Embedded rapid cooling orthopedic twist drill and manufacturing method

A rapid cooling, embedded technology, applied in medical science, surgery, etc., can solve the problems of bone necrosis, cooling performance patient harm, poor thermal conductor, etc., and achieve the effect of free structural parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with specific embodiments.

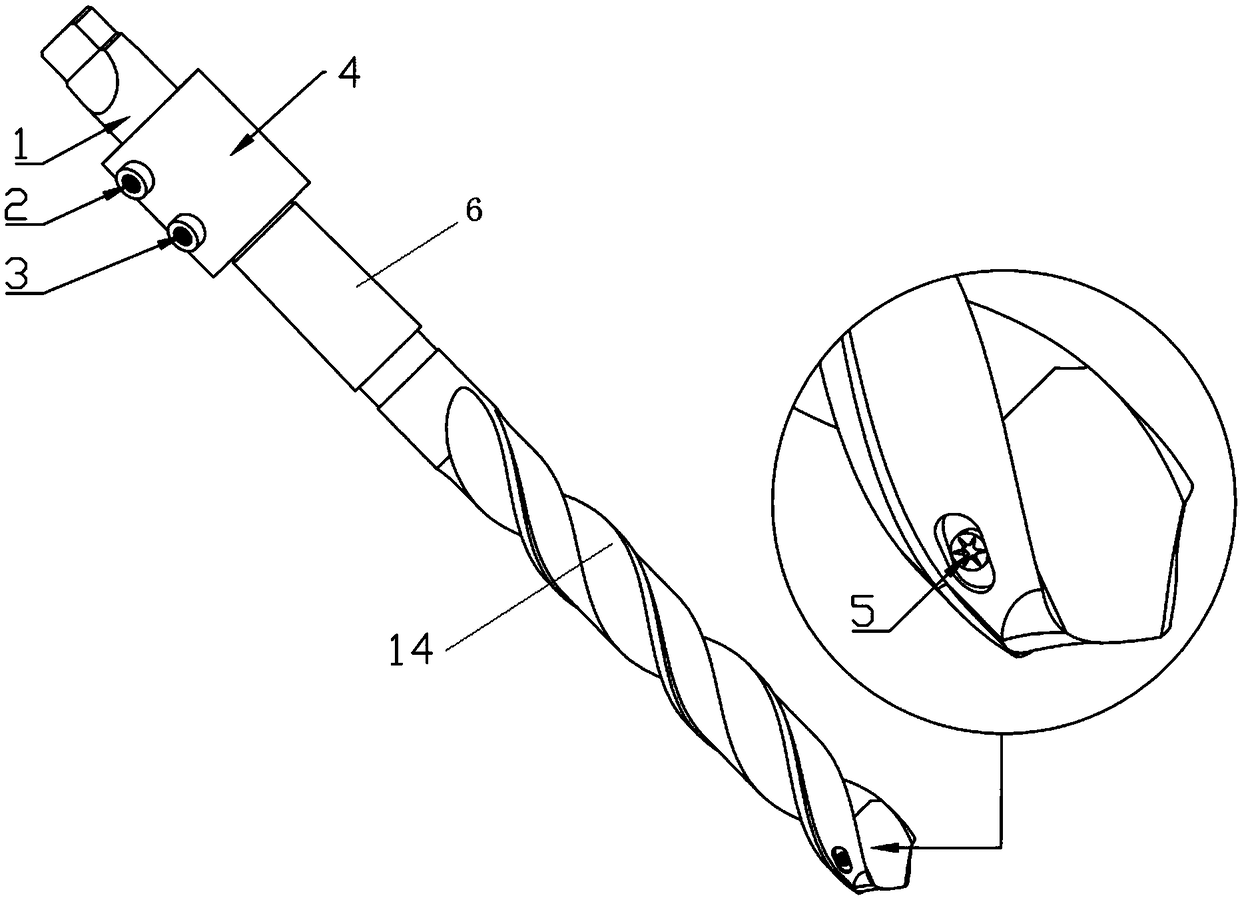

