Patents

Literature

31results about How to "Stable and reliable process conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

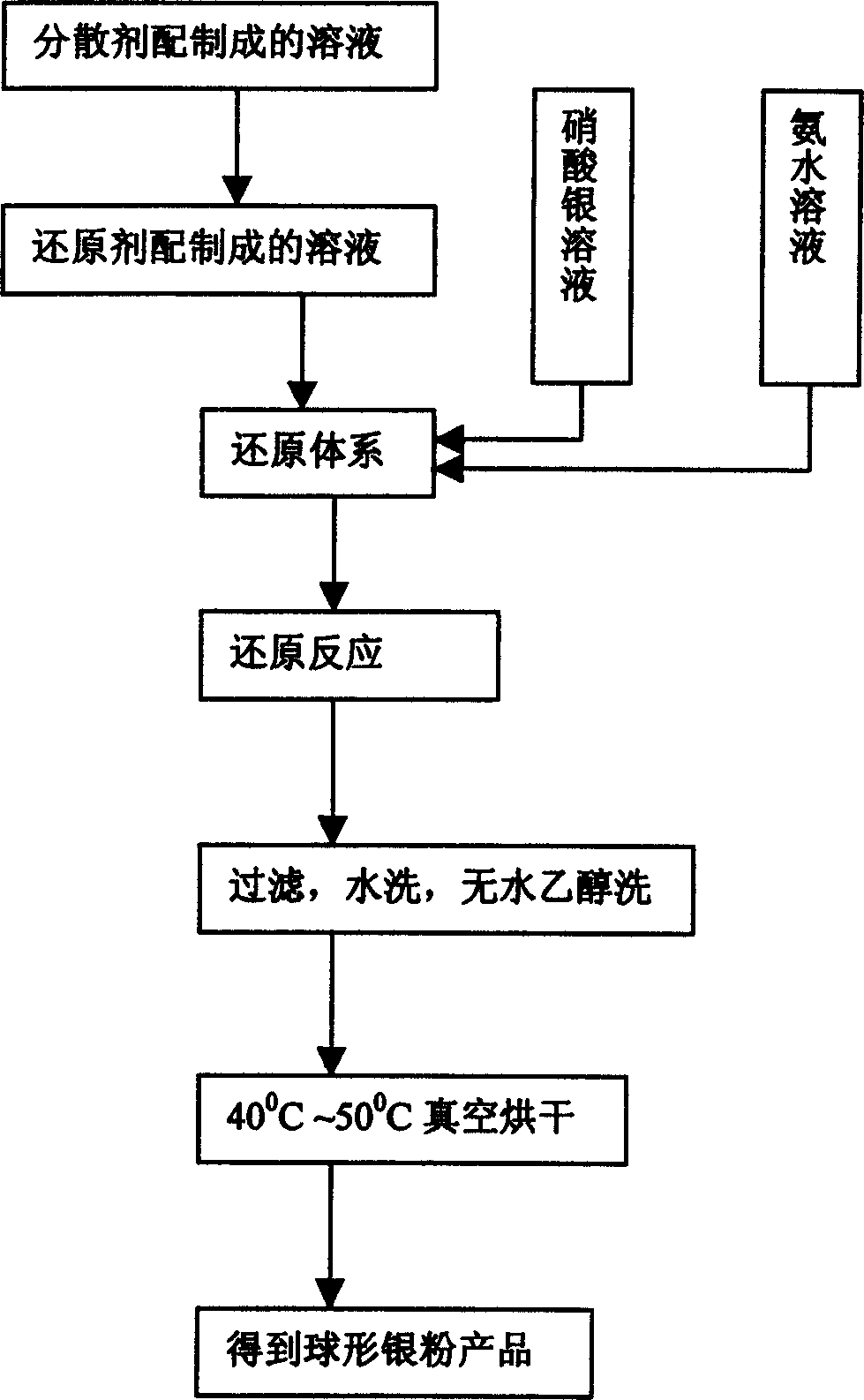

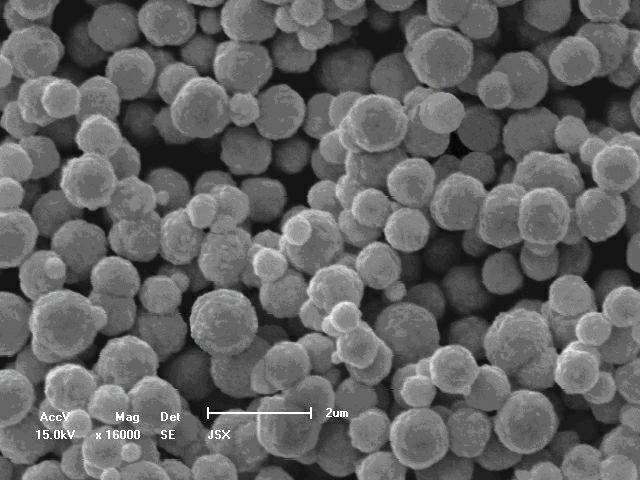

Preparation method of micron grade ball shape silver powder for conductive silver paste

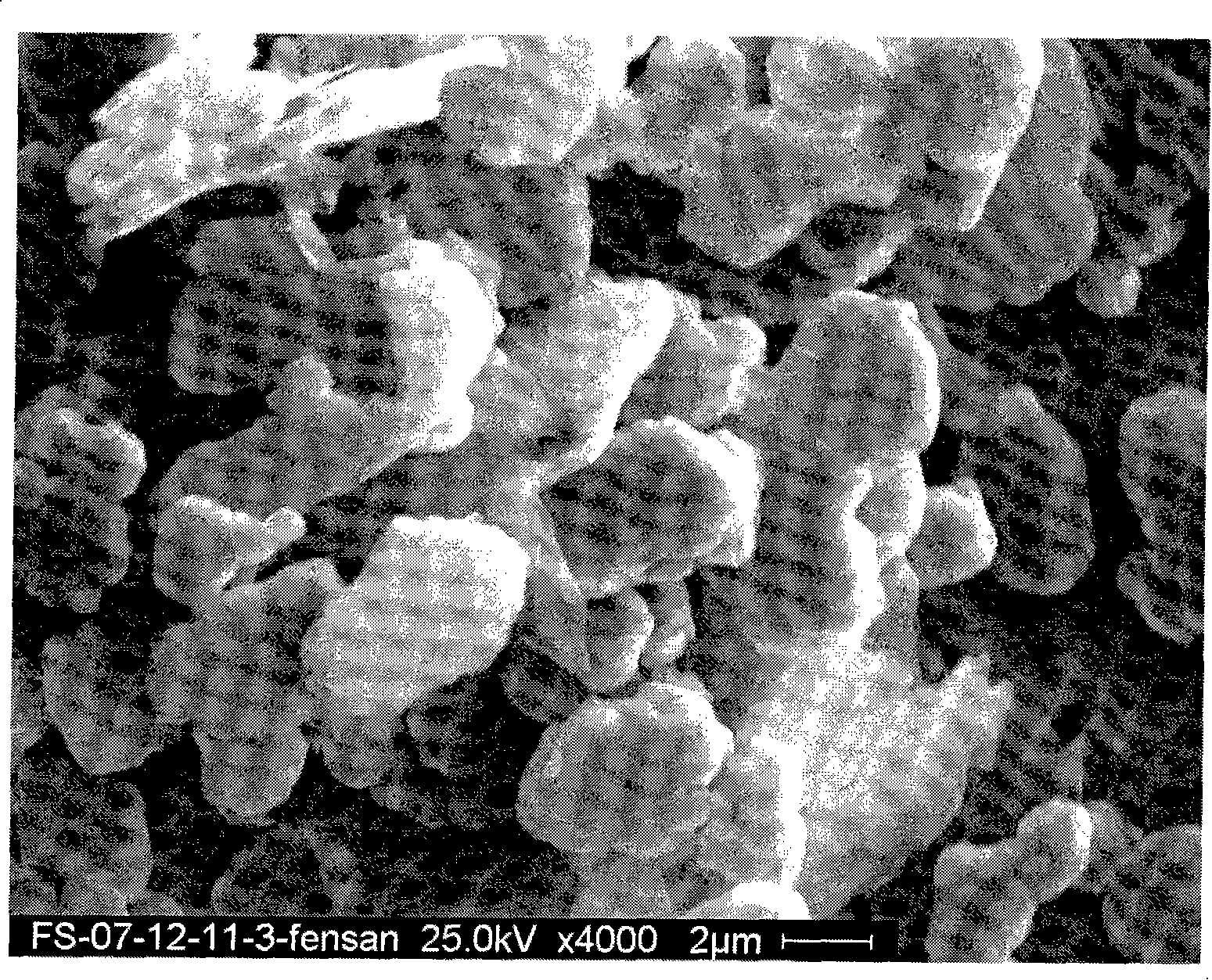

A process for preparing the micron-class spherical silver powder used for electrically conductive Ag slurry features that in the redox procedure, the silver nitrate solution is dripped into reducer and disperser while the ammonia water is used to regulate the pH value of solution, and the kind of disperser, stirring speed, and reaction temp and time are regulated.

