Battery cell winding device, battery cell production method and power battery

A technology of a winding device and a production method, applied in the field of battery production and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

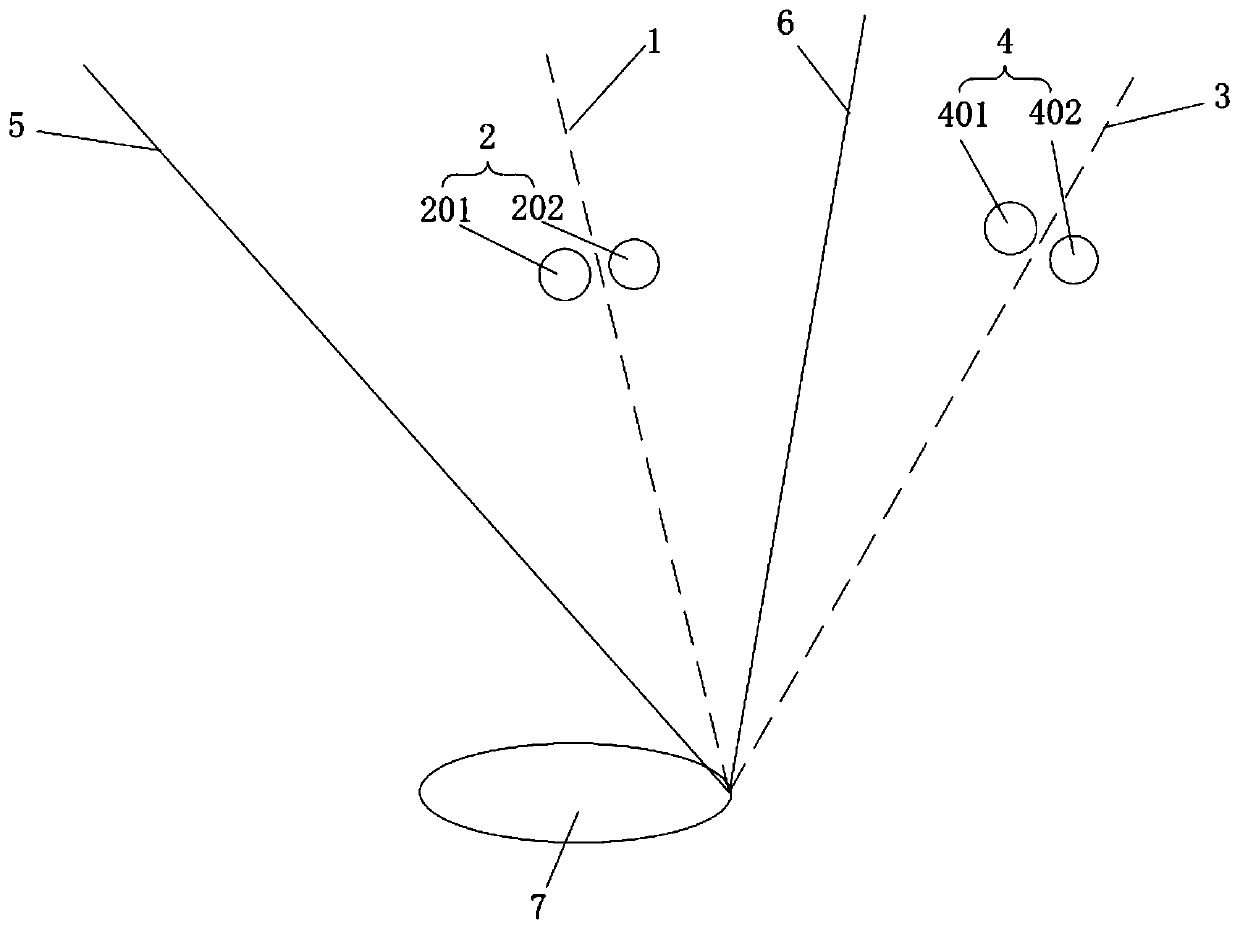

[0057] This embodiment provides a battery winding device, such as figure 1 As shown, the cell winding device includes a first coating bonding roller group 2 , a second coating bonding roller group 4 and a winding needle 7 . Wherein, the first coating adhesive roller group 2 is used to modify the thickness of the inner adhesive coating on the inner diaphragm 1, and the second coating adhesive roller group 4 is used to modify the thickness of the outer adhesive coating on the outer diaphragm 3, after modification The final inner diaphragm 1 and outer diaphragm 3 are laminated with positive electrode sheet 5 and negative electrode sheet 6 to form an electric chip. One end of the electric chip is placed at the winding needle 7, and the winding needle 7 rotates under the drive of the power source, so that the stacked electric chips are wound on the winding needle 7 along the circumferential direction of the winding needle 7 to form a battery cell 8.

[0058] In this embodiment, th...

