Preparation method of micron grade ball shape silver powder for conductive silver paste

A conductive silver paste, micron-scale technology is applied in the field of preparation of conductive silver paste in the electronic industry, which can solve the problems of difficulty in controlling the pH value of the system, increase cost, toxicity, etc., achieve stable and reliable process conditions, improve economic benefits, and process Simple and feasible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

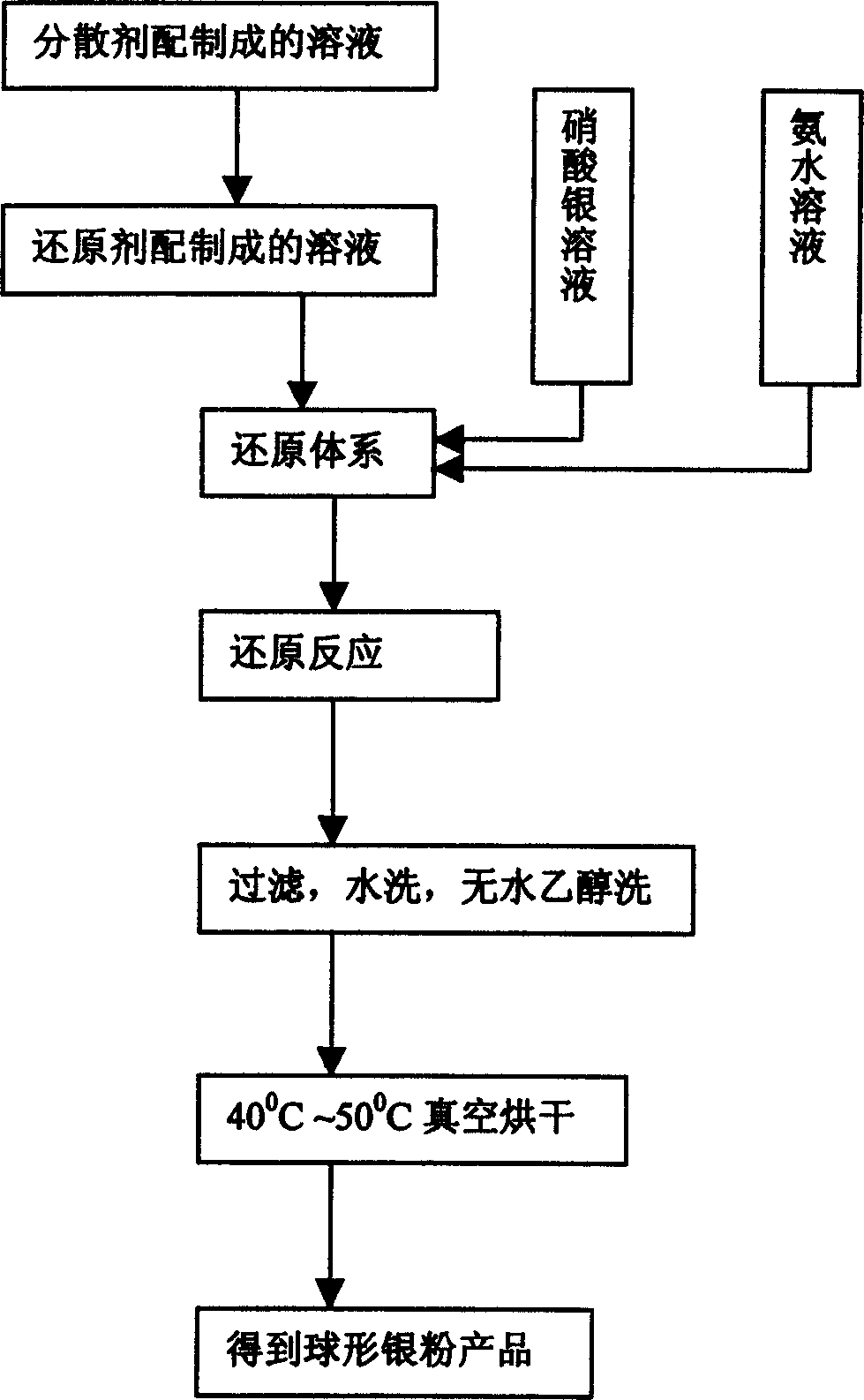

[0018] According to attached figure 1 As shown in the process flow chart, first, weigh 3g of ascorbic acid, dissolve it in 30ml deionized water, and make solution A; weigh 0.2g polyvinylpyrrolidone, dissolve it in 20ml deionized water, and make solution B; Pour solution A into a 250ml four-neck round bottom flask, heat it in a water bath to a temperature of 60°C, and adjust the stirring speed to 300r / min; then, add the prepared solution B into solution A, and stir for about ten minutes until the entire reduction The system is a homogeneous phase; take 5ml of 25-28% ammonia water and add 25ml of deionized water to make dilute ammonia solution C; weigh 5g of silver nitrate and dissolve it in 25ml of deionized water to make solution D; The solutions C and D were poured into two 250ml constant pressure dropping funnels respectively, and the dropping speed of solutions C and D was adjusted so that the pH value of the system was stabilized at 6±0.2; After the silver solution is add...

example 2

[0020] According to attached figure 1 As shown in the process flow chart, first, weigh 3g of ascorbic acid, dissolve it in 30ml deionized water, and make solution A; weigh 1g OP emulsifier, dissolve it in 20g of absolute ethanol, and make solution B; Pour A into a 250ml four-necked round-bottomed flask, heat it to a temperature of 35°C in a water bath, and adjust the stirring speed to 300r / min; then, add the prepared B solution into solution A, and stir for about ten minutes until the entire reduction system It is a homogeneous phase; take 5ml of 25-28% ammonia water, add 27ml of deionized water to make the concentration of the ammonia solution about 4%, and make solution C; weigh 5g of silver nitrate, dissolve it in 25ml of deionized water, and make solution D Then, pour solution C and D prepared into two 250ml constant-pressure dropping funnels respectively, adjust the dropping speed of solutions C and D so that the pH value of the system is stable at 4.4~4.6; control the wh...

example 3

[0022] According to attached figure 1 Shown process flow diagram, at first, take by weighing 3g ascorbic acid, be dissolved in 60ml deionized water, be made into solution A; Take by weighing 0.2g copper nitrate and 0.2g magnesium nitrate, be dissolved in 40ml deionized water, be made into solution B; Pour the prepared solution A into a 250ml four-neck round bottom flask, heat it in a water bath to a temperature of 60°C, and adjust the stirring speed to 400r / min; then, add the prepared solution B into solution A, and stir for ten minutes From left to right until the entire reduction system is a homogeneous phase; weigh 5g of silver nitrate, dissolve it in 50ml of deionized water, and make solution C; then, pour the prepared solution C into a 250ml constant pressure dropping funnel, and adjust the concentration of solution C. The dropping speed is such that the whole dropping process takes 5-10 minutes. After the silver nitrate solution is added dropwise, react for half an hour,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com