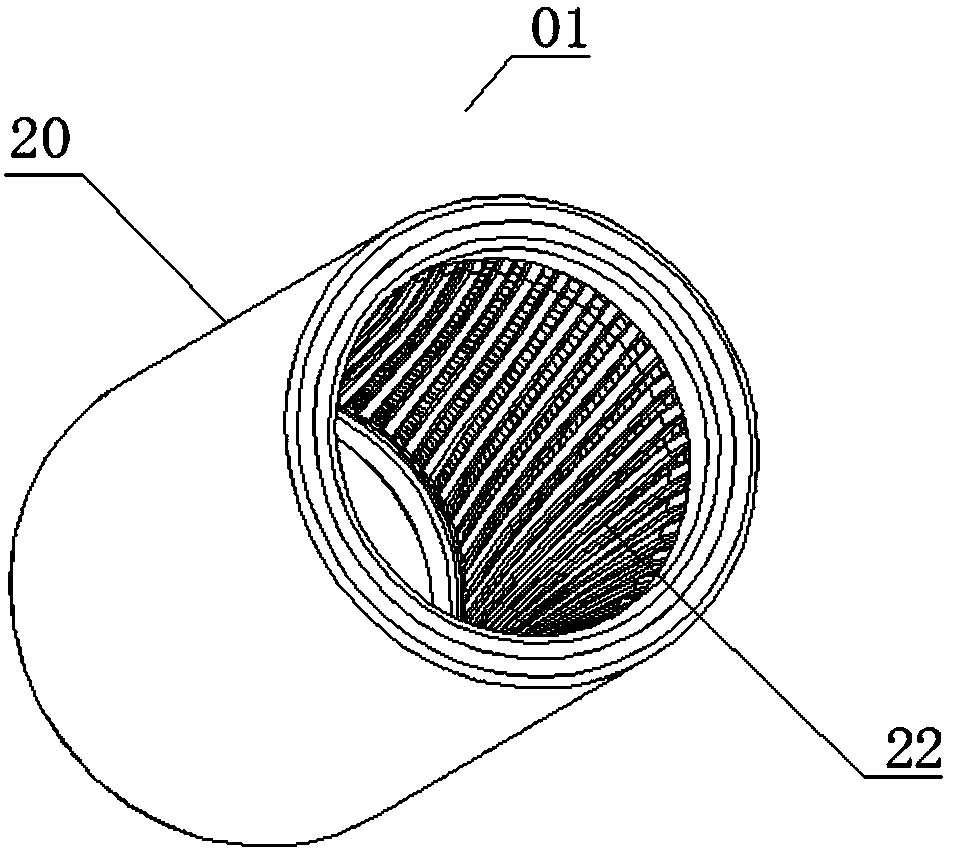

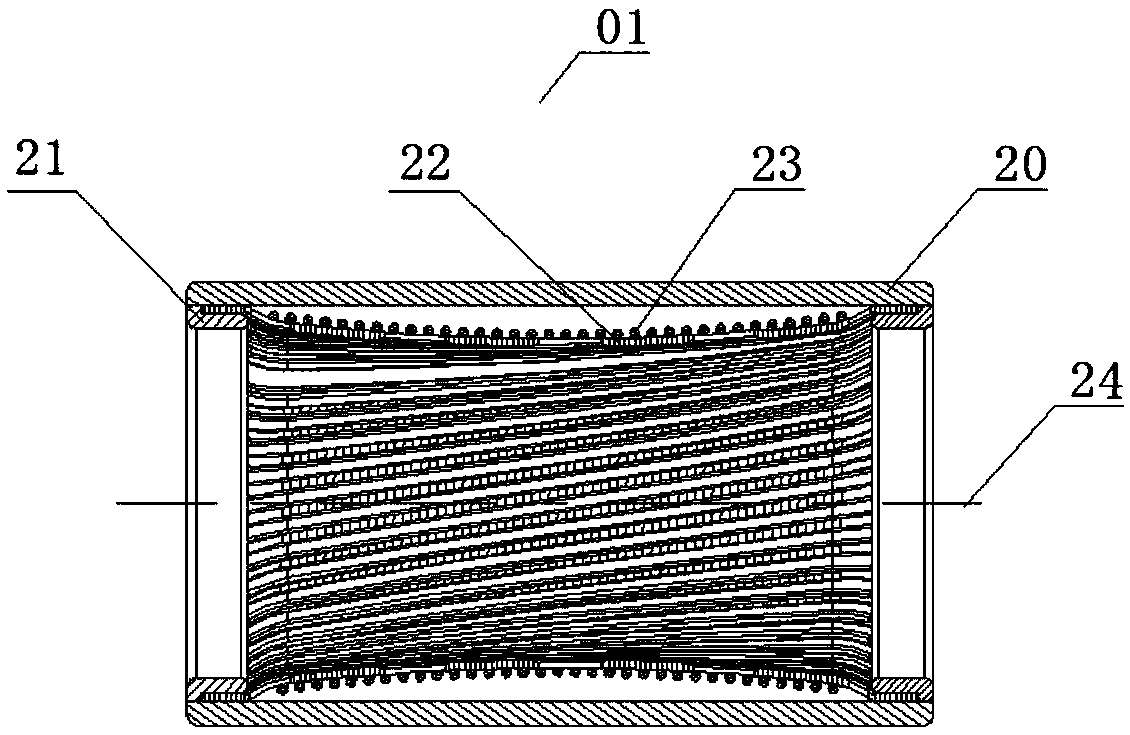

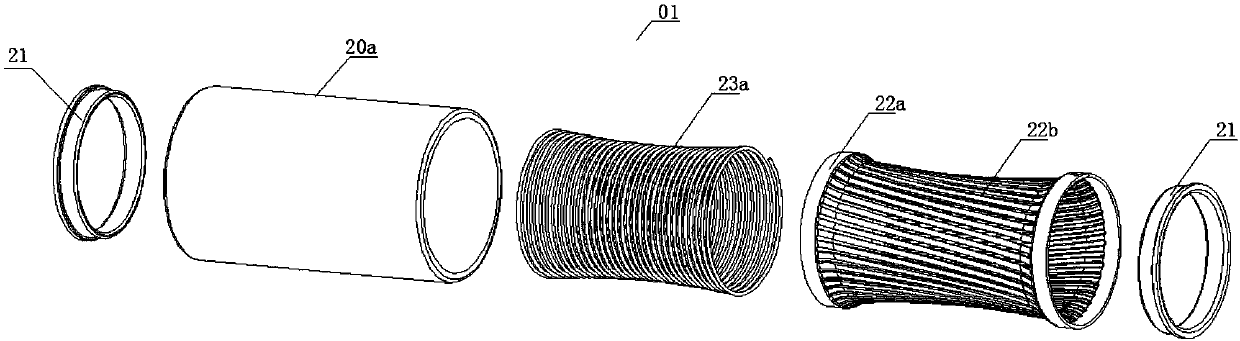

[0081] Figure 1a A perspective view of the jack connector according to the first embodiment of the present application is shown. Figure 1b A sectional view along the axis of the receptacle connector according to the first embodiment of the present application is shown. Figure 1c An exploded view of the jack connector according to the first embodiment of the present application is shown. Figure 1d A perspective view of the contact and the pressure part according to the first embodiment of the present application is shown.

[0082] Such as Figure 1a , 1b , 1c and 1d, the receptacle connector 01 according to the first embodiment of the present application includes a receptacle sleeve 20, two inner ferrules 21, a cage type cylindrical contact 22 and a pressure part 23. The socket sleeve 20 further includes a cylindrical contact sleeve 20a. The cage-type cylindrical contact piece 22 is a single-section leaf spring, including two ring-shaped fixed contact parts 22a that are ...

no. 2 approach

[0089] Figure 2a It shows an exploded view of the jack connector related to the second embodiment of the present application, Figure 2b A perspective view of a contact and a pressure portion according to a second embodiment of the present application is shown. Figure 2c A perspective view of the O-ring silicone elastomer according to the second embodiment of the present application is shown.

