Zinc-nickel battery negative electrode material

A negative electrode material, zinc-nickel battery technology, applied in the field of energy storage, can solve the problems of unsuitable lithium-ion battery negative electrode materials, inability to intercalate and deintercalate lithium ions, and decline in the utilization rate of zinc oxide, and achieve excellent electrochemical performance. The effect of stable and reliable process conditions and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The basic zinc carbonate / carbon composite material prepared by embodiment 1, urea

[0037] Weigh 100 mg of carbon material (carbon nanotubes, carbon fibers, conductive carbon black or graphene), add it to 50 mL of water for ultrasonic dispersion for 30 min, and then add 1 g of divalent zinc salt (ZnCl 2 ) after fully dissolved by stirring, continue ultrasonic dispersion for 10min; weigh a certain amount of urea (1.32g, 1.50g or 1.77g) and dissolve it in 30mL water; The reaction was continued for 12 h under magnetic stirring in an oil bath. After the reaction is completed, filter, wash with deionized water until neutral, and dry at 50°C to obtain the basic zinc carbonate / carbon composite material.

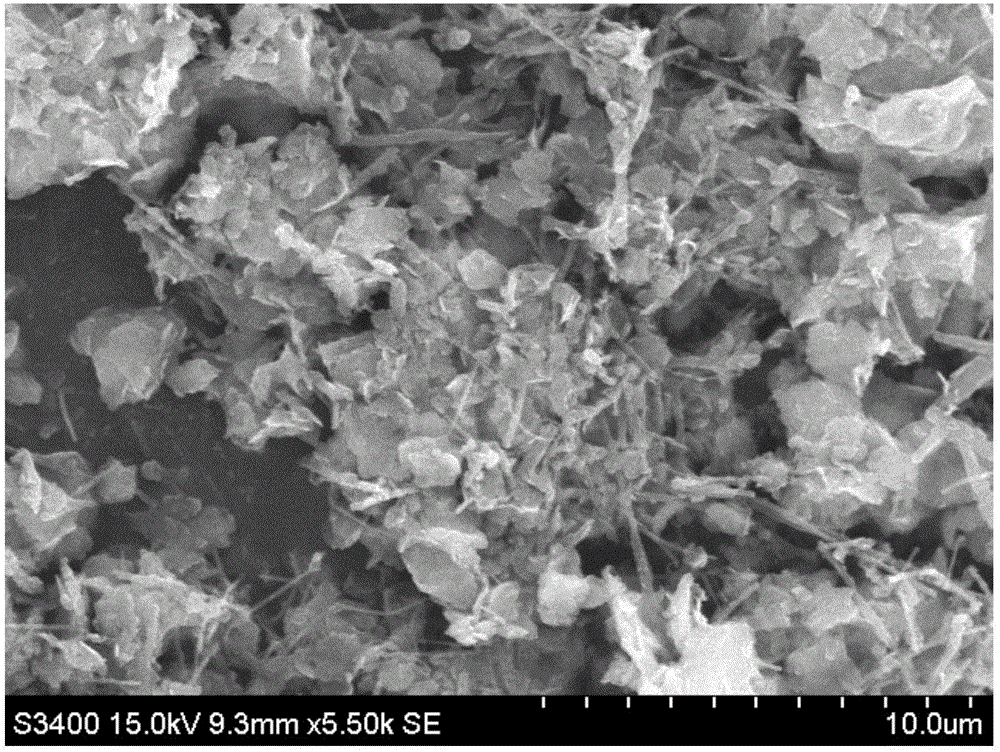

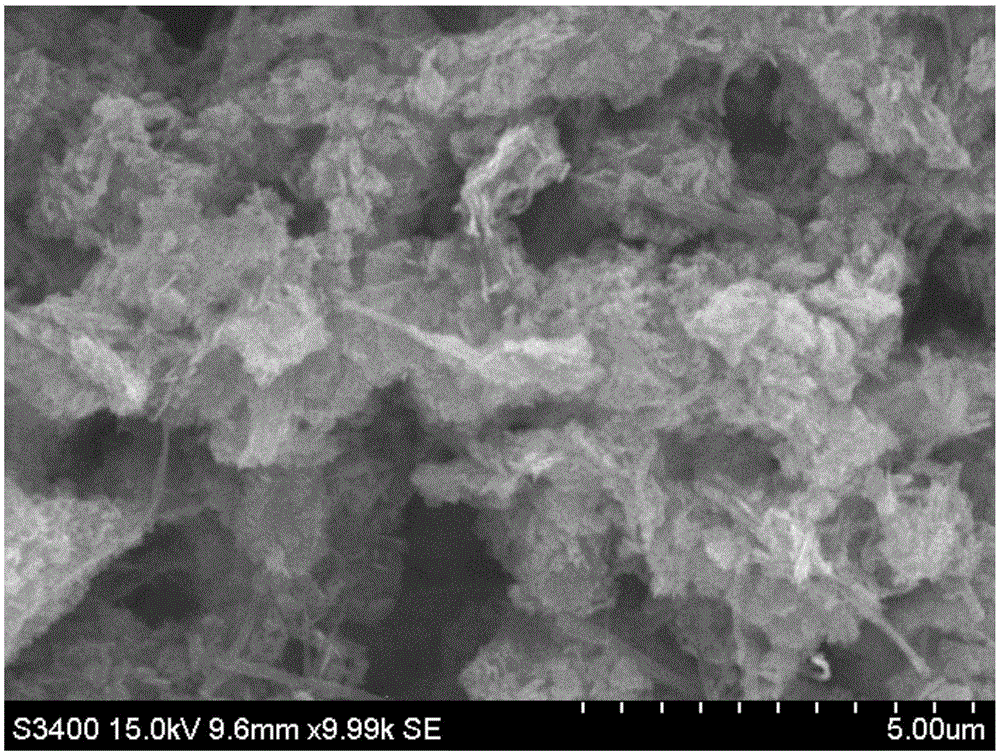

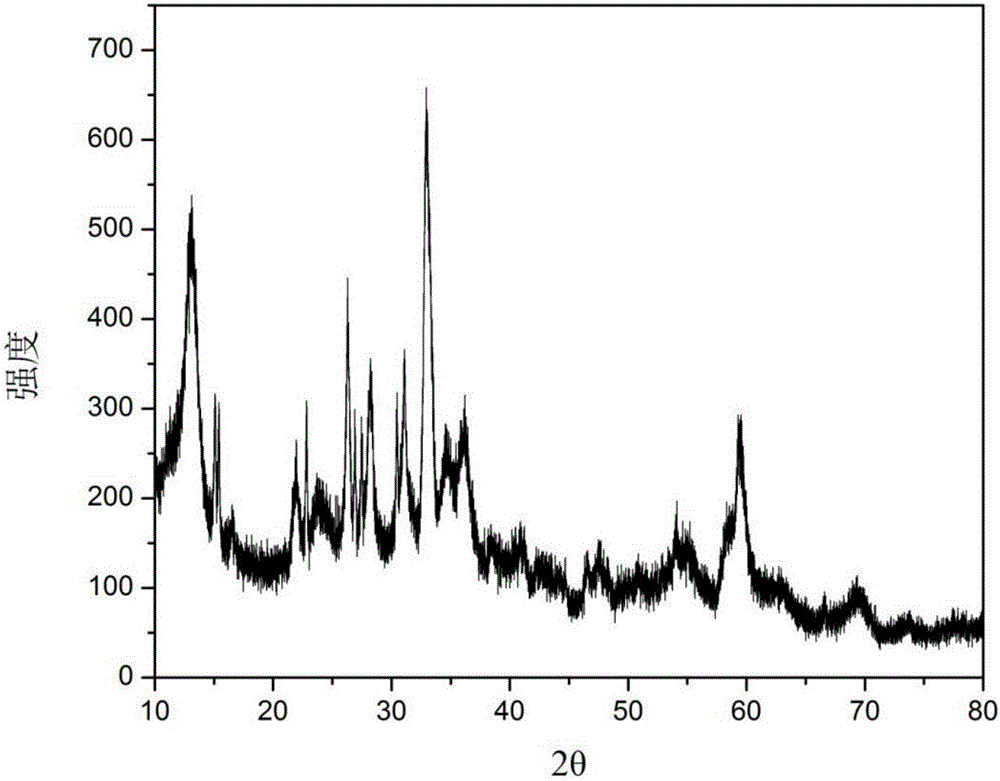

[0038] The electron micrograph and XRD figure of the prepared basic zinc carbonate / carbon composite material are as attached figure 1 And attached image 3 shown.

Embodiment 2

