Patents

Literature

124results about How to "Economically viable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

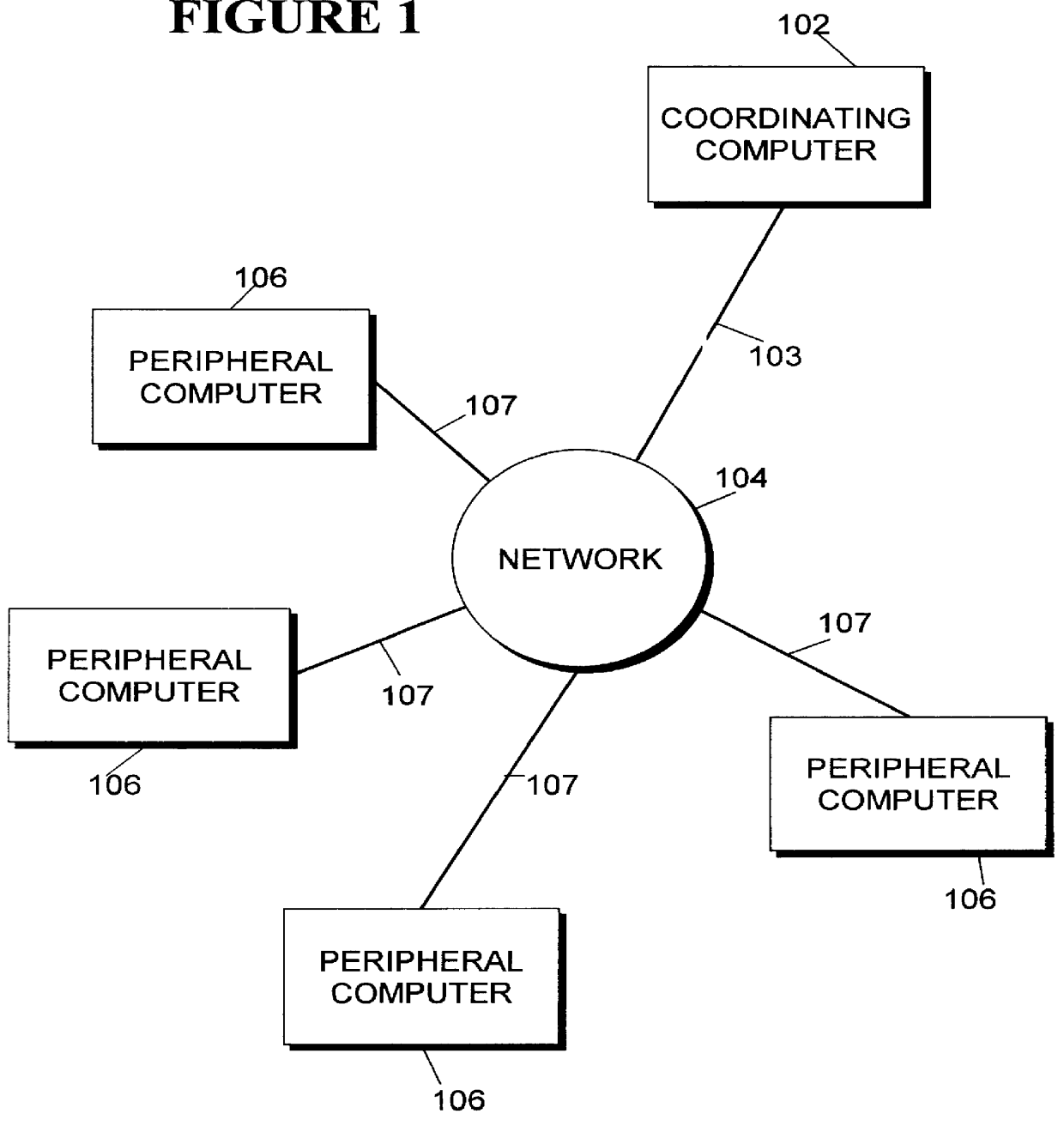

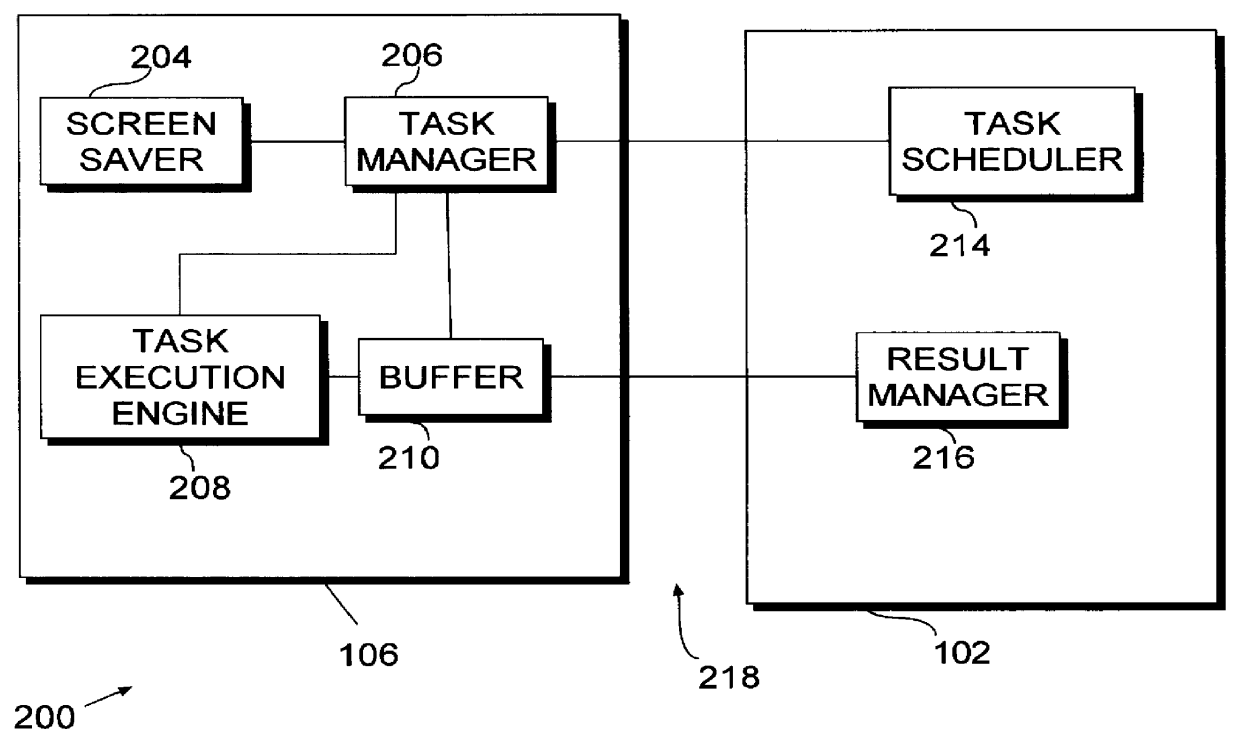

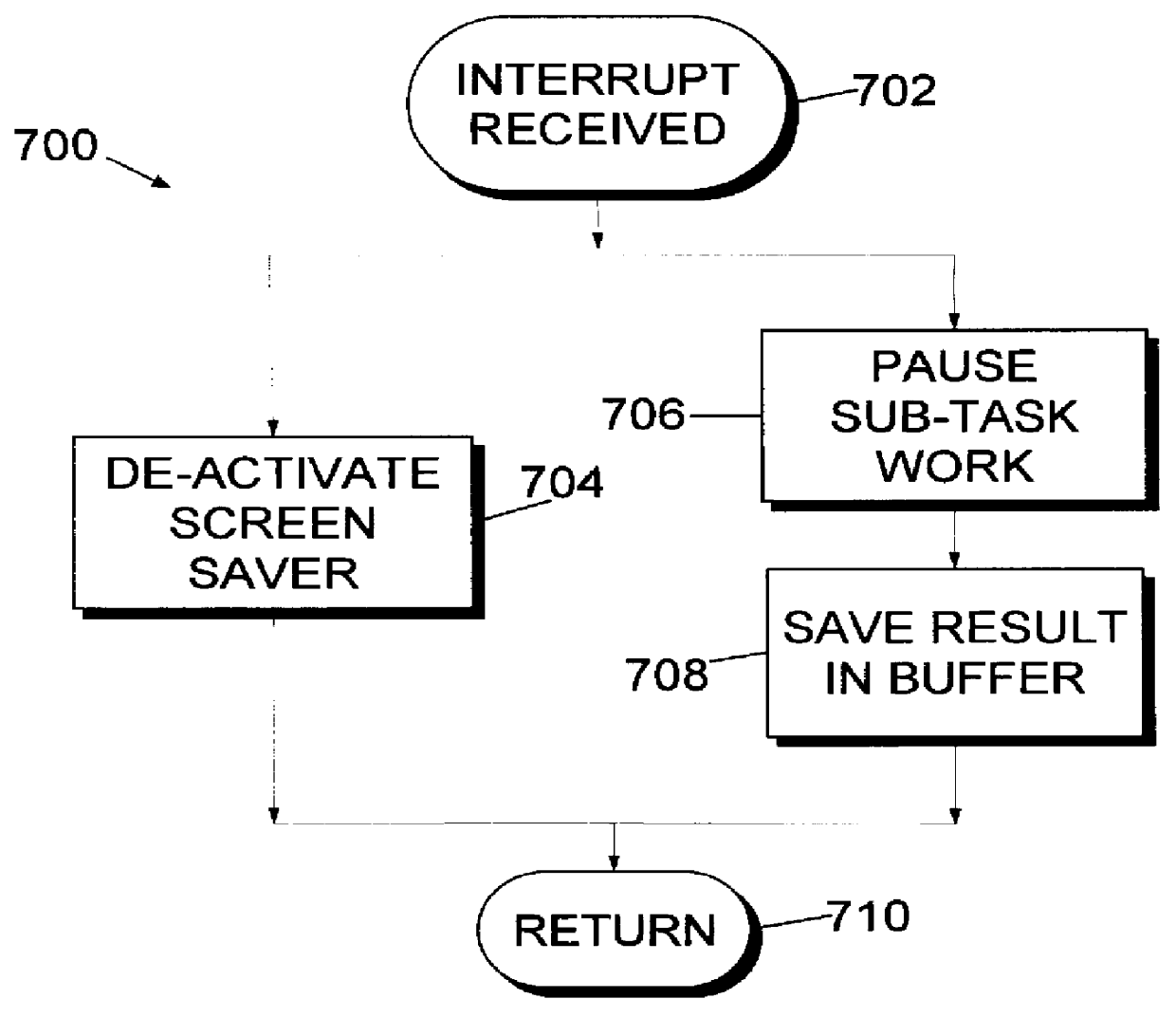

Task distribution processing system and the method for subscribing computers to perform computing tasks during idle time

InactiveUS6112225ALittle administrationLittle effortResource allocationGeneral purpose stored program computerAs DirectedTelecommunications link

A computer executable "aggregate" task is processed by dividing it into subtasks and distributing the subtasks "on demand" to remotely located subscribing computers via a computer network. The aggregate task originates at a coordinating computer, coupled to one or more peripheral computers by appropriate communications links. The coordinating computer divides the aggregate task into multiple independent subtasks. Each peripheral computer begins to "subscribe" to the coordinating computer's aggregate task by obtaining an "idle time activation program" from the coordinating computer, and then installing the program locally. The idle time activation program which may include a screen saver, activates automatically when the subscribing computer is inactive. Continuing the subscription process, each peripheral computer requests a subtask from the coordinating computer. In response, the coordinating computer distributes different subtasks among the subscribing computers, completing the subscription process. The subscribing computers automatically work on their respective subtasks whenever they are idle, as directed by the local idle time activation program. When a subscribing computer completes its subtask, it transmits results back to the coordinating computer. When results of all subtasks have been received from subscribing computers, the coordinating computer compiles and stores these results, concluding the aggregate task.

Owner:IBM CORP

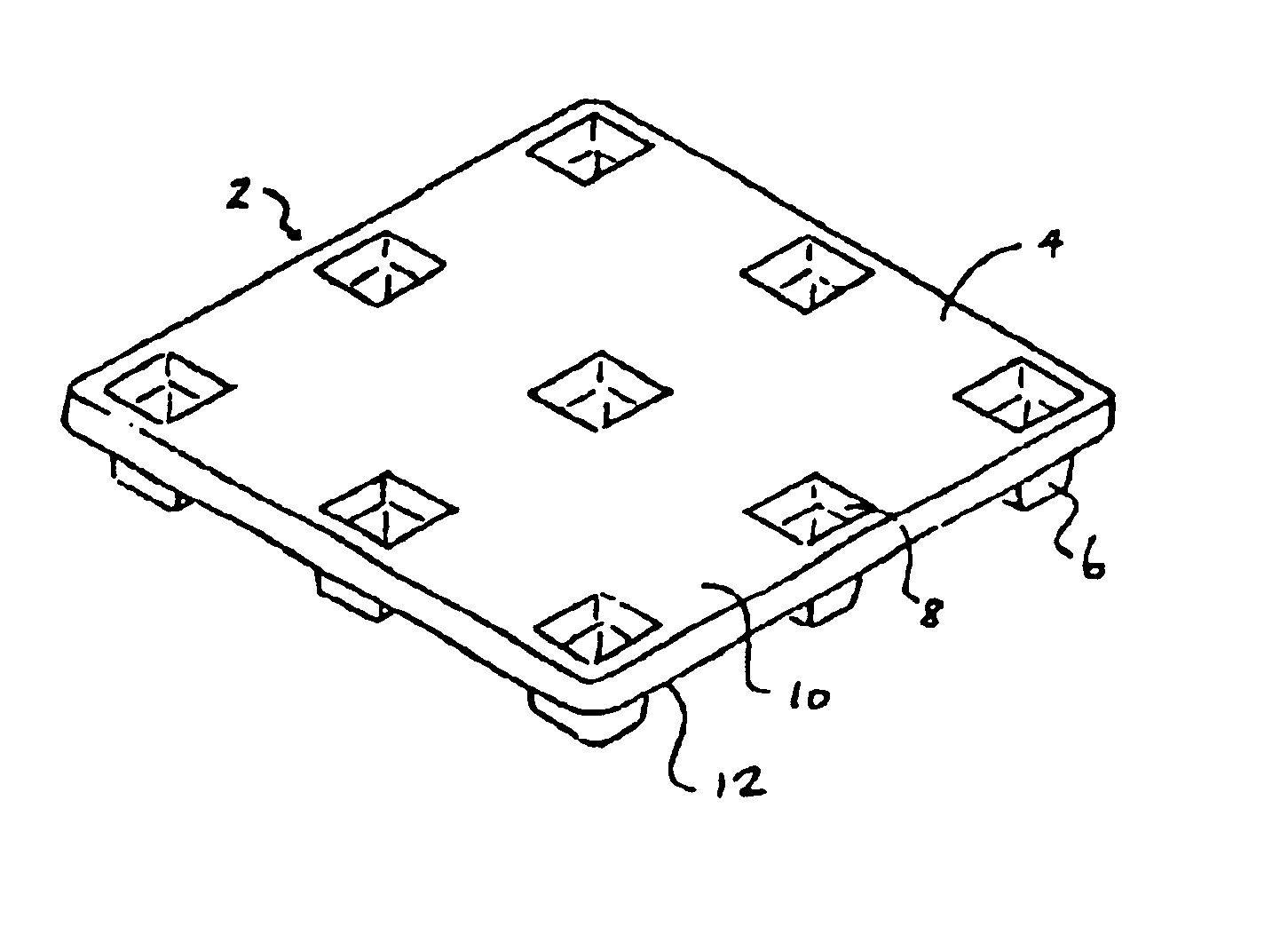

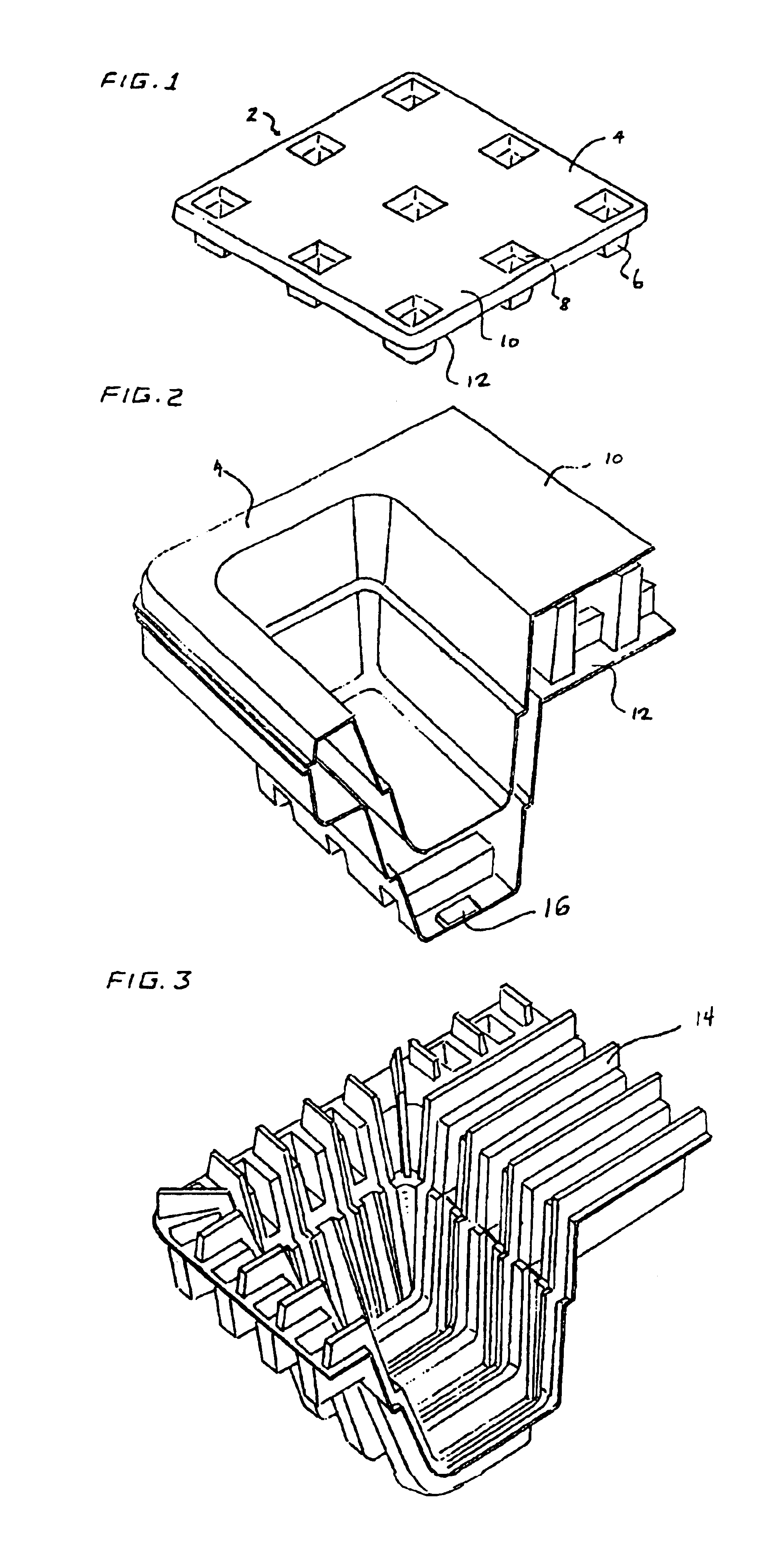

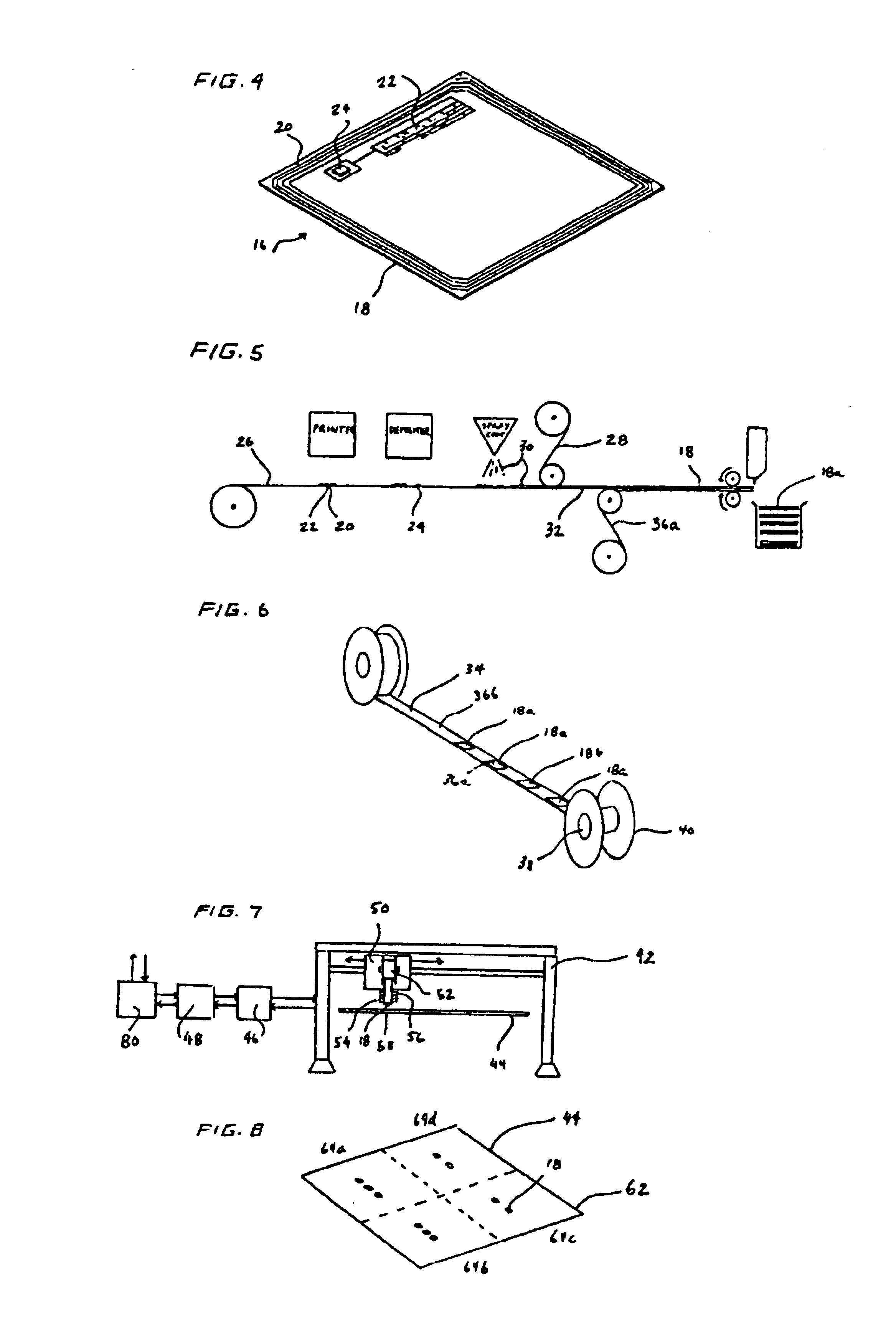

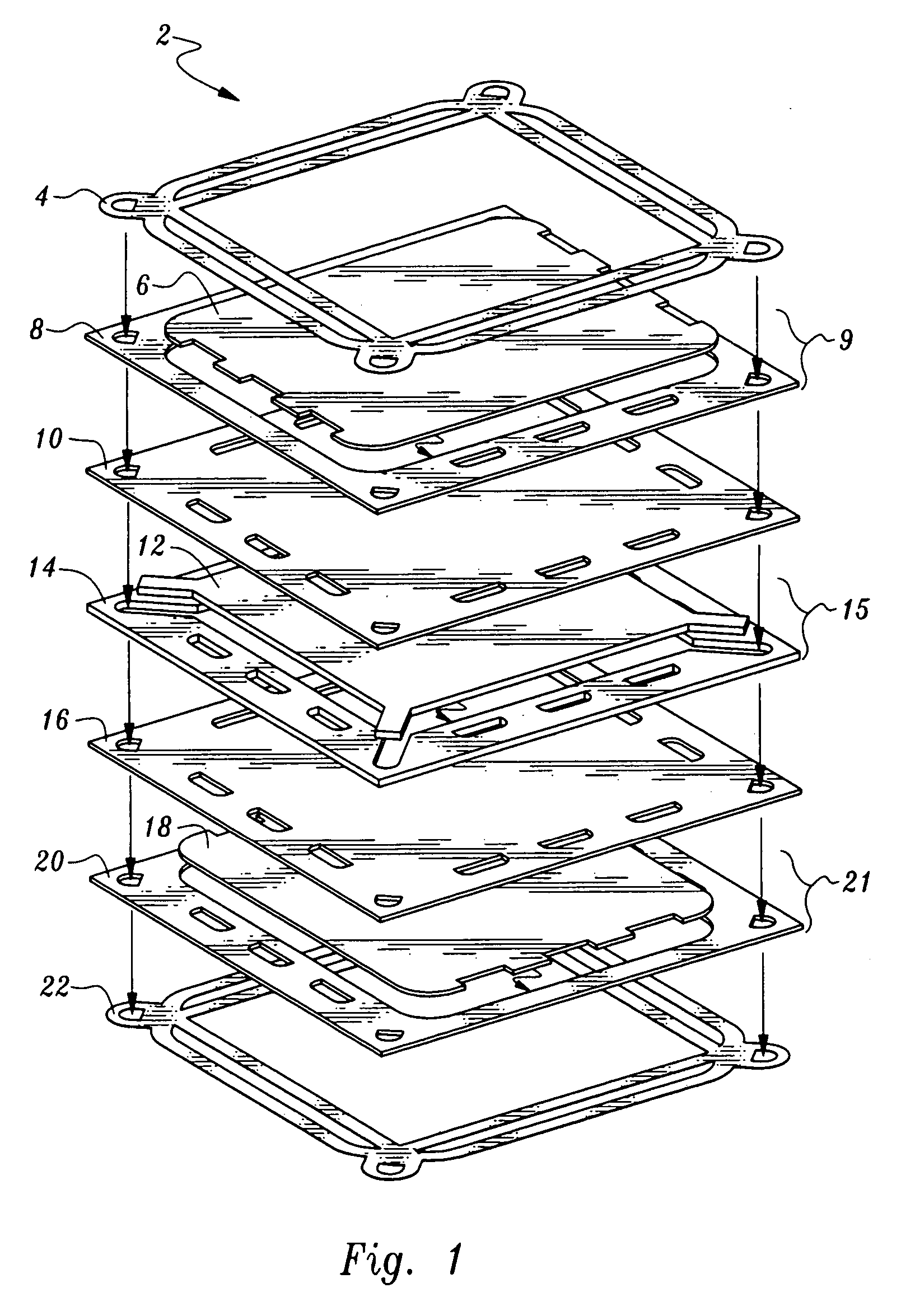

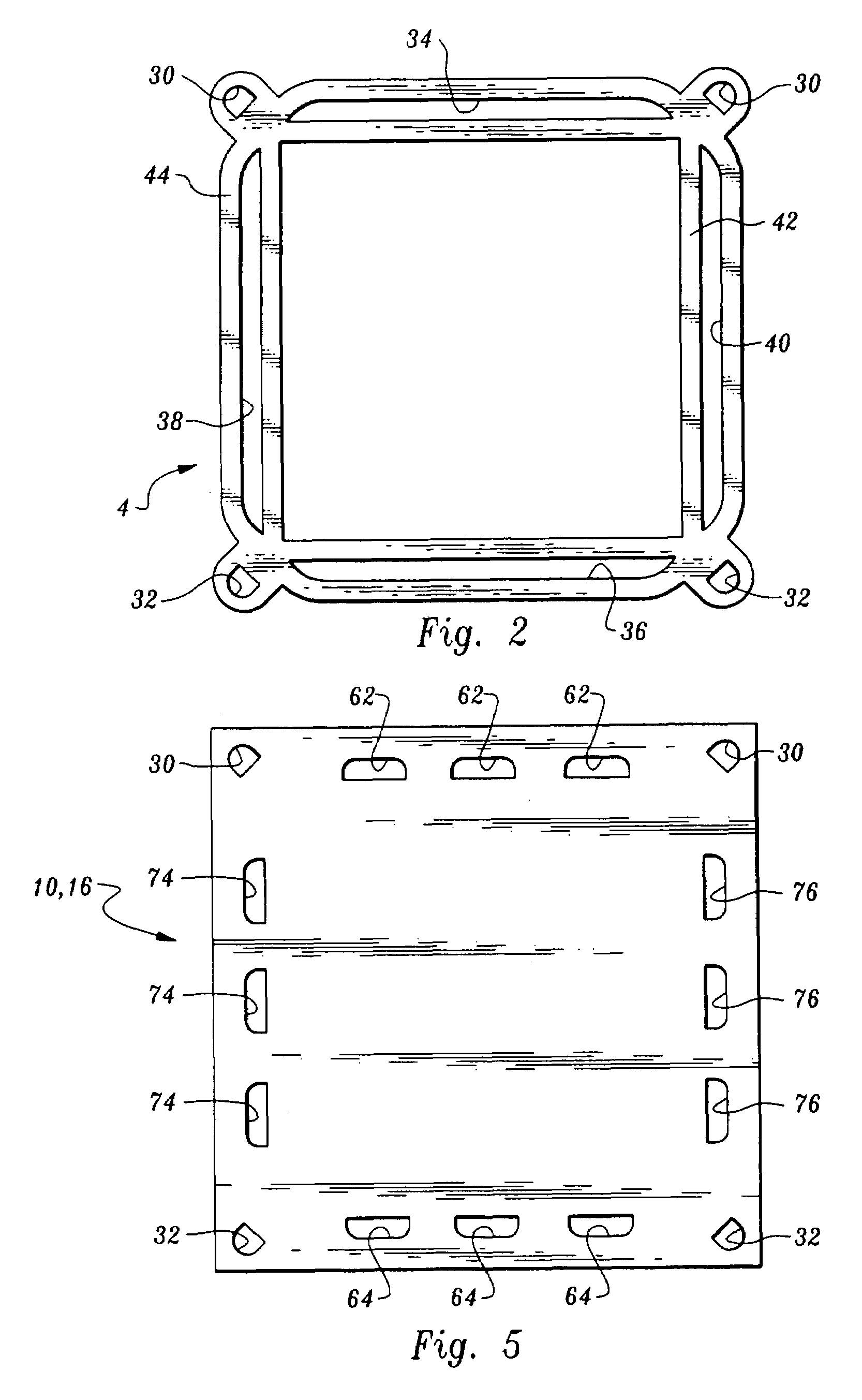

Thermoformed apparatus having a communications device

InactiveUS6943678B2Improve protectionIncreased durabilityRecord carriersDigital data processing detailsThermoformingEngineering

An apparatus has a communications device associated therewith. In another aspect of the present invention, a pallet is made from thermoformed polymeric sheets with an attached communications device. A further aspect of the present invention provides a radio frequency identification device attached to an apparatus. In still another aspect of the present invention, a communications device is incorporated into one or more sheets of a pallet or other container prior to forming. Methods of making and using a thermoformed pallet and container, having a communications device, are also provided.

