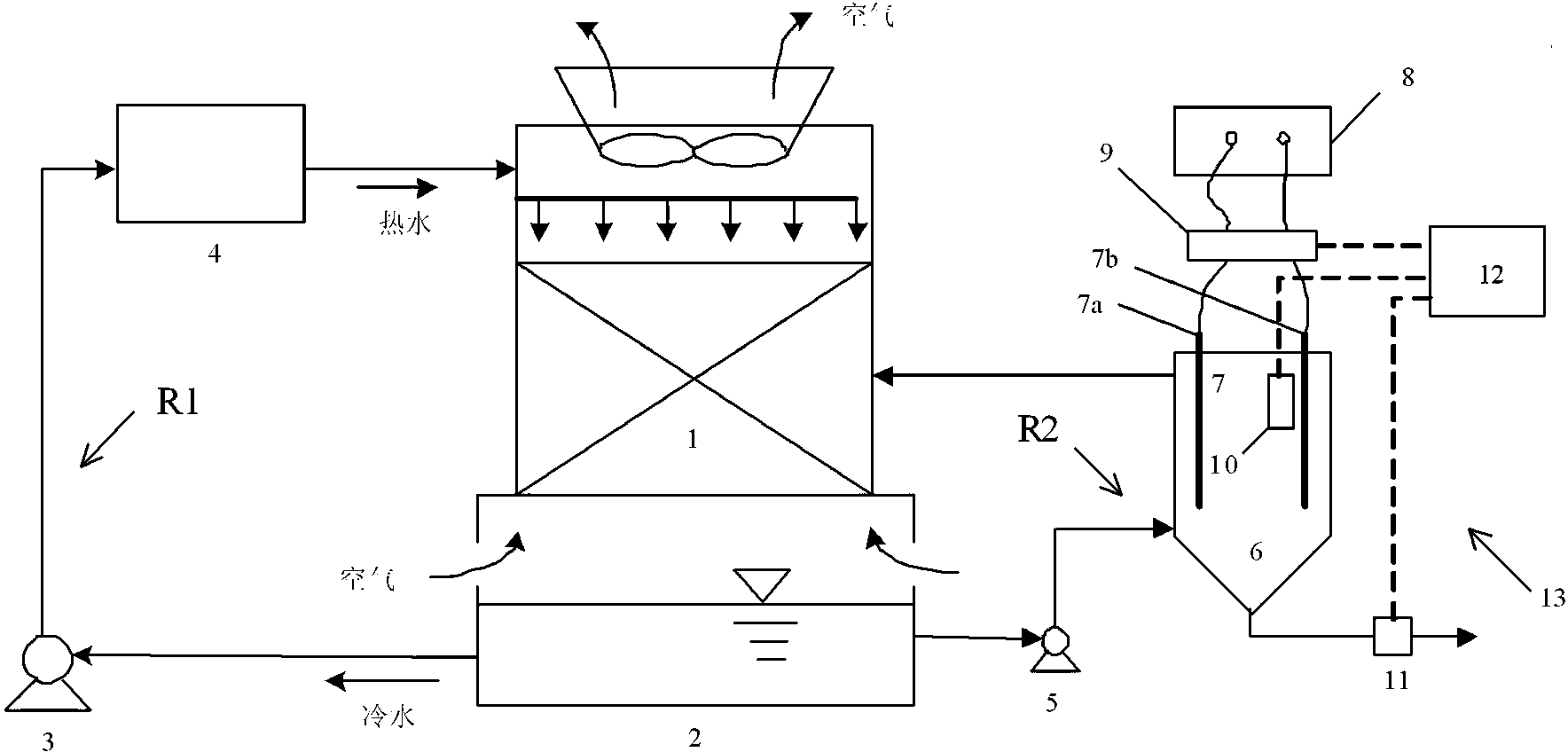

Direct-current electrolytic treatment process and equipment for circulating cooling water

A technology of circulating cooling water and DC electrolysis, applied in the field of water treatment, can solve the problems of increased operation and maintenance costs, increased system turbidity, water saving restrictions, etc., to save labor costs, ensure continuous and stable operation, and prevent electrochemical corrosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Overview

[0055] The cooling system of pure water filling production line of Shenyang Zhongfu Preform Co., Ltd. was selected as the experimental research object. This system is mainly used for cooling of pure water canning production equipment, with a scale of 50m 3 / h. Due to the lack of professional maintenance personnel, the water replenishment of the system is controlled by the opening of the water replenishment valve controlled by the float level gauge. In addition to the wind loss, the system rarely drains water, resulting in a long-term extremely high concentration multiple (according to the conductivity and hardness test results) It is judged that the system is operated under the condition that the concentration ratio of the system is greater than 600 times), and the system rarely performs chemical treatment and maintenance, resulting in serious scaling and corrosion of the system. less than 2 degrees Celsius.

[0056] In order to verify the content of th...

Embodiment 2

[0070] (1) Overview

[0071] The cooling system of pure water filling production line of Shenyang Zhongfu Preform Co., Ltd. was selected as the experimental research object. This system is mainly used for cooling of pure water canning production equipment, with a scale of 50m 3 / h. Due to the lack of professional maintenance personnel, the water replenishment of the system is controlled by the opening of the water replenishment valve controlled by the float level gauge. In addition to the wind loss, the system rarely drains water, resulting in a long-term extremely high concentration multiple (according to the conductivity and hardness test results) It is judged that the system is operated under the condition that the concentration ratio of the system is greater than 600 times), and the system rarely performs chemical treatment and maintenance, resulting in serious scaling and corrosion of the system. less than 2 degrees Celsius.

[0072] In order to verify the content of th...

Embodiment 3

[0086] (1) Overview

[0087] The cooling system of pure water filling production line of Shenyang Zhongfu Preform Co., Ltd. was selected as the experimental research object. This system is mainly used for cooling of pure water canning production equipment, with a scale of 50m 3 / h. Due to the lack of professional maintenance personnel, the water replenishment of the system is controlled by the opening of the water replenishment valve controlled by the float level gauge. In addition to the wind loss, the system rarely drains water, resulting in a long-term extremely high concentration multiple (according to the conductivity and hardness test results) It is judged that the system is operated under the condition that the concentration ratio of the system is greater than 600 times), and the system rarely performs chemical treatment and maintenance, resulting in serious scaling and corrosion of the system. less than 2 degrees Celsius.

[0088] In order to verify the content of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com