Owner:SOUTHEAST UNIV

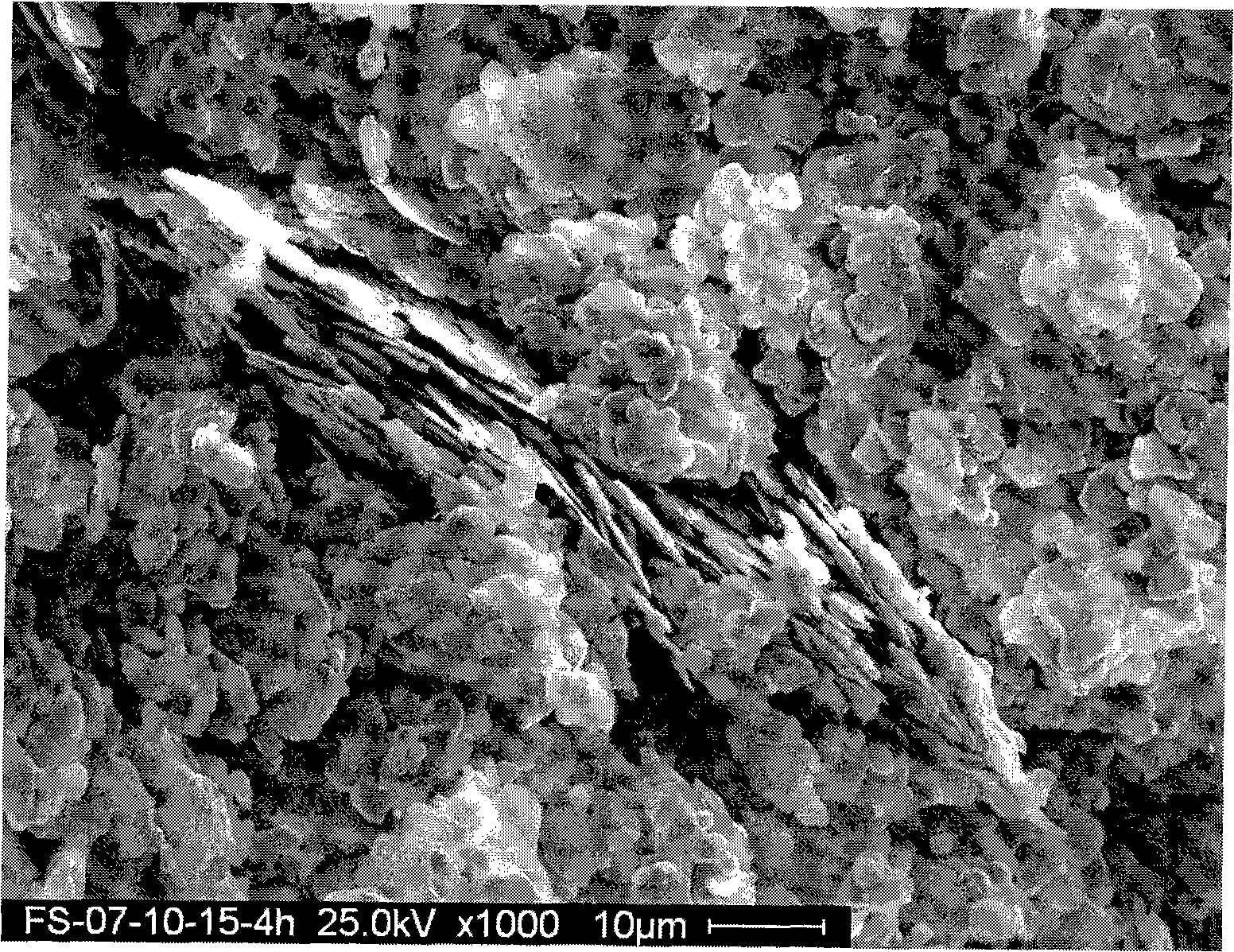

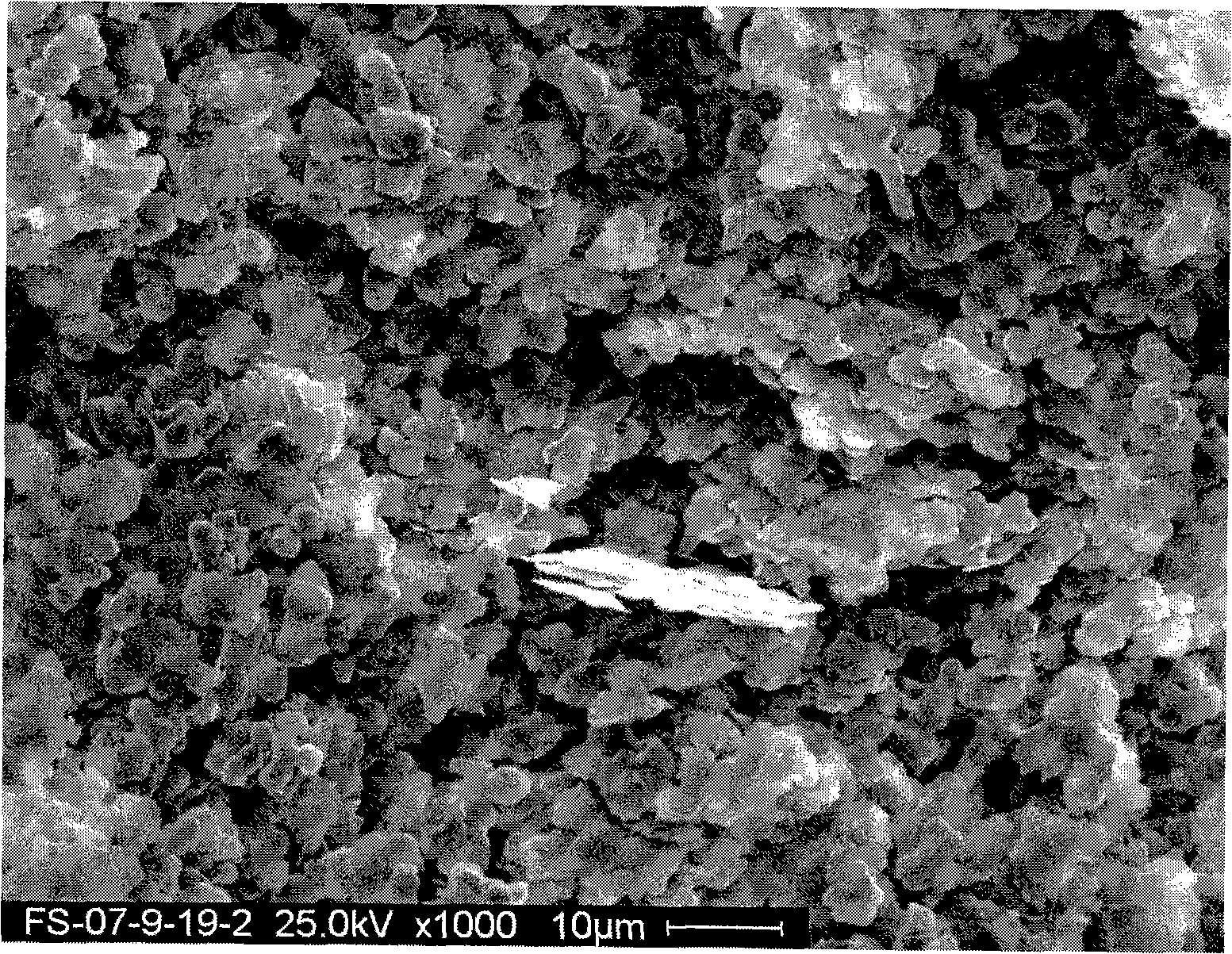

Method for preparing sheet silver powder with high dispersibility

ActiveCN101279369AGood dispersionMeet different performance requirementsShaking/oscillating/vibrating mixersApparent densityMetallurgy