Owner:NEXTREME

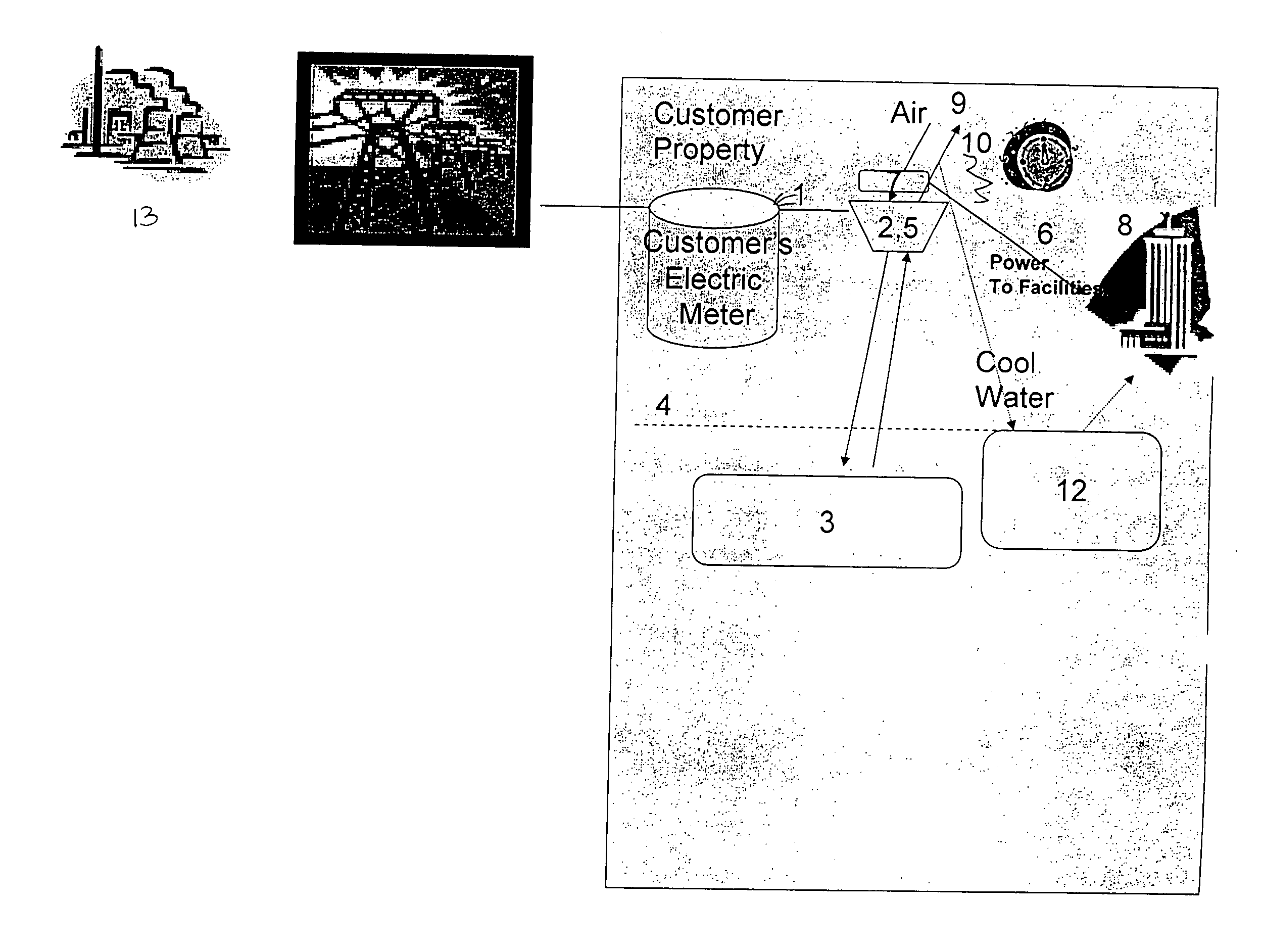

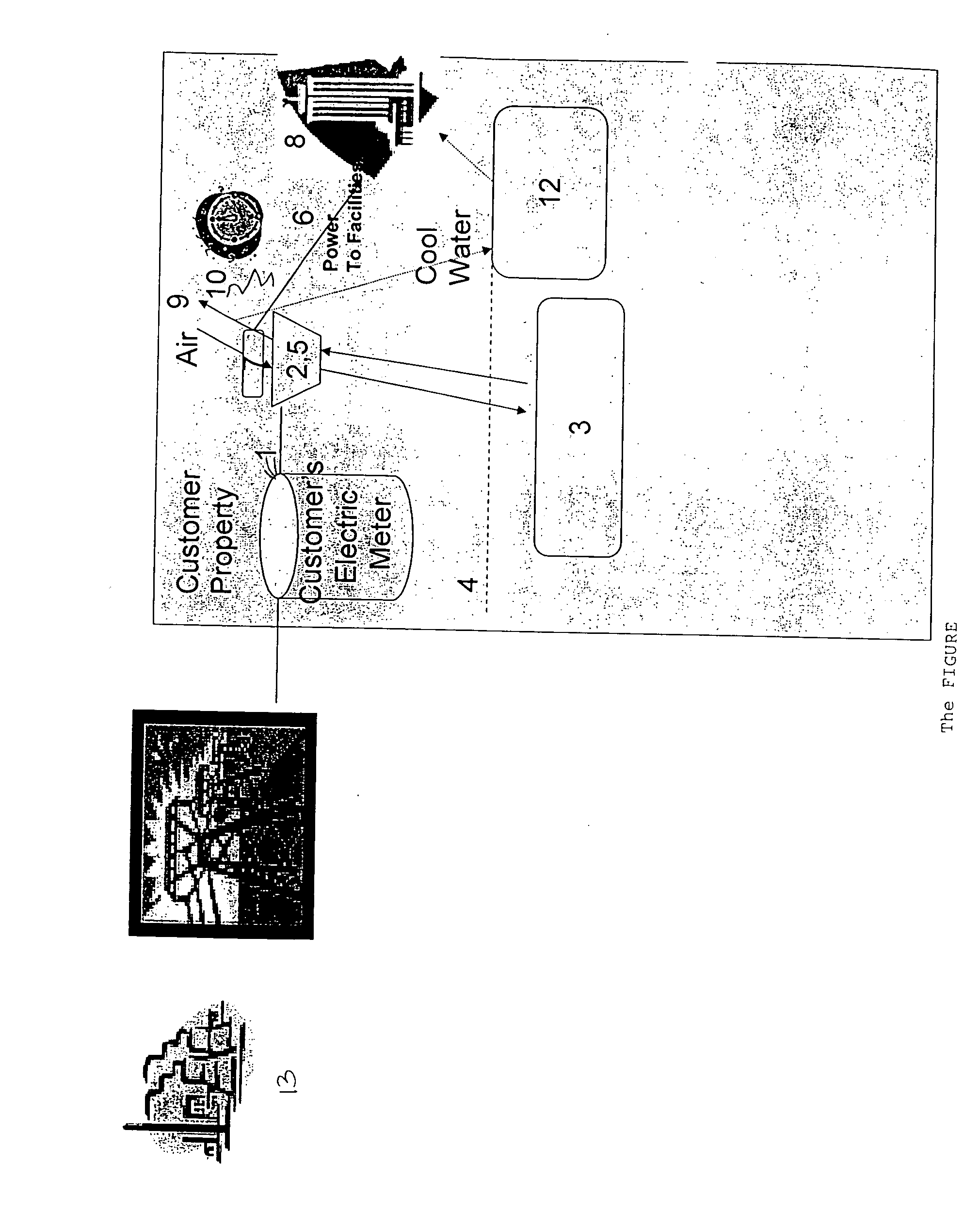

Serving end use customers with onsite compressed air energy storage systems

InactiveUS20070006586A1Easy to chargeRelieve energyGas turbine plantsMechanical power devicesElectricityCombustion

The invention relates to systems for stored compressed air without use of combustion. The systems can be installed on the customer side of the meter and creates electricity during peak hours after it has been stored in off peak hours. The invention creates a financial incentive for conserving energy costs by building compressed air storage systems which heretofore have seen little application.

Owner:MECHANOLOGY INC

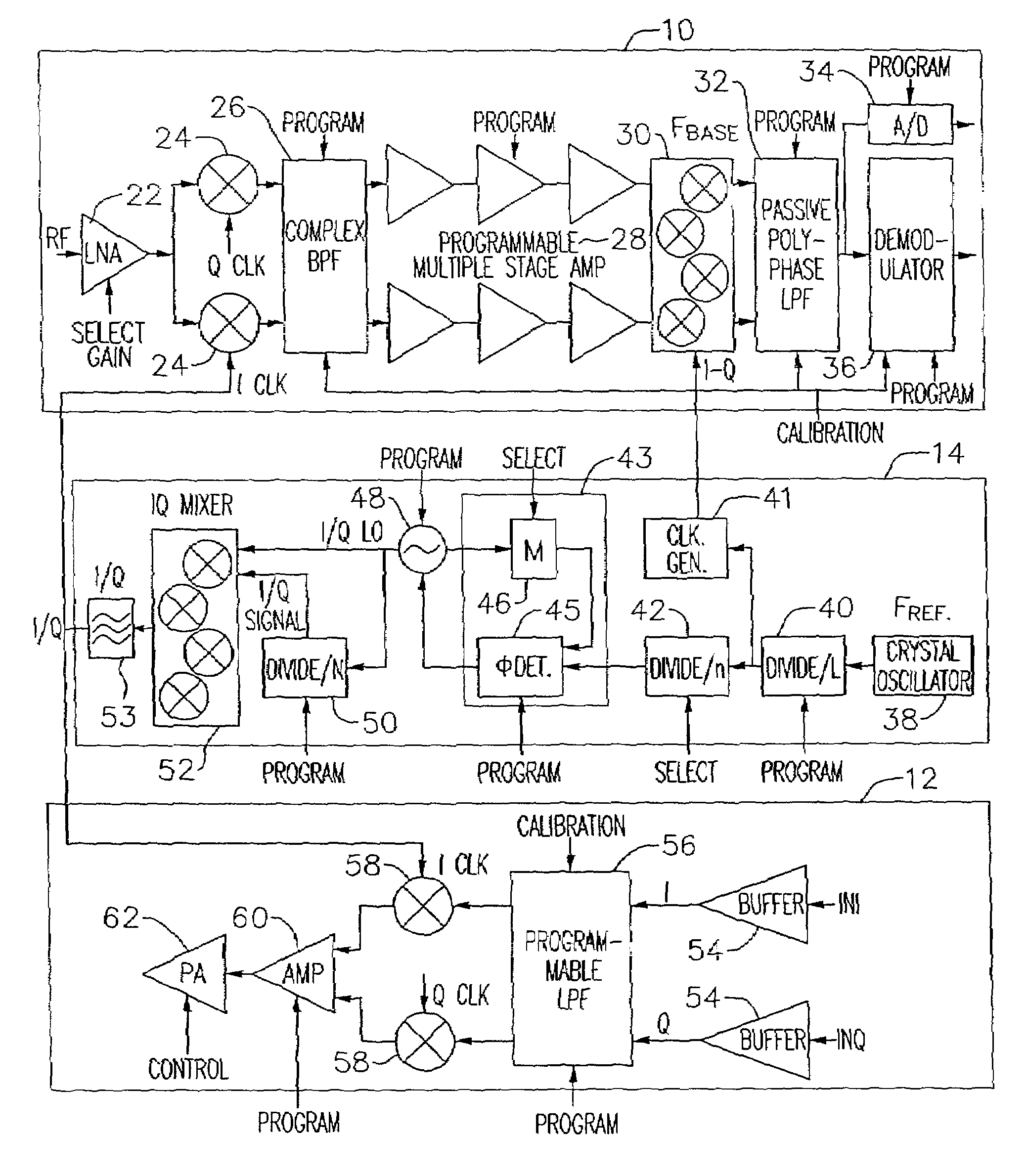

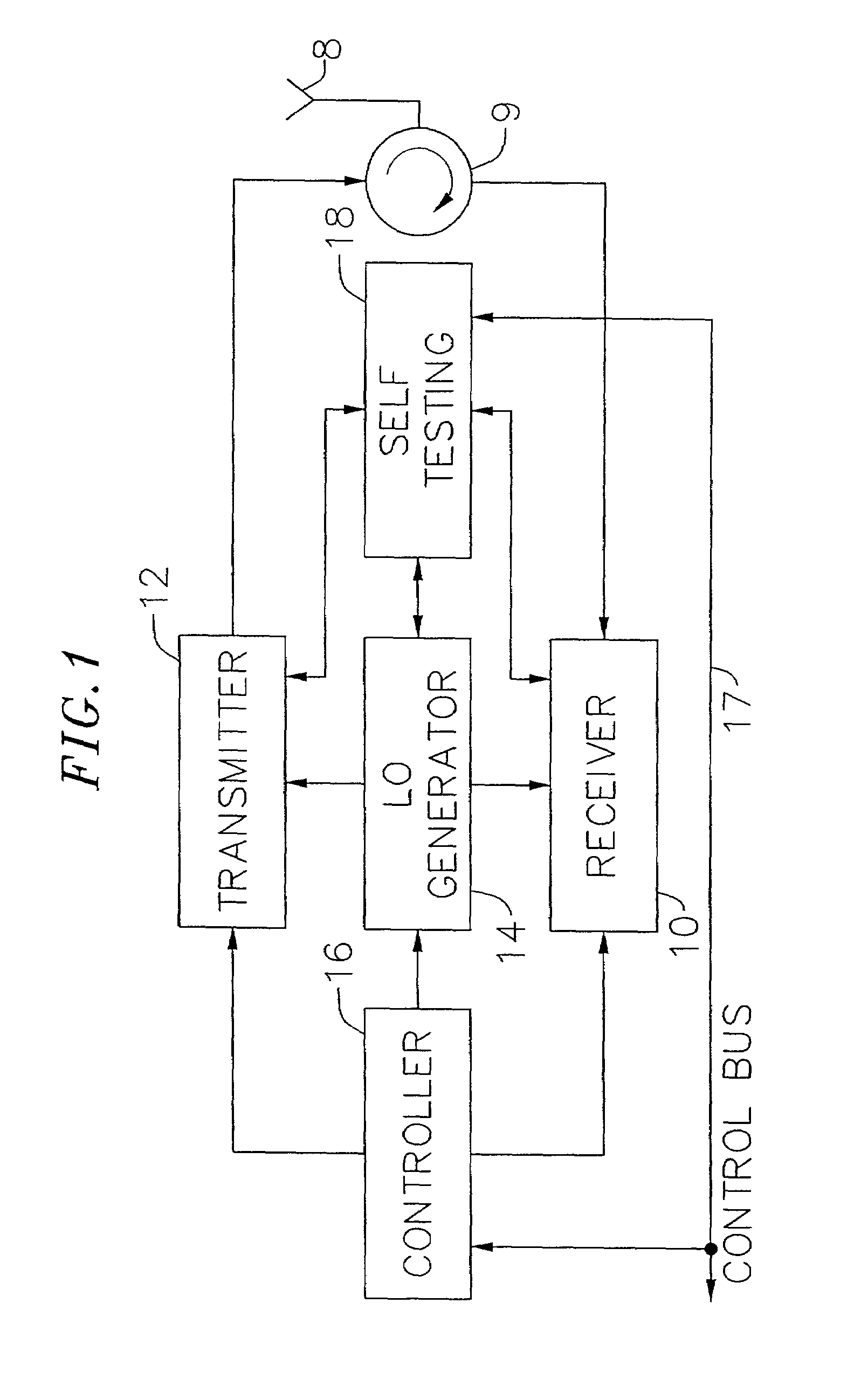

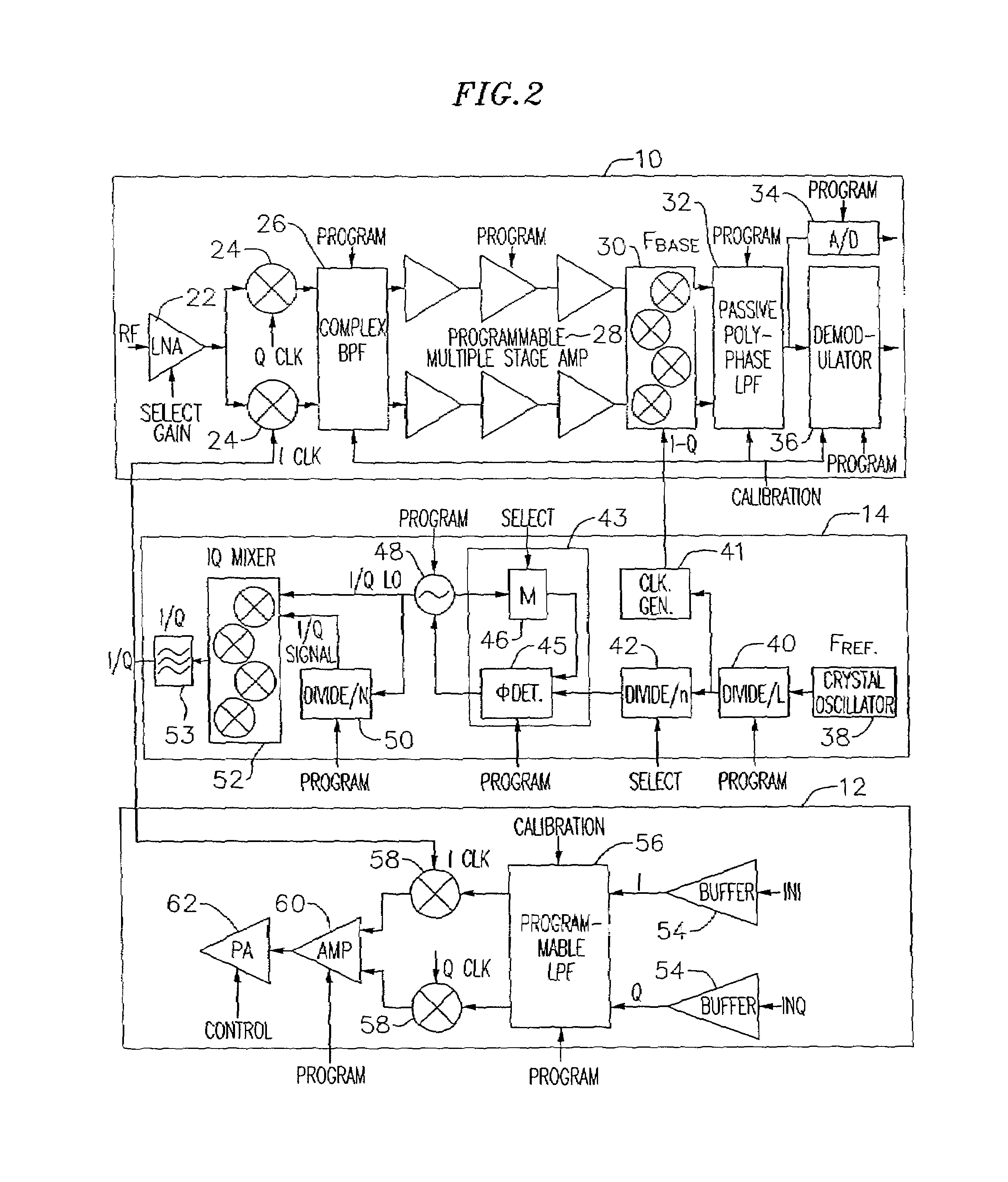

Adaptive radio transceiver with a local oscillator

InactiveUS7031668B2Increase data rateIncrease costTransmitters monitoringResonant circuit tuningTransceiverAdaptive programming

An exemplary embodiment of the present invention described and shown in the specification and drawings is a transceiver with a receiver, a transmitter, a local oscillator (LO) generator, a controller, and a self-testing unit. All of these components can be packaged for integration into a single IC including components such as filters and inductors. The controller for adaptive programming and calibration of the receiver, transmitter and LO generator. The self-testing unit generates is used to determine the gain, frequency characteristics, selectivity, noise floor, and distortion behavior of the receiver, transmitter and LO generator. It is emphasized that this abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or the meaning of the claims.

Owner:AVAGO TECH INT SALES PTE LTD

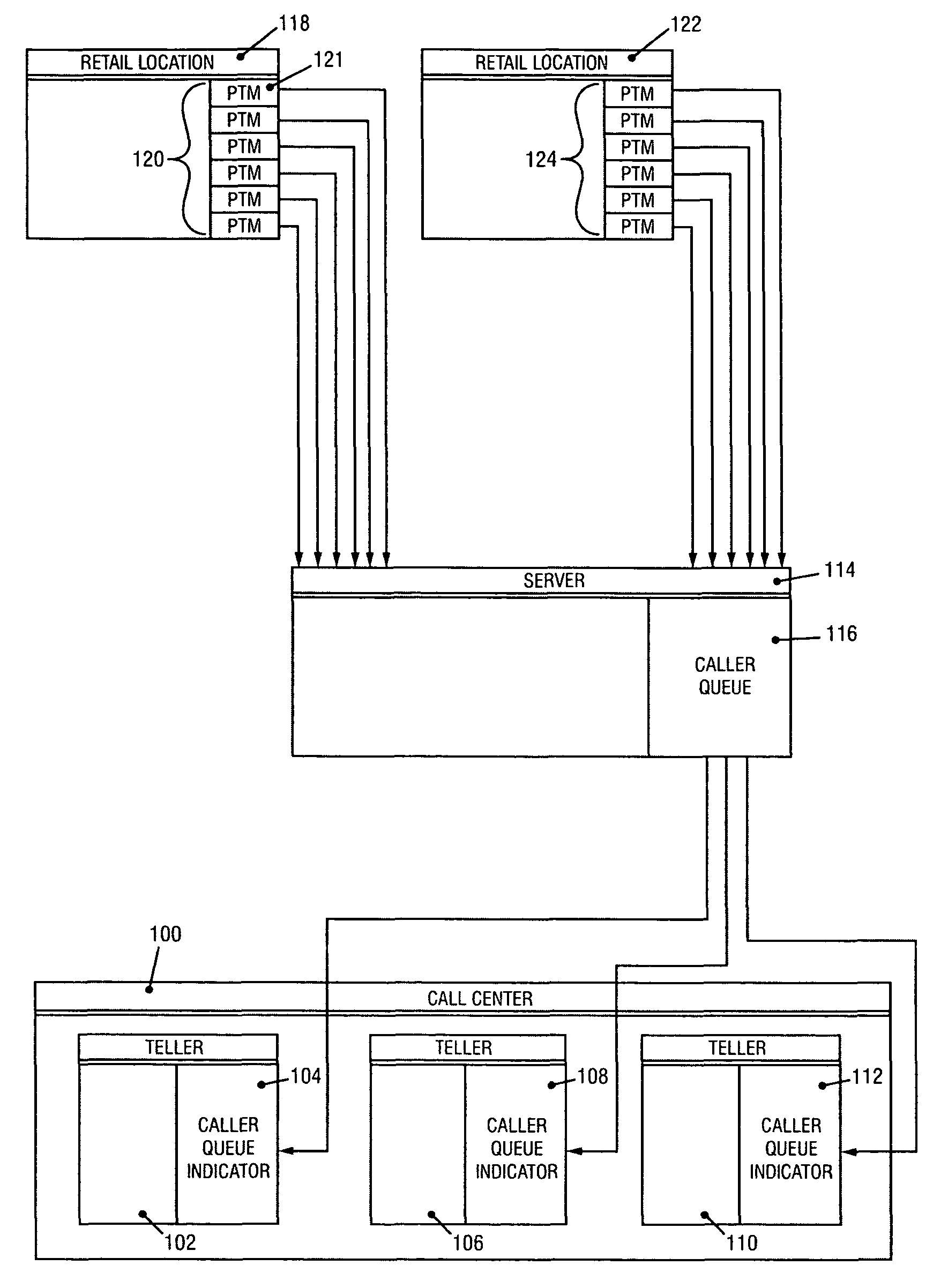

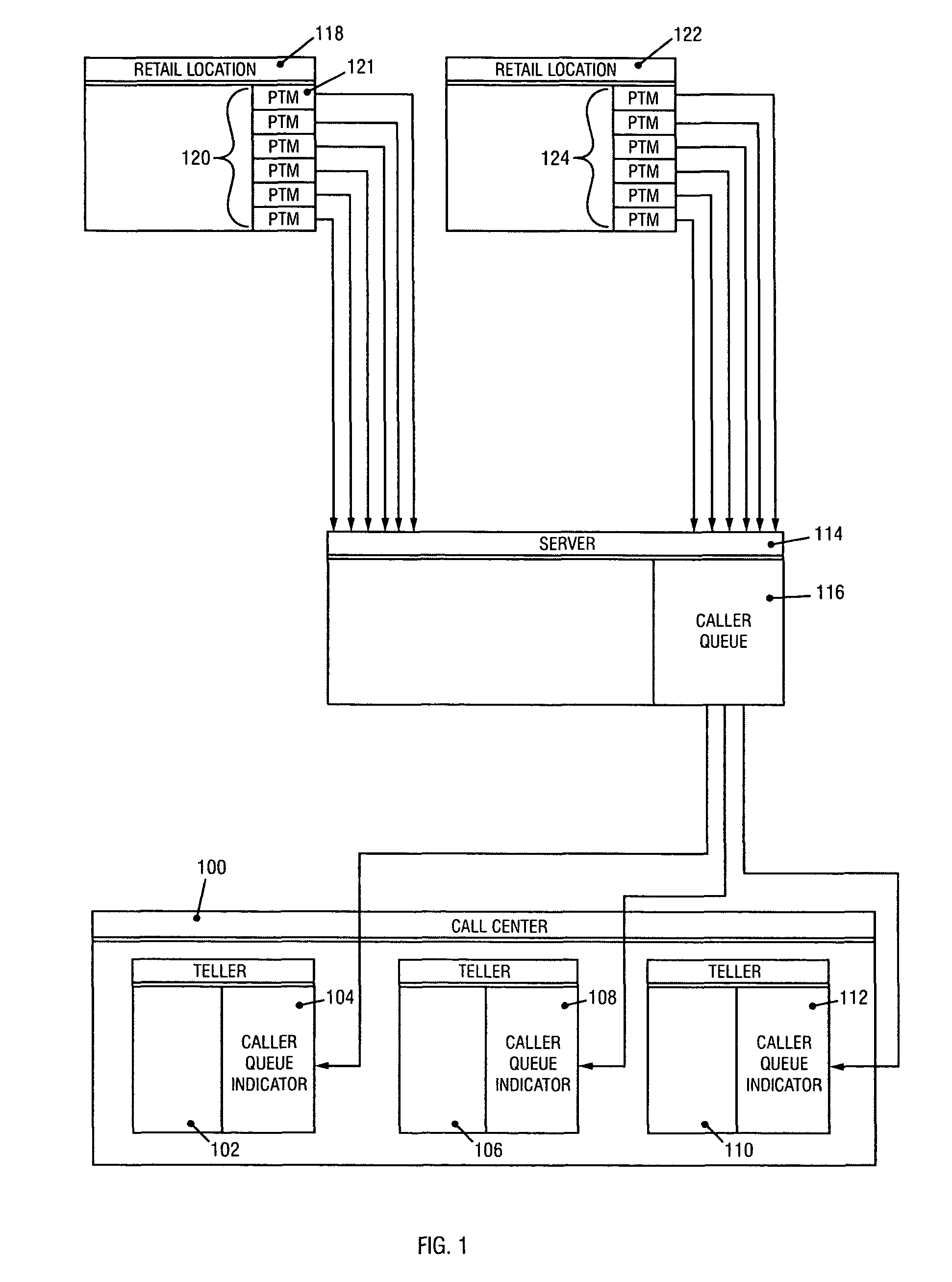

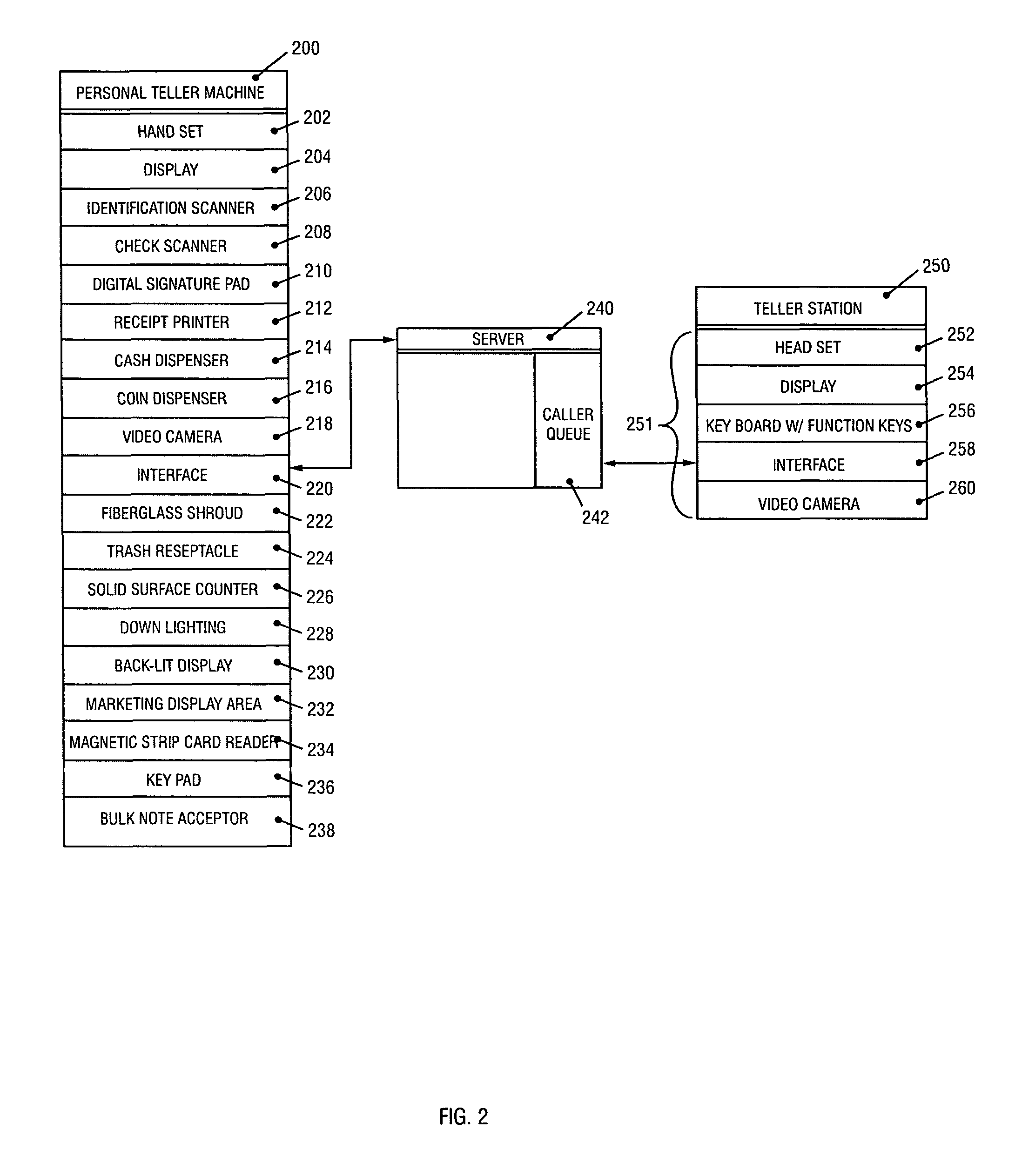

Personal teller system and method of remote interactive and personalized banking

ActiveUS7814016B2Effectively participateQuick serviceFinancePayment architectureFinancial transactionHuman–computer interaction

Systems and methods for providing personalized services to remote customers using personal teller machines (PTM) from a centralized call center. The customer initiates the transaction providing identification at a PTM. The identification of the customer is verified and audio and / or video communication is established between the customer at the PTM and a teller at a teller station in the call center. Upon establishment of video and audio connection, the customer may request the performance of specific financial transactions that are controlled by a teller through the teller station that is connected with the PTM over a network. Upon completion of the transactions of the customer by the teller, a receipt is printed for the customer and the video and audio connections are closed.

