Windshield adhesive tape and manufacturing method thereof

A production method and adhesive strip technology, applied in vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve the problems of high cost and reduce material cost, and achieve the effect of tight and firm combination, reduced material cost, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

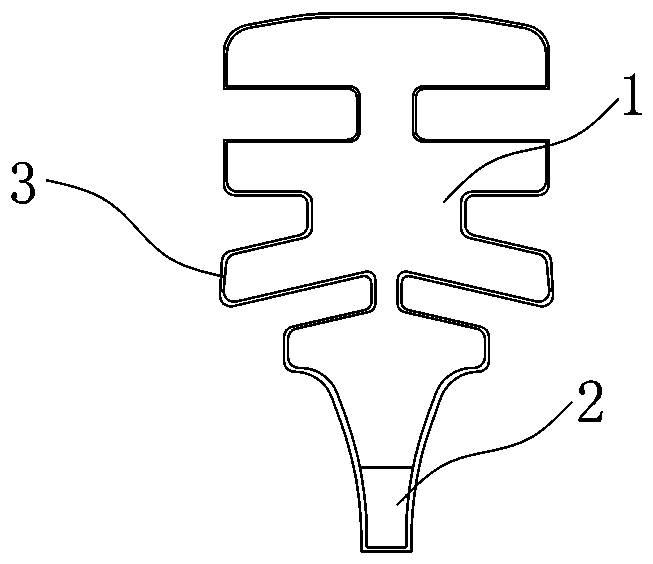

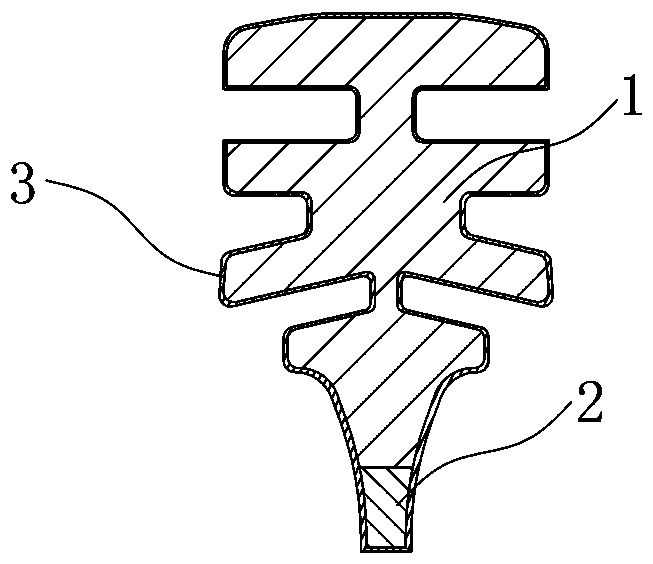

[0025] Cooperate figure 1 and figure 2 As shown, the present invention discloses a wiper rubber strip, which includes a strip body 1 made of a first rubber material and a blade portion 2 made of a second rubber material; the blade portion 2 and the rubber strip body 1 Integral co-extrusion.

[0026] Compared with the existing wiper rubber strip made of the same material, the rubber strip main body 1 and the blade part 2 according to the present invention can choose different rubber materials according to their different performance requirements to meet their respective performance requirements, and The blade part 2 and the rubber strip main body 1 are integrally co-extruded, so that the blade part 2 and the rubber strip main body 1 can be combined tightly and firmly.

[0027] Specifically, the hardness valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com