High-carbon high-vanadium powder high-speed steel composite roll collar and manufacturing method thereof

A manufacturing method and technology of high-speed steel, applied in the field of high-carbon high-vanadium powder high-speed steel composite roll rings, high-carbon high-vanadium powder high-speed steel composite roll rings, can solve the problems of difficult processing, large hardness gradient, high scrap rate, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

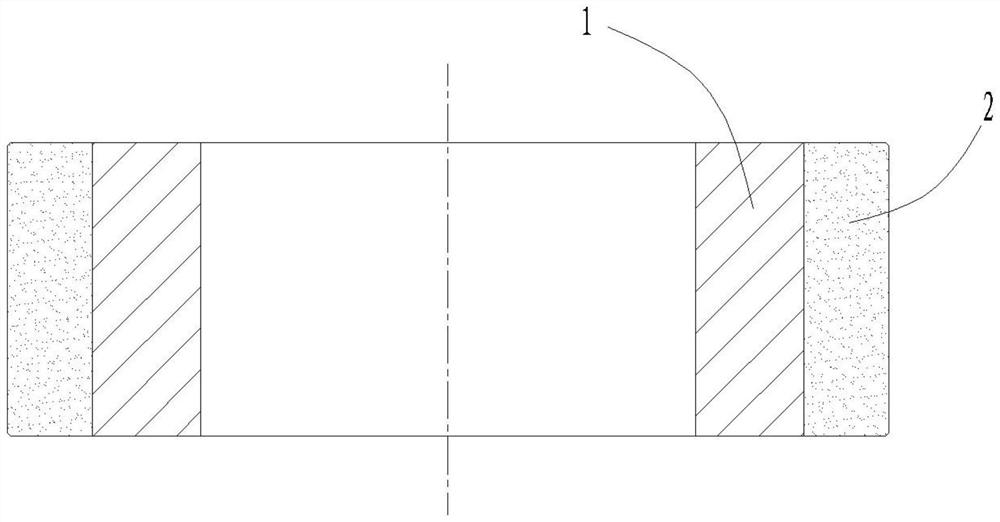

[0037] Please refer to Figure 1 to Figure 5 , a high-carbon and high-vanadium powder high-speed steel composite roller ring in this embodiment, the composite roller ring includes: an inner steel pipe 1 and an outer powder high-speed steel 2, the inner steel pipe 1 is a prefabricated cylindrical inner steel pipe, and the outer Layer powder high-speed steel 2 is a cylindrical high-speed steel pipe coated on the outer periphery of inner steel pipe 1 by hot isostatic pressing; the ratio of the thickness of inner steel pipe 1 to the thickness of outer powder high-speed steel 2 is 1: (0.6- 1.5). Preferably, the ratio of the thickness of the inner steel pipe 1 to the thickness of the outer powder high speed steel 2 is 1: (0.9-1.2).

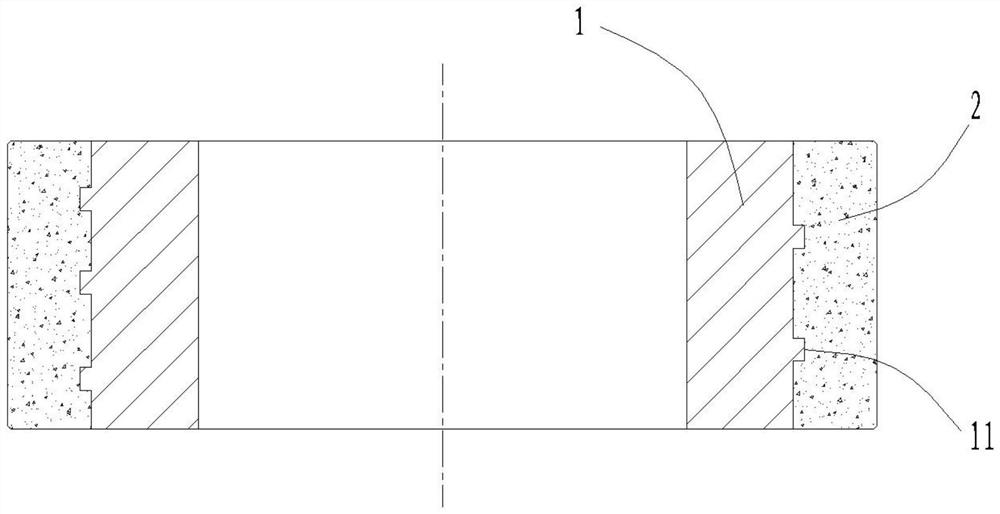

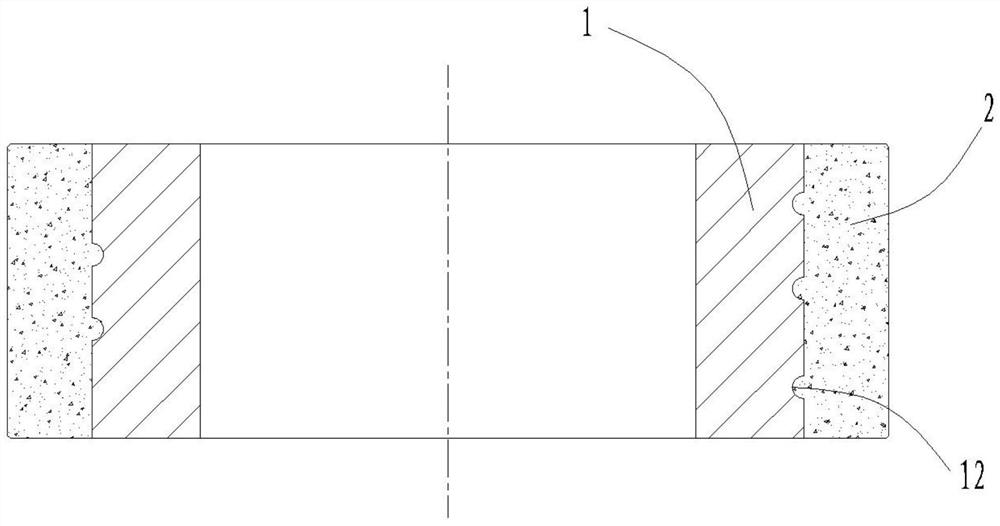

[0038] As a further improvement of this implementation, see figure 2 with image 3 The outer surface of the inner steel pipe 1 is prefabricated with several protrusions 11 or pits 12, and the height of the protrusions 11 or the depth of the recesses...

Embodiment 2

[0043] Please refer to Image 6 with Figure 7 , a method for manufacturing a high-carbon and high-vanadium powder high-speed steel composite roller ring according to the present embodiment, the manufacturing method includes the following steps:

[0044] Step 1: Prepare the inner layer steel pipe 1 according to the predetermined size and chemical composition, clean and remove impurities and then use it; prepare the hot isostatic pressing jacket 3 according to the predetermined size, and combine the hot isostatic pressing jacket 3 with the inner layer Steel pipe 1 combined installation.

[0045] Step 2: Prepare the alloy powder for the outer layer powder high-speed steel 2 according to the predetermined chemical composition, the particle size of the alloy powder is 40 μm-100 μm, and fill the space surrounded by the inner layer steel pipe 1 and the hot isostatic pressing jacket 3 with the alloy powder , welding and sealing the inner steel pipe 1 and the jacket 3 for hot isosta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com