Large-expansion steel for seamless steel tube and preparation method thereof

A technology of seamless steel pipe and expansion, which is applied in the field of seamless steel pipe, can solve the problems of reducing production efficiency, increasing process cost, and heat treatment process is unfavorable for large-scale industrial production, and achieves the effect of solving high cost and high plastic deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and Embodiment 2

[0035]Low-cost and large-expansion seamless petroleum casing, the composition of raw materials in terms of mass percentage is: C: 0.03wt%, Si: 0.3wt%, Mn: 5.8wt%, P: 0.01wt%, S: 0.0020wt%, The balance is Fe and unavoidable impurities, which are smelted and cast into steel billets by converter.

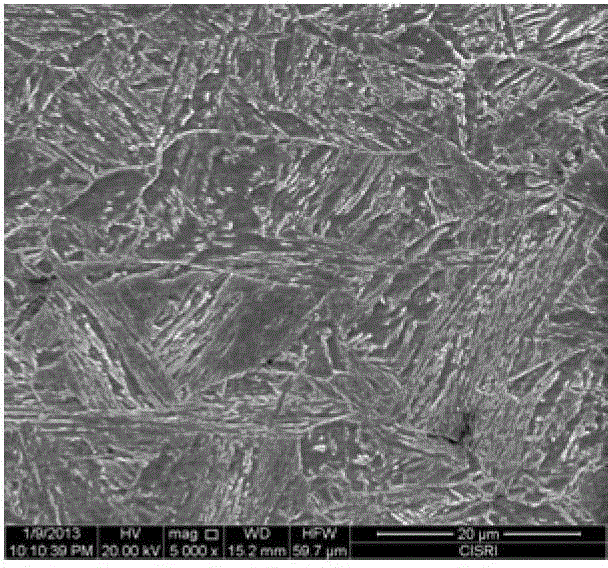

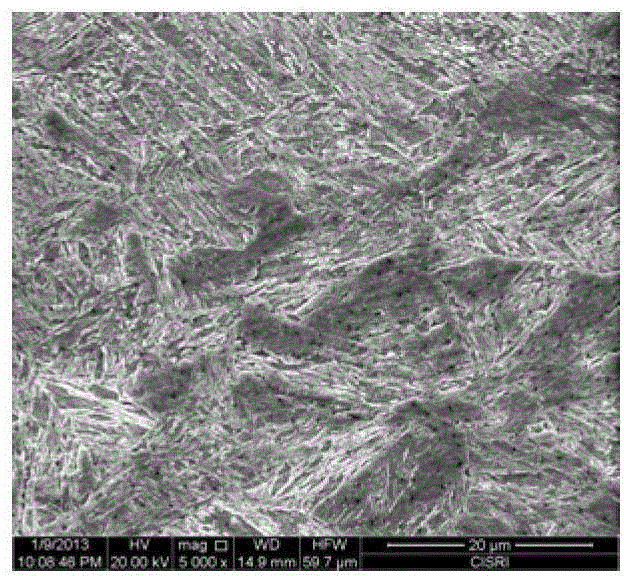

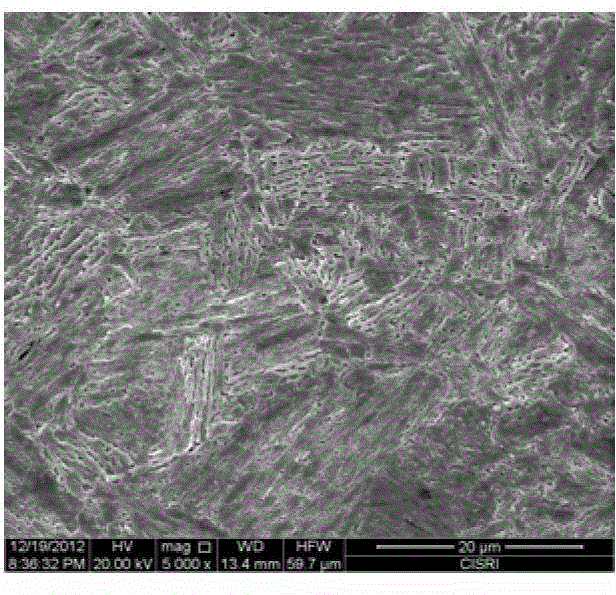

[0036] Using the seamless tube forming technology, the above-mentioned tube blank is heated to 1200°C, soaked and perforated. After rolling at 900 °C, two cooling methods, air cooling and water spray cooling, were used to obtain two room temperature microstructures, such as figure 1 and figure 2 shown. Finally, the steel pipes of these two structures were heated to 650°C at a heating rate of 5°C / S, and after holding for 8 hours, they were cooled to room temperature with the furnace. The final microstructure is obtained as image 3 and Figure 4 shown.

[0037] After inspection, the mechanical properties of steel pipes under the two cooling methods are shown in Table 1. Its vari...

Embodiment 3~ Embodiment 6

[0041] Low-cost large-expansion seamless petroleum casing, the composition of raw materials in terms of mass percentage is: C: 0.02~0.08wt%, Si: 0.3wt%, Mn: 3~8wt%, P≤0.015wt%, S≤0.0030 wt%, and the balance is Fe and unavoidable impurities. The specific chemical cost is shown in Table 2. It is smelted in a converter and cast into a steel billet.

[0042] Using the seamless tube forming technology, the above-mentioned tube blank is heated to 1200°C, soaked and perforated. Water spray cooling is used after rolling at 900°C. Finally, the steel pipes of these two structures were heated to 630°C at a heating rate of 5°C / S, and after holding for 10 hours, they were cooled to room temperature with the furnace.

[0043] After inspection, the mechanical properties of several steel pipes with different chemical compositions are shown in Table 3. Its various mechanical performance indicators fully meet the requirements of API and other relevant standards.

[0044] Table 2 Chemical co...

Embodiment 7~ Embodiment 10

[0049] Large expansion capacity seamless petroleum casing, the raw materials are: C: 0.04wt%, Si: 0.3wt%, Mn: 5.0wt%, P: 0.012wt%, S: 0.0020wt%, the balance It is Fe and unavoidable impurities. It is smelted in a converter and cast into a steel billet.

[0050] Using seamless tube forming technology, the above-mentioned tube blank is heated to 1150 ℃ ~ 1200 ℃, soaked and pierced. Water spray cooling is adopted after rolling at 800~1000°C. Finally, the steel pipes were heated to 610°C, 630°C and 650°C at a heating rate of 5°C / S, respectively, and then kept at different times, and then cooled to room temperature with the furnace. The specific heat treatment process is shown in Table 4.

[0051] After inspection, the mechanical properties of several steel pipes with different chemical compositions are shown in Table 5. Its various mechanical performance indicators fully meet the requirements of API and other relevant standards.

[0052] Table 4 Detailed heat treatment proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com