[0039] The basic zinc carbonate / carbon composite material prepared by embodiment 2, ammonium bicarbonate

[0040] Weigh 100 mg of carbon material (carbon nanotubes, carbon fibers, conductive carbon black or graphene), add it to 50 mL of water for ultrasonic dispersion for 30 min, and then add 1 g of ZnSO 4 Continue to ultrasonically disperse for 10 minutes after stirring to fully dissolve; weigh a certain amount of ammonium bicarbonate (0.92, 1.0g or 1.05g) and add 15mL of water to fully dissolve; place the mixed solution in an oil bath at 60°C and stir magnetically at the same time, The prepared ammonium bicarbonate solution was slowly added dropwise to the mixed solution. After the dropwise addition, the reaction was continued for two hours. After the reaction was completed, it was filtered, washed with deionized water until neutral, and dried at 50°C to obtain the basic zinc carbonate / carbon composite material.

[0041] The electron micrograph and XRD figure of the prepare...

Embodiment 3

[0042] Embodiment 3, basic zinc carbonate / carbon composite material is used as the negative plate preparation method of active material

[0043] Basic zinc carbonate / carbon composite material, calcium hydroxide, bismuth oxide, binder PTFE (0.1%wt water suspension) are mixed in a ratio of 92:1:3:4, adjusted into a paste, and applied Based on brass mesh or three-dimensional tinned copper mesh, drying, pressing, and cutting to obtain the negative electrode sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com