Owner:NCR CORP

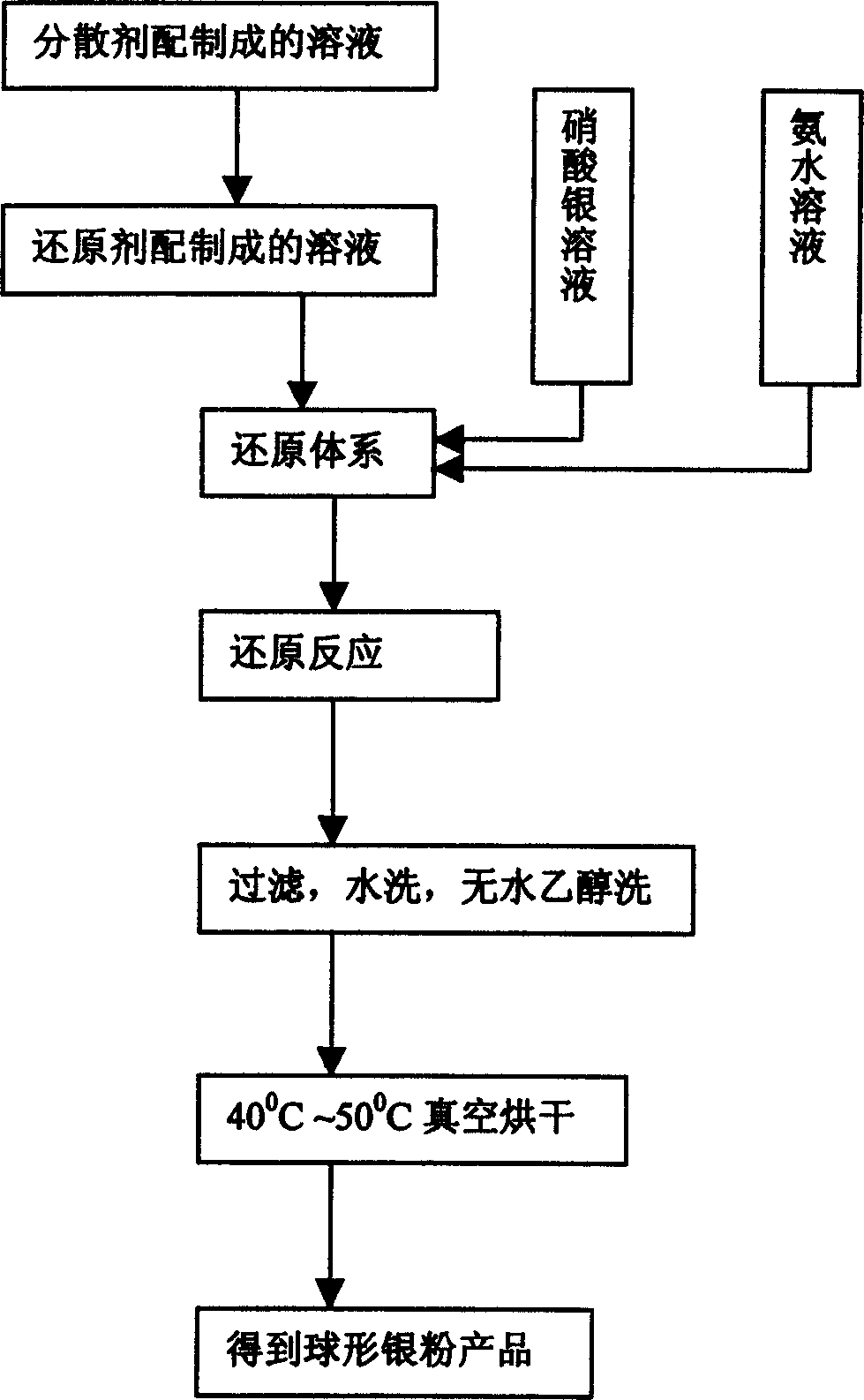

Preparation method of micron grade ball shape silver powder for conductive silver paste

A process for preparing the micron-class spherical silver powder used for electrically conductive Ag slurry features that in the redox procedure, the silver nitrate solution is dripped into reducer and disperser while the ammonia water is used to regulate the pH value of solution, and the kind of disperser, stirring speed, and reaction temp and time are regulated.

Owner:SOUTHEAST UNIV

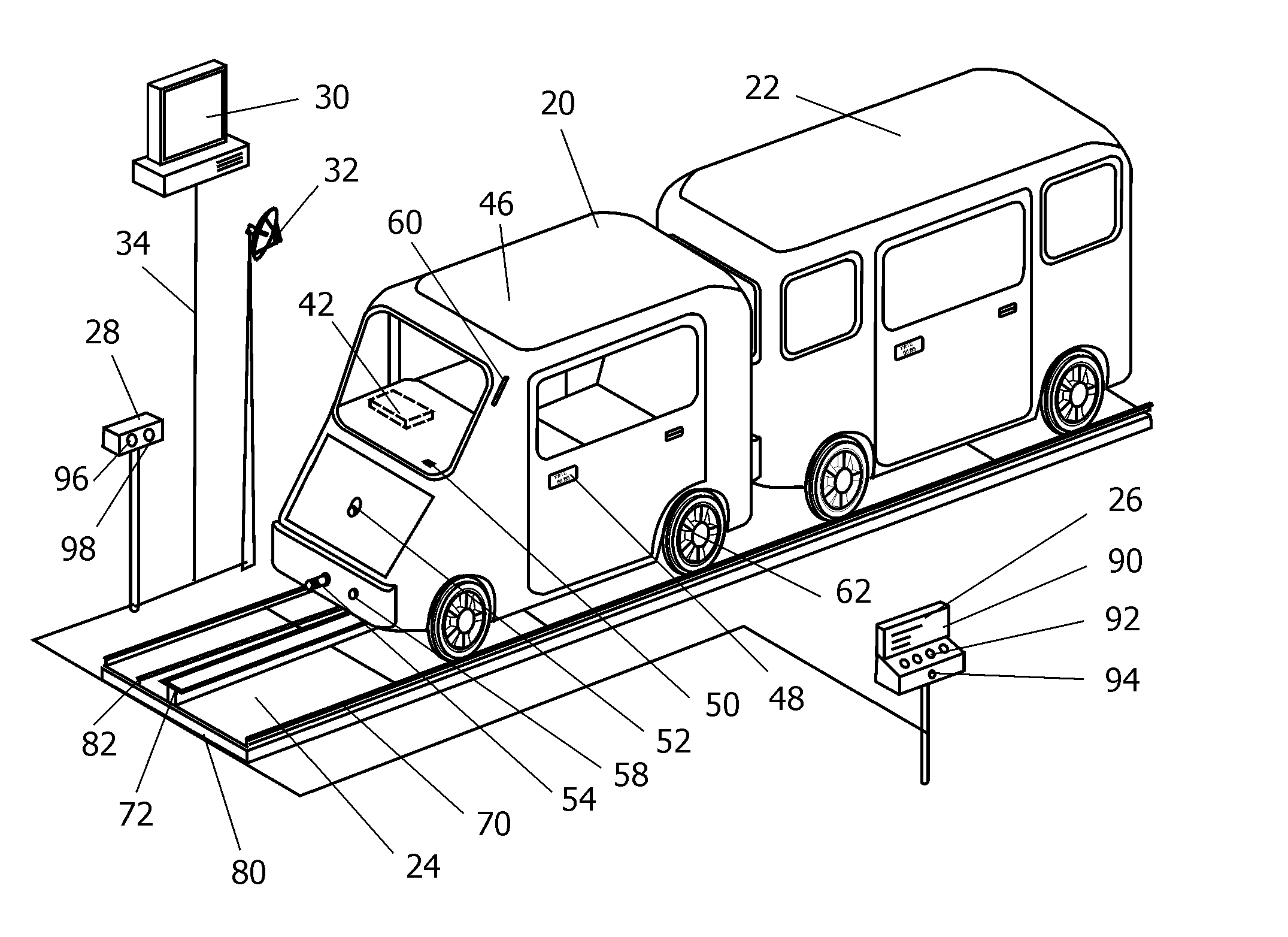

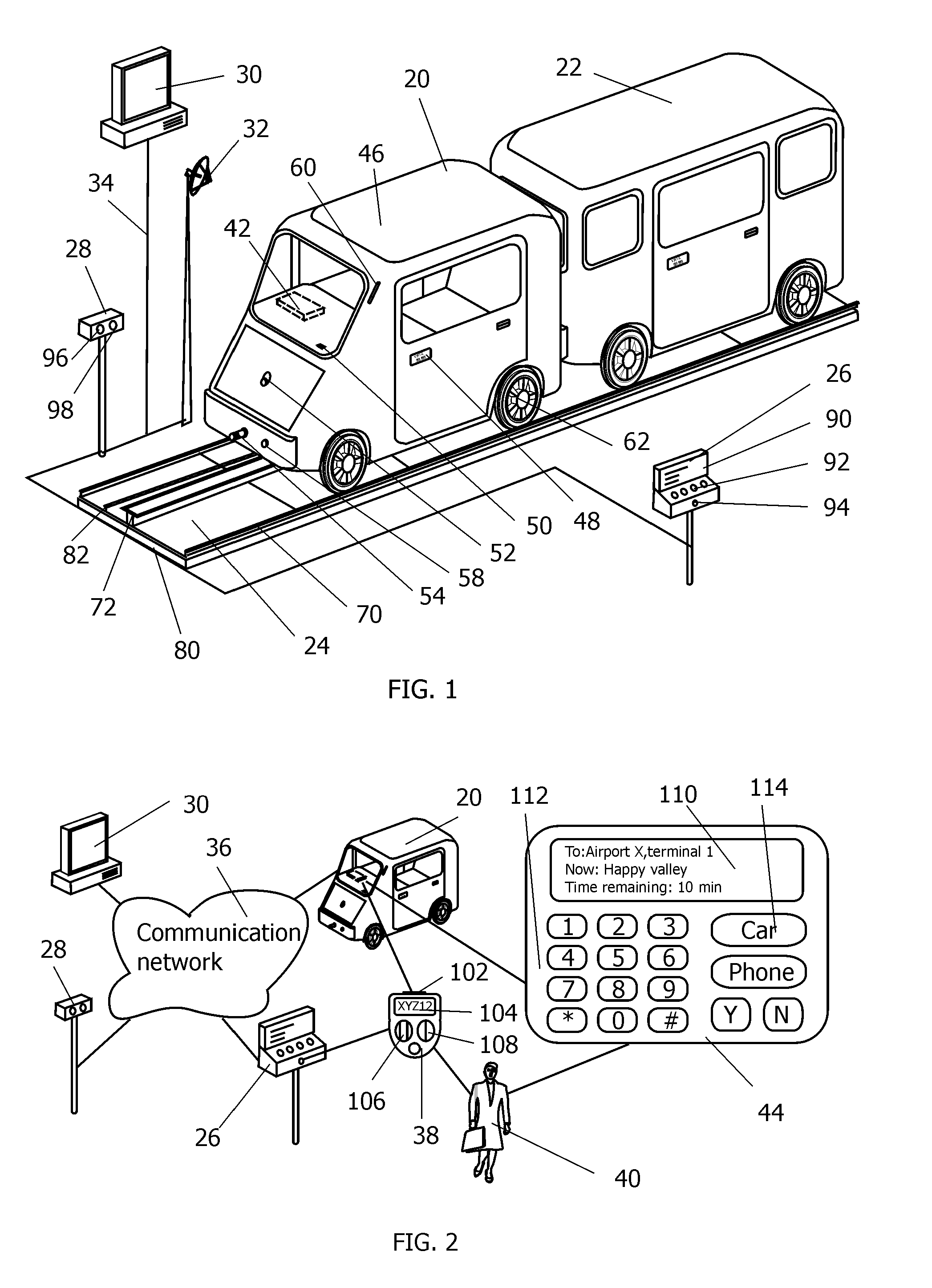

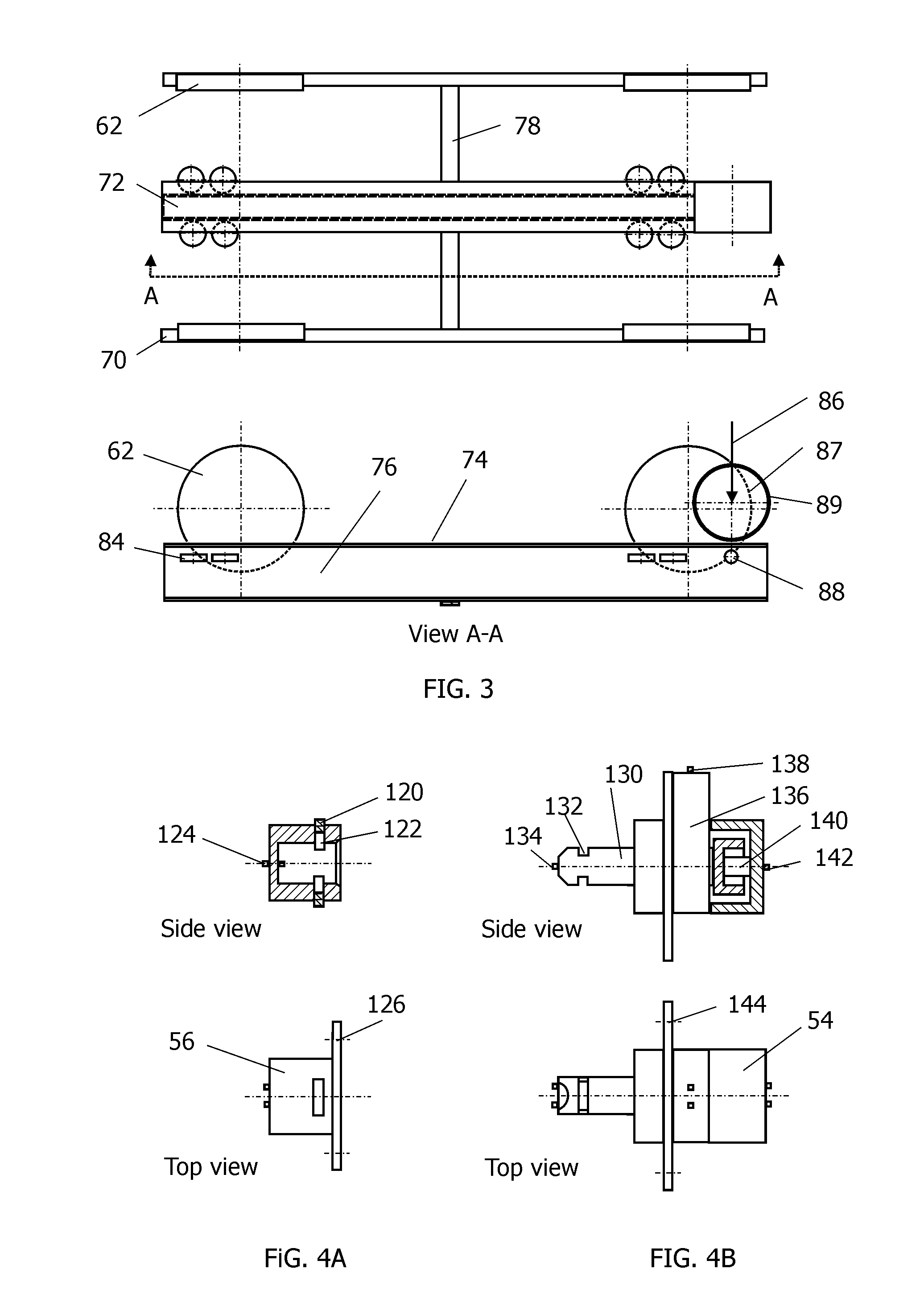

Personal Transportation System

InactiveUS20050038575A1Increase speedTransportation is highRefuge islandsAutomatic systemsThree levelControl system

An autonomous personal transportation system for moving passengers and light freights is constructed with a track network and small vehicles on the track network. There are a number of stations and stops for loading and unloading on side tracks off the mainline of the track network. The vehicle width is limited to a dimension for one seat. The vehicles can be coupled statically or dynamically to form a train. The track has side rails for the rigid wheels of the vehicle and a central rail for centering the vehicle on the guideway and providing additional acceleration and braking capability. The control system for the movement of vehicles is divided into three levels: the central control system, the wayside control system and the vehicle control system.

Owner:WU HENGNING

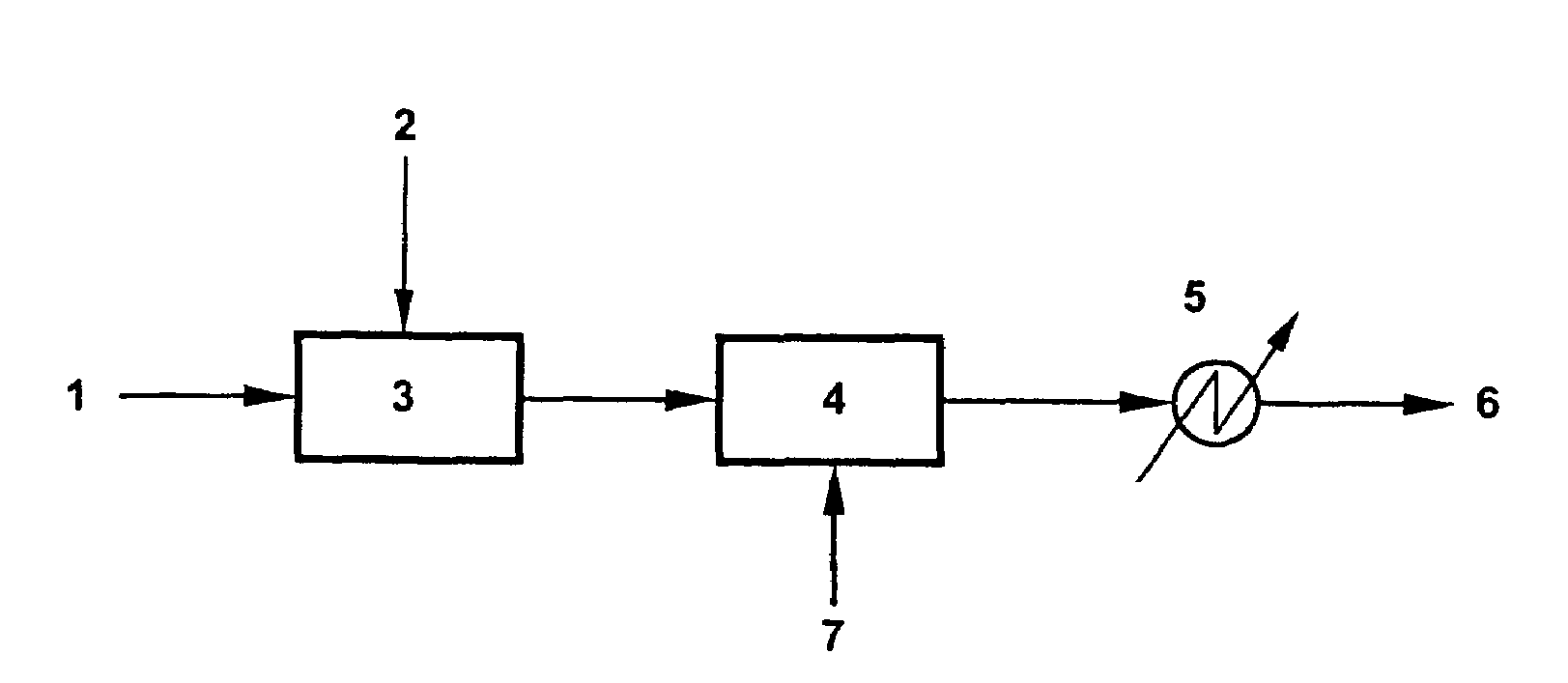

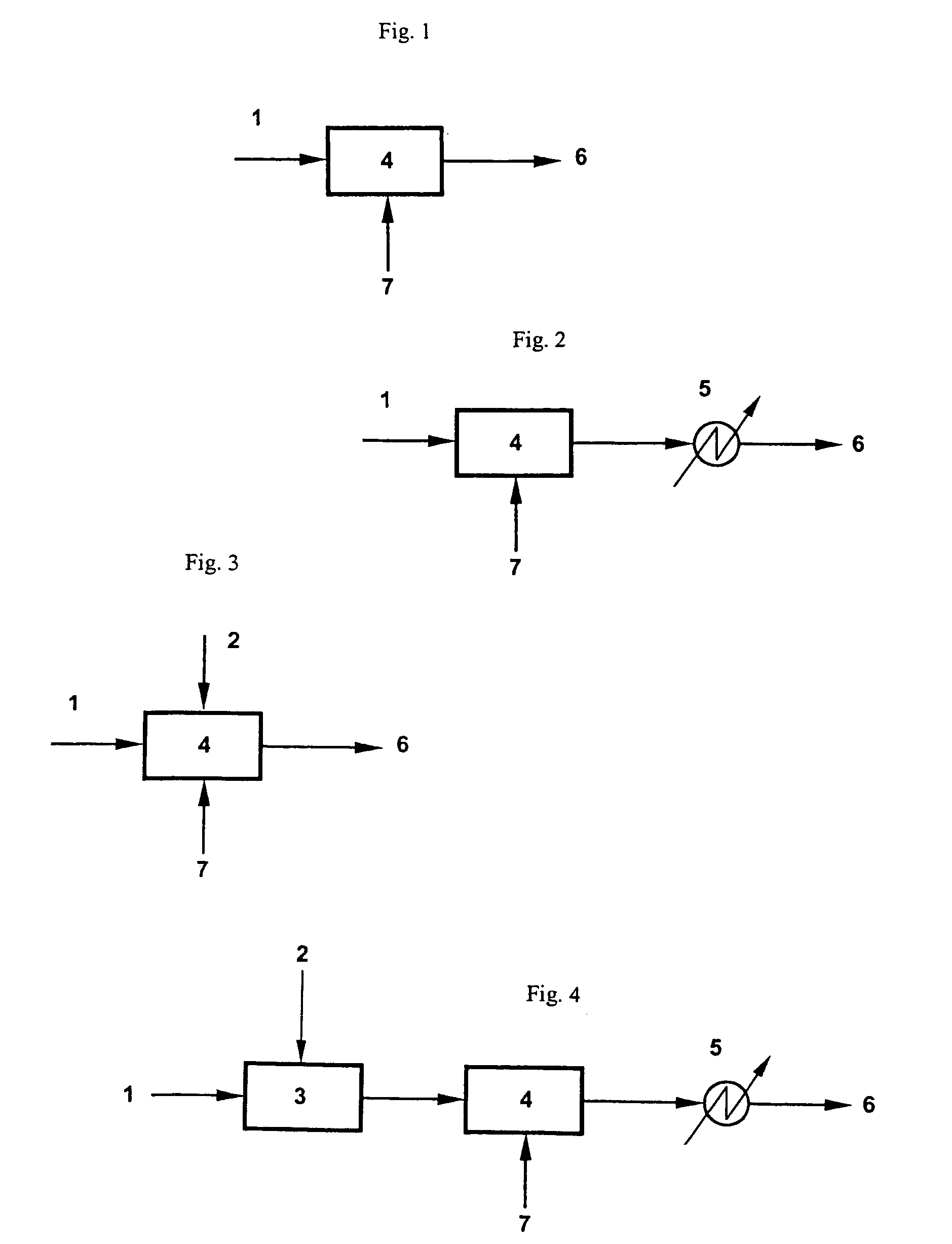

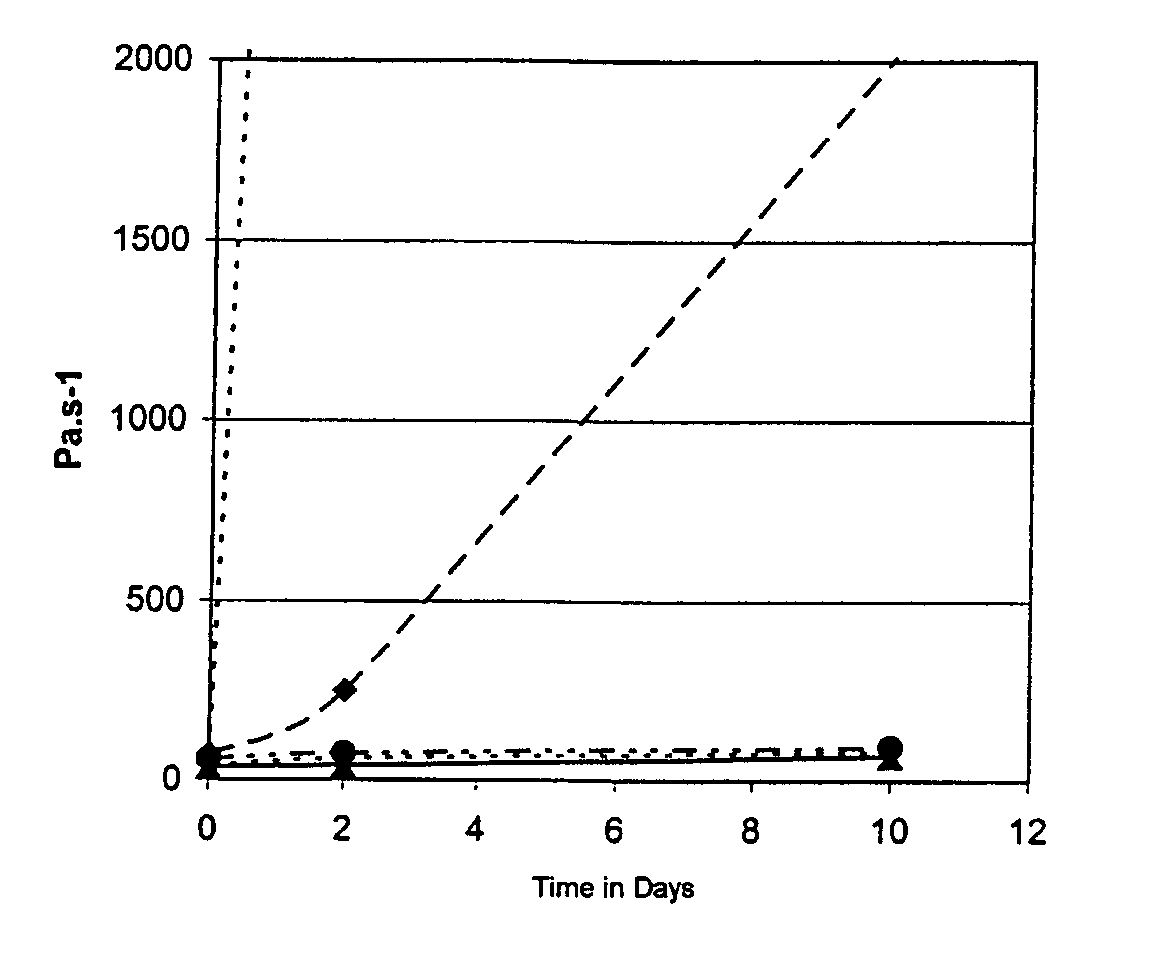

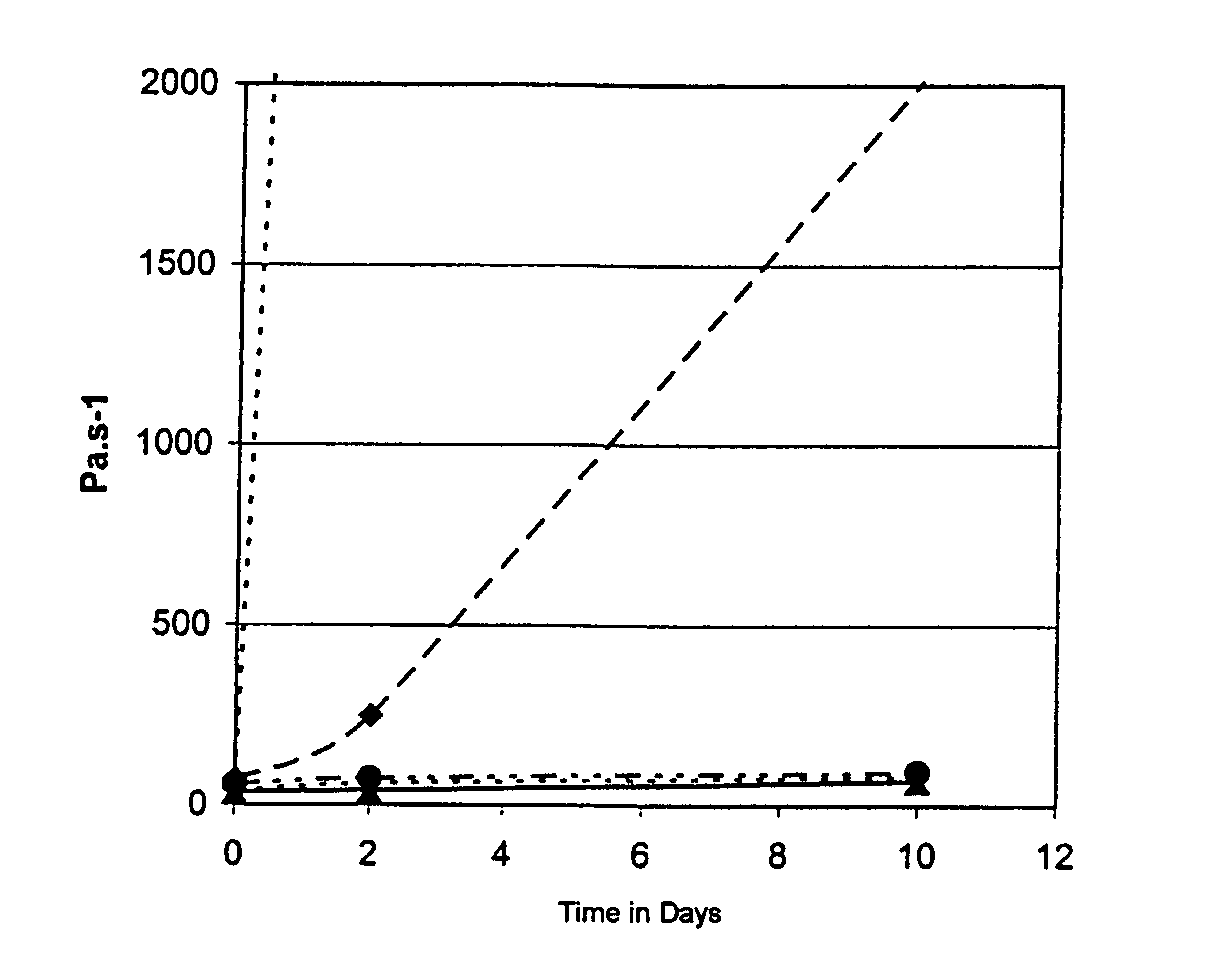

Method and system for transporting flows of fluid hydrocarbons containing wax, asphaltenes, and/or other precipitating solids

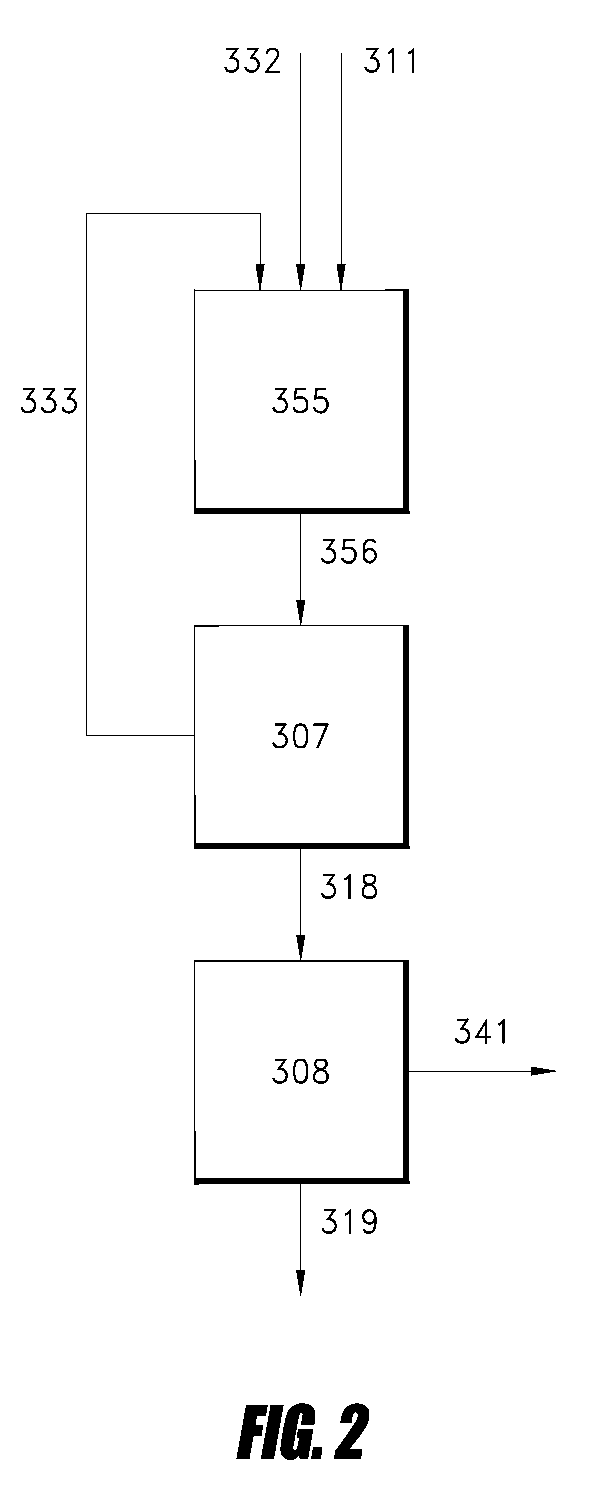

ActiveUS7261810B2Costly removalSimpler and steady operationRefining by heating/coolingWorking-up pitch/asphalt/bitumenWaxCrystallization temperature

A method and a system for transporting a flow of fluid hydrocarbons containing wax and / or asphaltenes or any other precipitating solids through a treatment and transportation system including a pipeline are disclosed. The flow of fluid hydrocarbons is introduced into a reactor (4), where it is mixed with another fluid flow having a temperature below a crystallization temperature for the wax and / or asphaltenes or other solids and containing particles or crystals acting as nucleating and / or growth cores for the wax and / or asphaltenes or other solids, the mixing temperature providing precipitation of the wax and / or asphaltenes or other solids from the flow of fluid hydrocarbons, and the effluent flow of hydrocarbons and particles is conveyed from the reactor (4) to a pipeline (6) for transportation.

