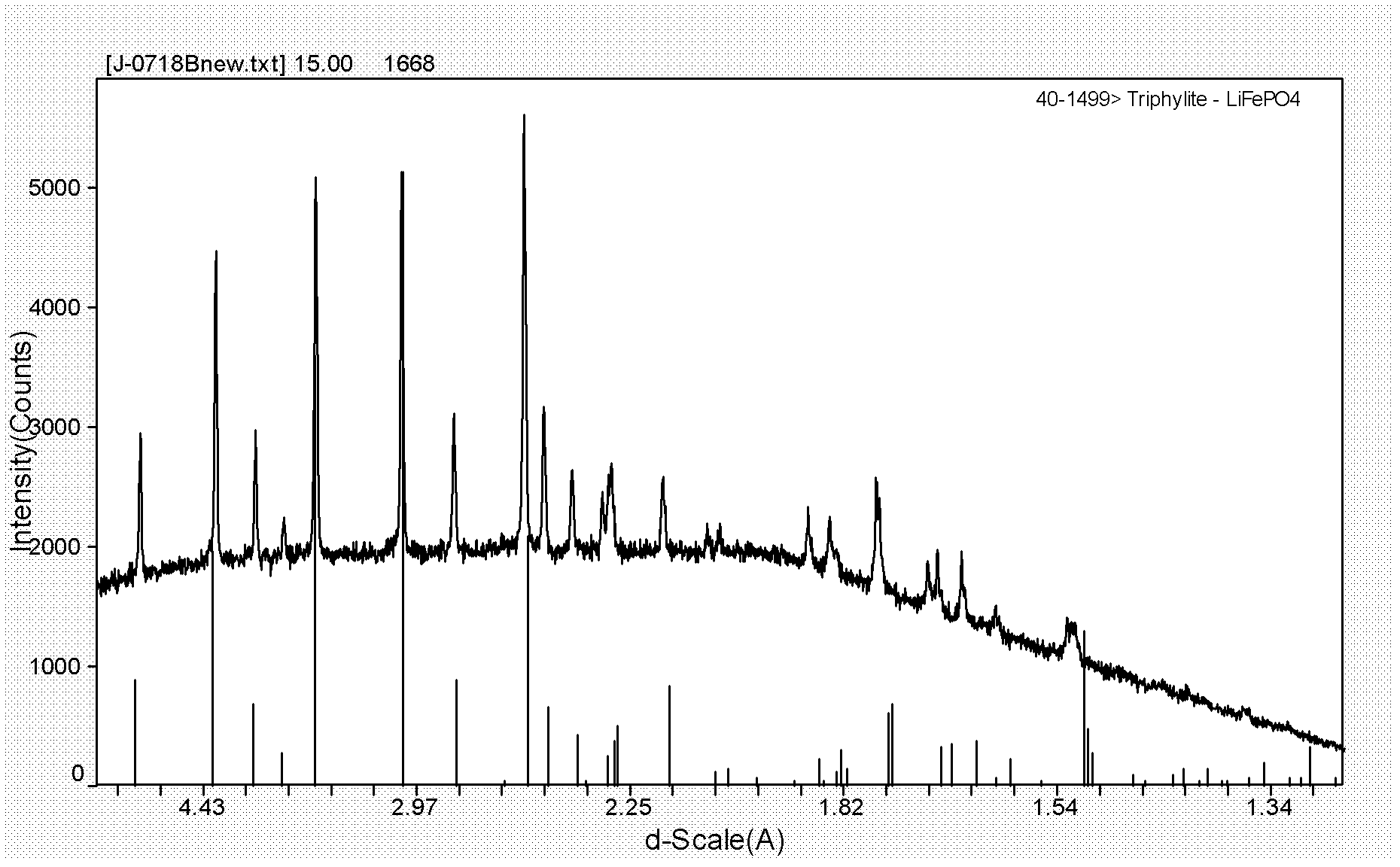

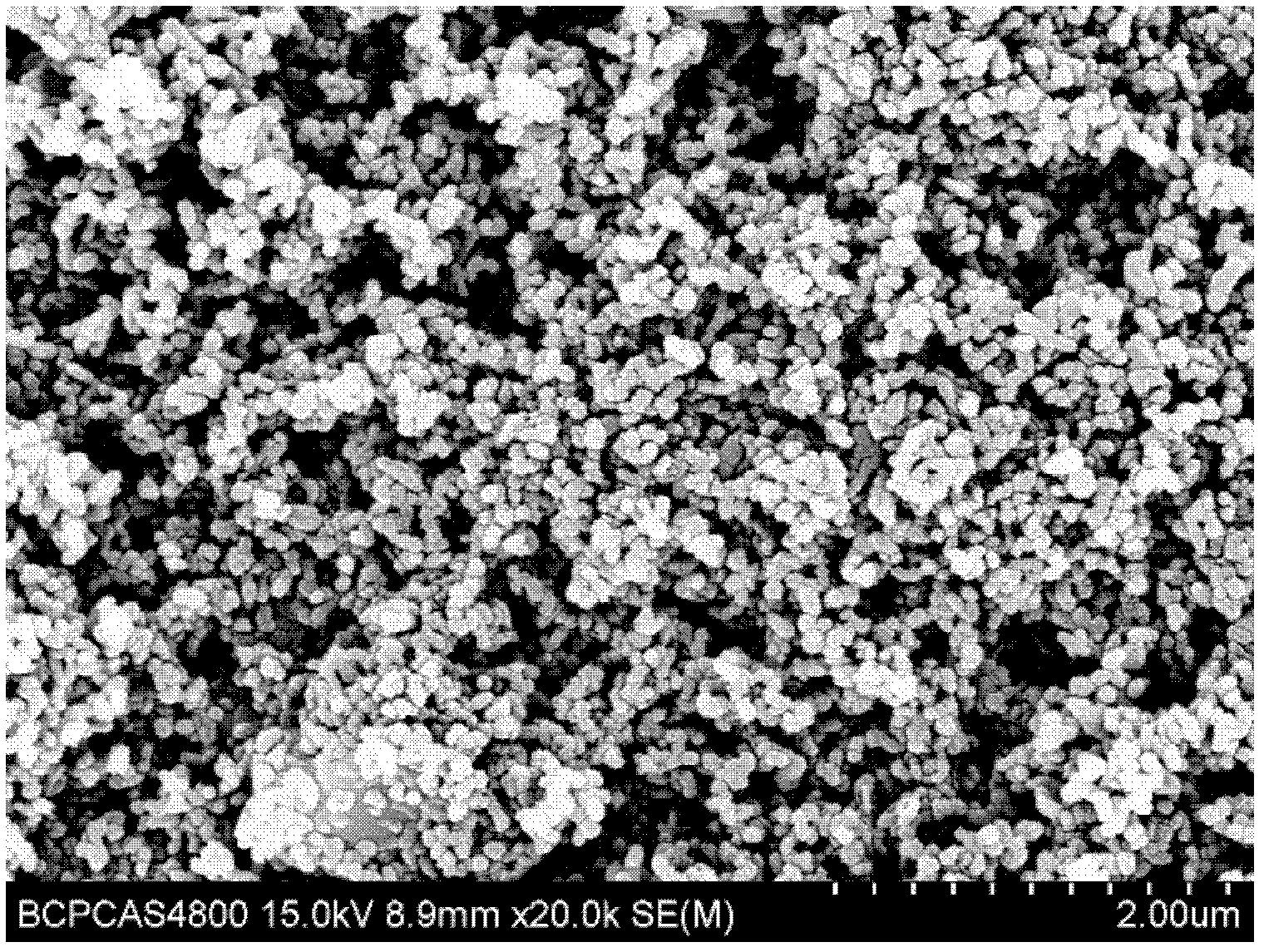

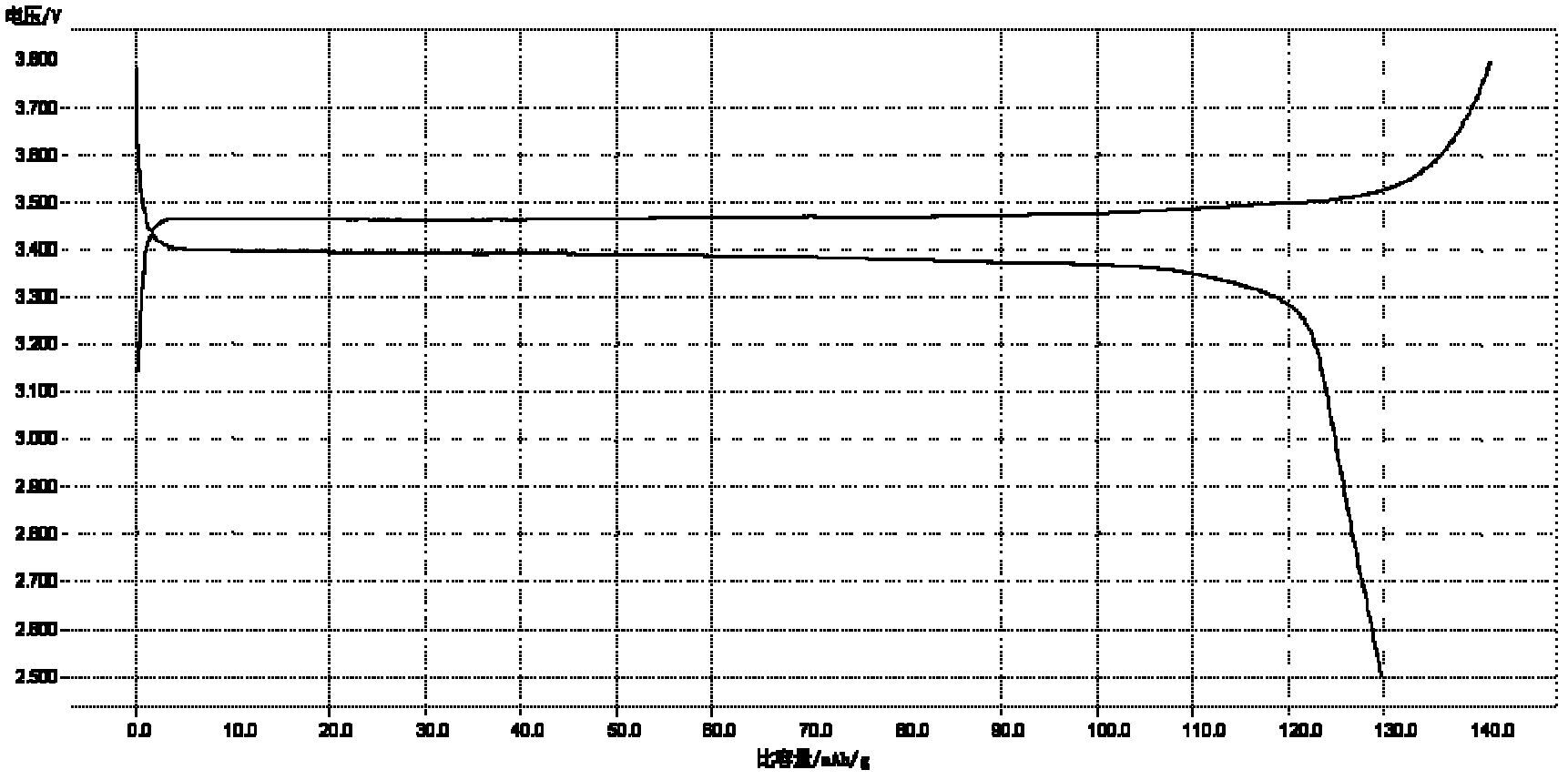

Preparation method for LiFePO4 (lithium iron phosphate) superfine powder serving as power battery anode materials

A positive electrode material, power battery technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of difficult dispersion of ultrafine powder, difficult coating, etc., to improve conductivity, reduce difficulty, and widely used. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Power battery cathode material LiFePO 4 The preparation method of superfine powder, comprises the following steps:

[0026] 1) Weigh LiOH and FeSO according to the lithium:iron:phosphorus molar ratio of 3:0.98:1 4 ·7H 2 O and H 3 PO 4 , and then take by weighing the surfactant oleic acid of above-mentioned three kinds of raw material quality summations 1%, then above-mentioned raw material is dissolved in water respectively;

[0027] 2) Under nitrogen protection atmosphere, H 3 PO 4 , FeSO 4 ·7H 2 The aqueous solution of O and oleic acid is mixed and then added to the reactor to 2+ Play an anti-oxidation effect; then heat to 40°C with stirring, add