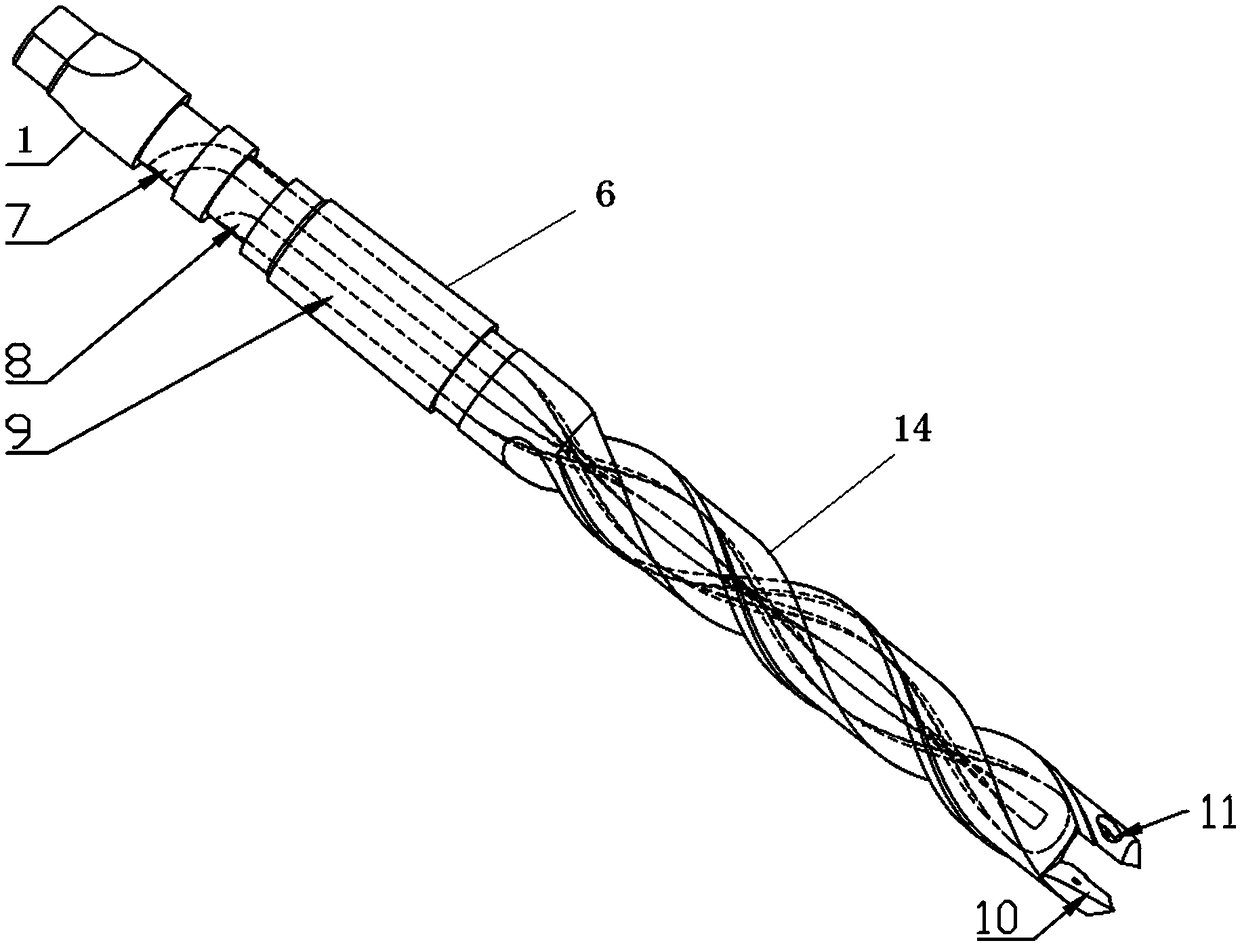

[0033] The invention discloses an embedded rapid cooling orthopedic twist drill, which comprises a drill handle 1, a drill body connecting rod 6 and a drill body 14 connected in sequence;

[0034] There is a connecting section between the drill shank 1 and the connecting rod 6 of the drill body, and two cooling water ring grooves are opened along the outer peripheral wall of the connecting section;

