Pre-oxidation furnace

A technology of pre-oxidation furnace and furnace body, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, etc. It can solve the problems of increasing the production cost of pre-oxidation furnace, achieve the effect of simple structure, save equipment and production cost, and prevent spontaneous combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

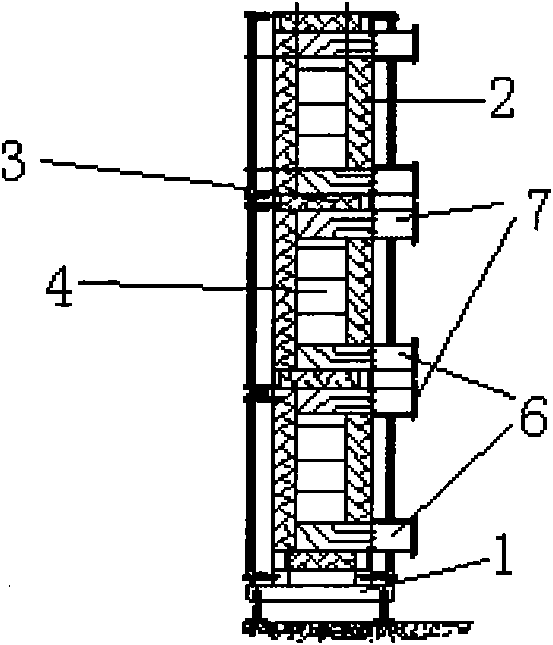

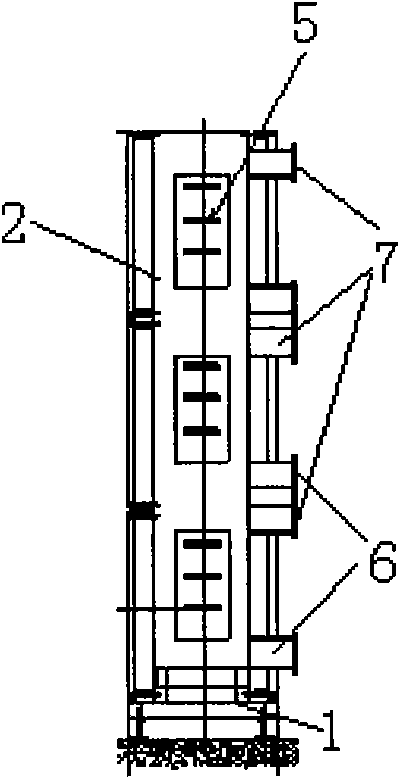

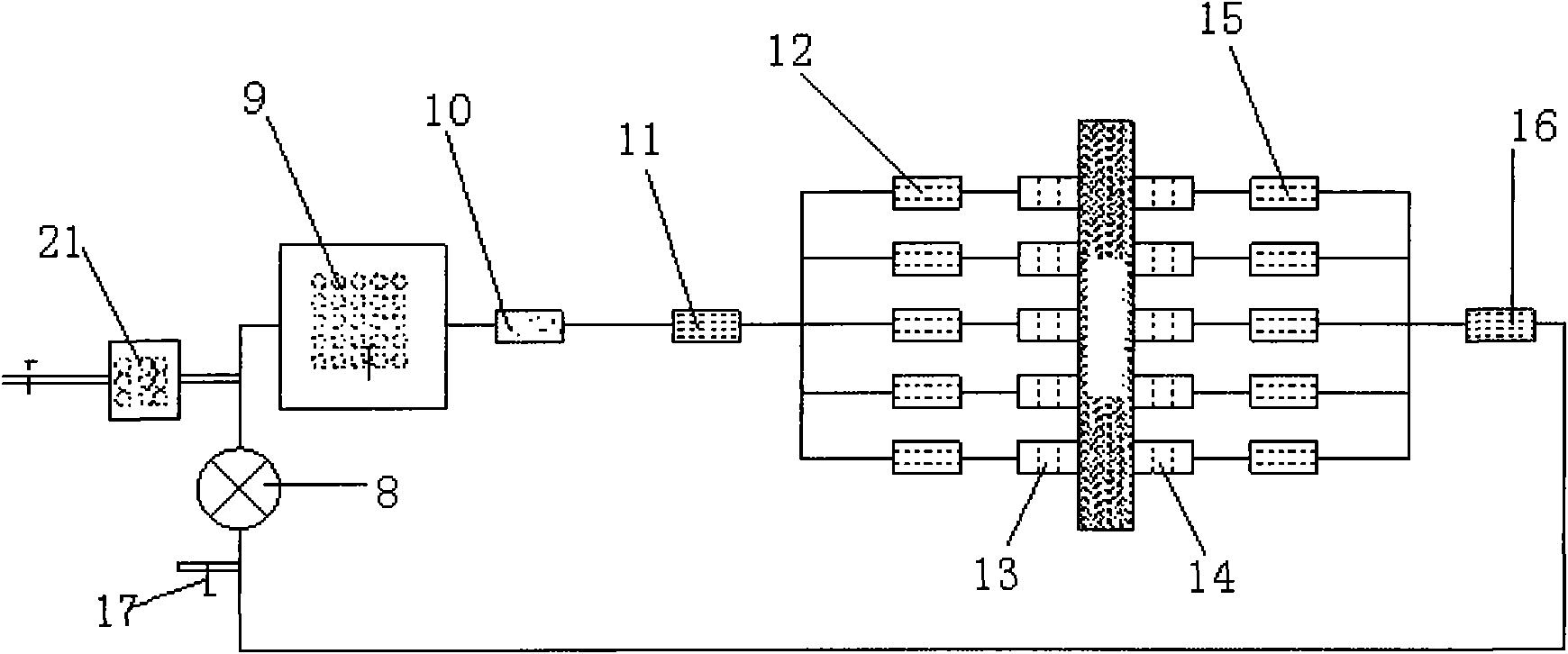

[0030] A kind of pre-oxidation furnace comprises a furnace frame 1, a furnace body 2 is fixed on the furnace frame 1, and a horizontal dividing plate 3 is fixed in the furnace body 2, and the furnace chamber in the furnace chamber is divided into three by the dividing plate 3. Layers of furnace chambers 4 are independent of each other; the front and rear end faces of each layer of furnace chambers 4 are respectively provided with wire inlets 5 and wire outlets, and the corresponding side walls of each layer of furnace chambers are provided with air inlets 6 and air outlets 7; include a fan 8, the air outlet of the fan 8 communicates with the air inlet 6 on the furnace chamber 4 of each layer through the air inlet system, and the air inlet of the fan 8 communicates with the air inlet 6 on the furnace chamber 4 of each layer through the air outlet system. 7 air outlets are connected.

[0031]The air inlet system includes a heating chamber 9 communicating with the air outlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com