Owner:SINVENT AS +2

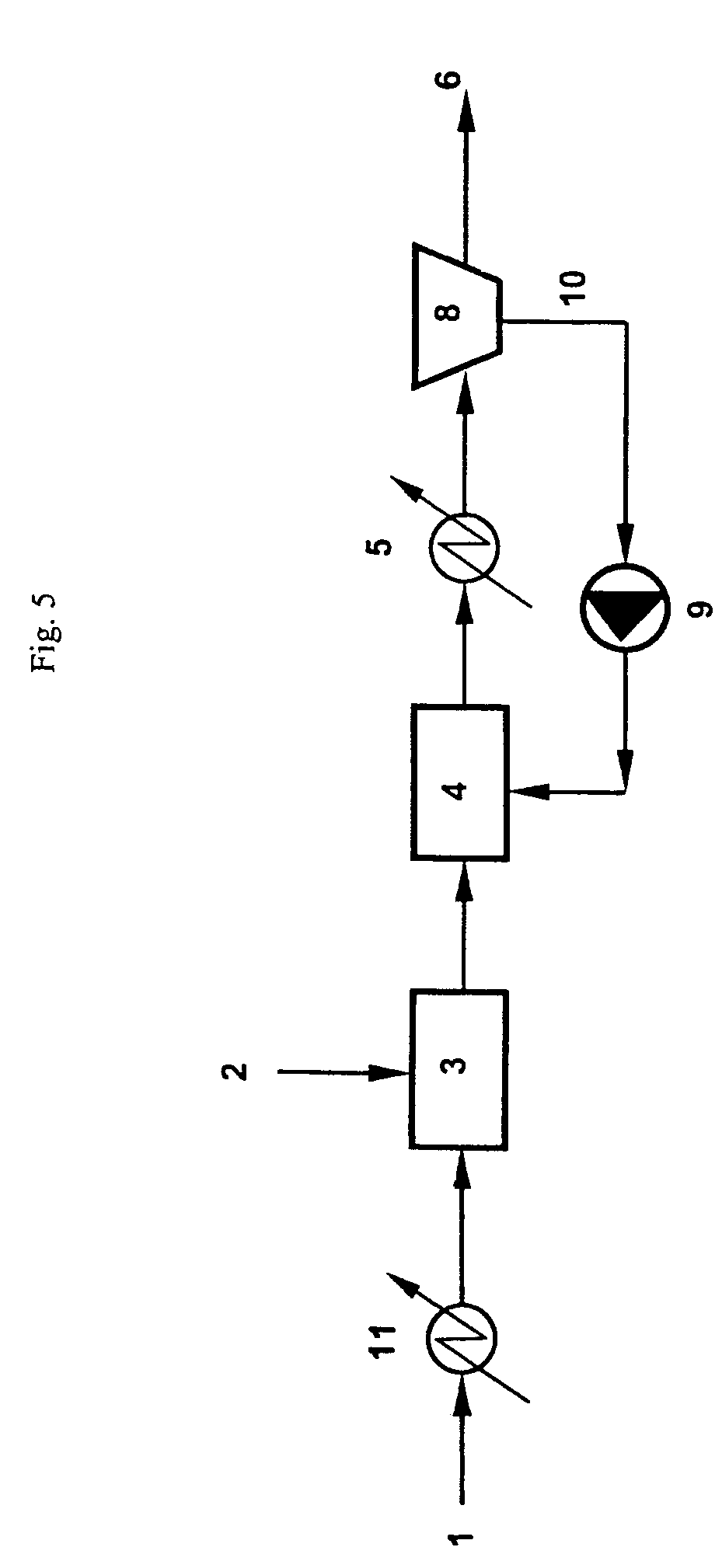

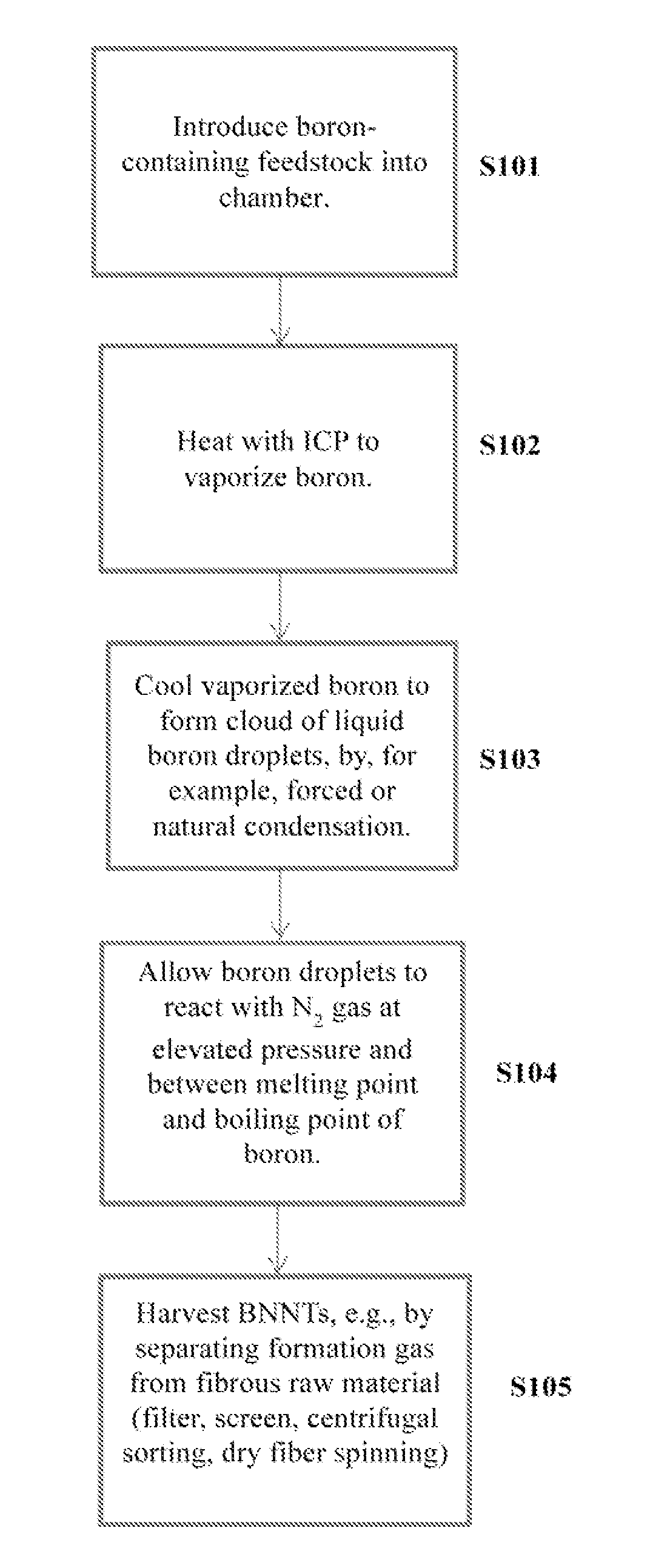

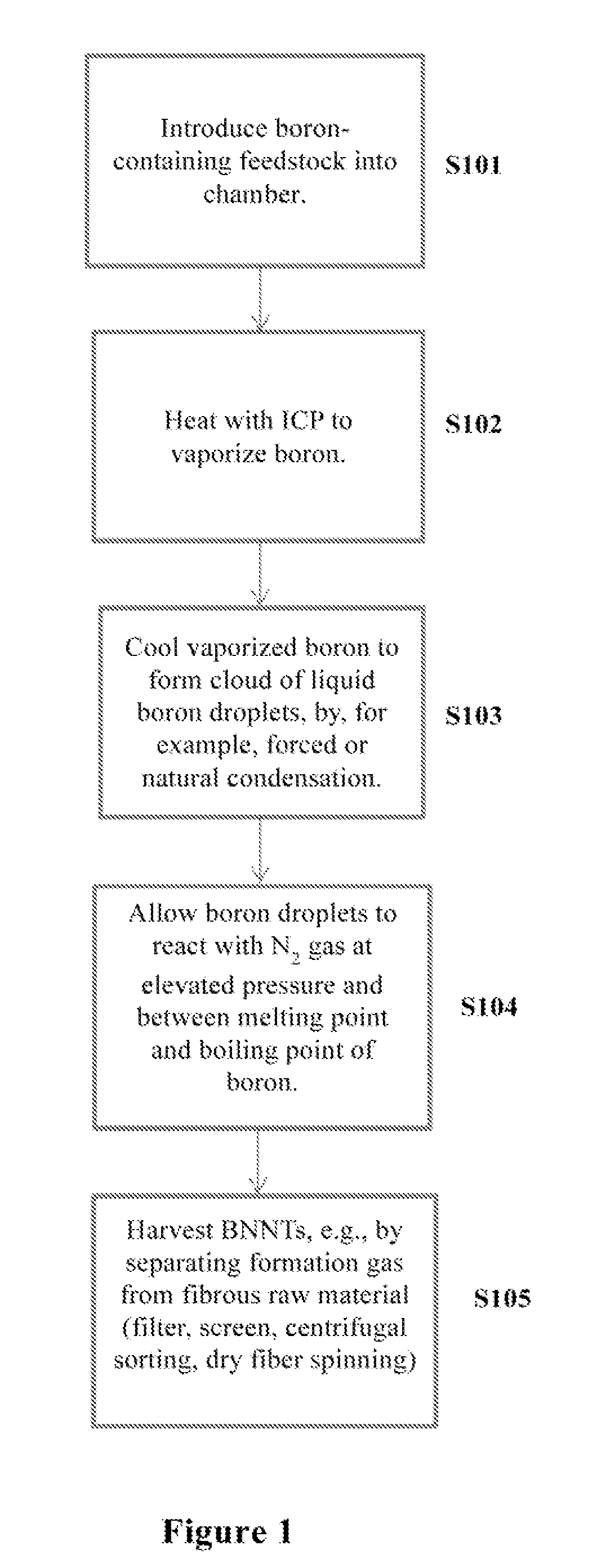

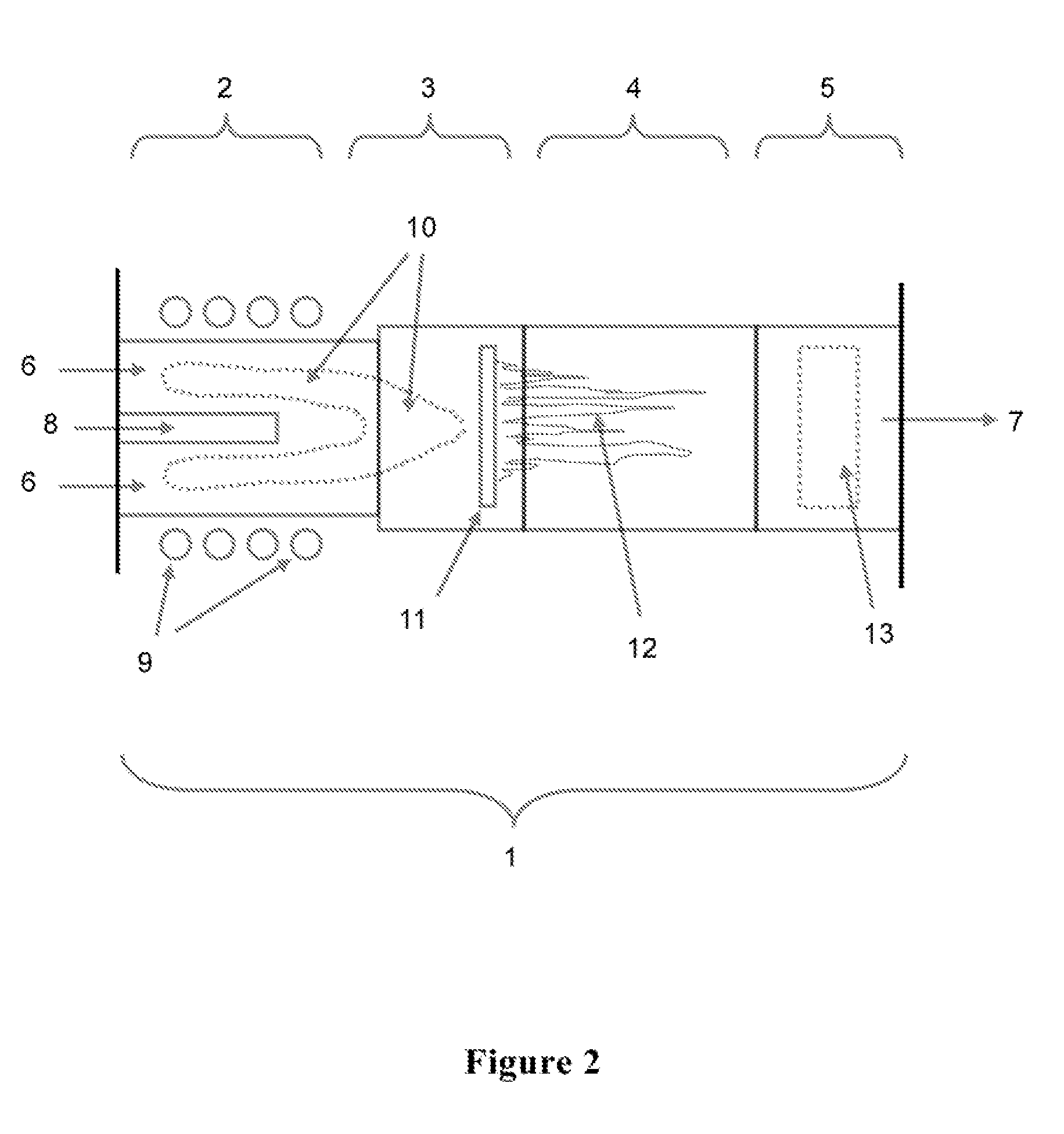

Induction-coupled plasma synthesis of boron nitride nanotubes

ActiveUS20150125374A1Few crystalline structure defectHigh yieldNitrogen compoundsHigh temperature liquid-gas reactionBoron nitrideNitrogen gas

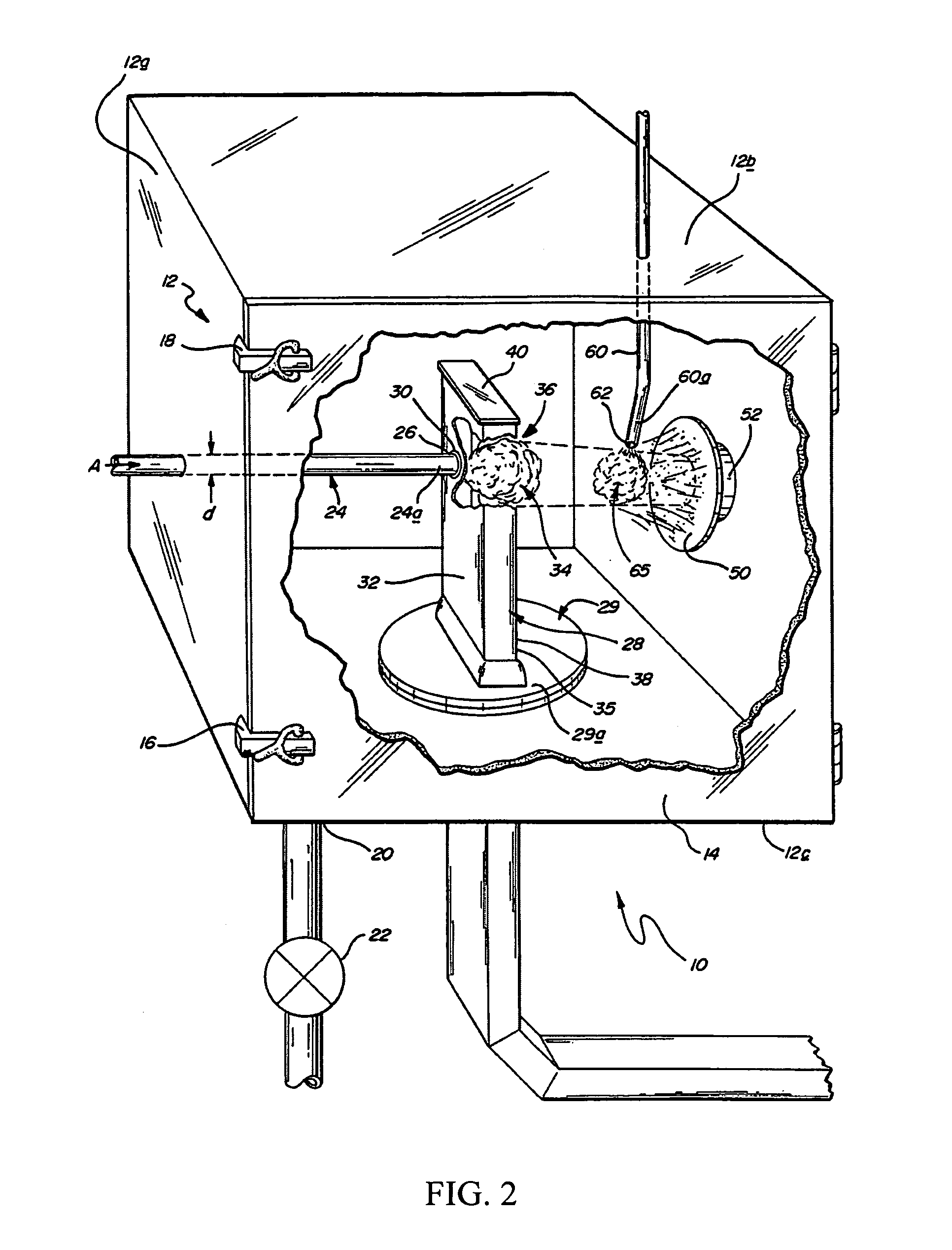

Described herein are processes and apparatus for the large-scale synthesis of boron nitride nanotubes (BNNTs) by induction-coupled plasma (ICP). A boron-containing feedstock may be heated by ICP in the presence of nitrogen gas at an elevated pressure, to form vaporized boron. The vaporized boron may be cooled to form boron droplets, such as nanodroplets. Cooling may take place using a condenser, for example. BNNTs may then form downstream and can be harvested.

Owner:BNNT

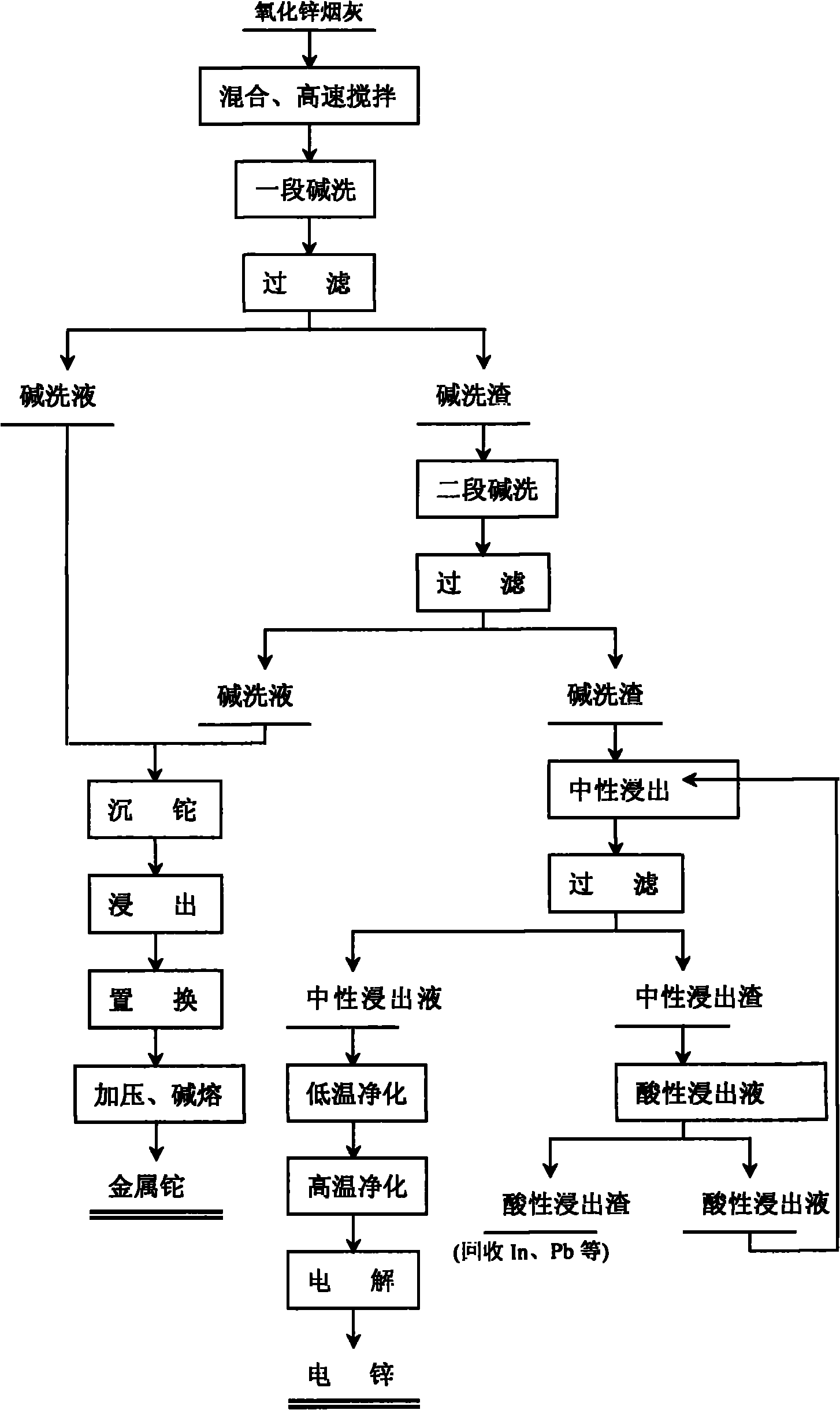

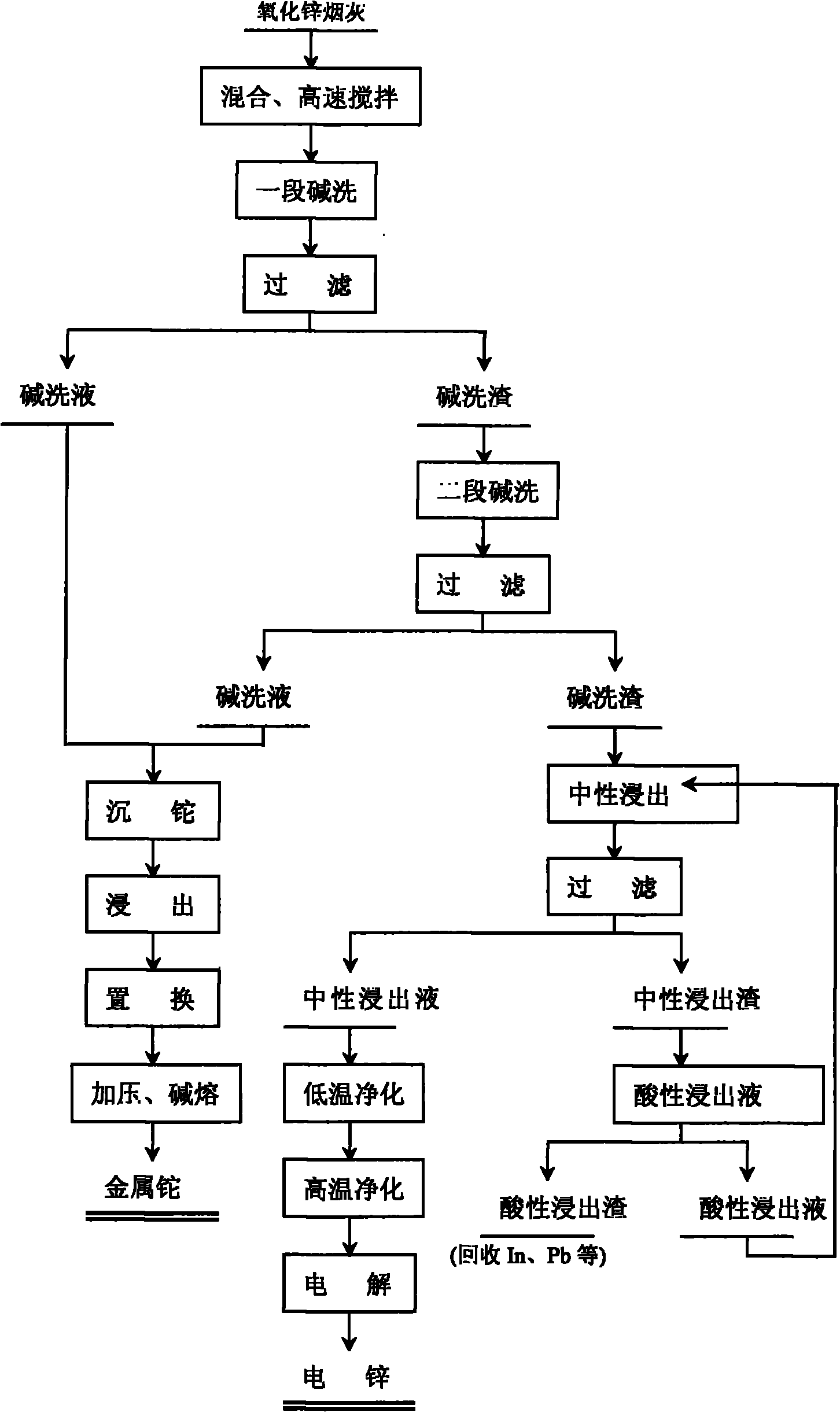

Comprehensive recovery method of zinc oxide fume dust

The invention relates to a comprehensive recovery method of zinc oxide fume dust. The method comprises the following steps: 1. performing alkali-washing on zinc oxide fume dust with Na2CO3 and NaOH in different stages: in the first stage of alkali wash, evenly mixing the zinc oxide fume dust and solid Na2CO3, adding water, stirring at high speed to dissolve the solid into solution with slag, and filtering to obtain first-stage alkali wash liquid and alkali wash slag; in the second stage of alkali wash, adding solid Na2CO3 and NaOH into the first-stage alkali wash slag, adding water, stirring to dissolve the solid, regulating the pH value, and filtering to obtain second-stage alkali wash liquid and alkali wash slag; and carrying out neutral leaching on the second-stage alkali wash slag, purifying and electrodepositing to obtain electric zinc; 2. leaching, displacing and the like to process the low temperature purified slag to obtain sponge cadmium; and 3. processing acid leached slag to obtain coarse indium, using high-temperature high-acidity leached slag as the raw material for recovering lead, and using alkali wash liquid for recovering thallium. In the invention, metals in ZnCl2, ZnF2 and PbCl2 form carbonate solid slag, chlorine and fluorine are dissolved in solution in the form of sodium salts, the slag and the liquids are respectively processed subsequently, and the products in every stage are refined processed to comprehensively recover zinc, cadmium, lead, thallium and indium.

