Preparation and water treatment application of super-hydrophobic stainless steel-carbon nanotube composite membrane

A carbon nanotube composite, stainless steel technology, applied in water/sewage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc. To achieve the effect of achieving anti-pollution and anti-corrosion properties, and enhancing anti-pollution and anti-corrosion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

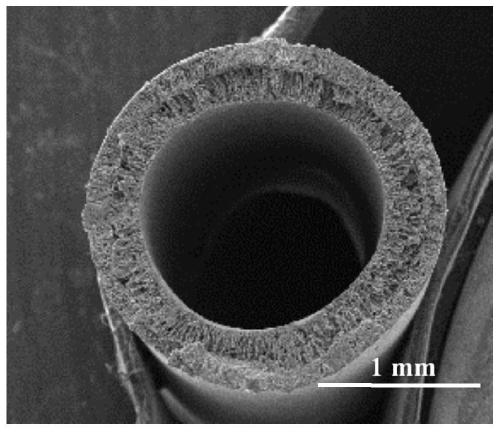

[0032] Embodiment 1: preparation of stainless steel carrier

[0033]The preparation of the stainless steel carrier is very important for the subsequent research on the formation of the stainless steel-carbon nanotube composite membrane and the water treatment performance. In this example, the stainless steel hollow fiber carrier is selected for illustration. Dissolve an appropriate amount of PES (5g) and additive PVP (3g) in NMP (PES:NMP=1:4), put it into a polytetrafluoroethylene ball mill tank, and perform wet ball milling on a planetary ball mill for 6 hours to form a homogeneous mixture. Phase organic solution was prepared as polymer slurry. The stainless steel powder is placed in an oven to dry in advance, and then a certain amount of powder is weighed and added to the above polymer solution for continuous ball milling for 24 hours to prepare a casting film slurry with a solid content of 75%. Then place it in a closed drying oven and vacuumize for 30min to remove the air...

Embodiment 2

[0035] Embodiment 2: Preparation of stainless steel-carbon nanotube composite film

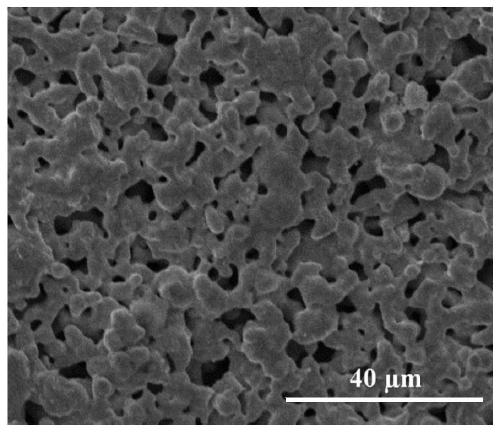

[0036] (1) Surface activation of stainless steel carrier

[0037] The stainless steel membrane has an asymmetric structure of porous surface and exhibits hydrophobicity with a water contact angle of ∼122°. The stainless steel film contains Ni and Fe elements, and carbon nanotubes can be constructed in situ on the stainless steel film without an external catalyst. Through simple surface activation, that is, the oxidation-reduction process, the surface activation of the catalytic sites of the stainless steel carrier is carried out, and the pores of the stainless steel carrier are filled with water by immersion in tap water containing oxygen at atmospheric pressure for 3 hours, and the stainless steel carrier filled with water is placed on the Heat and oxidize in an air atmosphere at 60°C for 48 hours to fully oxidize the passivation layer on the surface of the stainless steel film. Place the o...

Embodiment 3

[0040] Example 3: Application of stainless steel-carbon nanotube composite membrane in the treatment of high-salt wastewater

[0041] Vacuum membrane distillation experiments were carried out at different temperatures (55°C, 65°C, 75°C, 85°C, 95°C) with a salinity of 3.5wt.%. The salt rejection rate of the stainless steel-carbon nanotube composite membrane is greater than 99.9%, indicating that the stainless steel-carbon nanotube composite membrane has excellent desalination performance. When the operating temperature increased from 55°C to 95°C, the water flux increased significantly, while the salt rejection rate of the stainless steel-carbon nanotube composite membrane hardly changed; similarly, at different salinities (0.5wt%, 2wt%, 3.5 wt%, 5wt%, 6.5wt%) membrane distillation experiments were carried out at a temperature of 75°C. The results showed that when the salt concentration increased from 0.5wt% to 6.5wt%, the water flux decreased to varying degrees, but the salt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com