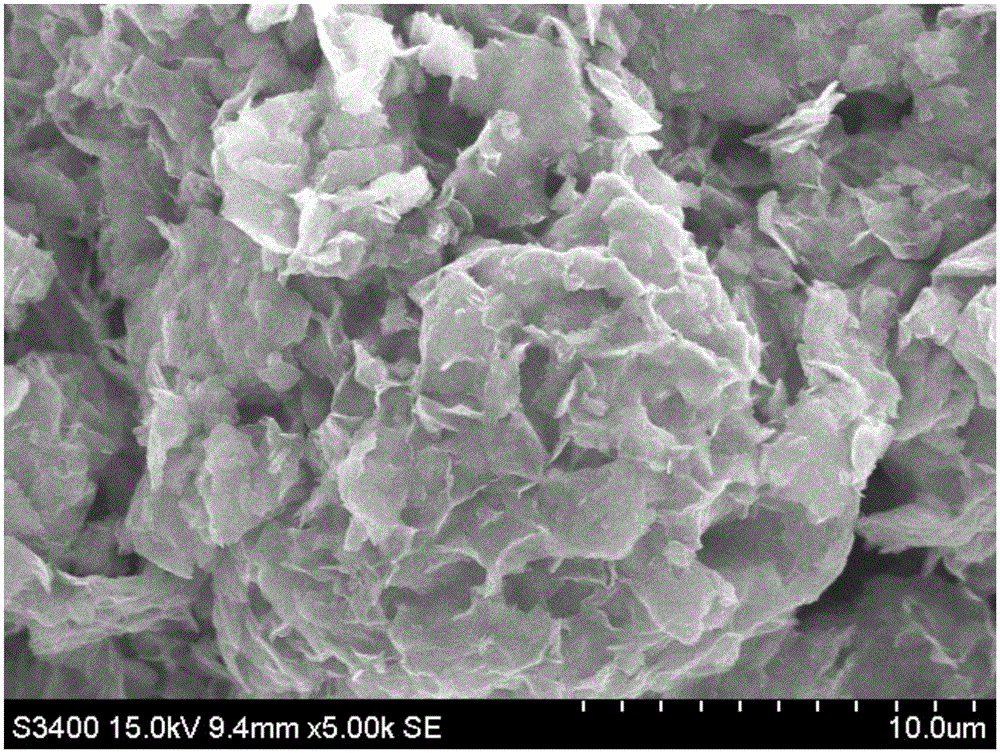

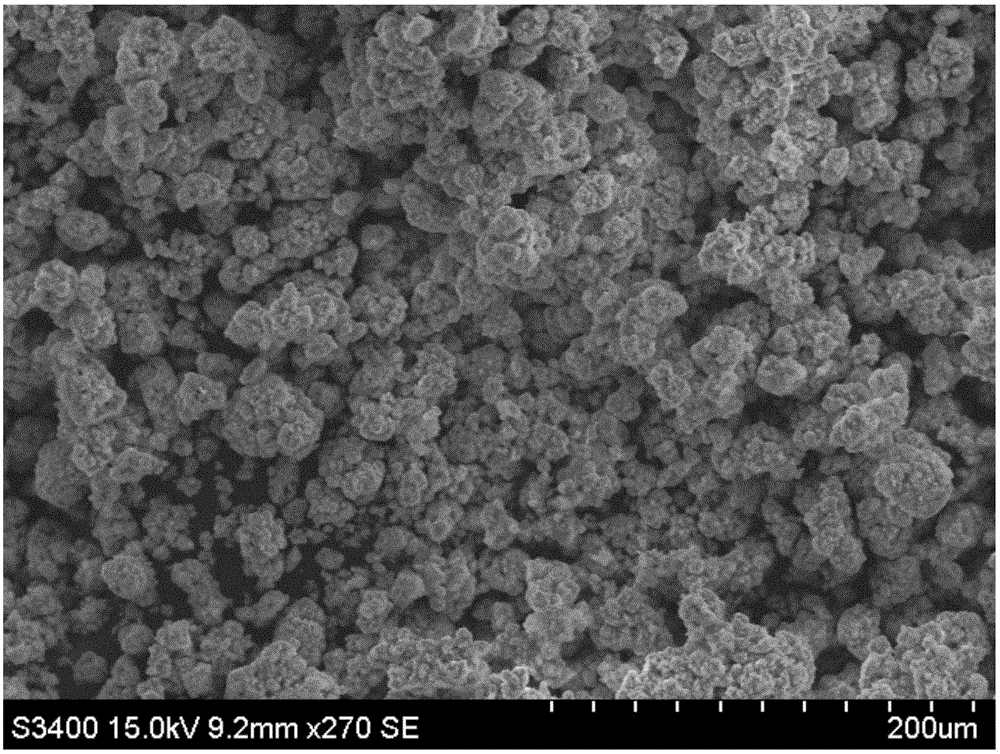

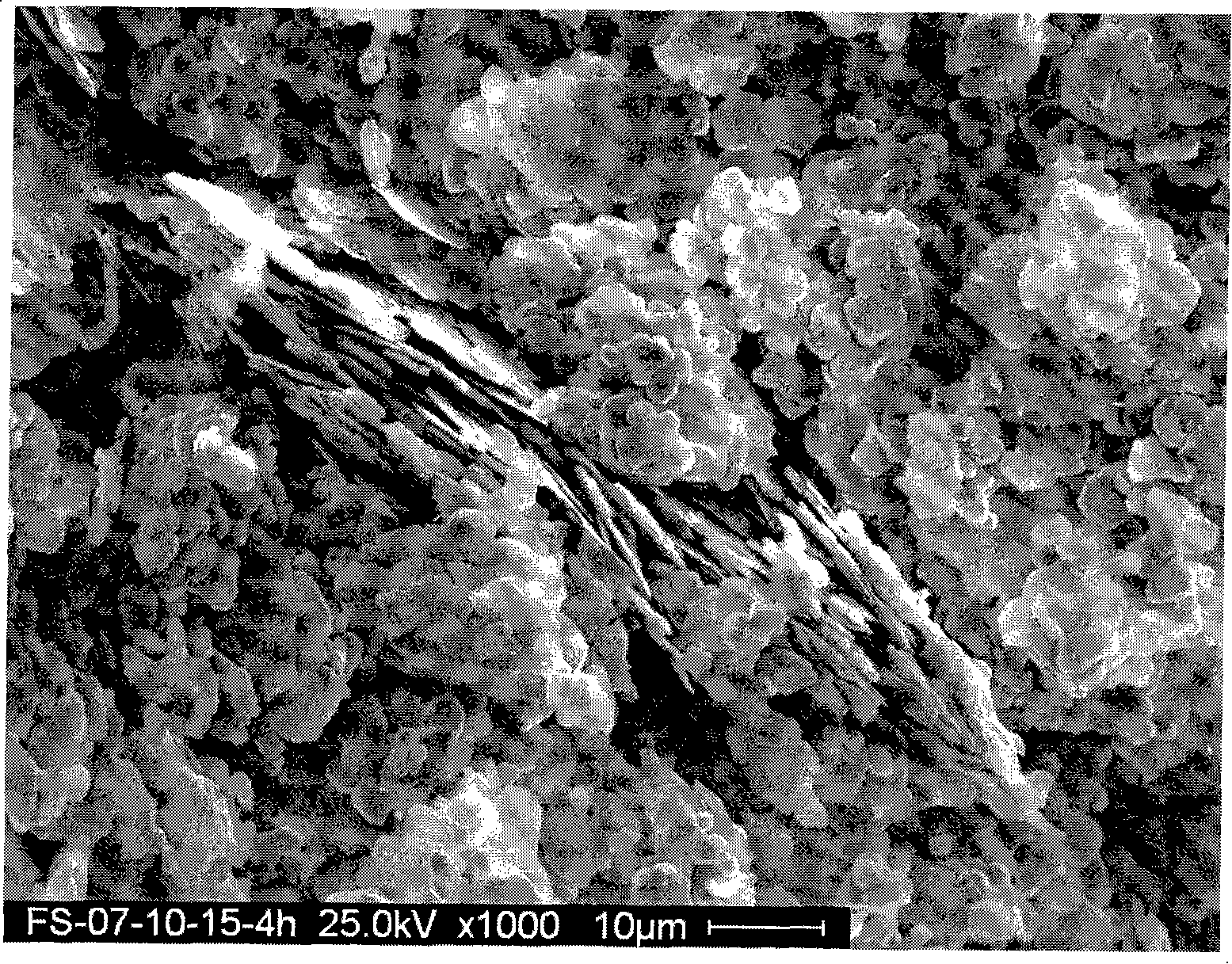

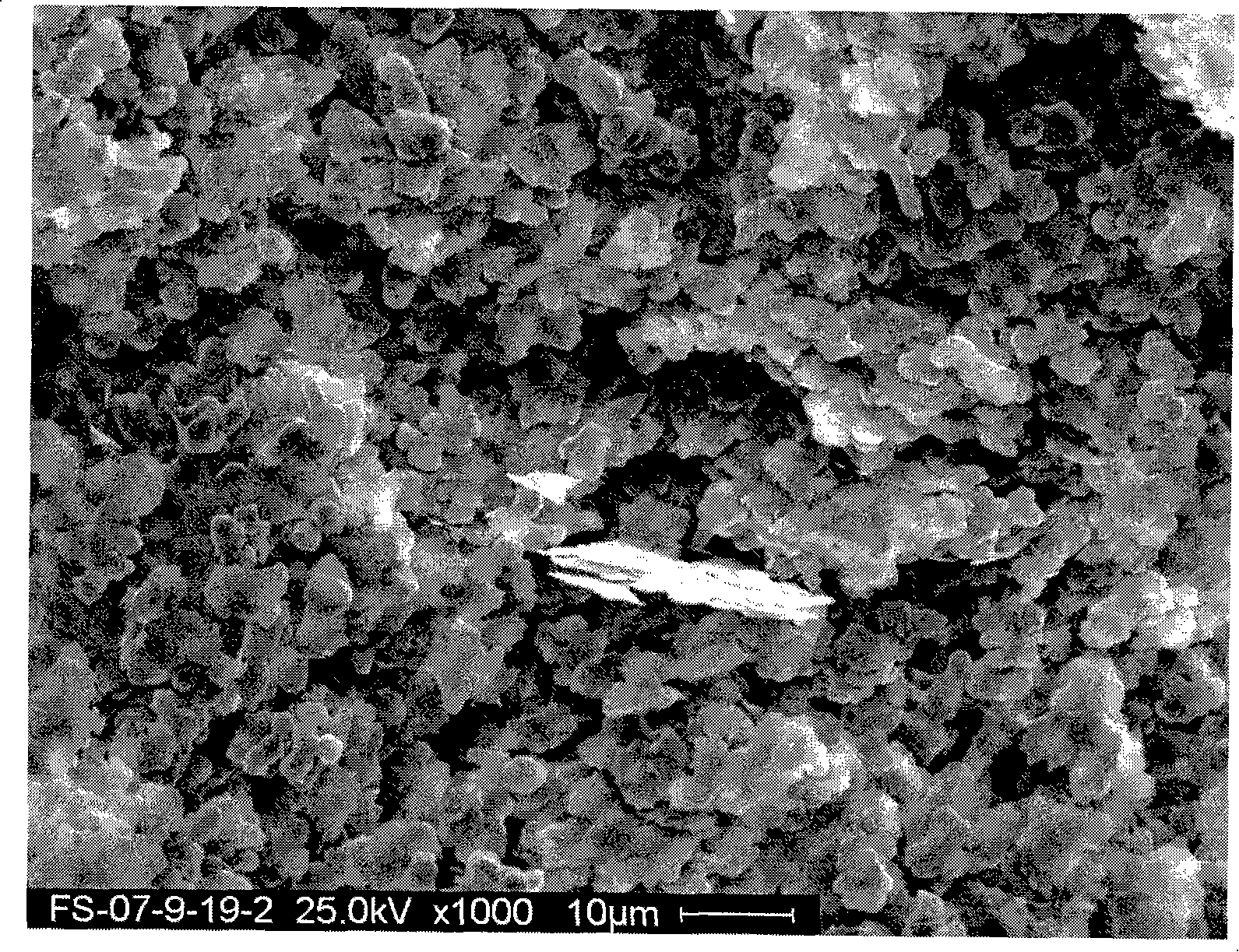

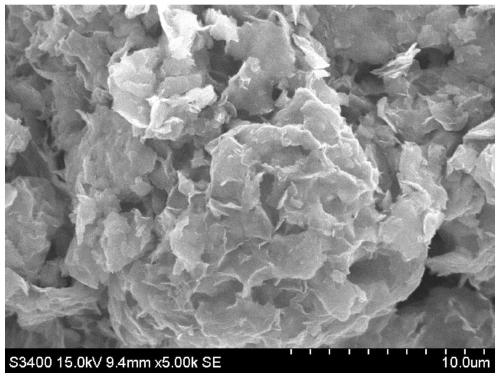

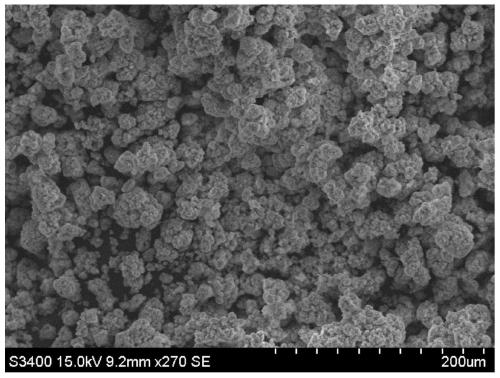

The invention discloses a preparation method of high-dispersion flake silver powder, which is characterized in that spherical raw material silver powder with the1 to 3Mum of particle size D50 and the more than 99.95 percent of silver content is ground into the flake silver powder by adopting a grinding machine, the dispersion is then improved by ultrasonic dispersion and airflow dispersion, and the high-dispersion flake silver powder with the 3 to 25Mum of flake diameter D50 and the apparent density of 0.5 to 1.8g / cm<3> is obtained. The preparation process has simple process flow, which is applicable to the industrial mass production of flake silver powder.