Embodiment 2

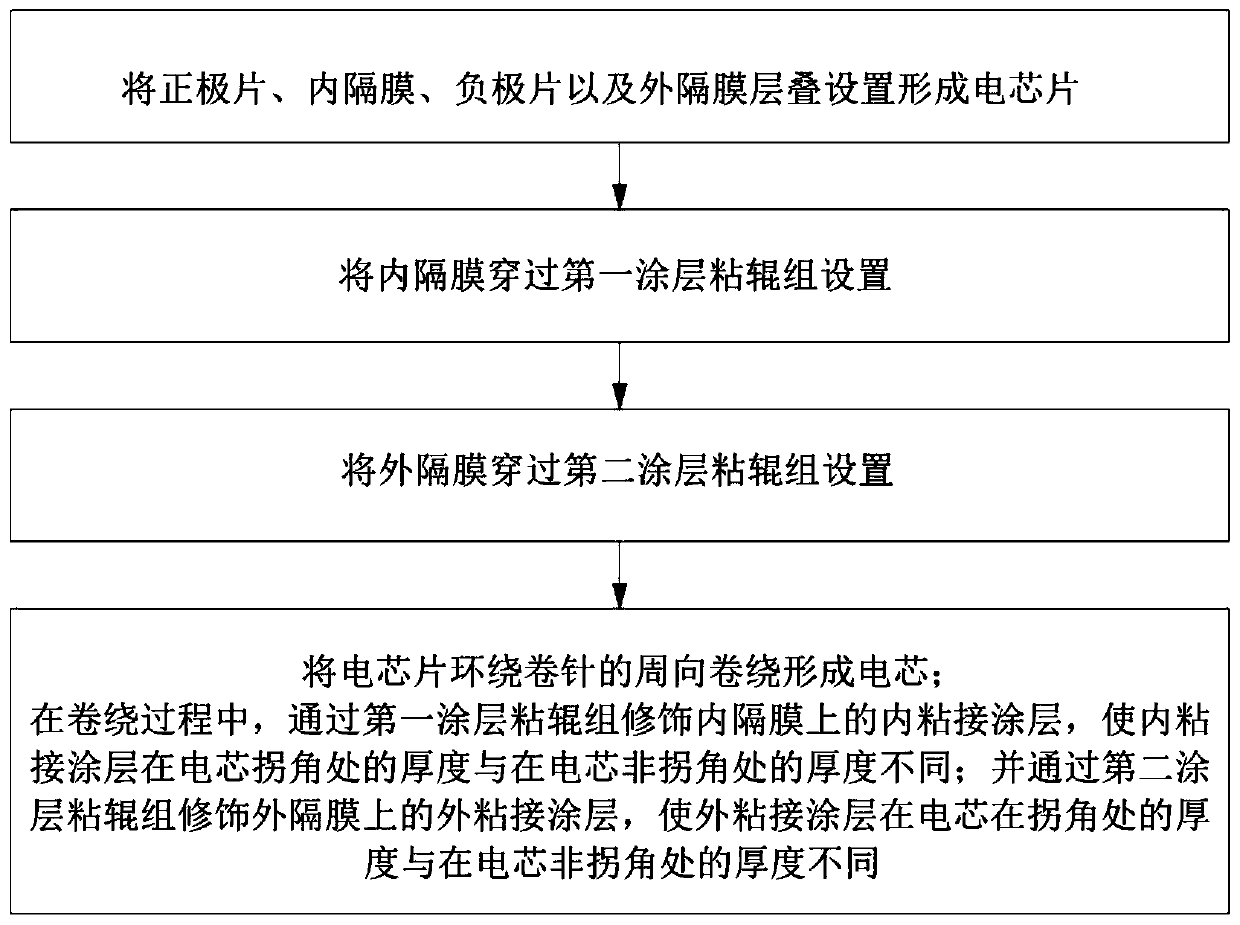

[0064] On the basis of Embodiment 1, this embodiment also provides a battery production method, such as figure 2 As shown, it specifically includes the following steps:

[0065] The positive electrode sheet 5, the inner diaphragm 1, the negative electrode sheet 6 and the outer diaphragm 3 are stacked to form an electric chip;

[0066] Setting the inner diaphragm 1 through the first coating sticky roller group 2;

[0067] Setting the outer diaphragm 3 through the second coating sticky roller group 4;

[0068] The electric chip is wound around the circumference of the winding needle 7 to form an electric core 8; during the winding process, the inner adhesive coating on the inner diaphragm 1 is modified by the first coating adhesive roller group 2, so that the inner adhesive coating The thickness at the corner of the electric core 8 is different from the thickness at the non-corner of the electric core 8; The thickness at the corners of the core 8 is different from the thickn...

Embodiment 3

[0082] On the basis of Embodiment 1 and Embodiment 2, this embodiment also provides a power battery. The power battery is a lithium-ion battery, specifically including a casing and an electric cell 8 placed in the casing. The electric cell 8 includes sequentially stacked The positive electrode sheet 5, the inner diaphragm 1, the negative electrode sheet 6 and the outer diaphragm 3 are wound, and the inner diaphragm 1 is provided with an inner adhesive coating, and the thickness of the inner adhesive coating at the corner of the electric core 8 is the same as that of the inner adhesive coating at the corner of the electric core 8. The thickness of the non-corner is different, and the outer diaphragm 3 is provided with an outer adhesive coating, and the thickness of the outer adhesive coating at the corner of the battery cell 8 is different from that at the non-corner of the battery cell 8, which can improve the battery performance in a targeted manner. performance to form a powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com