Owner:ZHUZHOU SMELTER GRP

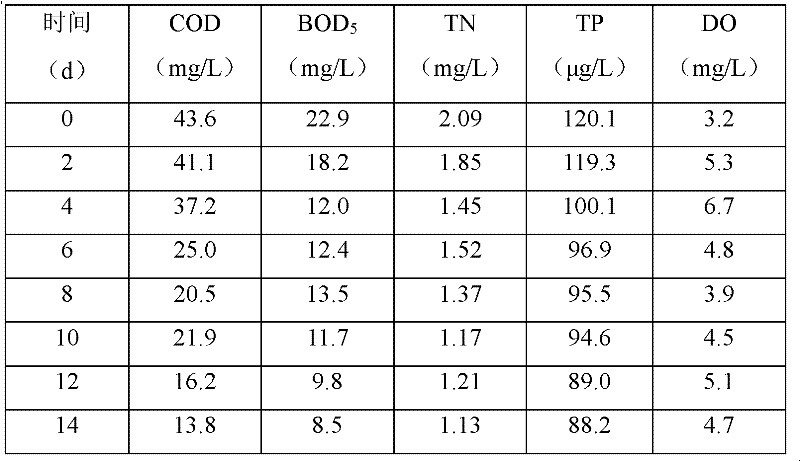

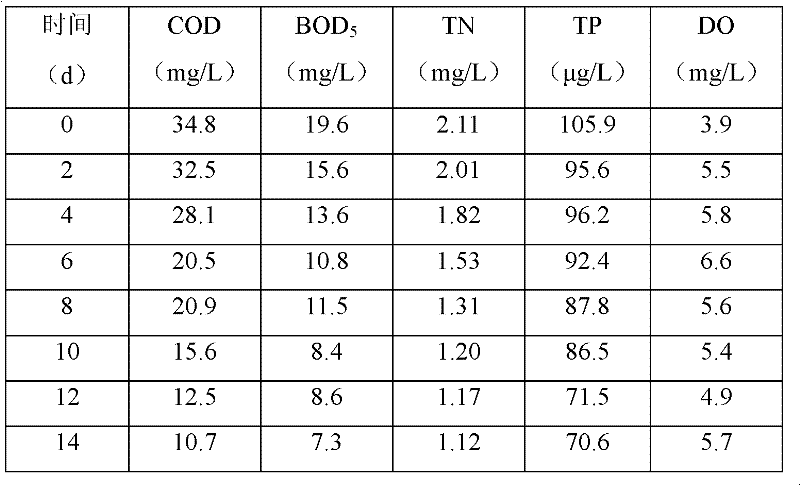

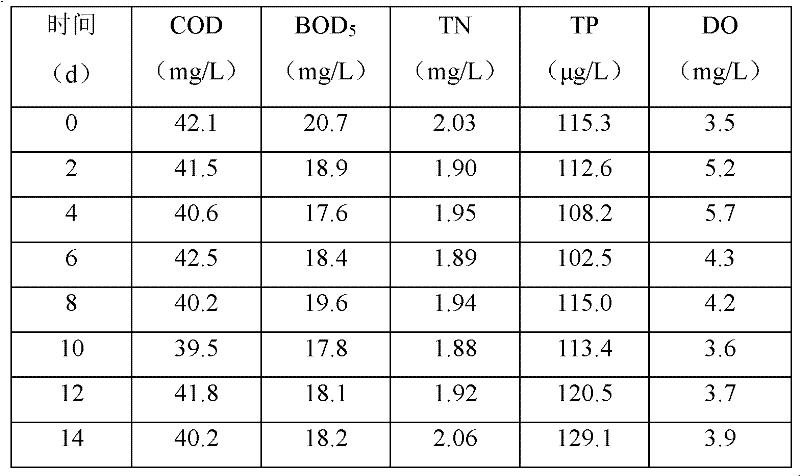

Method for purifying mariculture wastewater by utilizing compound microbial inoculant

InactiveCN102381768AImprove water qualityImprove the quality of farmingBiological water/sewage treatmentAquaculture industryNitrifying bacteria

The invention discloses a method for purifying mariculture wastewater by utilizing a compound microbial inoculant. The method comprises the following steps: (1) screening the compound microbial inoculant which consists of photosynthetic bacteria, nitrobacteria, denitrifying bacteria, candida utilis, lactobacillus acidophilus and bacillus; (2) activating the compound microbial inoculant by utilizing a culture medium: directly adding the strain into the culture medium based on 1% of inoculation amount (w / v), and activating the strain by a shaker at the temperature of 37 DEG C with the speed of 150rpm (revolution per minute) for 24 hours so that the total content of microbes is 7*10<8>-9*10<8>CFUs (colony forming units) / mL; and (3) adding the activated compound inoculant into the treated aquaculture wastewater, wherein the compound inoculant accounts for 0.06%-0.12% of the total weight of the aquaculture wastewater. The method has the advantages of no toxicity and harm on aquaculture animals, simple process, fast organic matter degradation speed, obvious effect, no drug residues and no secondary pollution. Therefore, the method has economic feasibility and is applicable to popularization and application to coastal aquaculture industry.

Owner:QUANZHOU NORMAL UNIV +1

Method for producing metal nanoparticles and nanoparticles obtained in this way and use thereof

InactiveUS20120037041A1Economically viableLimitation in dispersibilityCosmetic preparationsMaterial nanotechnologyMaterials scienceReducing agent

The invention relates to a method for producing metal nanoparticles, wherein metal ions are reduced by means of at least one reducing agent in the presence of at least one polymer stabilizer and are converted into metal nanoparticles. The invention further relates to metal nanoparticles obtained in this way and to the use thereof.

Owner:BYK CHEM GMBH

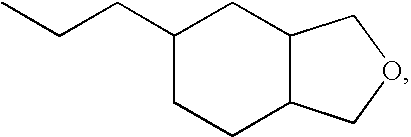

Gas phase process for monoalcohol production from glycerol

InactiveUS20090005614A1Economically viableOrganic compound preparationOxygen compounds preparation by reductionGlycerolBiodiesel production

Owner:BIOFUEL SOLUTION I MALMO

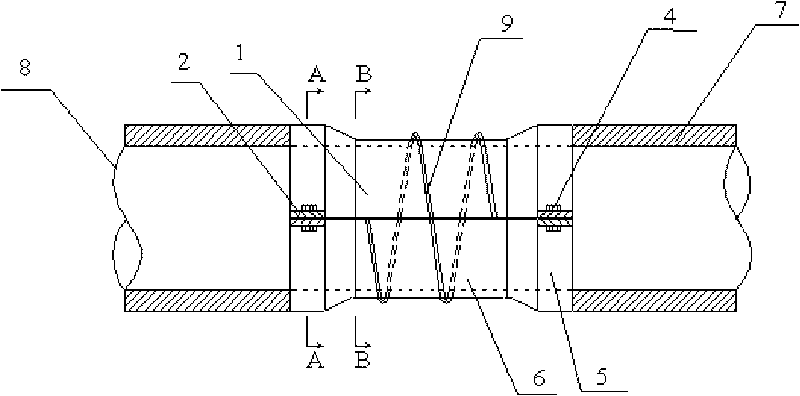

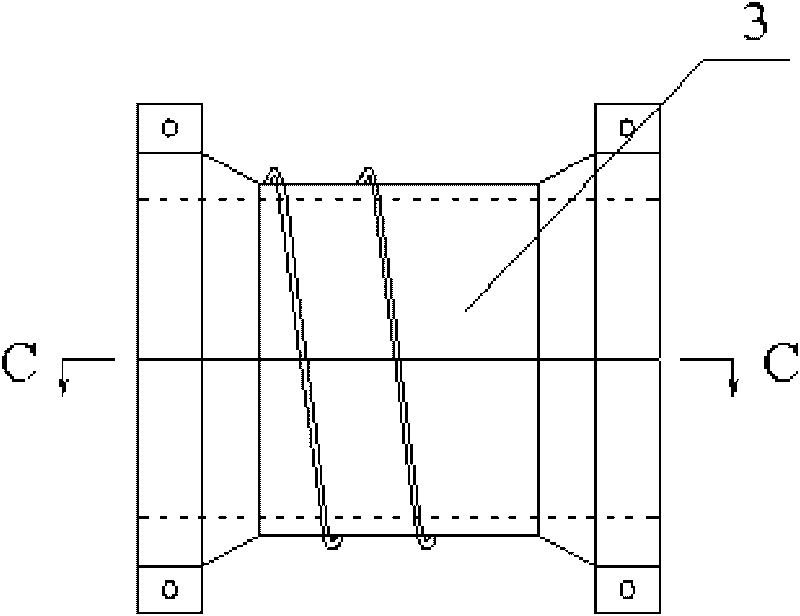

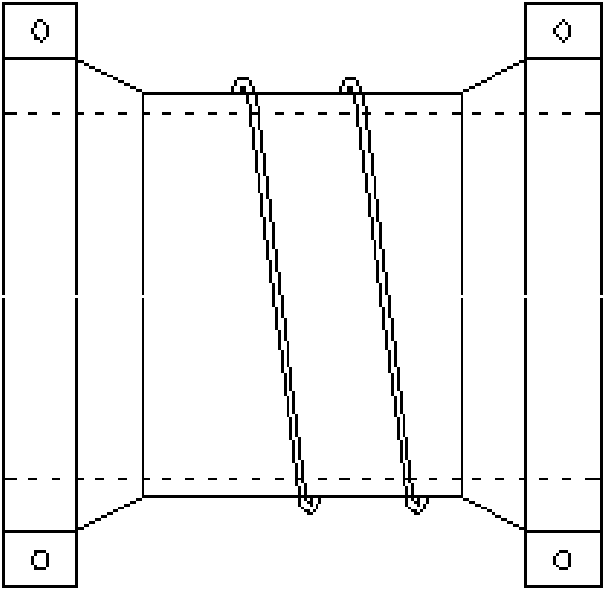

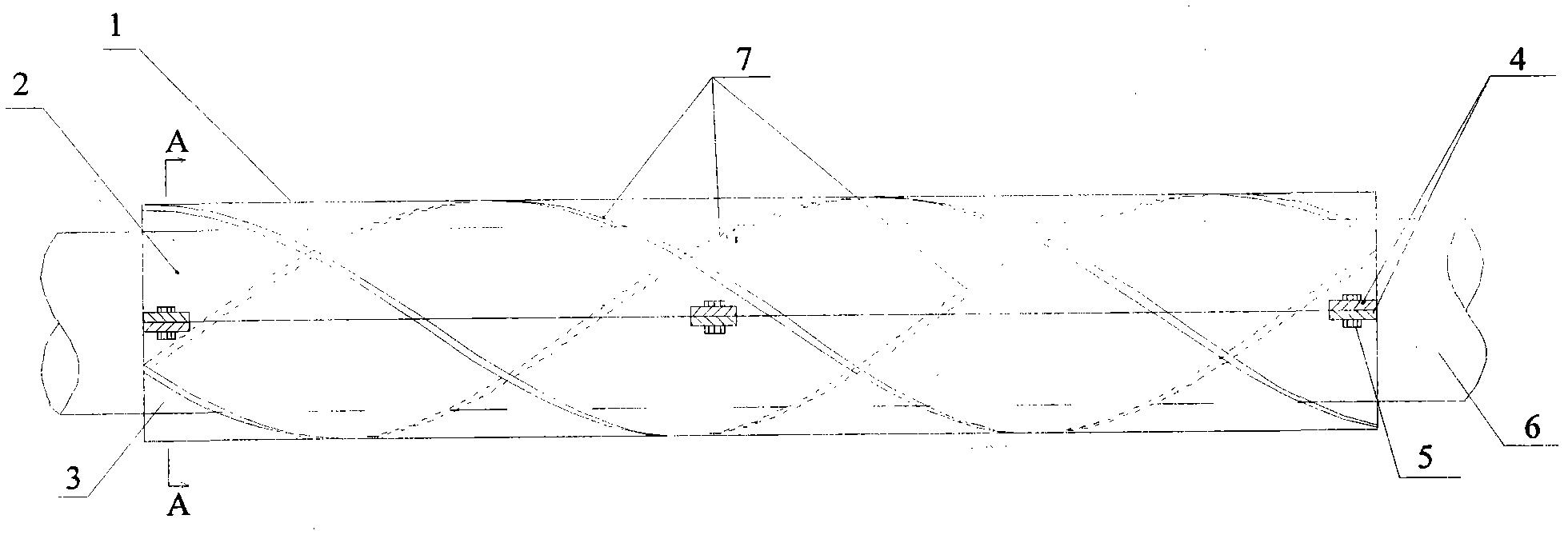

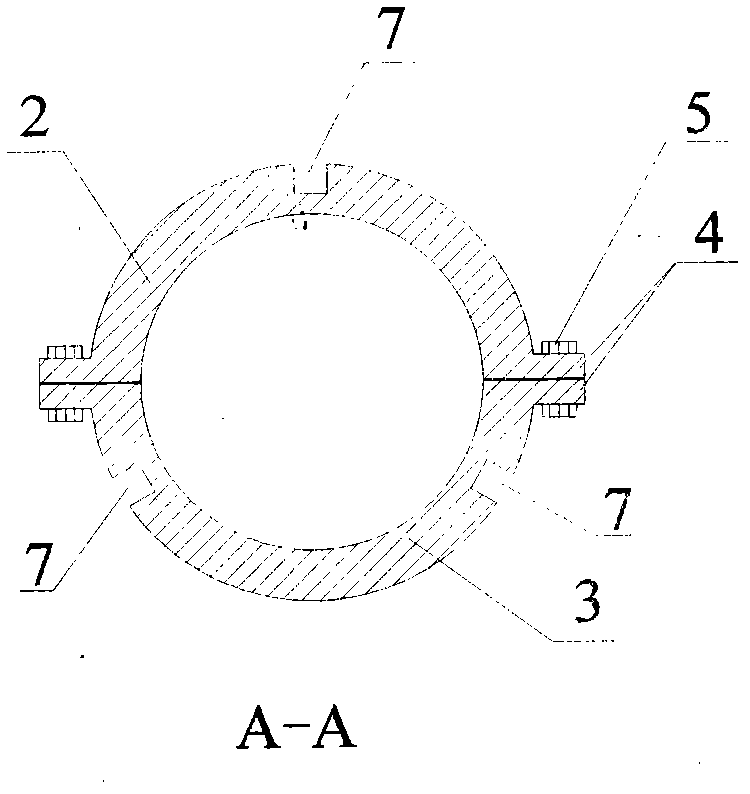

Method for preventing buckle propagation and inhibiting vortex-induced vibration of benthal pipeline

InactiveCN101696751AAvoid spreadingIntegrity guaranteedPipe laying and repairPipe elementsOcean bottomEngineering

The invention belongs to the technical field of paving benthal pipeline facility and relates to a method for preventing buckle propagation and inhibiting vortex-induced vibration of a benthal pipeline. According to the dimensions of an outside diameter and the wall thickness of the benthal pipeline, the method manufactures a plurality of pairs of variable-section and semicircular shells with the same dimensions and structures; the size of an inside diameter of each shell is equal to that of the outside diameter of the benthal pipeline; the outside diameter is changed along the axial direction and makes transition through a bevel; two ends of each shell are thick; the middle part is thin; the outer surface of the middle part of each shell is fixed with a spiral lateral plate and provided with an extended ocular plate; after one pair of the shells is connected to form a variable-section circular column, the spiral lateral plates in the middle parts of the shells are mutually coincided to form the same spiral structure to form a buckle arrestor; and one buckle arrestor is arranged in the radial direction of the benthal pipeline at intervals of a certain distance in the following method. The method can reduce cost, effectively controls the buckle propagation and vortex-induced vibration of the benthal pipeline and realizes the unification of economy and safety.

Owner:TIANJIN UNIV

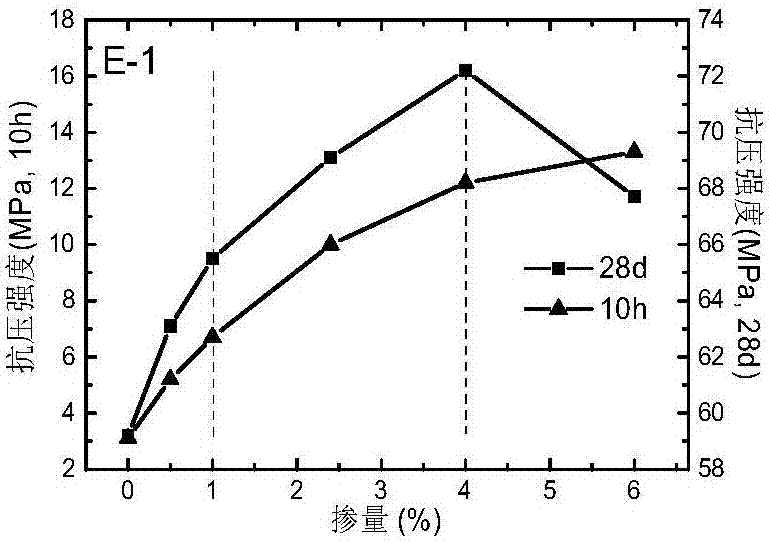

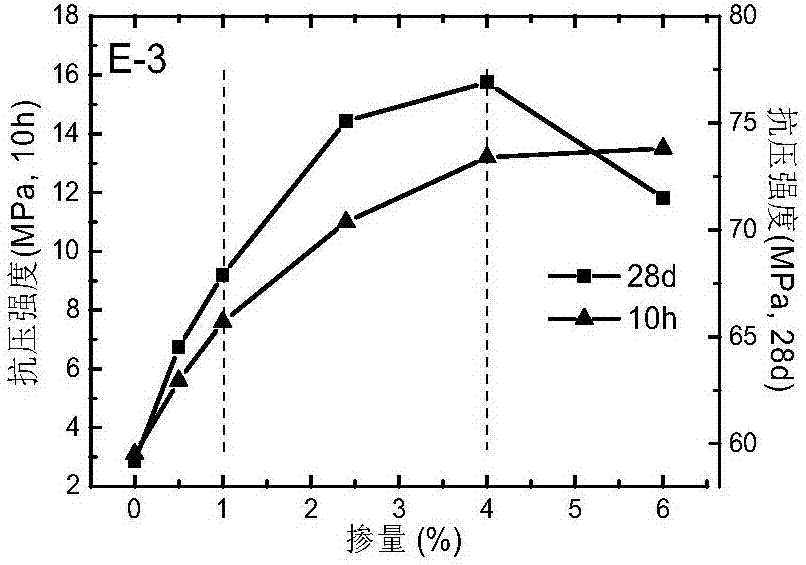

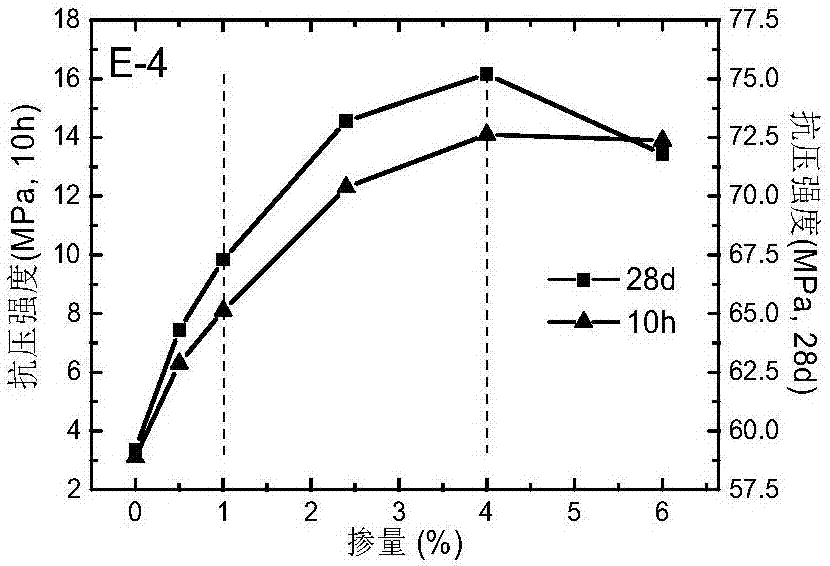

Additive capable of improving strength of cement-based material, and preparation method and application thereof

ActiveCN107311504ASimple manufacturing processRaw materials are cheap and easy to getCalcium silicateSilica particle

The invention discloses an additive capable of improving the strength of a cement-based material, and a preparation method and application thereof. The additive is prepared by mixing a dispersion liquid I prepared from nanometer silica A and a dispersant D with a solution II of a soluble calcium salt B and a solution III of soluble silicate C, wherein the dispersant D is a polymer with an anionic monomer as the sole or main constitutional unit. According the preparation method, the solution containing the soluble calcium salt and the solution containing the soluble silicate are separately and simultaneously added into a suspension containing the dispersant and nanometer silica particles drop by drop, and a calcium silicate hydrate nanometer gel is allowed to grow on the surface of the nanometer silica in virtue of the seed crystal effect of the nanometer silica, so the calcium silicate hydrate-nanometer silica composite cement additive is obtained; and the additive can substantially improve the early strength and later compressive strength of cement.

Owner:JIANGSU SOBUTE NEW MATERIALS

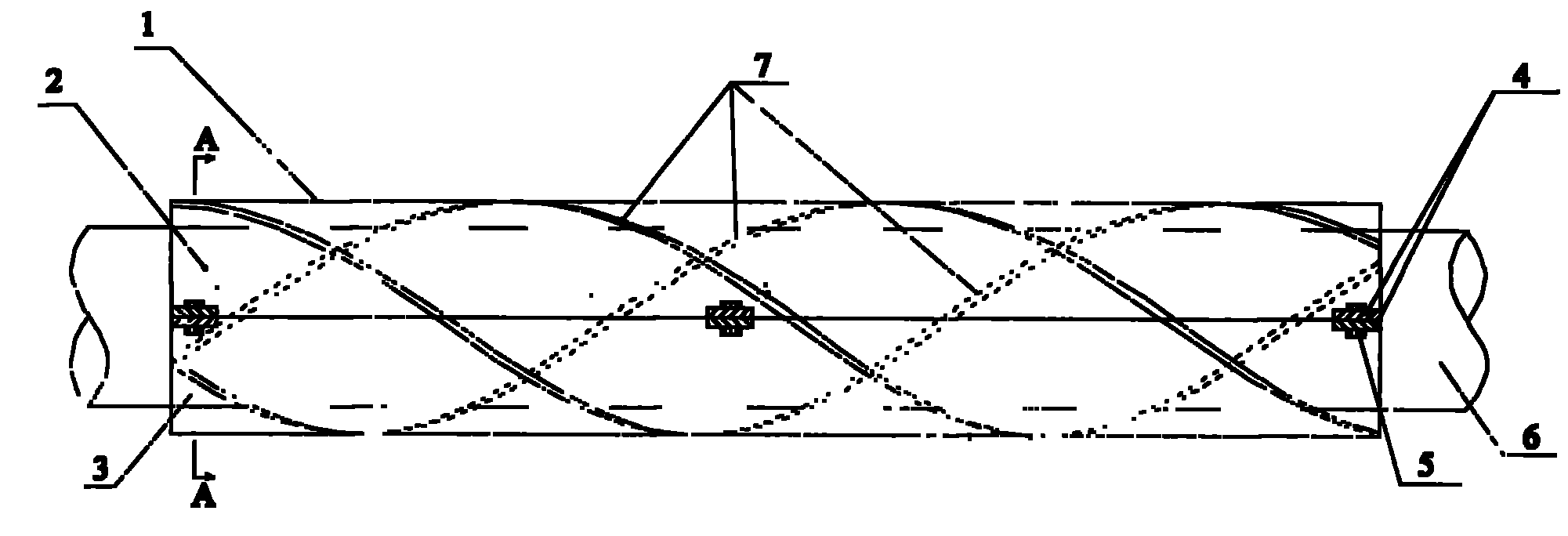

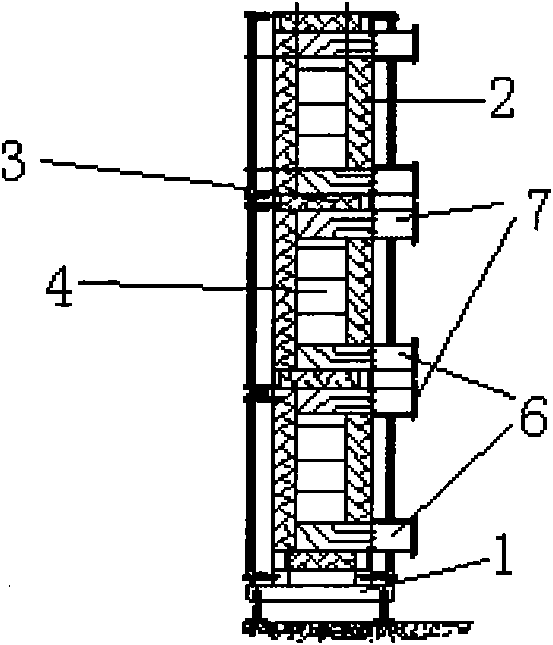

Method for suppressing vortex-induced vibration of marine oil pipeline

InactiveCN102352947ASuppression of vortex induced vibrationEconomically viablePipe laying and repairPipe elementsEngineeringSubmarine pipeline

The invention belongs to the technical field of pavement of marine oil pipeline facilities, and relates to a method for suppressing vortex-induced vibration of a marine oil pipeline. In the method, multiple pairs of semicircular shells which are of the same size and are provided with spiral grooves on the outer surfaces are made according to the outer diameter and the wall thickness of the marine oil pipeline; outwardly extending eye plates are arranged; after a pair of shells is connected into an annular post, the spiral grooves on the shells are matched with each other to form the same spiral structure for constituting a sleeve; and sleeves are arranged in the radial direction of the marine oil pipeline at a certain interval according to the method. Due to the adoption of the method, the vortex-induced vibration of the marine oil pipeline is controlled effectively, and unity of economic efficiency and safety is realized.

Owner:HEBEI UNIV OF ENG

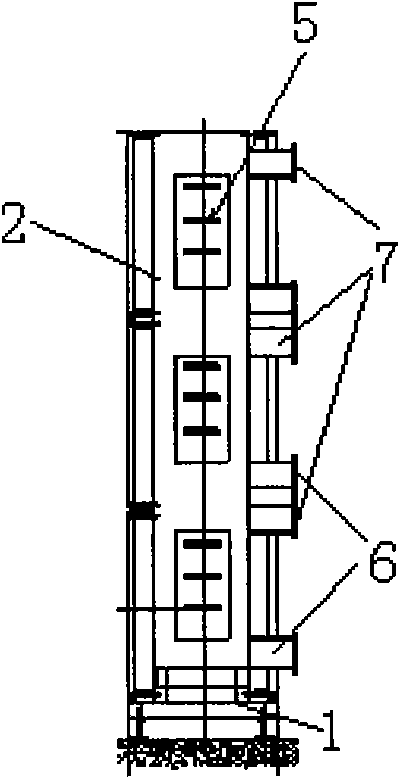

Pre-oxidation furnace

The invention discloses a pre-oxidation furnace, which comprises a furnace frame on which a furnace body is fixed; the inside of the furnace body is fixed with horizontally arranged clapboards which divide a furnace retort in the furnace body into a plurality of layers of mutually independent furnace chambers; a front end face and a rear end face which are opposite on each layer of furnace chamberare respectively provided with a yarn inlet and a yarn outlet; opposite side walls of each layer of the furnace chamber are provided with an air inlet and an air outlet; the pre-oxidation furnace comprises a fan; and an air outlet of the fan is communicated with the air inlet of each layer of the furnace chamber through an air intake system, while an air inlet is communicated with the air outletof each layer of the furnace chamber through an air outlet system. The pre-oxidation furnace has simple structure, and solves the problems of the prior pre-oxidation equipment in aspects of temperature uniformity, an oxygen content control system and a spontaneous precursor combustion phenomenon, and an effective space of a hearth is fully utilized, so equipment and production cost is saved, and the economic production of carbon fibers is feasible.