Owner:JINCHUAN GROUP LIMITED

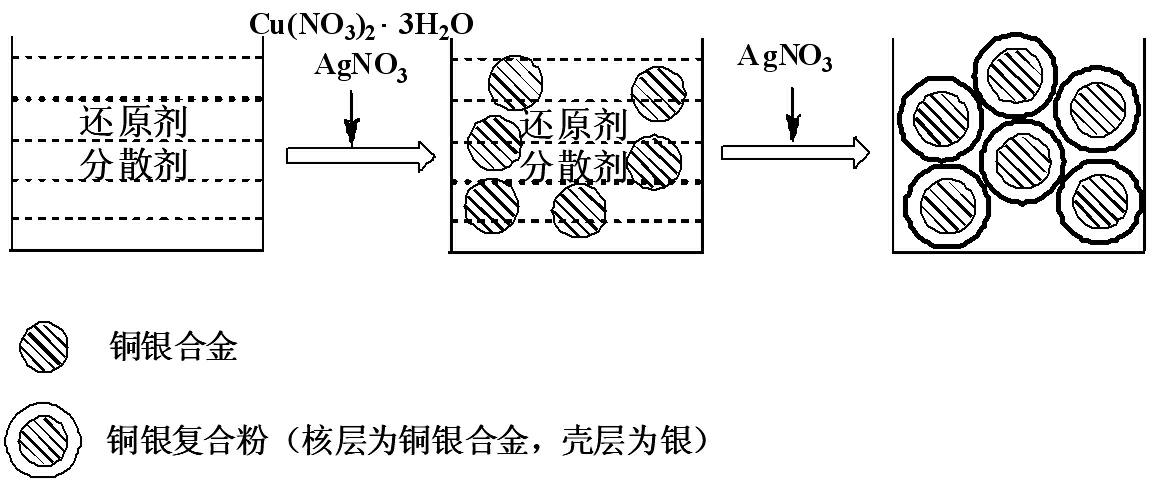

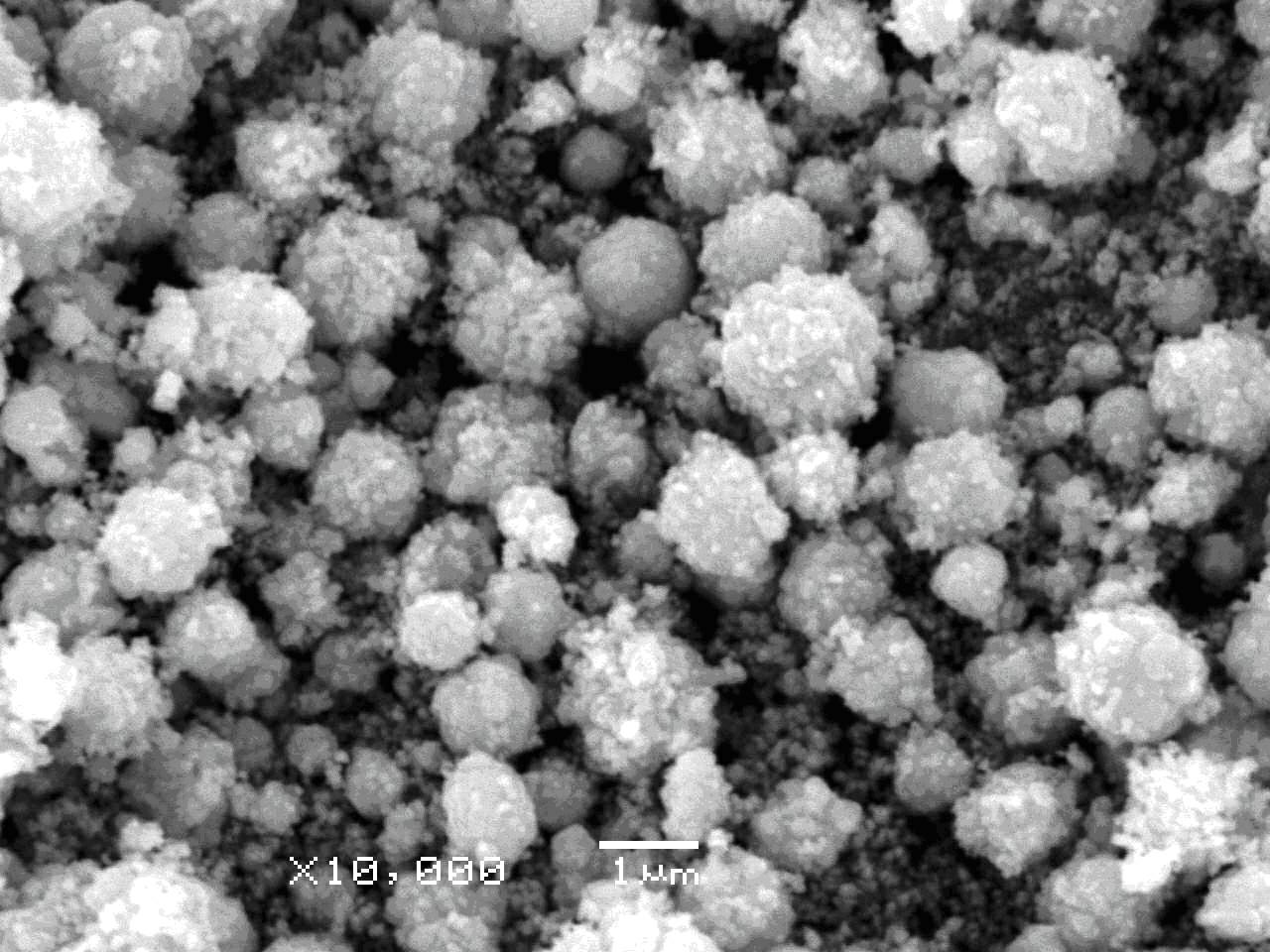

Preparation method of copper-silver composite powder

InactiveCN102161104AInhibition of spontaneous nucleation growthImprove efficiencyAqueous solutionReducing agent

The invention relates to a preparation method of copper-silver composite powder. The copper-silver composite powder has a coated nuclear-shell structure; a nuclear layer is made of copper-silver alloy, and the shell layer is made of silver. The preparation method comprises the steps: firstly, adding a mixed aqueous solution of AgNO3 and Cu(NO3)2.3H2O into a mixed aqueous solution consisting of a reducing agent and a dispersing agent to obtain a copper-silver alloy solution containing the reducing agent; then adding an AgNO3 aqueous solution into the copper-silver alloy solution containing the reducing agent, and leading silver to be deposited and coated on the surface of the copper-silver alloy; and then obtaining the 0.3-3mum copper-silver composite powder after filtering, cleaning, drying and surface densified treatment. In the obtained copper-silver composite powder, the coating of the outer-layer silver is uniform, the compact density is high, the conductivity is good, and the high-temperature oxidation resistance is strong.

Owner:SOUTHEAST UNIV

Preparation method for nanometer calcium hydroxide

InactiveCN104291371AHigh purityAvoid reunionMaterial nanotechnologyCalcium/strontium/barium oxides/hydroxidesCalcium hydroxideOrganic solvent

The invention provides a preparation method for nanometer calcium hydroxide. According to the preparation method, quick lime powder, organic solvent, and water are uniformly mixed according to a certain ratio, so that a suspending liquid is prepared; the suspending liquid is then placed into an ultrasound reactor for decomposition, so that calcium hydroxide particles with nanometer-scale grain size are prepared. The preparation method has the characteristics that the raw materials are cheap and can be easily obtained, the decomposition liquid can be repeatedly used, the preparation condition is mild, the preparation process is simple and convenient, and the prepared nanometer calcium hydroxide is high in purity and uniform in particle size distribution; the preparation method can satisfy different requirements for environment management, fire-resisting materials, medicine, and other special fields.

Owner:杨富巍

Nano silver paste for chip mounting and method for preparing nano silver paste

ActiveCN102935518ANo pollution in the processLower sintering temperatureMaterial nanotechnologyFlocculationSilver paste

The invention provides a method for preparing a nano silver paste. The method includes step A, a reducing agent and a dispersing agent are dropwise added in a silver nitrate solution and stirred; step B, the solution obtained through the step A is subjected to centrifugation to obtain nano silver particles with upper layers as mixed solutions and lower layers as sedimentation; step C, the nano silver particles separated through the step B is cleaned by deionized water and subjected to flocculation by a electrolyte solution, and nano silver particles capable of being subjected to centrifugation are re-precipitated; step D, the nano silver particles are subjected to cleaning, flocculation and centrifugation for a plurality of times to obtain a water-soluble nano silver paste; and step E, the nano silver paste is applied to a chip and a substrate surface to be interconnected, and the interconnected chip and substrate surface is heated in a hot air work bench or a stove to form a sintering joint.