[0035] Along the axial direction of the drill body 14, an internal circulation spiral cooling water channel 9 is embedded; the water inlet 7 of the internal circulation spiral cooling water channel 9 is located in one of the cooling water ring grooves, and the water outlet 8 is located in the other cooling water ring groove Inside;

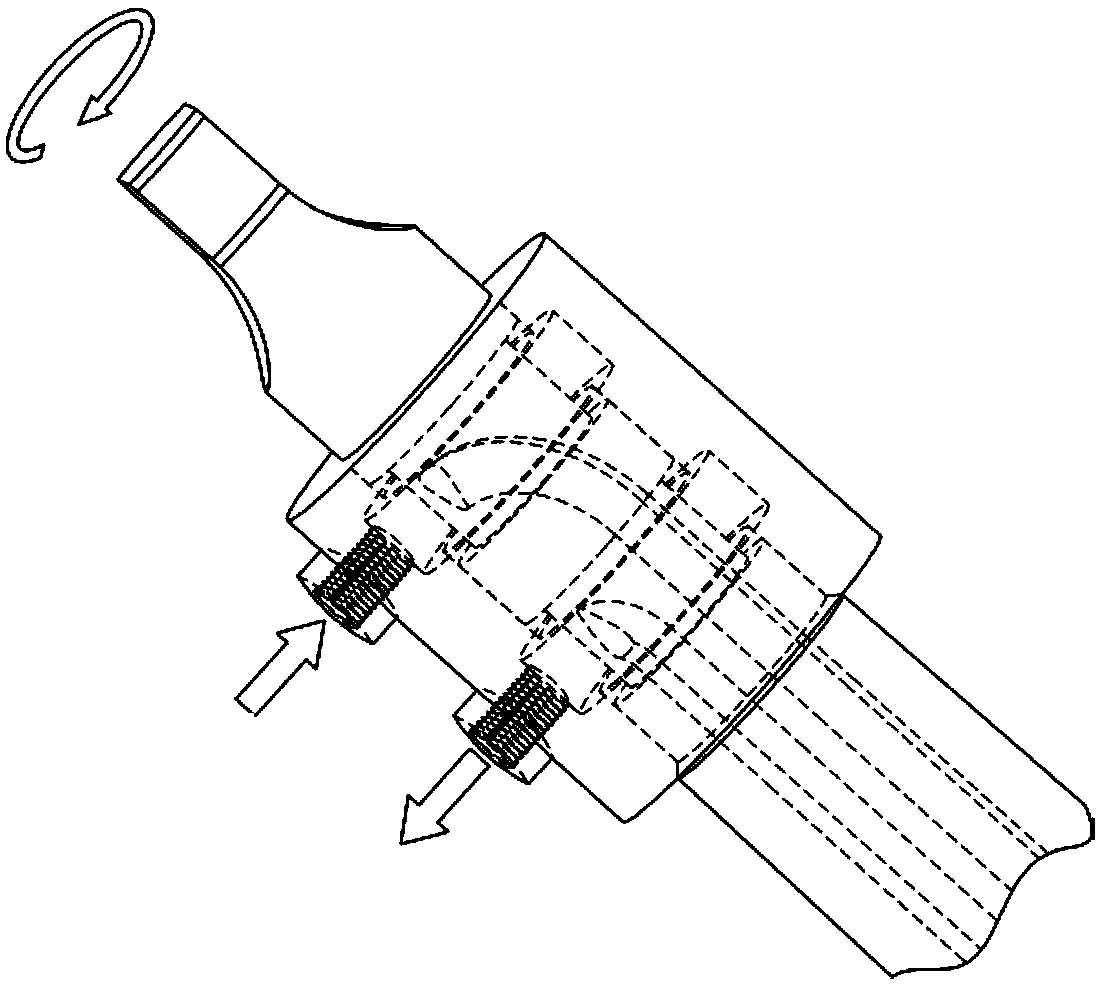

[0036] A rotatable collar 4 is sheathed on the outside of the two cooling water ring grooves; on the collar 4 corresponding to the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com