Owner:HEFEI RISINE HEATEK

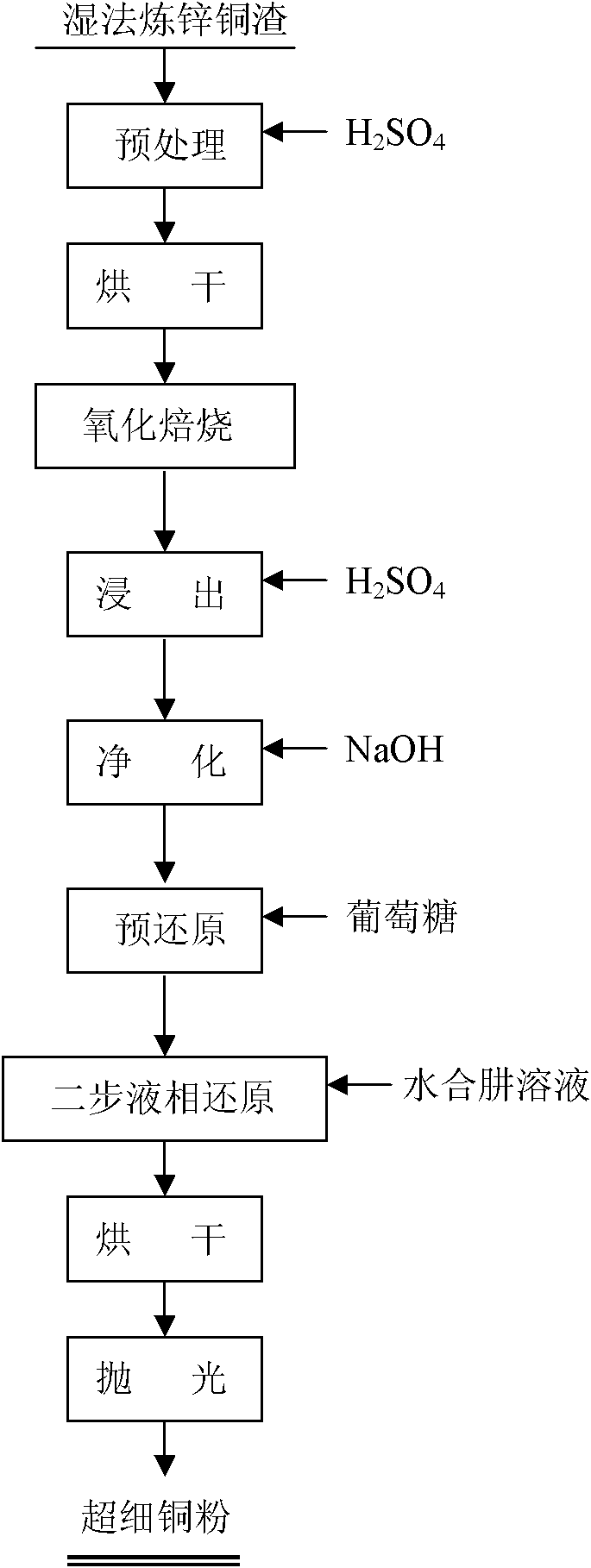

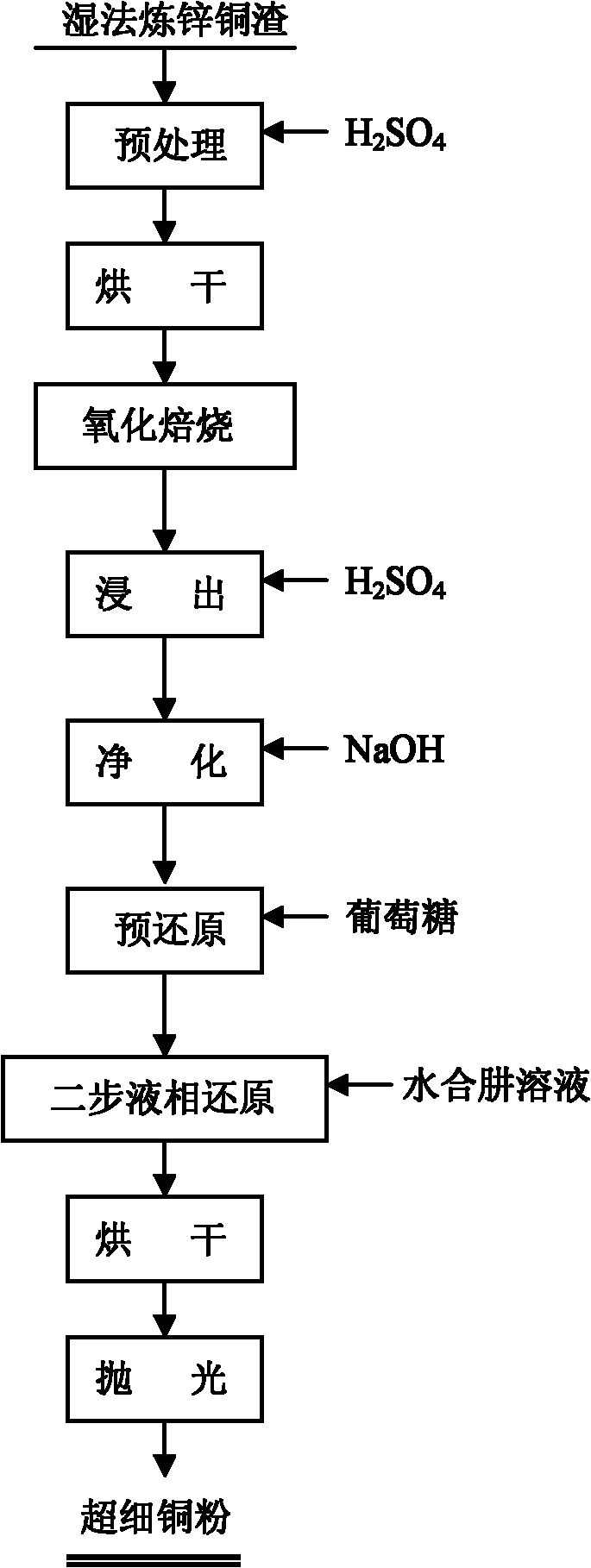

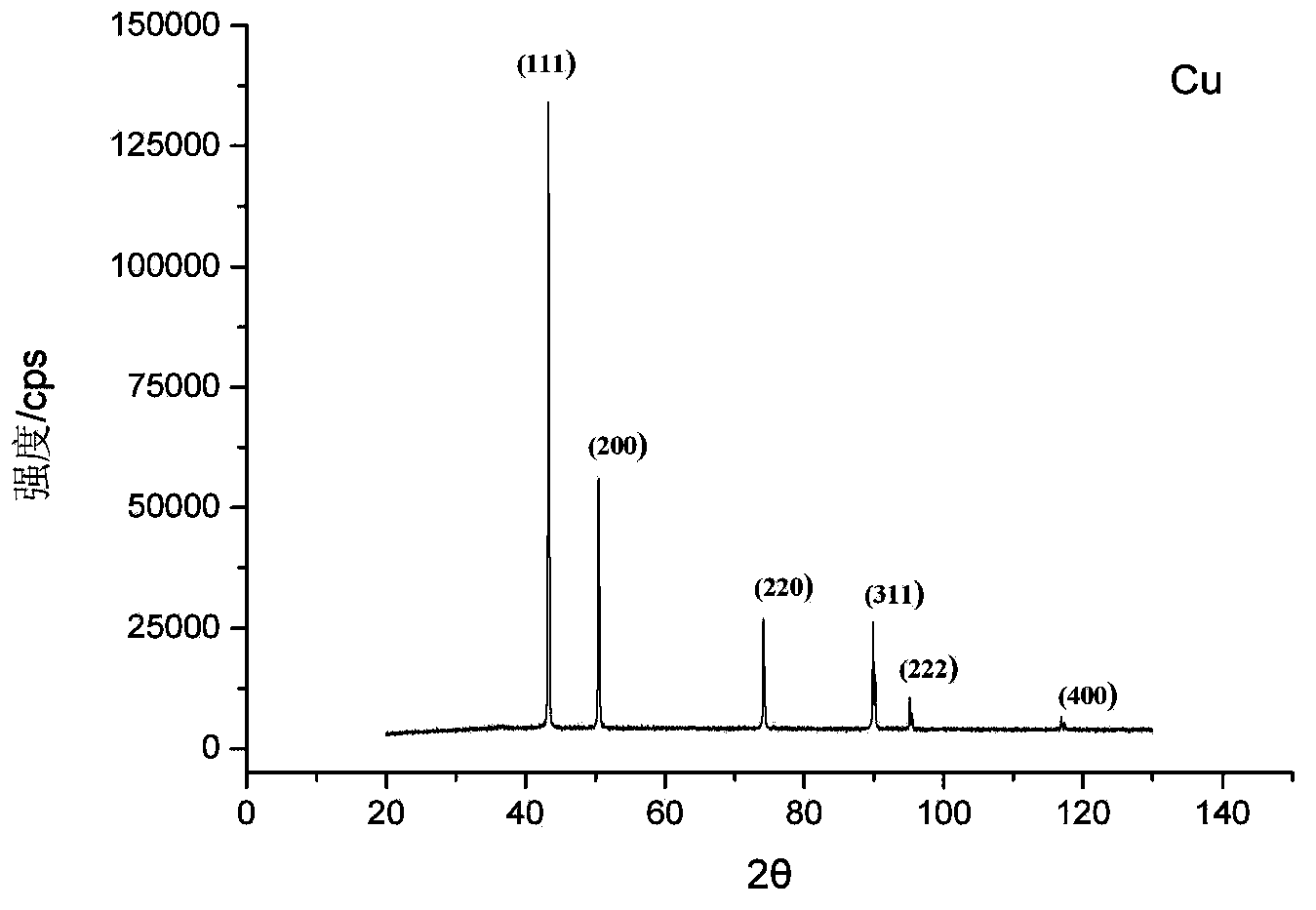

Superfine cupper powder and preparation method thereof

ActiveCN101890505AIncrease brightnessPrevent oxidationProcess efficiency improvementEconomic feasibilityOxide

The invention provides a preparation method of superfine cupper powder, which takes copper slag generated by hydrometallurgy of zinc as a raw material and is characterized by comprising the following steps: soaking the cupper slag in a sulfuric acid solution for pretreatment; filtering and drying; carrying out oxidization roasting to obtain roasted cupper slag; leaching the roasted cupper slag out by the sulfuric acid solution to obtain lixivium i.e. copper-bath; carrying out purification treatment on the copper-bath; and adjusting the pH value of the purified copper-bath; adding glucose in the copper-bath for pre-reduction to obtain the cuprous oxide sediment; adding a hydrazine hydrate solution in the cuprous oxide sediment to carry out reduction reaction to obtain solid reduced copper powder; and filtering the reduced copper powder, washing, drying and carrying out polished finish to obtain the superfine copper powder. The invention has the copper recovering rate as high as over 95% and simple process, produces the superfine cupper powder by hydrometallurgy of zinc with low cost and wide sources, and has the economic feasibility of industrialization production in a large scale.

Owner:ZHUZHOU SMELTER GRP

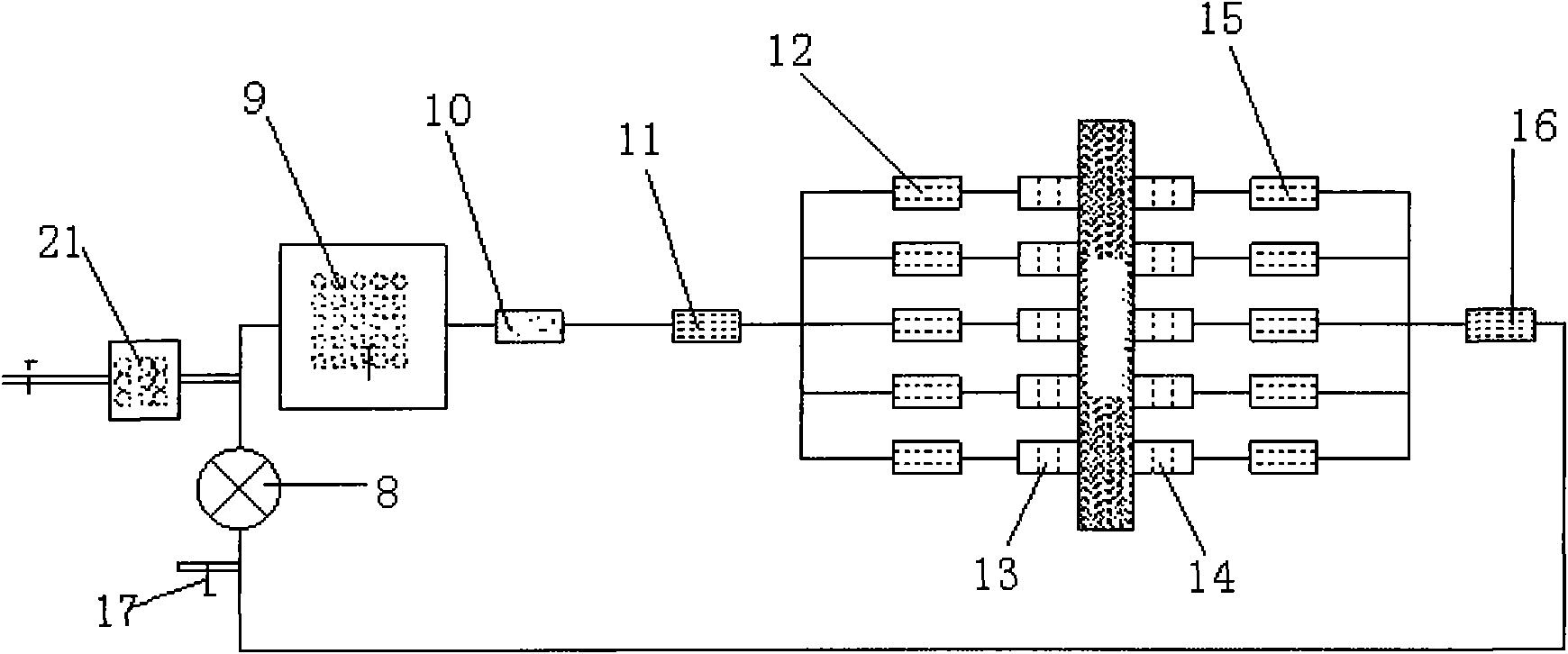

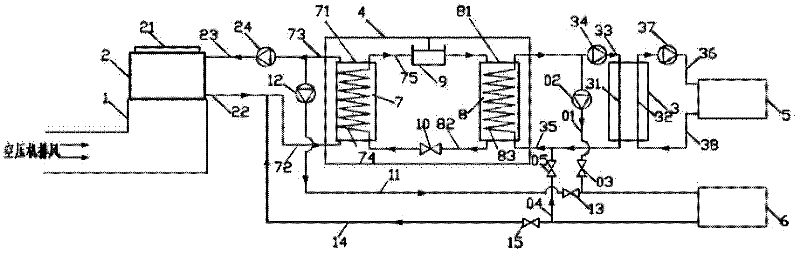

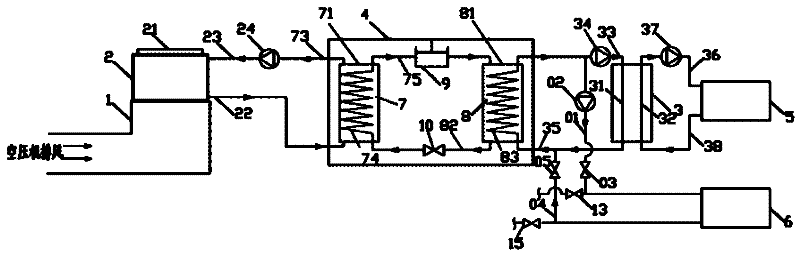

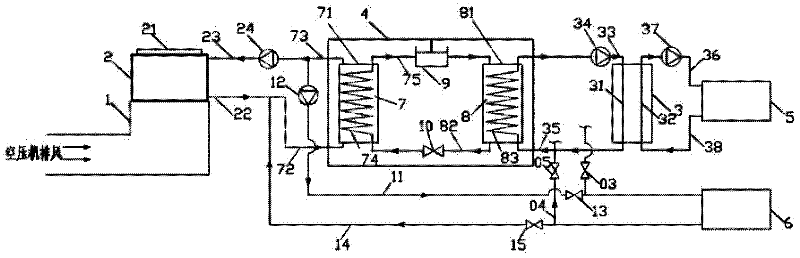

Waste heat recovery and utilization system for coal mine air compressor

ActiveCN102410665AIncrease profitMeet the protection requirementsClimate change adaptationHeating and refrigeration combinationsGas compressorEvaporation

The invention relates to a waste heat recovery and utilization system for a coal mine air compressor. The system comprises a heat pipe heat exchanger arranged at the top of the air discharge duct of the air compressor; a heat exchange circulation pipeline is formed between the heat pipe heat exchanger and the casing of a shell-and-tube evaporator through a heat exchange circulating water outlet pipeline and a heat exchange circulating water return pipeline; a refrigerant circulation pipeline is formed between the evaporation heat exchange pipeline of the shell-and-tube evaporator and the casing of a shell-and-tube condenser through a compressor and an expansion valve; a domestic hot water primary circulation pipeline is formed between the condensation heat exchange pipeline of the shell-and-tube condenser and the hot water pipeline of a plate heat exchanger; a domestic hot water secondary circulation pipeline is formed between the cold water pipeline of the plate heat exchanger and a domestic hot water tank; a winter user heating circulation water supply pipeline is formed between user equipment and the condensation heat exchange pipeline of the shell-and-tube condenser; and a summer user refrigerating circulation water supply pipeline is formed between the user equipment and the casing of the shell-and-tube evaporator. By adopting the invention, winter heating, summer refrigerating, and domestic hot water providing all year round for coal mine buildings are realized.

Owner:北京矿大节能科技有限公司

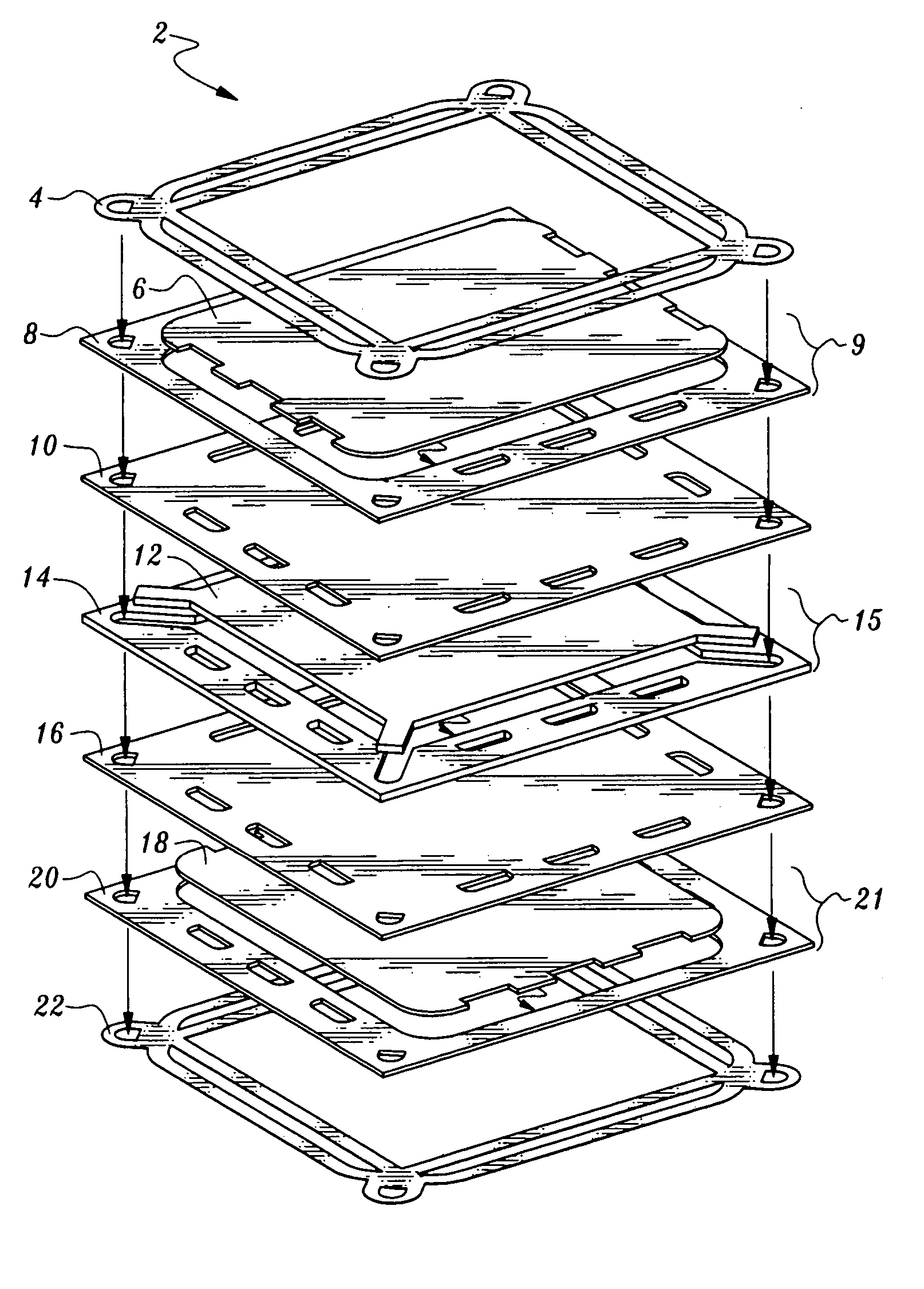

Channel-less proton exchange membrane fuel cell

InactiveUS7294425B2Mechanical load is thus especially greatPromote disseminationFuel cells groupingCell electrodesEngineeringProton exchange membrane fuel cell

The present invention is a proton exchange membrane fuel cell that includes a fuel cell assembly. The fuel cell assembly includes a bipolar separator, which includes an anode separator, a cathode separator and a membrane electrode assembly. The bipolar separator includes a highly porous, electrically conductive, non-metallic interface and a non-porous frame. The highly porous interface includes micro-channels for fluid communication and diffusion. Both the cathodic interface and anodic interface of the bipolar separator contain the highly porous material in a fluid diffusion region that interfaces with the active area of the MEA interposed between two bipolar separators. The highly porous material connects the fluid diffusion regions with their respective external sources of oxidant and fuel. The bipolar separator includes a non-porous frame that seals the highly porous material and isolates the fluids within the proton exchange membrane fuel cell.

Owner:TETROS INNOVATIONS LLC

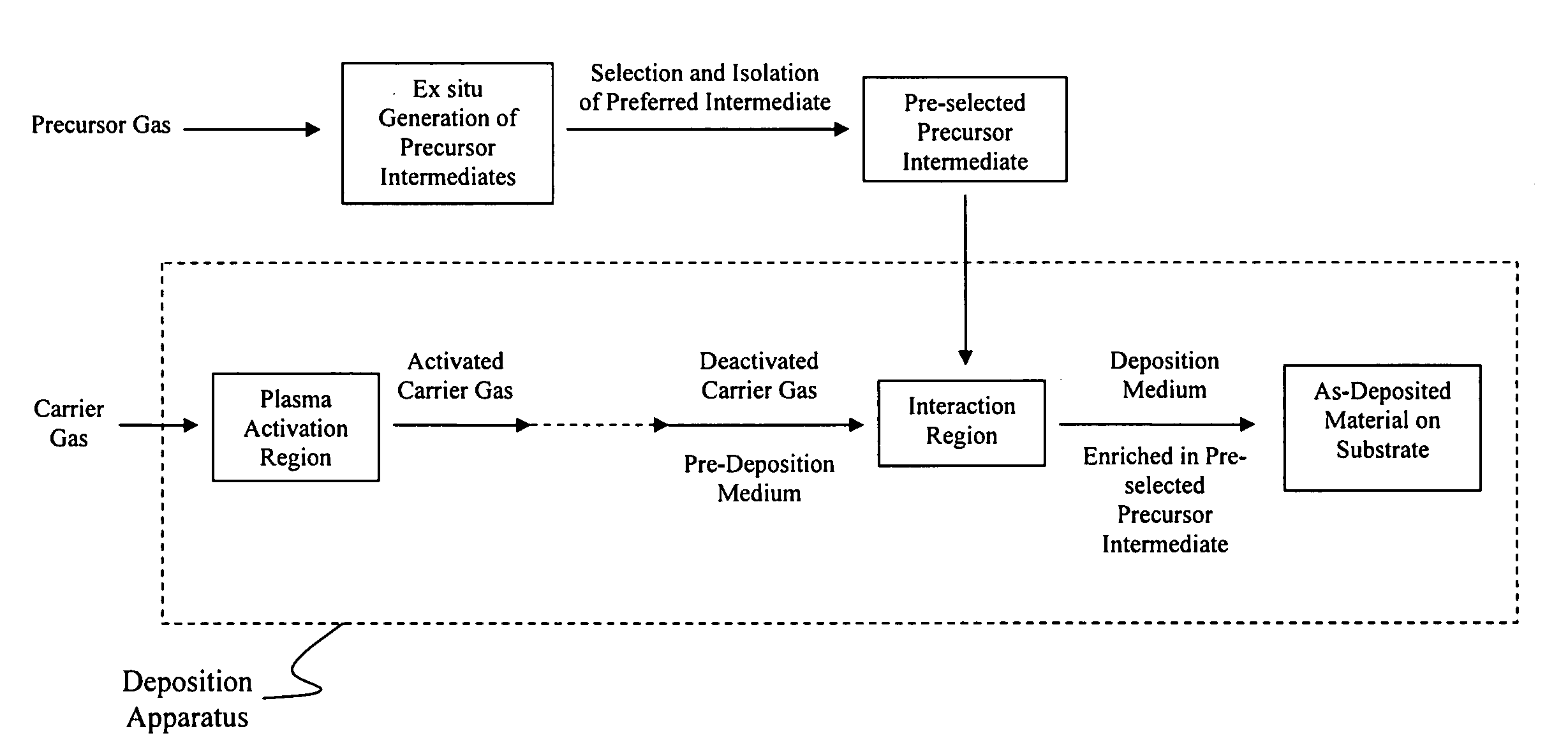

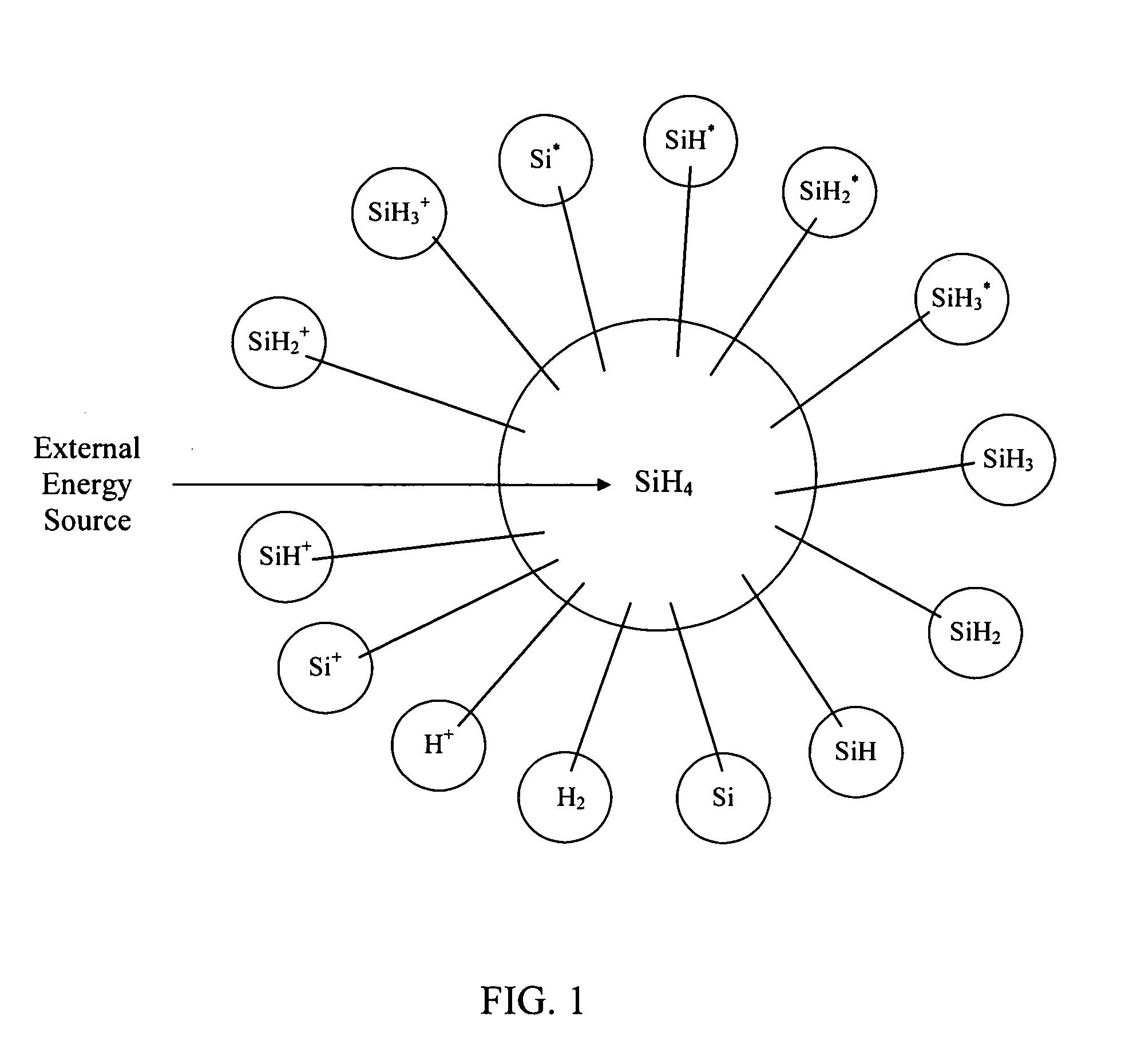

High Speed Thin Film Deposition via Pre-Selected Intermediate

InactiveUS20100068870A1Improve throughputIncrease in film formation ratePolycrystalline material growthFinal product manufactureHigh rateFilm material

A method and apparatus for the unusually high rate deposition of thin film materials on a stationary or continuous substrate. The method includes delivery of a pre-selected precursor intermediate to a deposition chamber and formation of a thin film material from the intermediate. The intermediate is formed outside of the deposition chamber and includes a metastable species such as a free radical. The intermediate is pre-selected to include a metastable species conducive to the formation of a thin film material having a low defect concentration. By forming a low defect concentration material, deposition rate is decoupled from material quality and heretofore unprecedented deposition rates are achieved. In one embodiment, the pre-selected precursor intermediate is SiH3. The method further includes combining the pre-selected precursor intermediate with a carrier gas, preferably in a deactivated state, where the carrier gas directs the transport of the pre-selected precursor intermediate to a substrate for deposition of the thin film material.

Owner:OVSHINSKY TECH

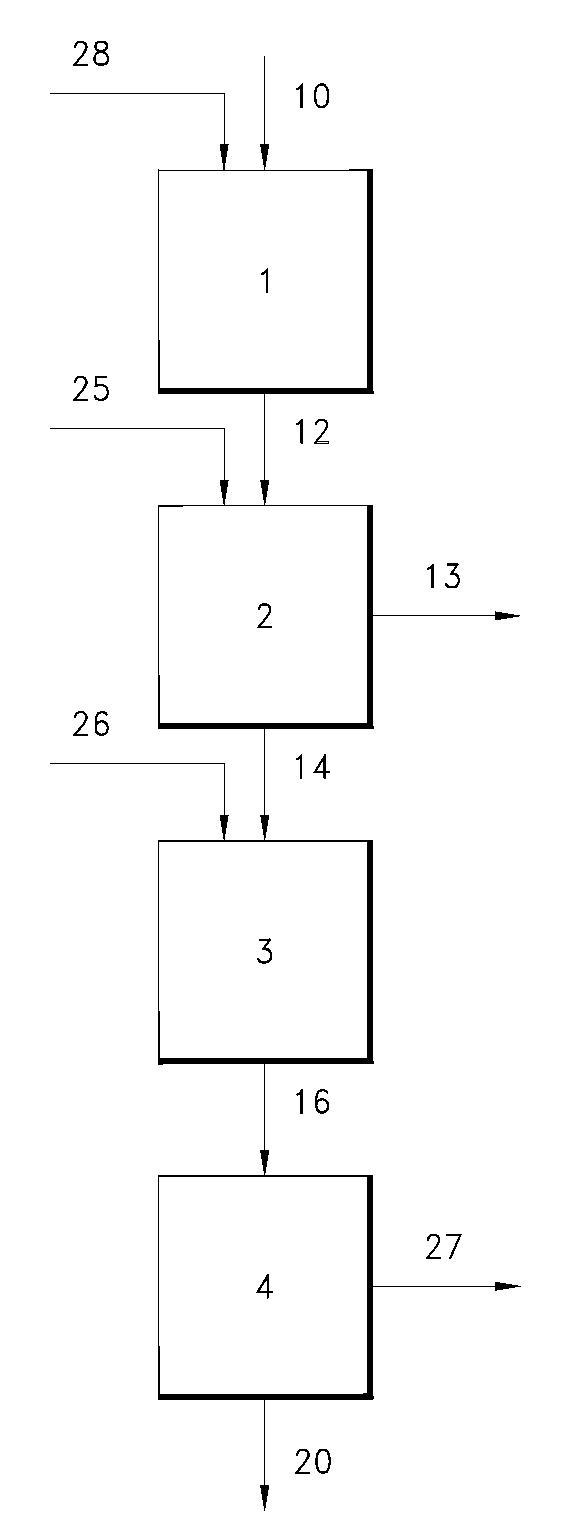

Conversion of Carbon Dioxide Utilizing Chemoautotrophic Microorganisms Systems and Methods

InactiveUS20160030884A1Rapid R & D phaseReduce riskBioreactor/fermenter combinationsGas treatmentMicroorganismNitrogen