Owner:深圳市先进连接科技有限公司

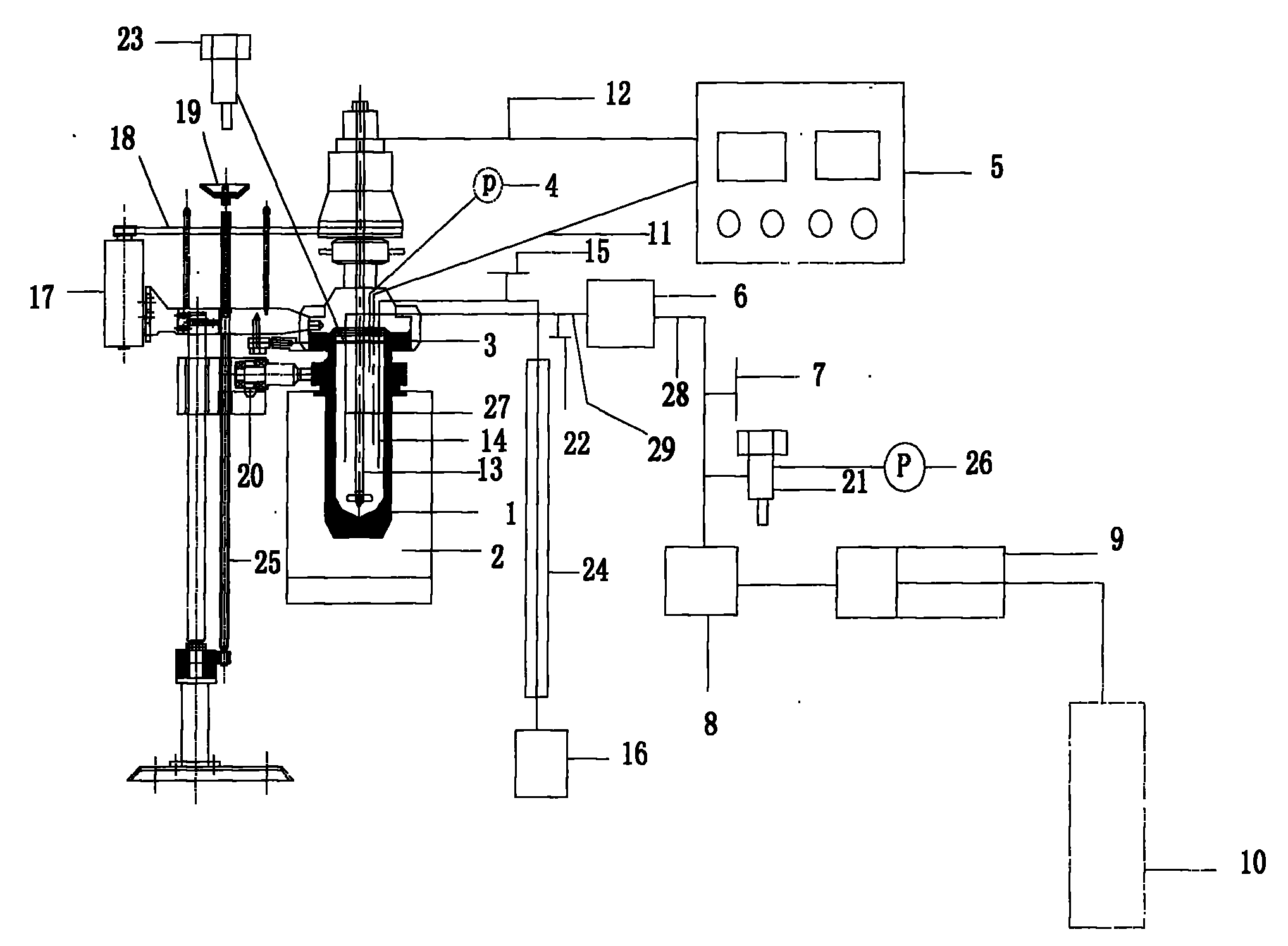

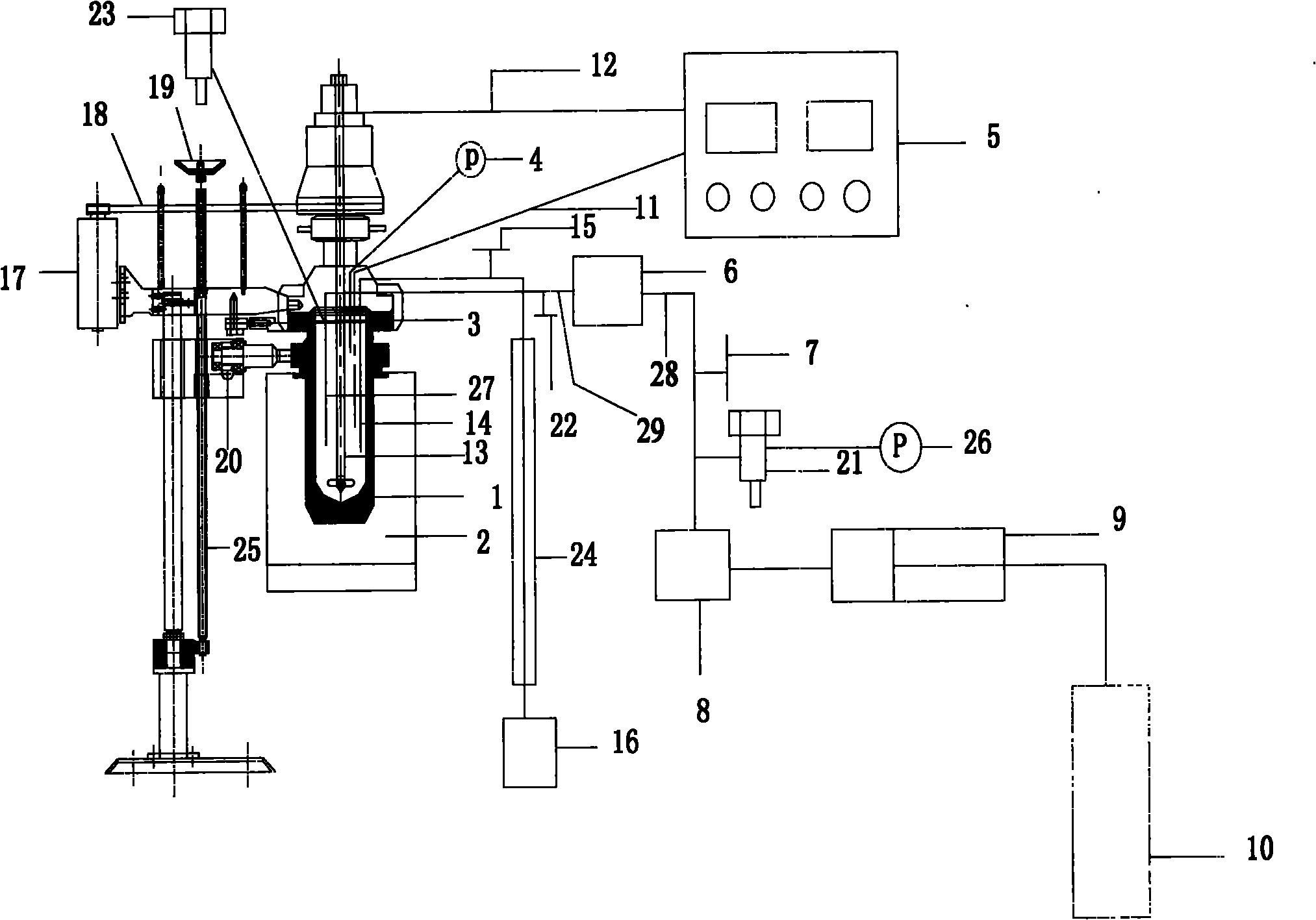

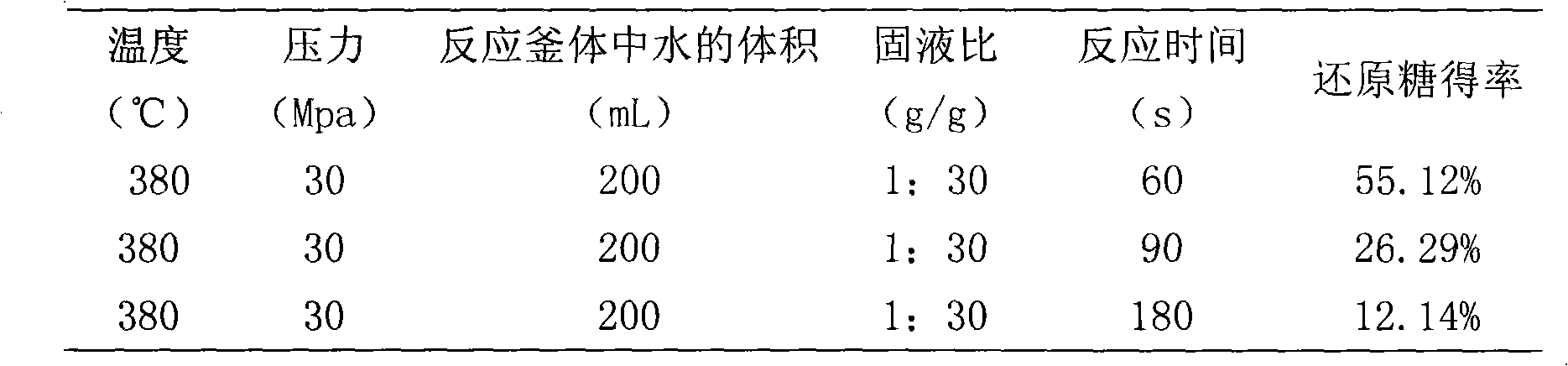

Method for preparing reducing sugar by supercritical hydrolysis of plant fibers and semi-continuous reactor thereof

InactiveCN101899537AAvoid coolingAvoid decompositionChemical/physical/physico-chemical stationary reactorsMonosaccharidesContinuous reactorFiber

The invention discloses a method for preparing reducing sugar by the supercritical hydrolysis of plant fibers and a semi-continuous reactor thereof. According to the method, supercritical hydrolysis is realized by high-pressure feeding and high-pressure sampling. The reaction conditions of a reactor are that: the temperature is between 380 and 400 DEG C; the pressure is 24 to 30MPa; the volume ofwater in a kettle is 150 to 200mL; solid-liquid ratio (g / g) of added plant fiber slurry is 1:30-1:65; and reaction time is 5s to 5min. The reactor comprises a feeding part, a reactor body and a product collecting part, wherein the feeding part presses materials into the reactor by the high pressure stored in a material storage tank; and the sampling part presses a reaction product into a sample receiving bottle through a sampling tube by the high pressure in the reactor. Because the volume of the supercritical water is much more than that of the materials, the materials can smoothly exchange heat in an instant to reach the set condition. The process is considered not to be subjected to other reactions beyond the supercritical condition. The yield of the reducing sugar prepared by the method can be over 50 percent.