LiOH solution; then heat to 180°C under airtight conditions, and react for 4 hours; after the reaction is completed, cool naturally, and after cooling down to below 100°C, filter and collect the filter residue Thoroughly wash with water and dry above 100°C to obtain LiFePO 4 Powder;

[0028] 3) The obtained LiFePO ...

Embodiment 2

[0031] Power battery cathode material LiFePO 4 The preparation method of superfine powder, comprises the following steps:

[0032] 1) Weigh LiOH, Fe(NO 3 ) 2 ·6H 2 O and H 3 PO 4 , and then weigh the glucose of 2% of the mass sum of the above three raw materials, and then dissolve the above raw materials in water respectively;

[0033] 2) In Fe(NO 3 ) 2 ·6H 2Add its mass 1% ascorbic acid in the solution dissolved in O water, to Fe 2+ play an antioxidant role, and then combine it with H 3 PO 4 , Glucose aqueous solution is mixed and added to the reaction kettle, and then heated to 50°C under stirring, and then LiOH solution is added;

[0034] Then heated to 200°C under airtight conditions, and reacted for 2 hours; after the reaction was completed, it was cooled naturally, and after cooling down to below 100°C, filtered, the collected filter residue was fully washed with water, dried above 100°C to obtain LiFePO 4 Powder;

[0035] 3) The obtained LiFePO 4 powder in...

Embodiment 3

[0038] Power battery cathode material LiFePO 4 The preparation method of superfine powder, comprises the following steps:

[0039] 1) Weigh LiOH and FeCl according to the lithium:iron:phosphorus molar ratio of 2.5:1.05:1 2 4H 2 O and H 3 PO 4 , and then weigh the lecithin of 2% of the mass sum of the above three raw materials, and then dissolve the above raw materials in water respectively;

[0040] 2) In FeCl 2 4H 2 Add its quality 3% ascorbic acid in the solution that O dissolves in water again, to Fe 2+ play an antioxidant role, and then combine it with H 3 PO 4 1. The aqueous solution of lecithin is mixed and added to the reaction kettle, then heated to 80°C under stirring, and then LiOH solution is added;

[0041] Then heated to 160°C under airtight conditions, and reacted for 5 hours; after the reaction was completed, it was cooled naturally, and after the temperature was lowered to below 100°C, it was filtered, and the filter residue was collected and washed wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com