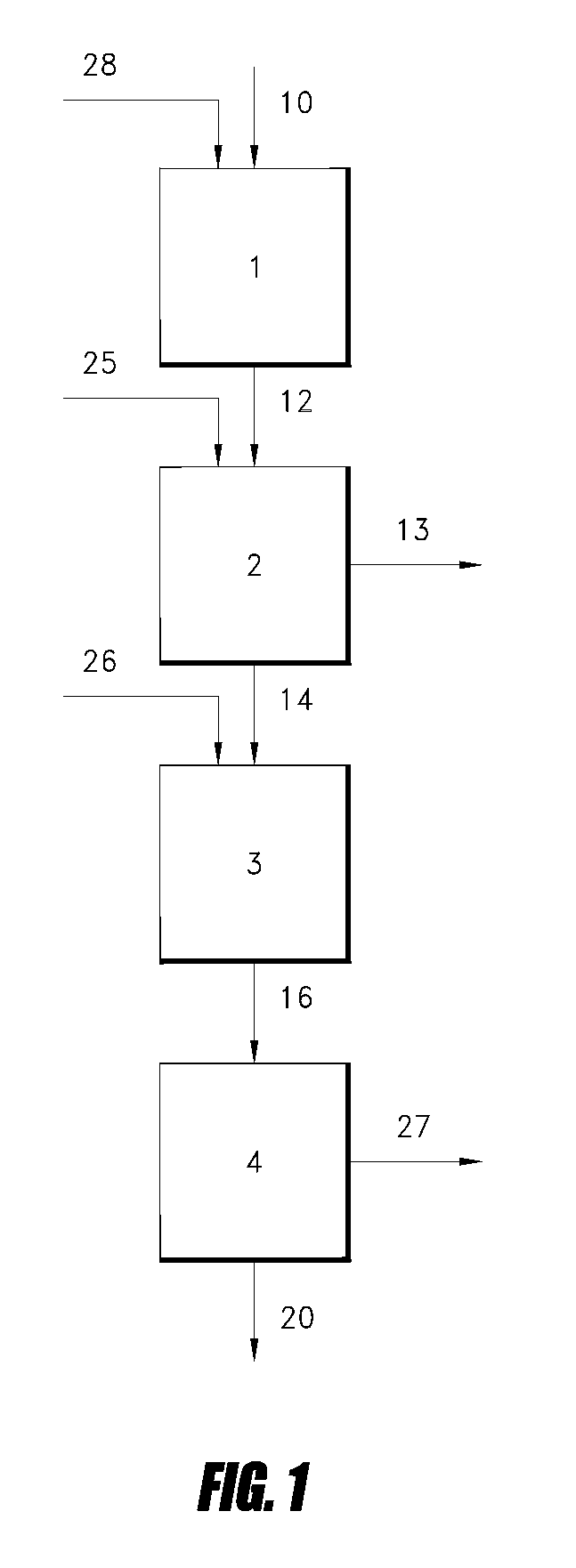

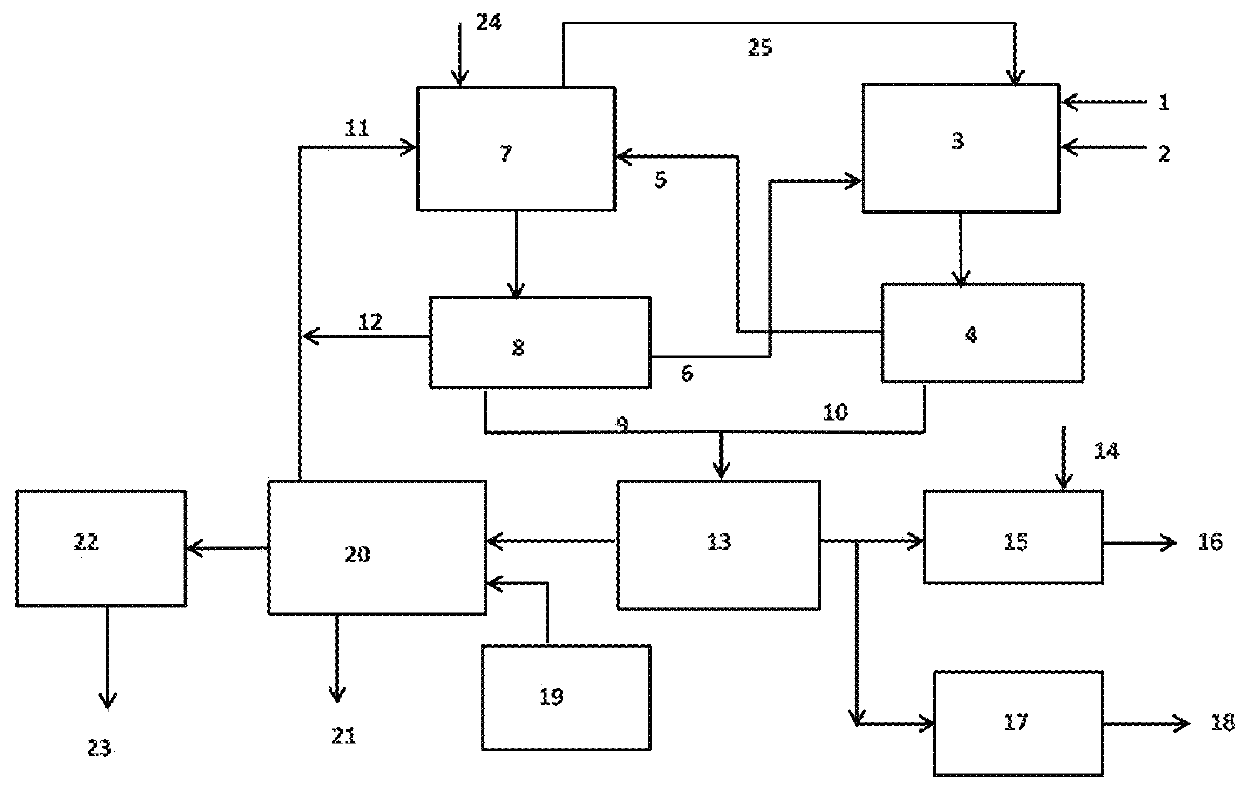

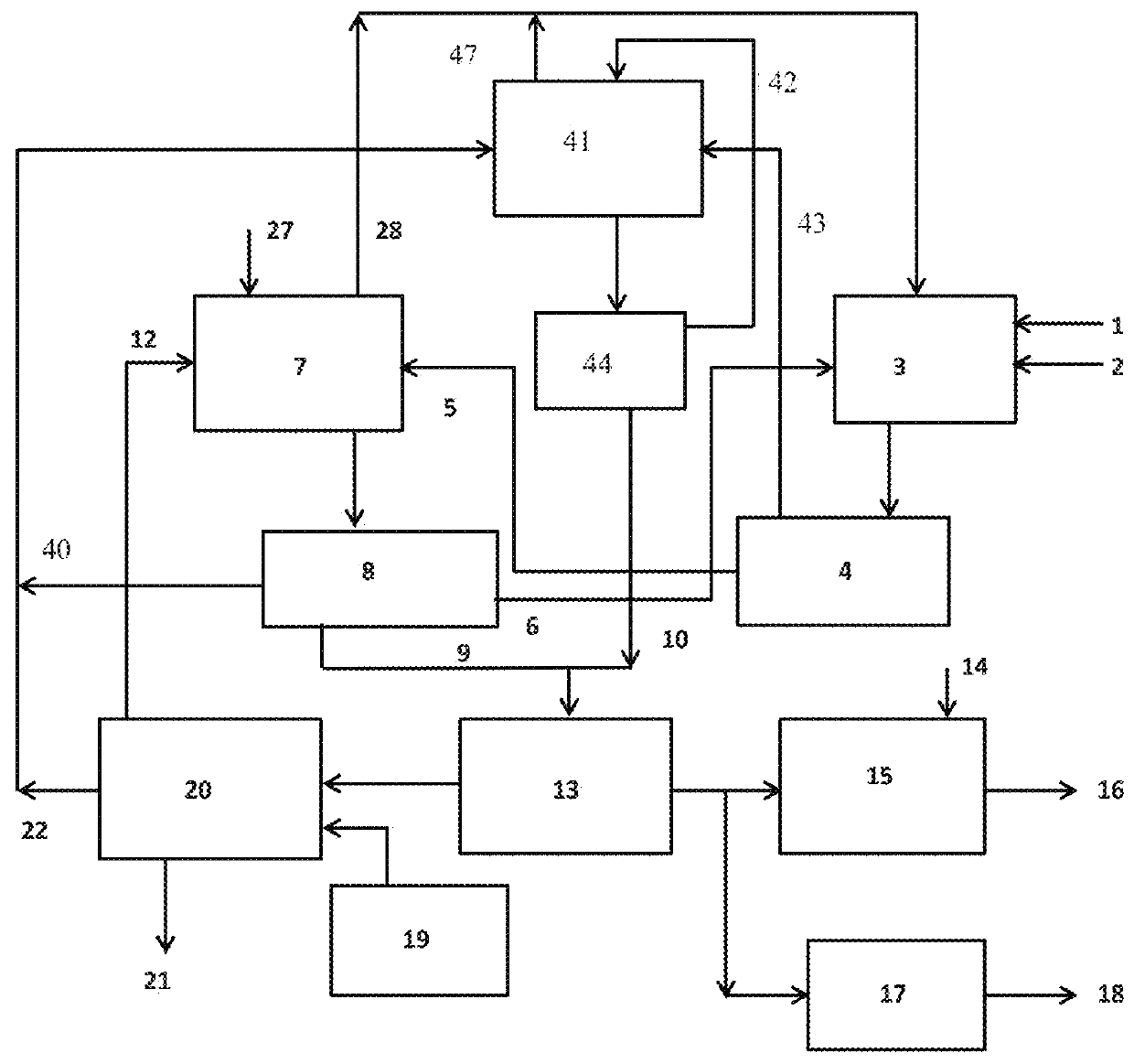

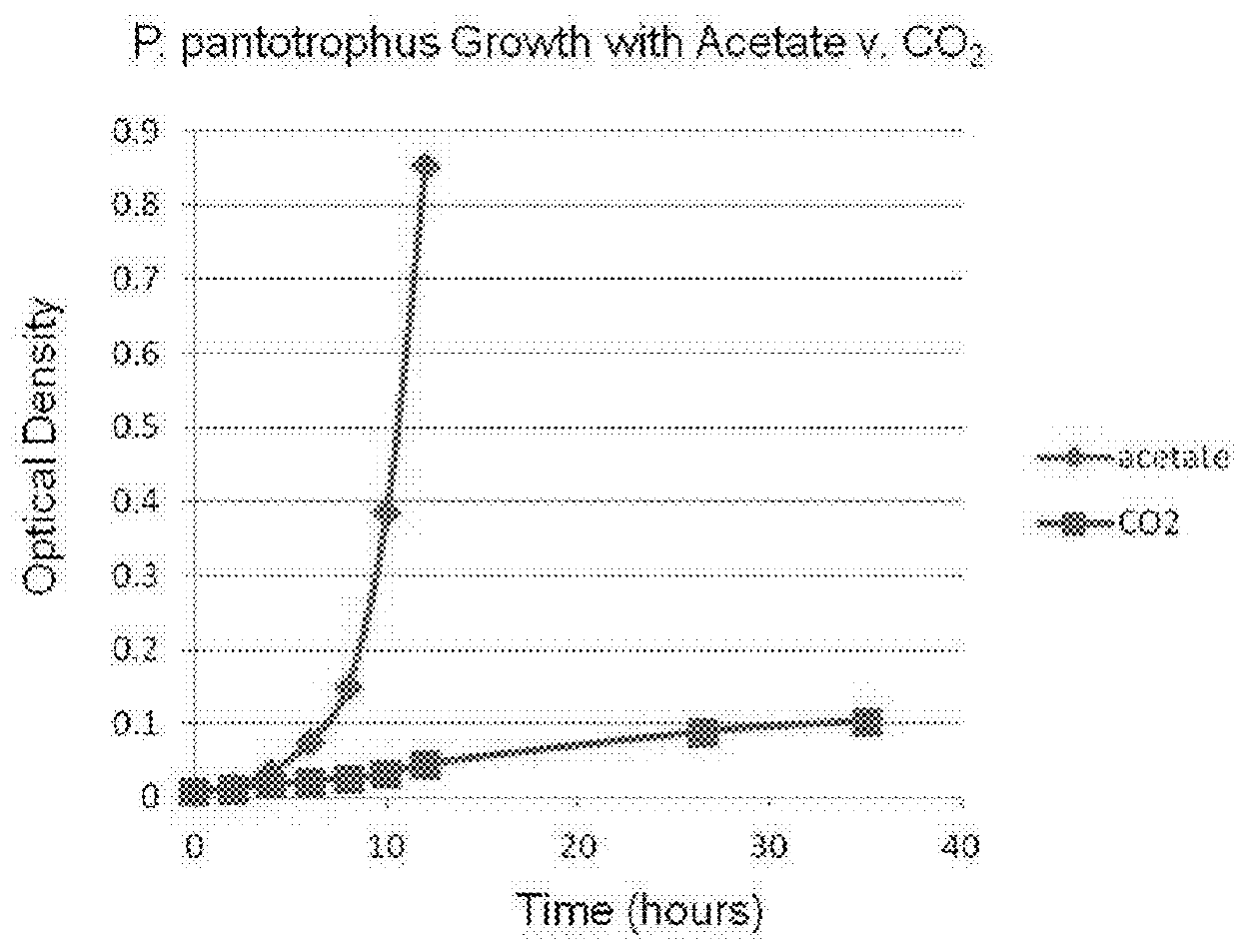

Methods and systems to achieve clean fuel processing systems in which carbon dioxide emissions (1) from sources (2) may be processed in at least one processing reactor (4) containing a plurality of chemoautotrophic bacteria (5) which can convert the carbon dioxide emissions into biomass (6) which may then be used for various products (21) such as biofuels, fertilizer, feedstock, or the like. Bacteria that reduce oxidized nitrogenous species (13) may be used to supply reduced nitrogenous compounds to the chemoautotrophic bacteria (5).

Owner:WESTERN RES INST INC

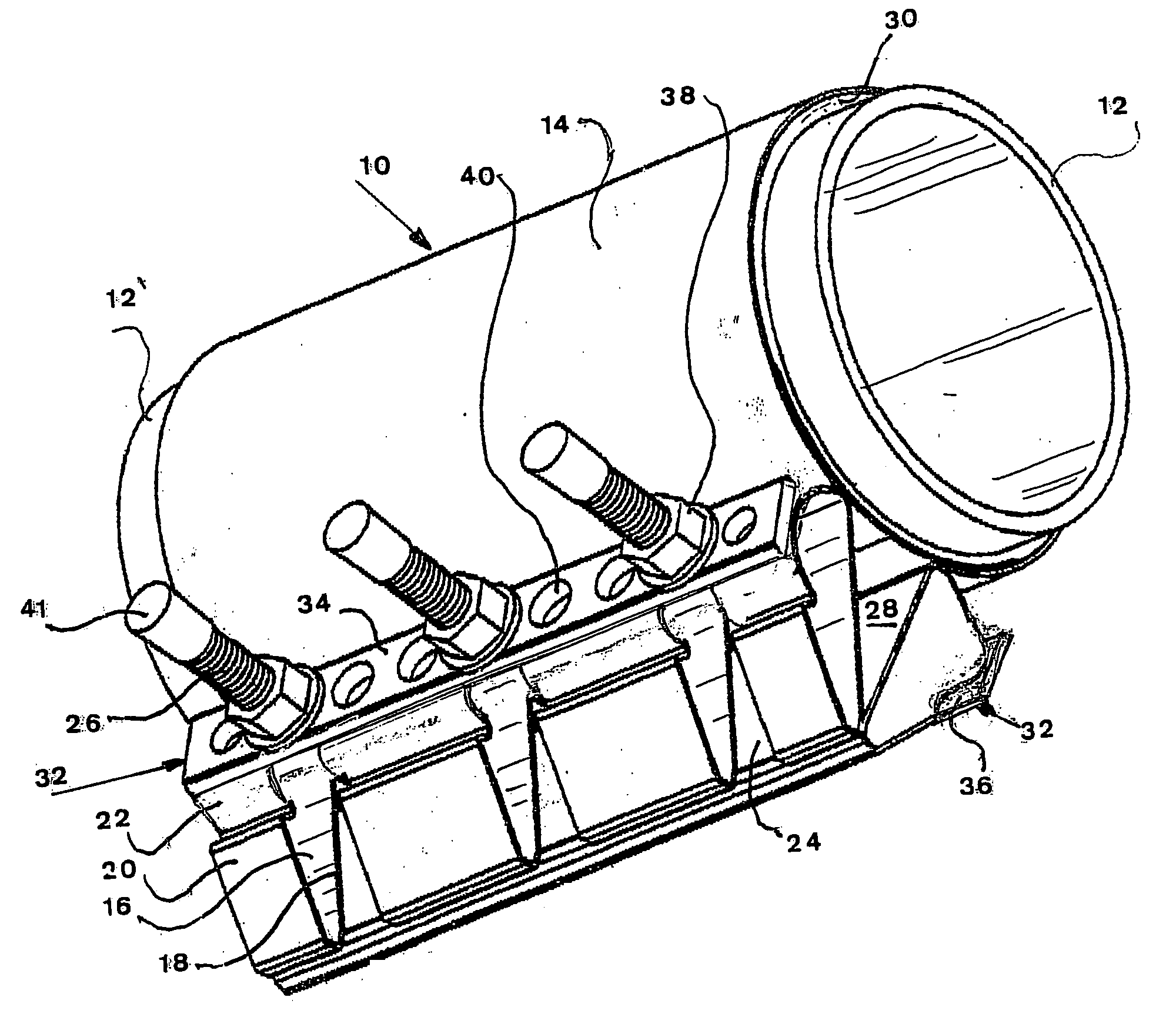

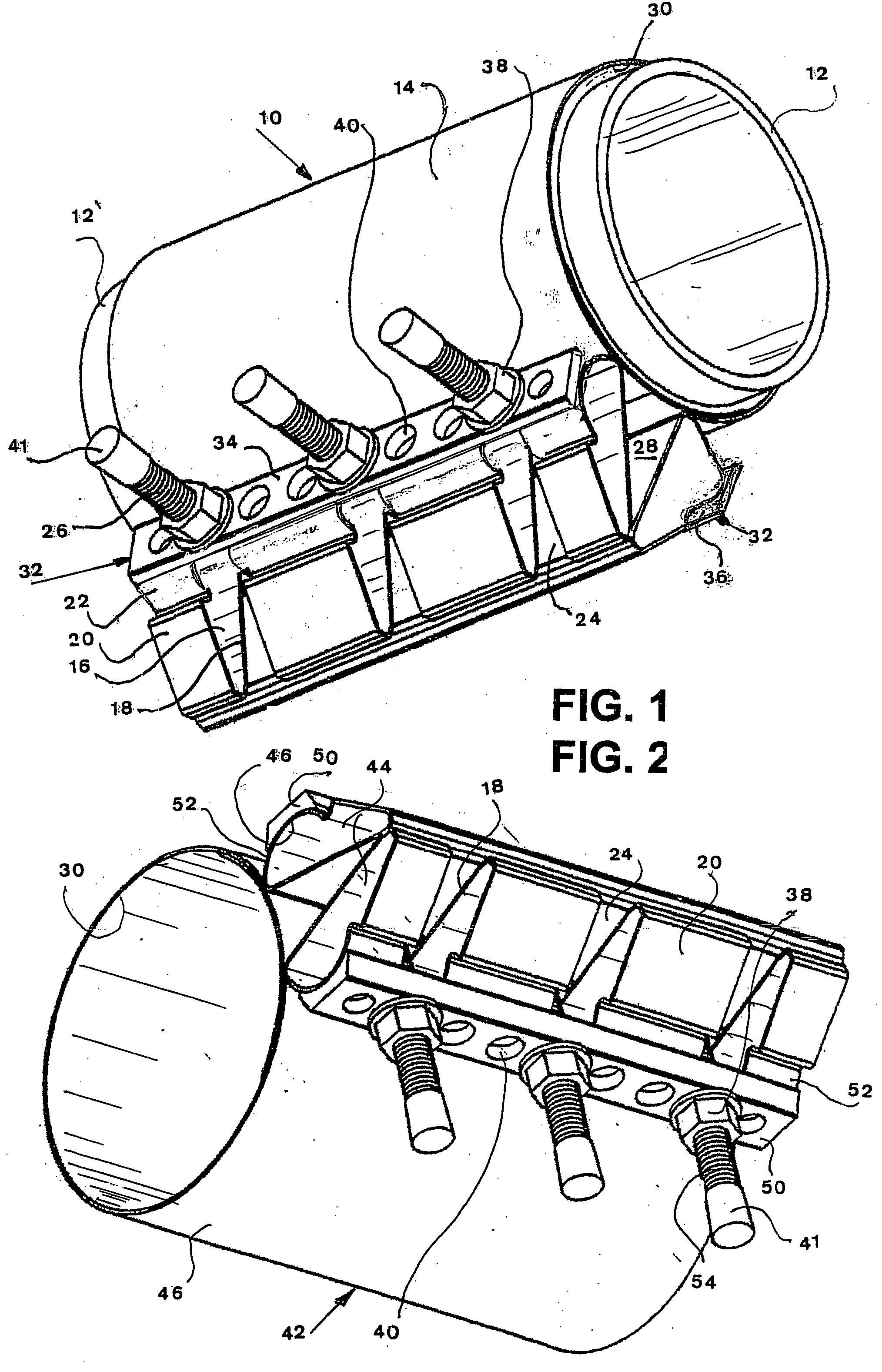

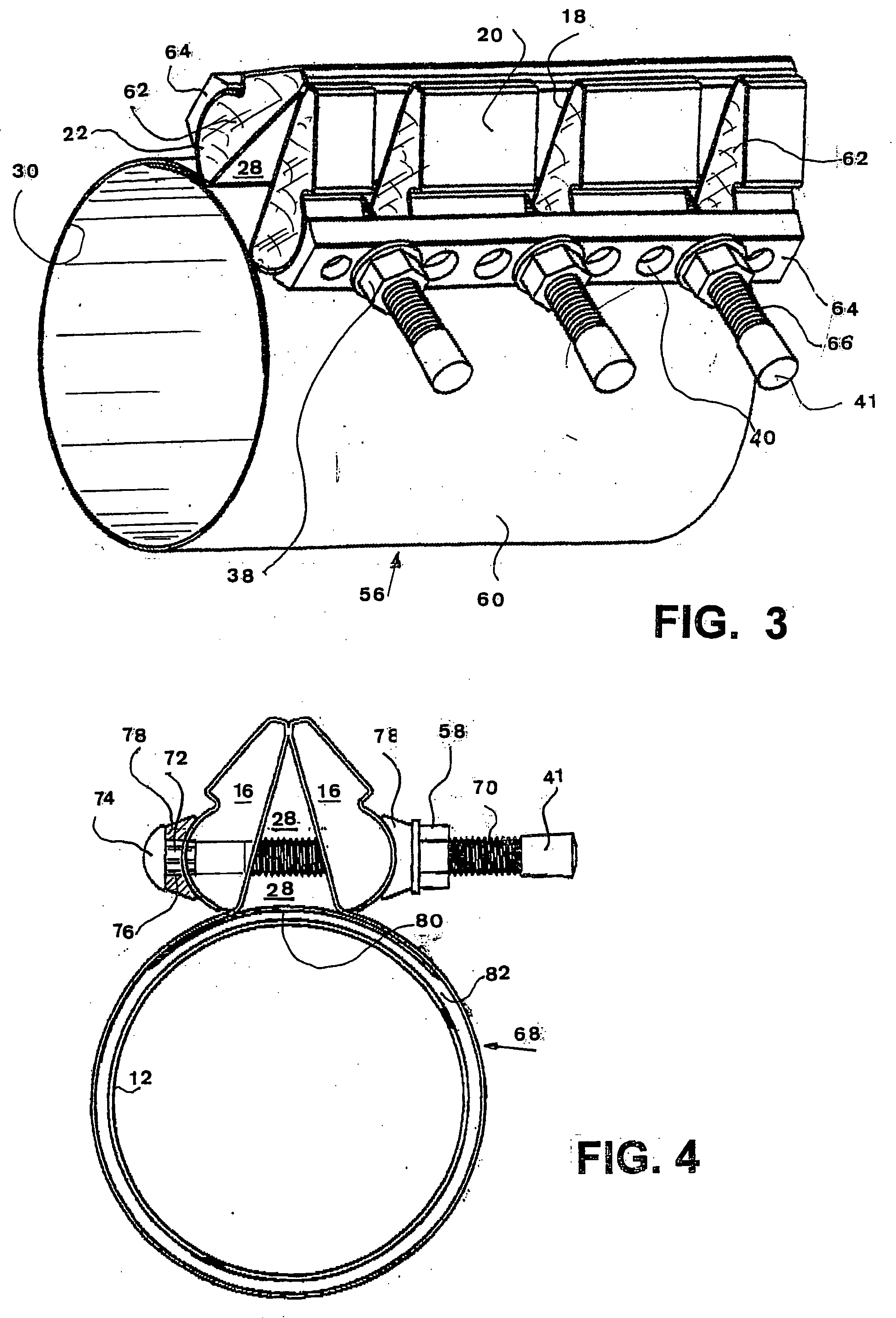

Pipe repair clamp

ActiveUS20040100091A1Reduce diametrical flexibilityAvoid squeezingSnap fastenersSleeve/socket jointsCouplingShoulder Support

The present invention relates to a repair clamp providing an improved pipe repair clamp. The clamp according to the invention could be used in some cases as a coupling to join two pipe ends. The clamp comprises; a) a metal clamping band to surround 3600 of a pipe. The band being extended at both ends to form a hollow shape including a flat base, a wedge-shaped section and a convex rounded section, elongated apertures being provided to allow passage for screw fasteners through the hollow shape, narrow edges of the wedge-shaped sections being in contact with each other to form a substantially triangularly shaped space between the formed ends; and a flexible inner sealing sleeve disposed inside the clamping band and a pair of profile strips each having a major face for contacting the outer surface of the convex rounded section, and an opposite seating face for shoulder support of a plurality of screw fasteners, the strips having apertures to allow passage of the fasteners, and a plurality of screw fasteners inserted into the apertures wherein the tightening of said screw fasteners reduces the size of the triangularly shaped space and tightens the metal clamping band to compress the flexible inner sleeve sealingly against the outer diameter of the pipes.

Owner:KRAUSZ INDS DEVMENT

Method for cleaning and separating main components of wood fibers

ActiveCN112144309AReduce lossesPromote dissolutionWashing/displacing pulp-treating liquorsCelluloseFiber

The invention provides a method for cleaning and separating main components of wood fibers, which comprises the following step: separating oligosaccharide, lignin and cellulose components from a lignocellulose raw material by adopting a hydrothermal method and a ternary eutectic solvent, wherein the ternary eutectic solvent is composed of a hydrogen bond acceptor, a first hydrogen bond donor and asecond hydrogen bond donor according to a certain molar ratio. Through the method, oligosaccharide, lignin and cellulose with relatively high purity can be efficiently obtained from the lignocellulose raw material. In addition, the ternary eutectic solvent used in the method is low in cost and easy to recover, so that the method also has environmental and economic feasibility.

Owner:BEIJING FORESTRY UNIVERSITY

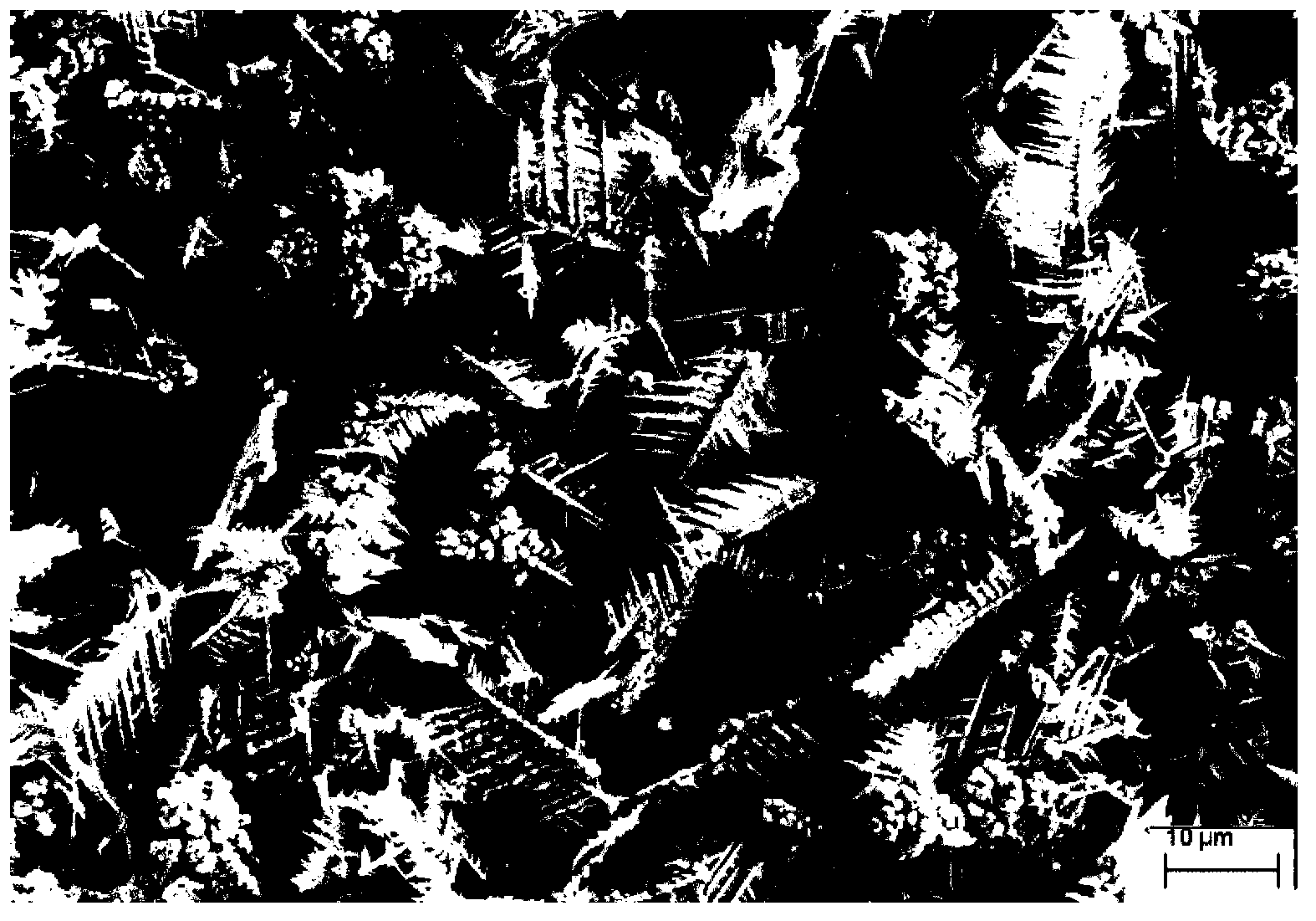

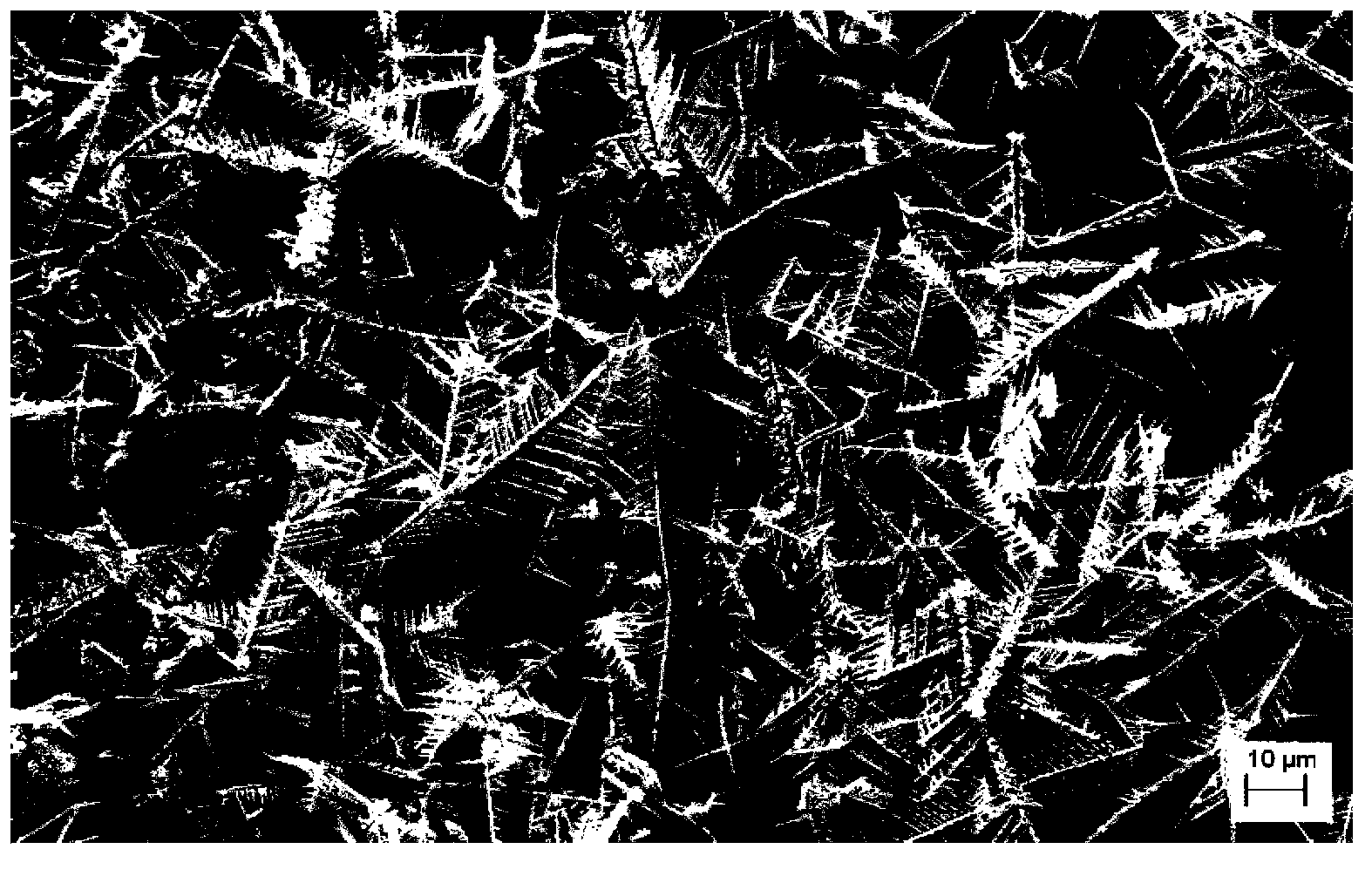

Preparation method of two-dimensional feathery copper powder under ammonia condition

The invention discloses a preparation method of two-dimensional feathery copper powder under an ammonia condition, and belongs to the technical field of metal materials and powder. The copper powder prepared by the method is regular and complete feathery copper powder, has an obvious trunk and multiple levels of branch structures; each level of branch and the former level form an angle of about 60 degrees; the first level of branch grows forwards relative to the trunk; the branches more than the first level grow backwards relative to the trunk. An electrolyte comprises the following components: 0.005-0.50mol / L copper sulfate, 0.05-0.20mol / L ammonium sulfate, 0.10-2.0mol / L ammonia water, 0-1g / L additive and the balance of water. Electrolysis is carried out under the conditions that the direct current is 0.6-5.0V and the temperature is 20-75 DEG C. The copper powder on a cathode is treated by virtue of ultrasonic removal, cleaning, filtering and vacuum drying and then the light purplish-red feathery copper powder is obtained. The obtained copper powder is complete and single in shape, uniform in granularity, good in dispersibility and high in purity; the preparation process is safe and environmentally-friendly, and is simple in operating procedure and low in cost.