Owner:SOUTH CHINA UNIV OF TECH

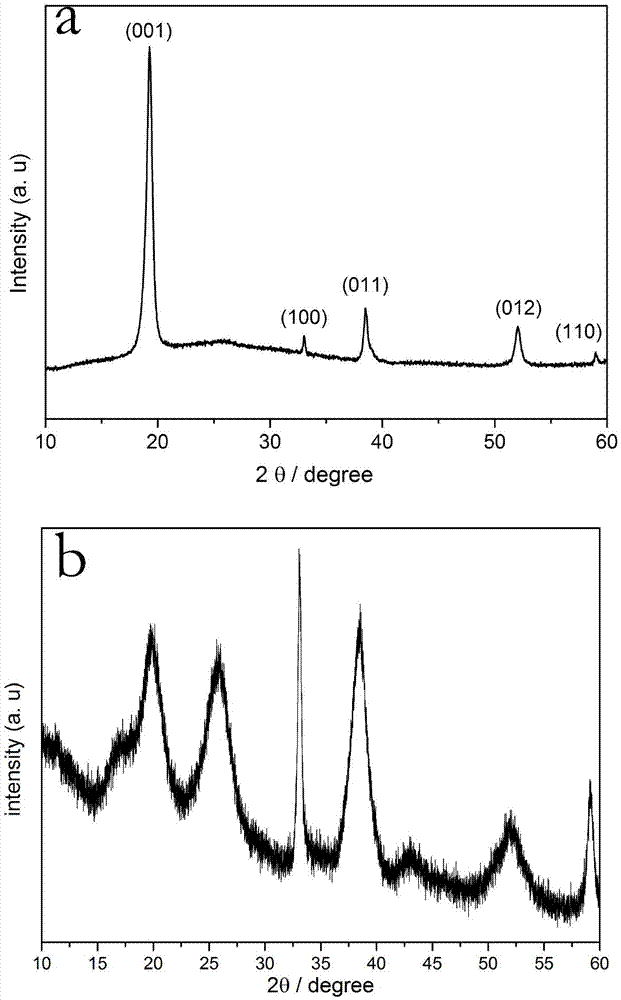

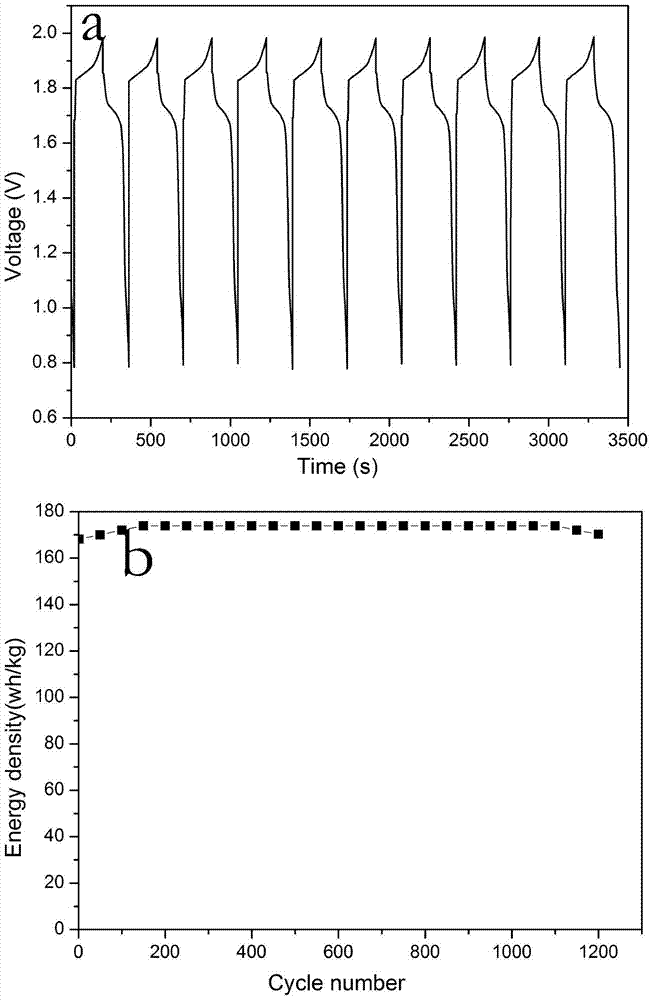

