Preparation method for BOPET high-imitation metal wiredrawing VCM film

A technology of imitating metal and film, which is applied in the field of BOPET high imitation metal wire drawing VCM film preparation, can solve the problems of large amount of materials, non-environmental protection production cost, non-energy saving and resource saving, and achieve strong weather resistance, low manufacturing cost, The effect of excellent anti-ultraviolet function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. BOPET high imitation metal wire drawing VCM film structure:

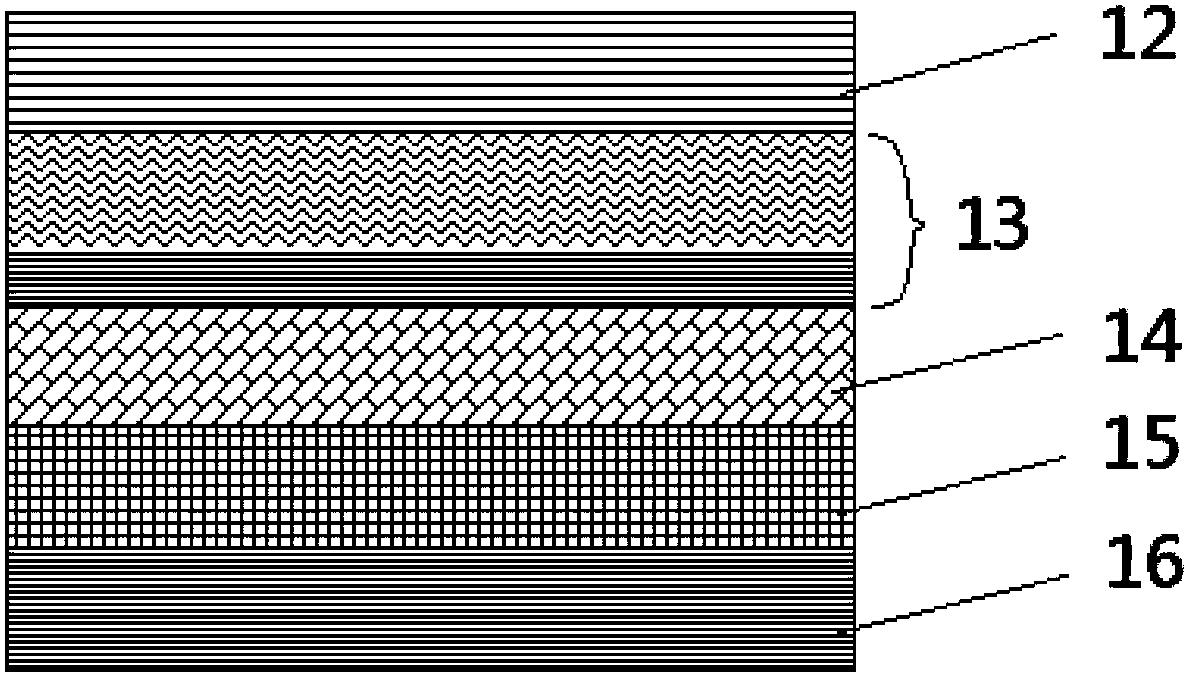

[0030] Such as figure 1 As shown, the BOPET high imitation metal wire drawing VCM film produced in this embodiment includes in turn: a hardened surface coating 12, a transparent BOPET film 13 with surface wire drawing treatment on one side, an enhanced fastness coating 14, a transparent A vacuum aluminized layer 15 with a light rate of 26-28% and an anti-oxidation protective coating 16; the side of the BOPET that has been brushed on the surface is connected to the fastness-enhancing coating 14.

[0031]Among them, the thickness of the BOPET film before wire drawing is 188 microns, the light transmittance of the original film is 90.2%, the 45° gloss is 138Gs, the haze is 1.96%, and other physical performance indicators meet the national standard GB / T16958-2008 of the People's Republic of China [Biaxially oriented polyester film for packaging].

[0032] The surface hardening coating is selected from the UV...

Embodiment 2

[0047] 1. BOPET high imitation metal wire drawing VCM film structure:

[0048] Such as figure 1 As shown, the BOPET high imitation metal wire drawing VCM film produced in this embodiment includes in turn: a hardened surface coating 12, a transparent BOPET film 13 with surface wire drawing treatment on one side, an enhanced fastness coating 14, a transparent A vacuum aluminized layer 15 with a light rate of 5-7% and an anti-oxidation protective coating 16; the side of the BOPET that has undergone surface brushing treatment is connected to the fastness-enhancing coating 14.

[0049] Among them, the thickness of the BOPET film before wire drawing is 23 microns, the light transmittance of the original film is 91%, the 45° gloss is 139Gs, the haze is 1.92%, and other physical performance indicators meet the national standard GB / T16958-2008 of the People's Republic of China [Biaxially oriented polyester film for packaging].

[0050] The surface hardening coating is the matte UV co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com