Multilayer modified casting nylon material

A technology of casting nylon and modification, applied in the field of multi-layer modified casting nylon material and its preparation, can solve the problems of complexity, increased cost and high design difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Example 1 (20% by weight of the wear-resistant layer + 40% by weight of the reinforcement layer + 40% by weight of the toughened layer):

[0089] (1) Weigh 320 kg of caprolactam raw materials, add them to the melting tank, and heat until they are completely melted.

[0090] (2) The temperature is raised to 125°C, 0.9 kg of sodium methoxide is added, the stirring device is turned on, the dehydration device is turned on, and the dehydration is performed for 40 minutes to complete dehydration to obtain activated caprolactam.

[0091] (3) Transfer 64kg of activated caprolactam to 1# reaction tank, add 5.12kg of polyethylene glycol lubricating grease, continue dehydration, stir and heat to 140°C.

[0092] (4) Transfer 128kg of activated caprolactam to 2# reaction tank, add 19.2kg of poly(butyl acrylate-styrene) whiskers, continue dehydration, stir and heat to 140°C.

[0093] (5) Transfer 128kg of activated caprolactam to 3# reaction tank, add 19.2kg of EVA-g-MAH, continue dehydration,...

Embodiment 2

[0099] Example 2 (30% by weight of the wear-resistant layer + 20% by weight of the toughened layer + 50% by weight of the reinforced layer):

[0100] (1) Weigh 100 kg of caprolactam raw materials, add them to the melting tank, and heat until they are completely melted.

[0101] (2) The temperature is raised to 120°C, 0.4 kg of sodium methoxide is added, the stirring device is turned on, and the dehydration device is turned on, and dehydrated for 30 minutes to complete dehydration to obtain activated caprolactam.

[0102] (3) Transfer 50kg of activated caprolactam to 1# reaction tank, add 5kg of potassium polytitanate whiskers, continue dehydration, stir and heat to 135°C.

[0103] (4) Transfer 20kg of activated caprolactam to 2# reaction tank, add 2kg of EVA-g-MAH, continue dehydration, stir and heat to 135°C.

[0104] (5) Transfer 30kg of activated caprolactam to 3# reaction tank, add 1.5kg of polyolefin base lubricating grease, continue dehydration, stir and heat to 135°C.

[0105] (6)...

Embodiment 3

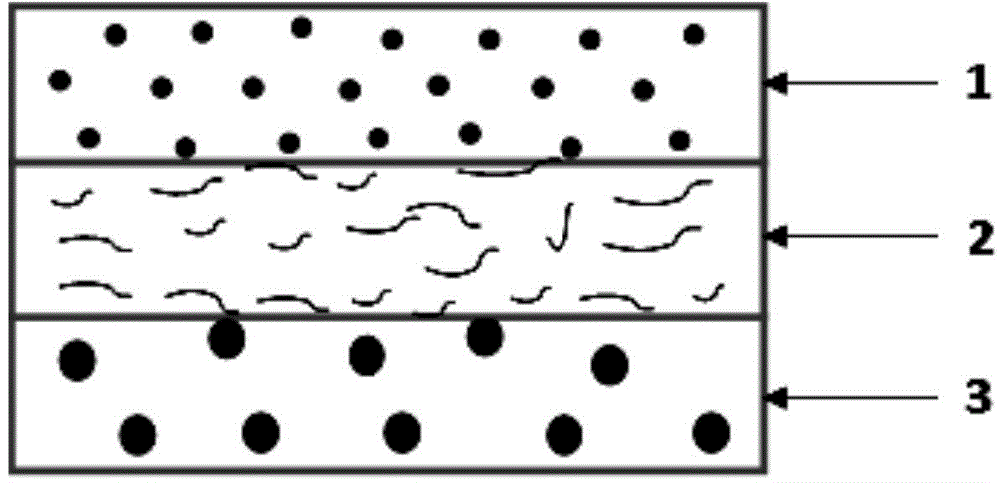

[0111] Example 3 provides a multilayer modified cast nylon board, which is made of the multilayer modified cast nylon of the present invention. figure 1 Show the cross-sectional view of the nylon plate, such as figure 1 As shown, the layers of the multilayer nylon board are toughened layer 1, reinforced layer 2, and wear-resistant layer 3 in sequence.

[0112] The middle layer of the multi-layer nylon board is reinforced layer 2, which has high mechanical strength, one side surface layer is toughened layer 1, which has high impact resistance, and the other side surface layer is wear-resistant layer 3, which has High anti-wear performance. The multi-layer modified composite nylon board has a reinforced matrix, abrasion resistance on one side and impact resistance on one side, and can be applied to various complicated working environments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com