Owner:UNIV OF SCI & TECH BEIJING

Purification process for lipopeptides

InactiveUS20100249371A1Reduces overall solvent and energy consumptionEconomically viablePeptide preparation methodsCyclic peptide ingredientsIndustrial scaleEchinocandin

The present invention provides simple, cost effective, rapid, and scalable at industrial scale and provide high purity and yield of Echinocandin-type compounds at low cost as compared to prior art. Moreover the process allows for the removal of impurities by using economical salt-adsorbent complex and provide highly purified Echinocandin type compounds which is highly improved in terms of purity and sufficient for further processing to obtain an active pharmaceutical ingredient such as, the antifungals caspogungin, anidulafungin, and micafungin.

Owner:CADILA HEALTHCARE LTD

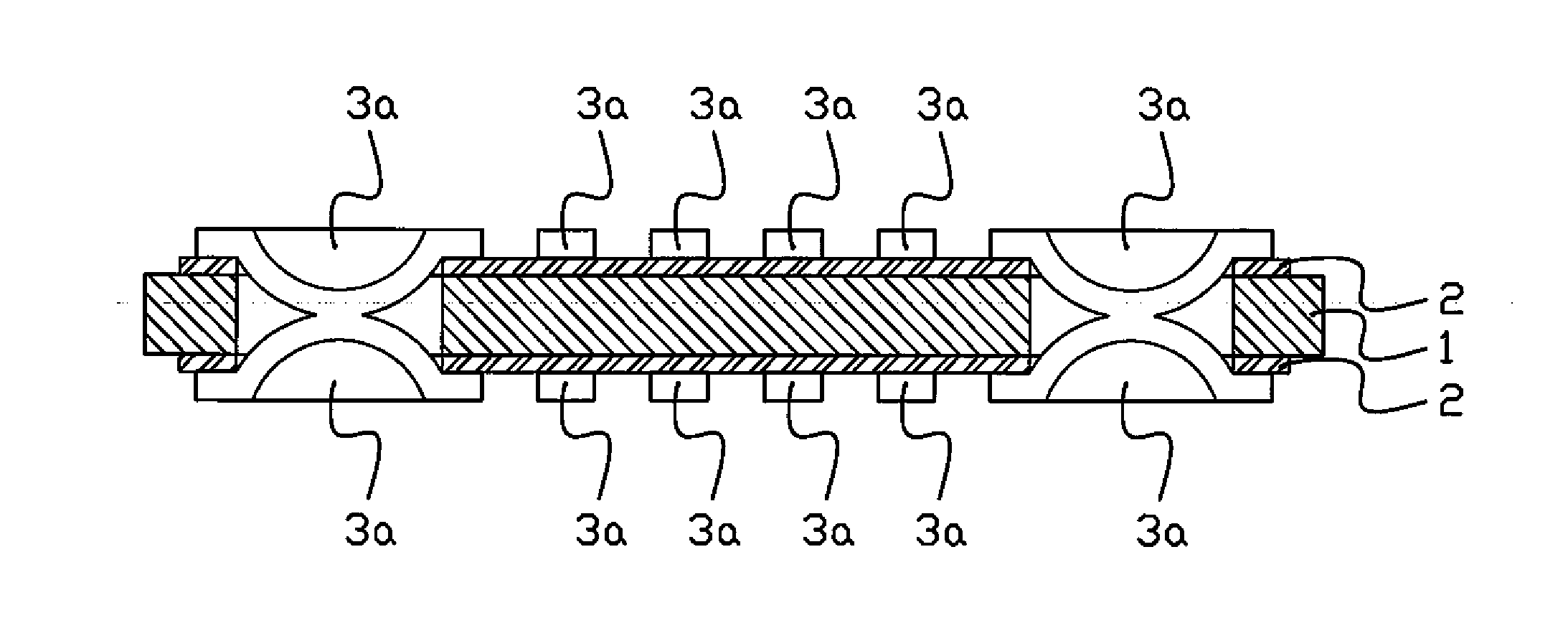

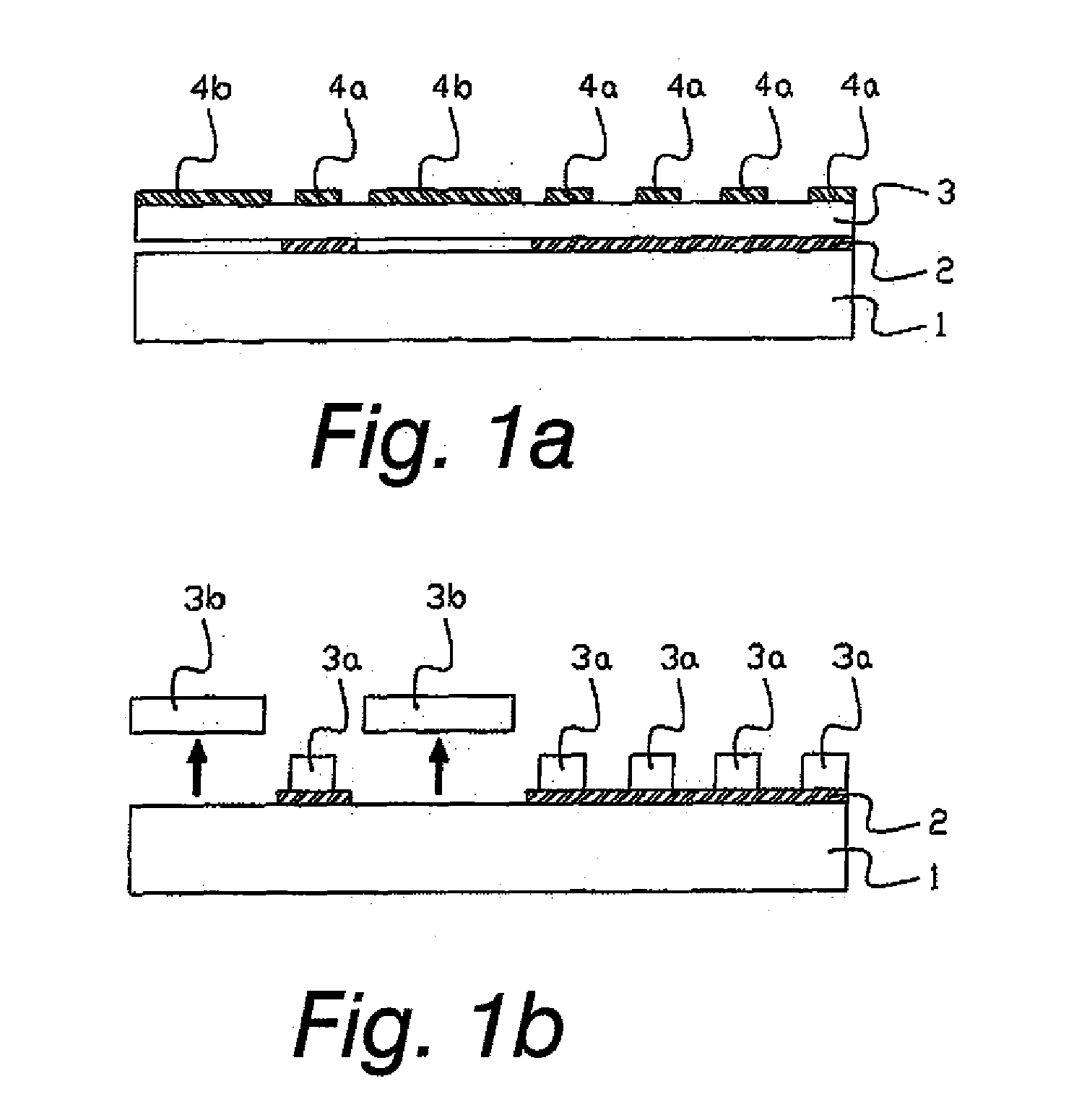

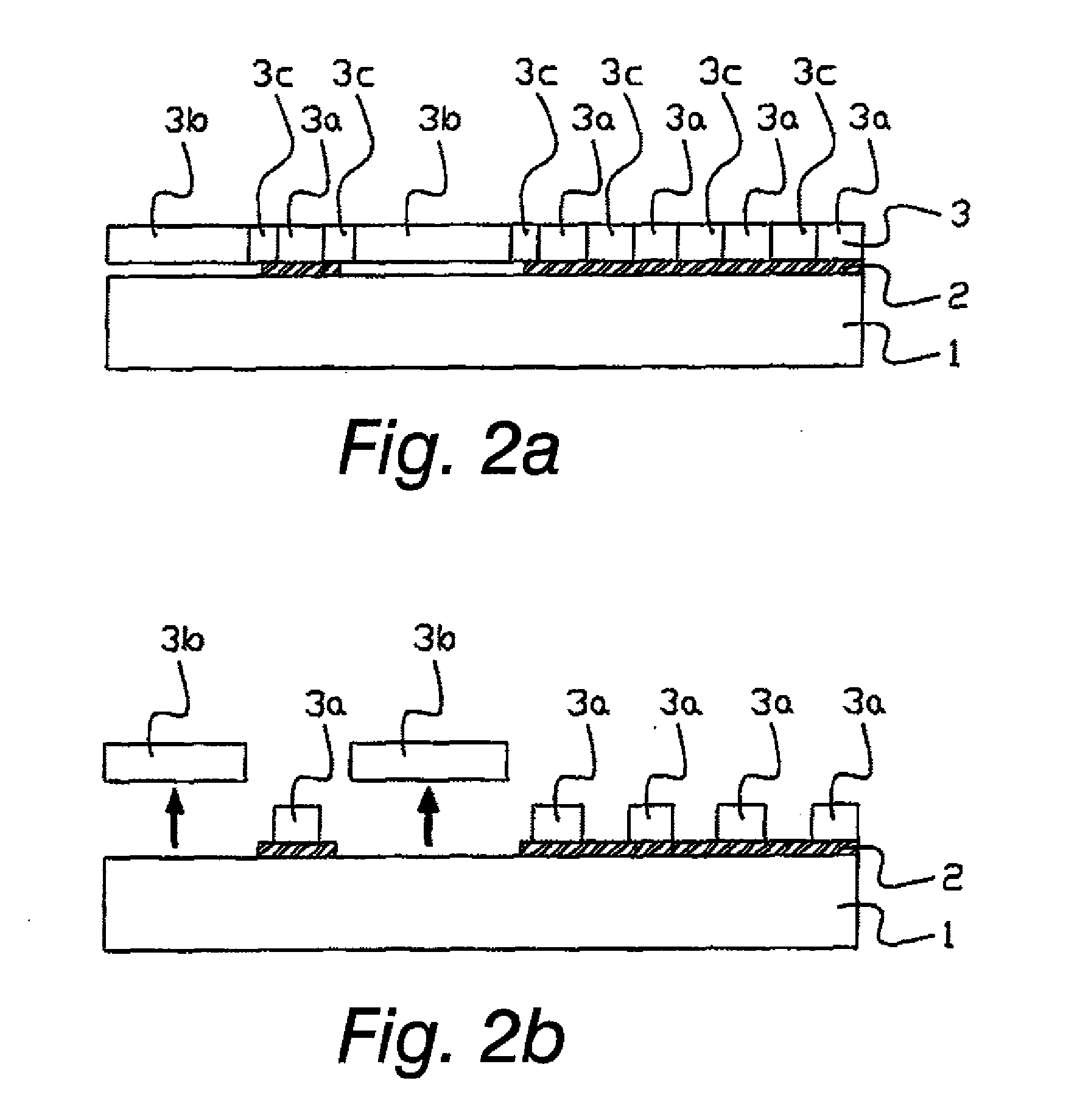

Method for manufacturing laminated circuit board

ActiveUS20110005821A1Easy to controlReduce the amount requiredLamination ancillary operationsLayered product treatmentMetal foilEdge region

A method for manufacturing a circuit board featuring conductive patterns, said method comprising the following steps of:i) affixing a conductive layer, such as a metal foil (3), to a substrate material (1) selectively, such that a part of the conductive layer, such as the metal foil (3), comprising desired areas (3a) for the final product and narrow areas (3c) between the final product's conducting areas, is affixed to the substrate material (1) by means of a bond (2), and removal-intended more extensive areas (3b) of the conductive layer, for example the metal foil (3), are left substantially unattached to the substrate material in such a way that the removable area (3b) is in attachment with the substrate material (1) by not more than its edge portion to be patterned in a subsequent step ii) and possibly by sites which preclude a release of the removable areas prior to a step iii);ii) patterning, by a removal of material, the conductive layer, such as the metal foil (3), from narrow gaps between the desired conducting areas (3a), and from an outer periphery of the area (3b) removable in a solid state, for establishing conductor patterns;iii) removing the removable areas (3b), not affixed to the substrate material (1), from the conductive layer, such as the metal foil (3), in a solid state after the conductive layer's edge area, which was removed from the removable area's outer periphery during the course of step ii), no longer holds the removable areas (3b) attached by their edges to the substrate material.

Owner:TECNOMAR

Stable, cationically polymerizable/crosslinkable dental compositions having high filler contents

InactiveUS20050059752A1Composition is stableImprove stabilityImpression capsSurgical adhesivesPotassium hydroxidePolymer chemistry

Stable, highly filled cationic dental compositions useful for the production of dental prostheses and dental restoration materials contain: (1) at least one compound which is reactive cationically when activated, advantageously at least one UV-and cationically reactive oxirane-functionalized silicone; (2) at least one dental filler, advantageously SiO2; (3) at least one organic polymer or copolymer dispersant having an amine index less than or equal to 100 mg of potassium hydroxide per gram of dispersant, advantageously a polyurethane / acrylate copolymer or alkylammonium salt thereof; (4) at least one cationic photoinitiator, advantageously iodonium borate; and (5) optionally, at least one photosensitizer.

Owner:RHODIA CHEM SA

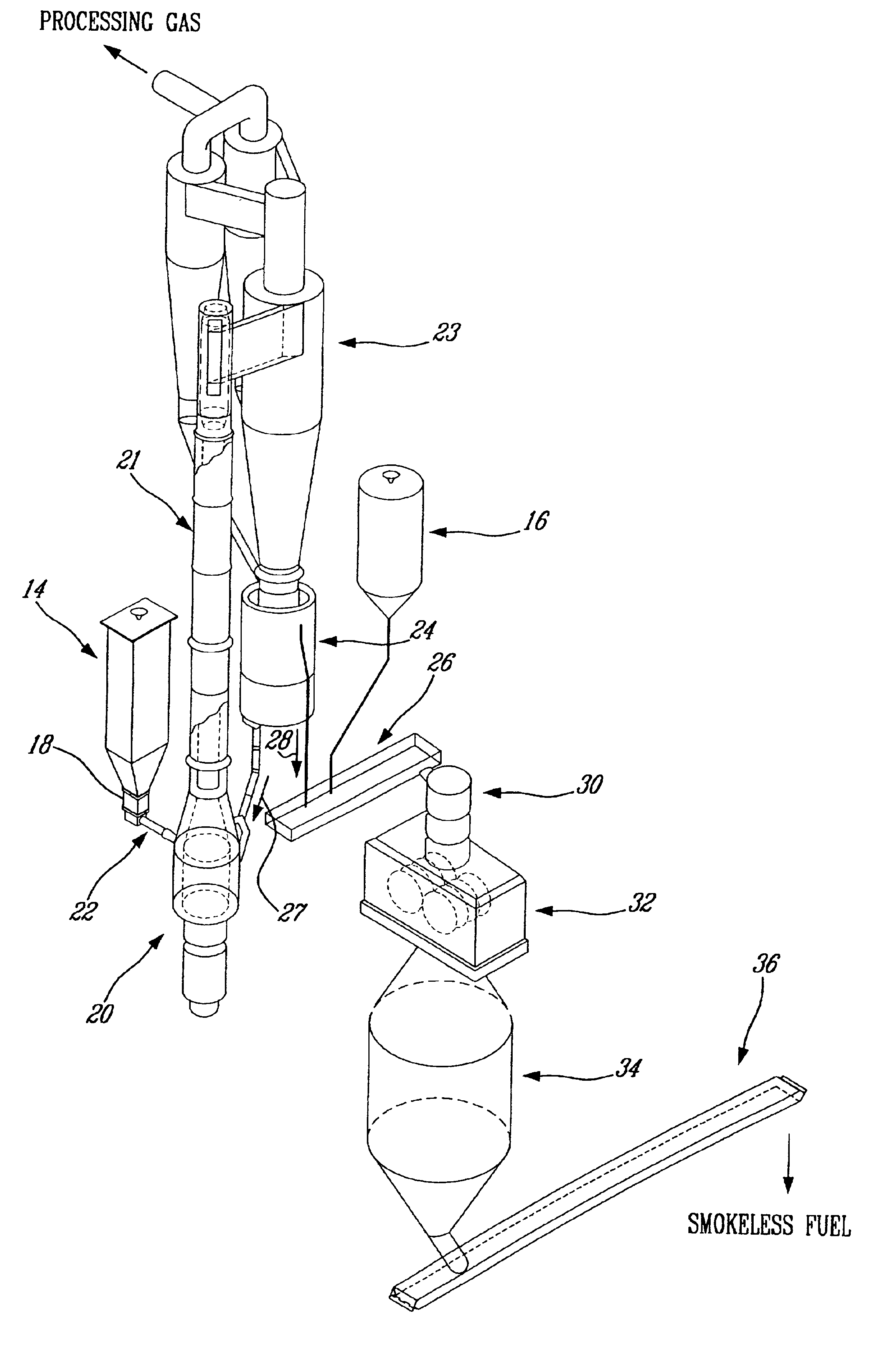

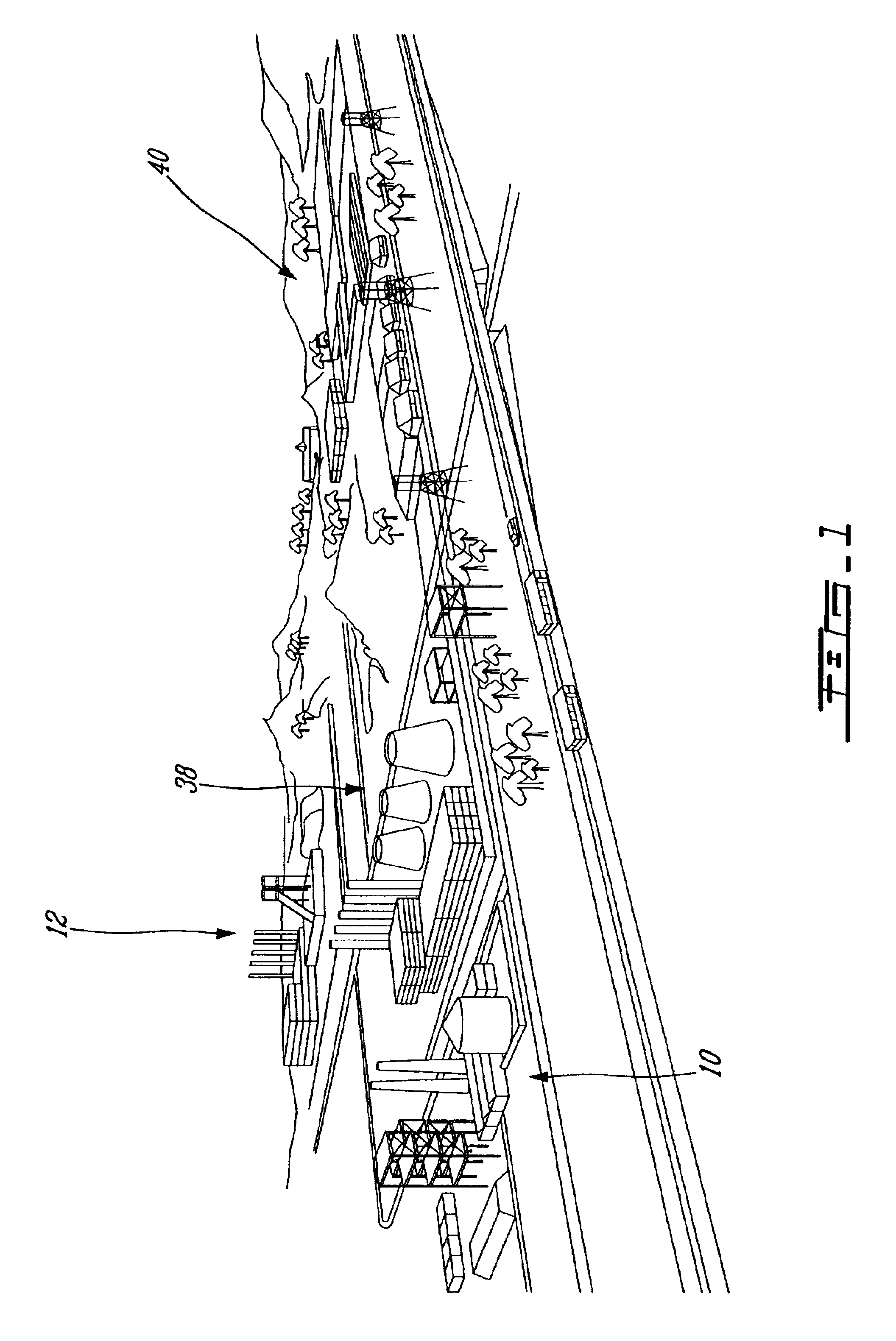

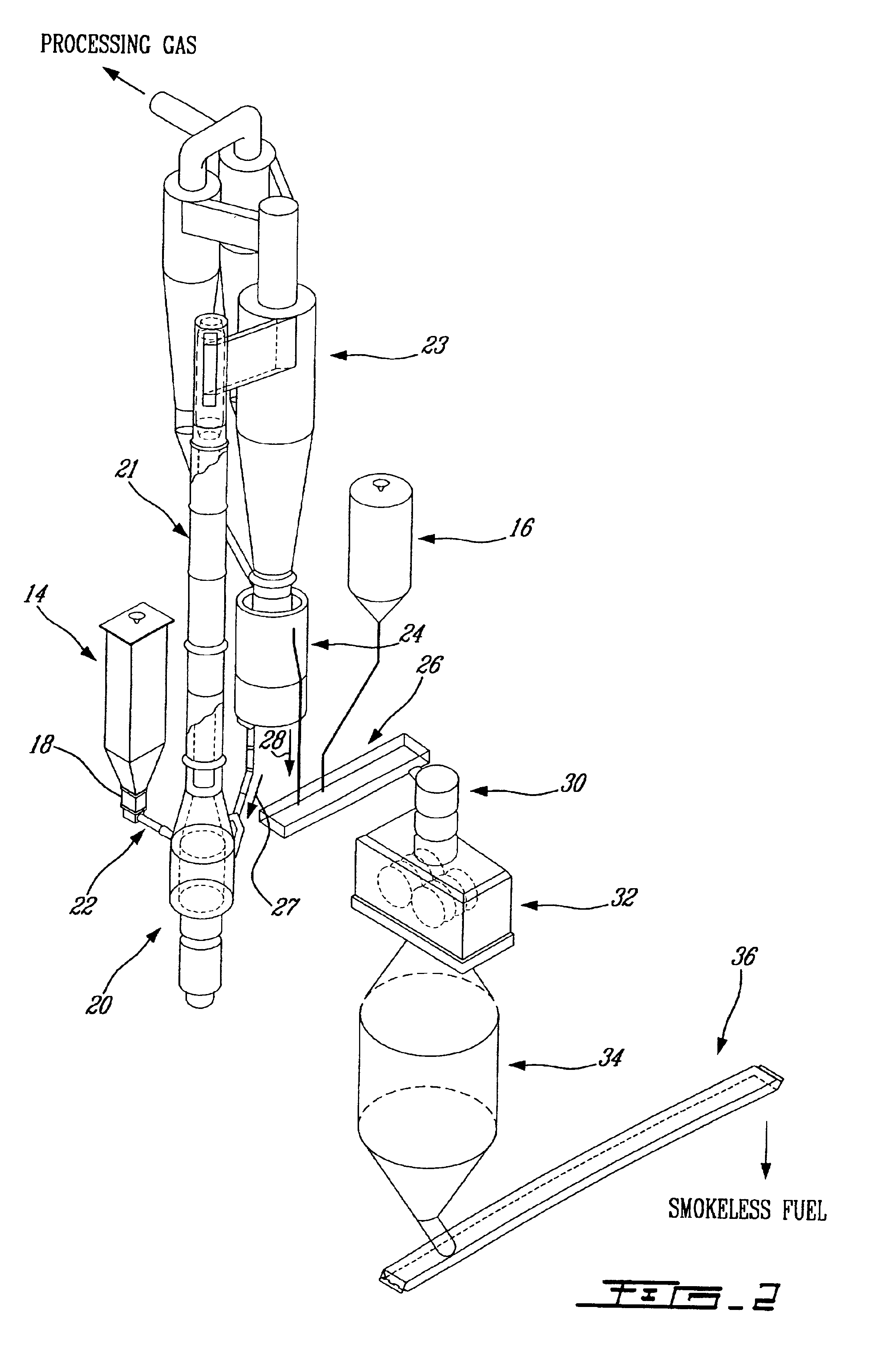

Valorization of by-products in the ecological coal transformation

InactiveUS6942707B2Increase profitabilityEconomically viableFuel supply regulationSolid fuel pretreatmentControl systemProduct gas

A coal transformation system comprises an ecological coal production unit for transforming raw coal into ecological coal. The production unit has an exhaust for carrying in a storage unit combustible, gaseous, waste by-products generated during the transformation of raw coal. A control system is provided for allowing the combustible, gaseous, waste by-products to be withdrawn and subsequently used as an additional source of energy when the system energy demand reaches a predetermined value, thereby contributing to reduce the energy costs during peak power needs.

Owner:ADALBERT W GORACZKO

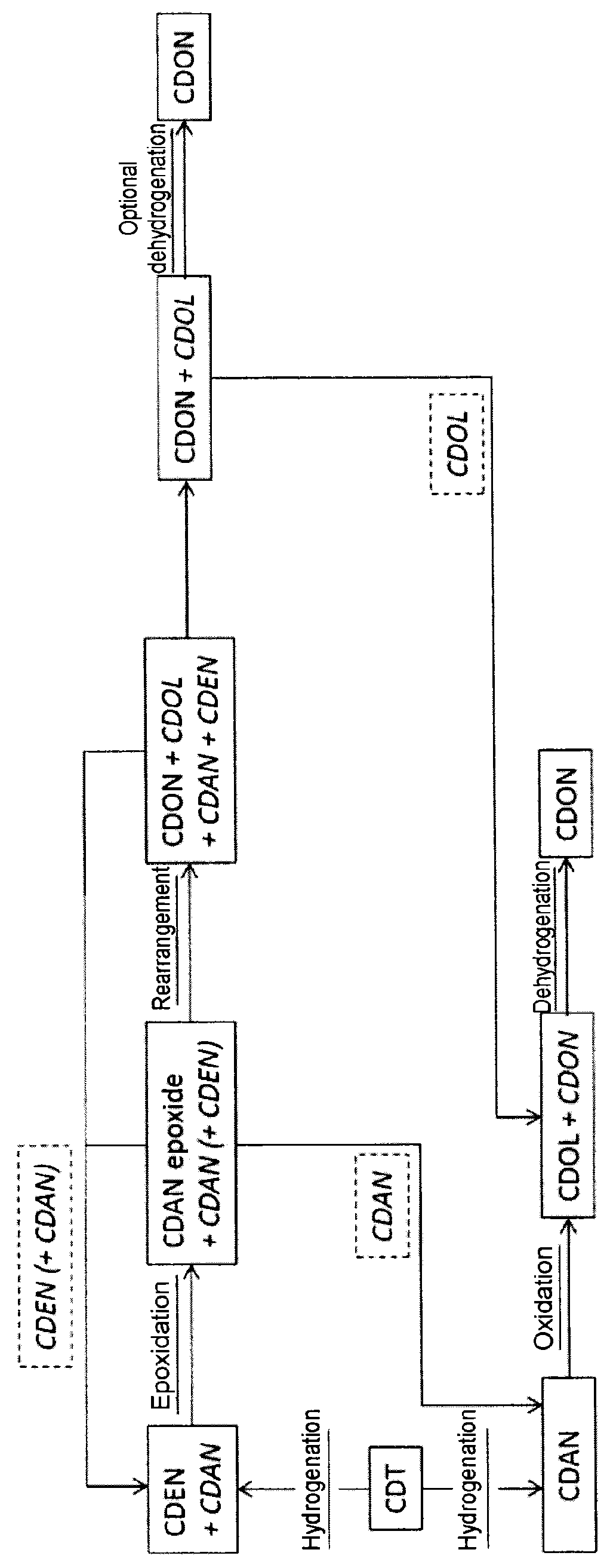

Process for preparing cyclododecanone

ActiveUS20160031784A1Increase productionReduce the ratioPreparation by oxidation reactionsLactams preparationCyclododecanoneEpoxide

Cyclododecanone (CDON) is prepared by epoxidizing cyclododecene (CDEN) to epoxycyclododecane (CDAN epoxide), and rearranging the CDAN epoxide to CDON to obtain a mixture comprising said CDON and CDEN, wherein CDEN is separated from the CDON-containing mixture and sent to the epoxidation to CDAN epoxide in step a.

Owner:EVONIK OPERATIONS GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com