[0090] Such as Figure 2a and 2b As shown, the second embodiment of the present application is a deformation of the first embodiment, the difference is that the pressure part 234 of the connector 02 is realized as an elastic body formed of a polymer material, and the pressure part 234 in this embodiment is a silicone elastic body 234a . Such as Figure 2aAs shown, the silicone elastic body 234a is a circular cylindrical body, and other elastic structures known to those skilled in the art may also be used, such as an O-ring (O-Ring), as shown in FIG. 2C . The pressure part 234 ca...

no. 3 approach

[0092] Figure 3a A perspective view of a jack connector according to a third embodiment of the present application is shown. Figure 3b A sectional view along the axis of the receptacle connector according to the third embodiment of the present application is shown. Figure 3c An exploded view of the jack connector according to the third embodiment of the present application is shown. Figure 3d A perspective view of a contact and a pressure portion according to a third embodiment of the present application is shown.

[0093] Such as Figure 3a , 3b , 3c and 3d, the third embodiment of the present application is a modification of the first embodiment, the difference is that the pressure part 235 of the connector 03 is implemented as a pressure bag structure, which includes a fluid inlet 235a, a fluid outlet 235b and a cavity 235c. The fluid filled in the cavity is gas or liquid. At the same time, the socket sleeve 201 also leaves gaps at corresponding positions of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com