Ultra-high molecular weight polyethylene lining pipe

An ultra-high molecular weight, polyethylene technology, applied in the field of lining pipes, can solve the problems of loss of anti-eccentric wear, high temperature resistance, and high processing costs, and achieve the effects of improving impact strength, heat distortion temperature, and fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

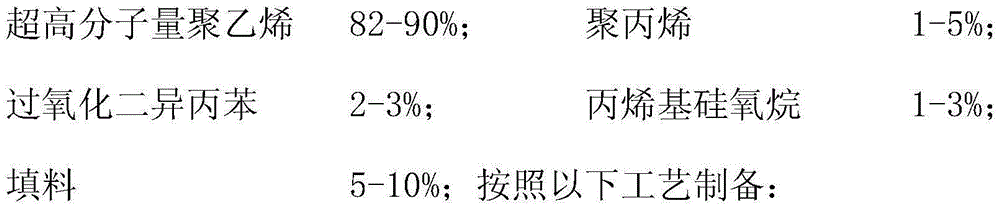

[0014] Ultra-high molecular weight polyethylene lined pipe, including the following raw materials in mass percentage:

[0015]

[0016] During preparation, the above-mentioned raw materials are prepared according to the formula requirements, and the raw materials are pulverized and stirred by a stirring particle grinder, and then the particle size of the powder material is determined through a vibrating sieve, and the vibrating sieve is 100 mesh; finally, the compounding is passed through a plastic material extruder Raw material with good ratio is extruded into inner liner. Wherein, during the preparation, the thickness of the inner tube wall is determined by adjusting the extrusion speed of the extruder, and the temperatures of the three temperature zones of the extruder are respectively: 200°C, 260°C, and 285°C.

[0017] The above-mentioned fillers are 2% by mass percentage of silicon dioxide, 2% of glass microspheres and 2% of acicular wollastonite.

[0018] Chemical mo...

Embodiment 2

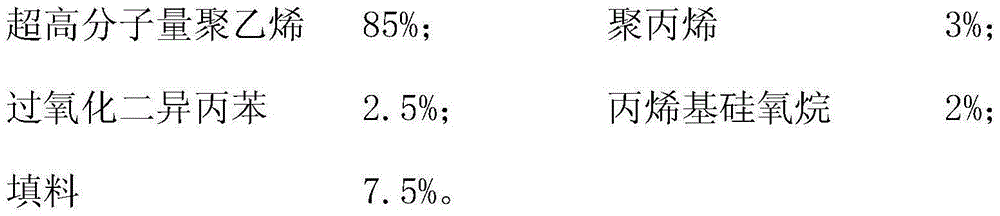

[0026] Ultra-high molecular weight polyethylene lined pipe, including the following raw materials in mass percentage:

[0027]

[0028] Others are basically the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

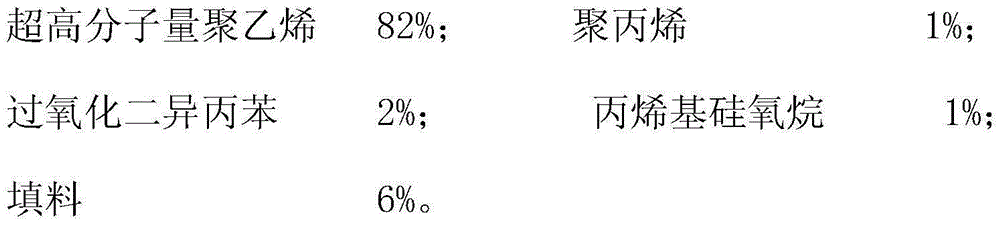

[0030] Ultra-high molecular weight polyethylene lined pipe, including the following raw materials in mass percentage:

[0031]

[0032] Others are basically the same as those in Embodiment 1, and will not be repeated here.

[0033] According to the inspection standard: Q / SH10201889-2011, the inner liner is inspected, and the inspection results are as follows:

[0034]

[0035] To sum up, the lining pipe made of these raw materials in the present invention can increase the wear resistance by 39.67%, and the temperature resistance can reach 150 degrees Celsius.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com