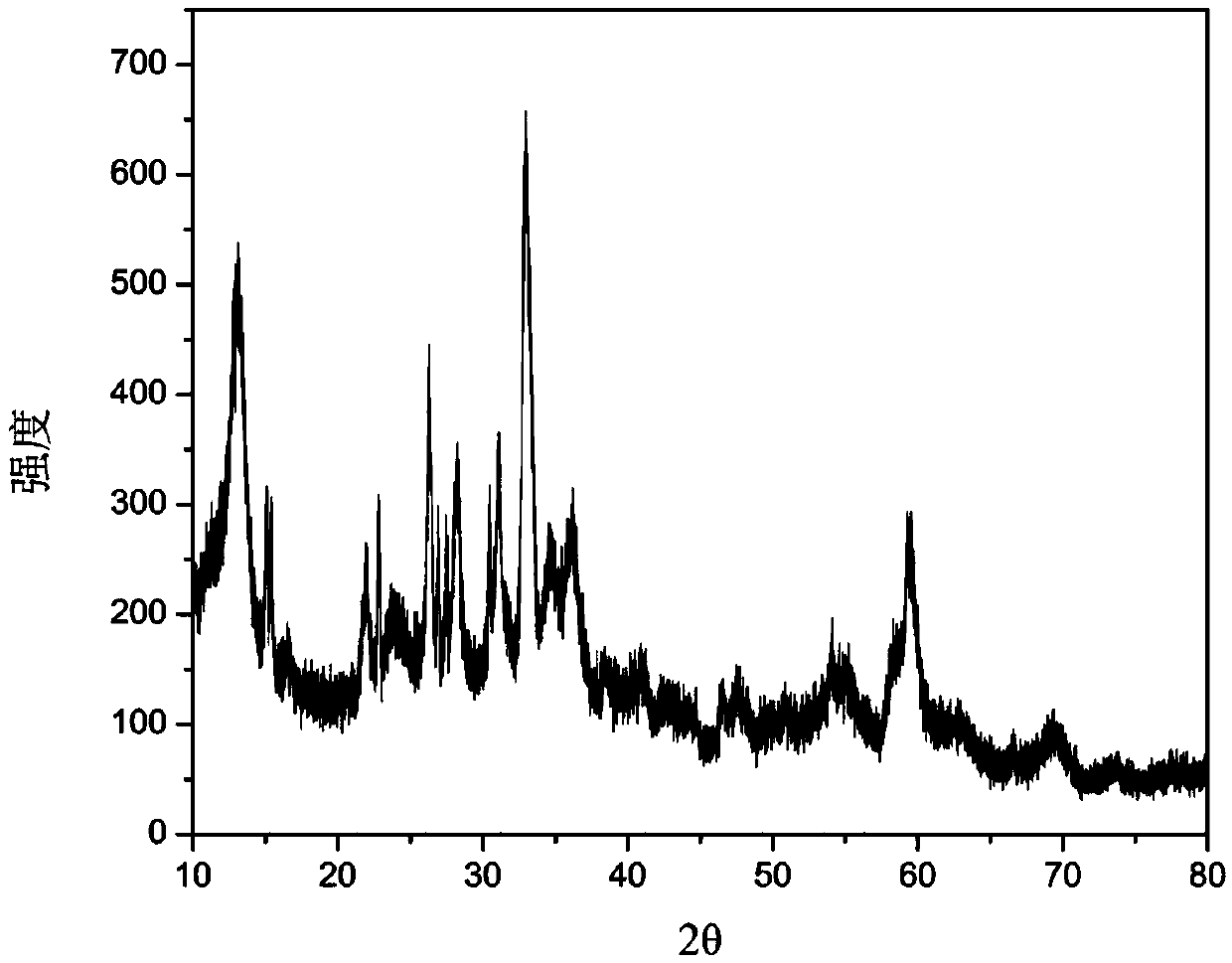

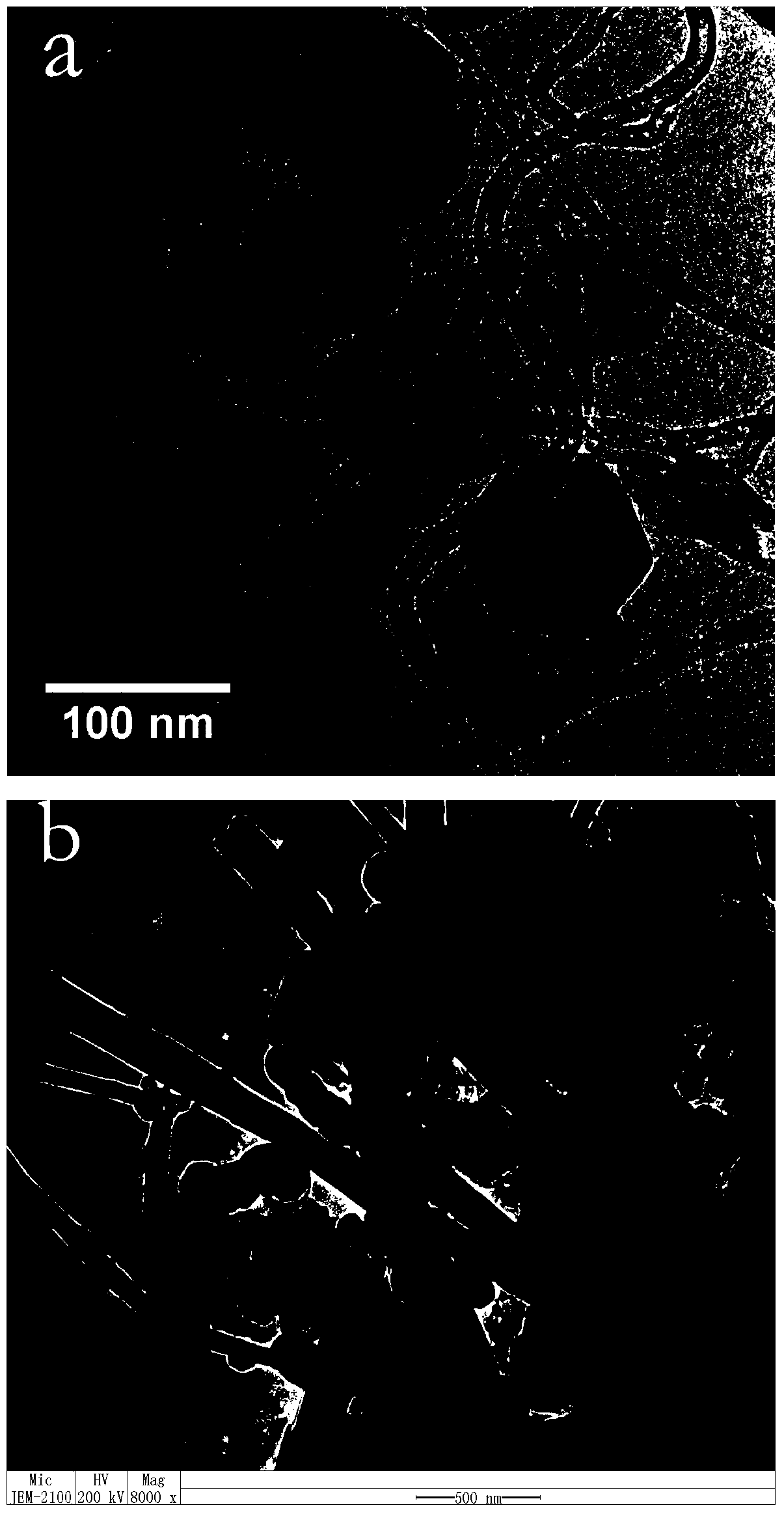

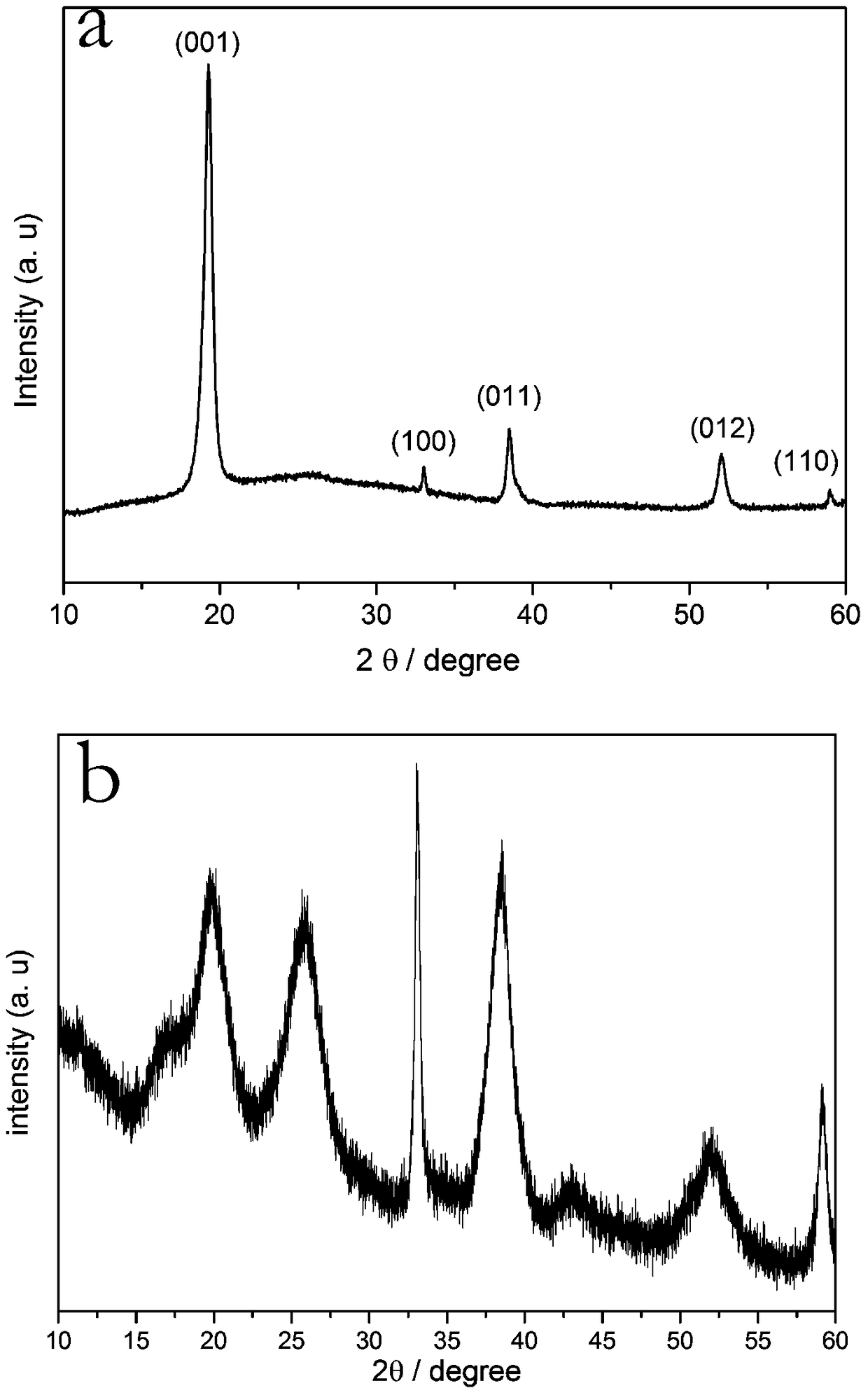

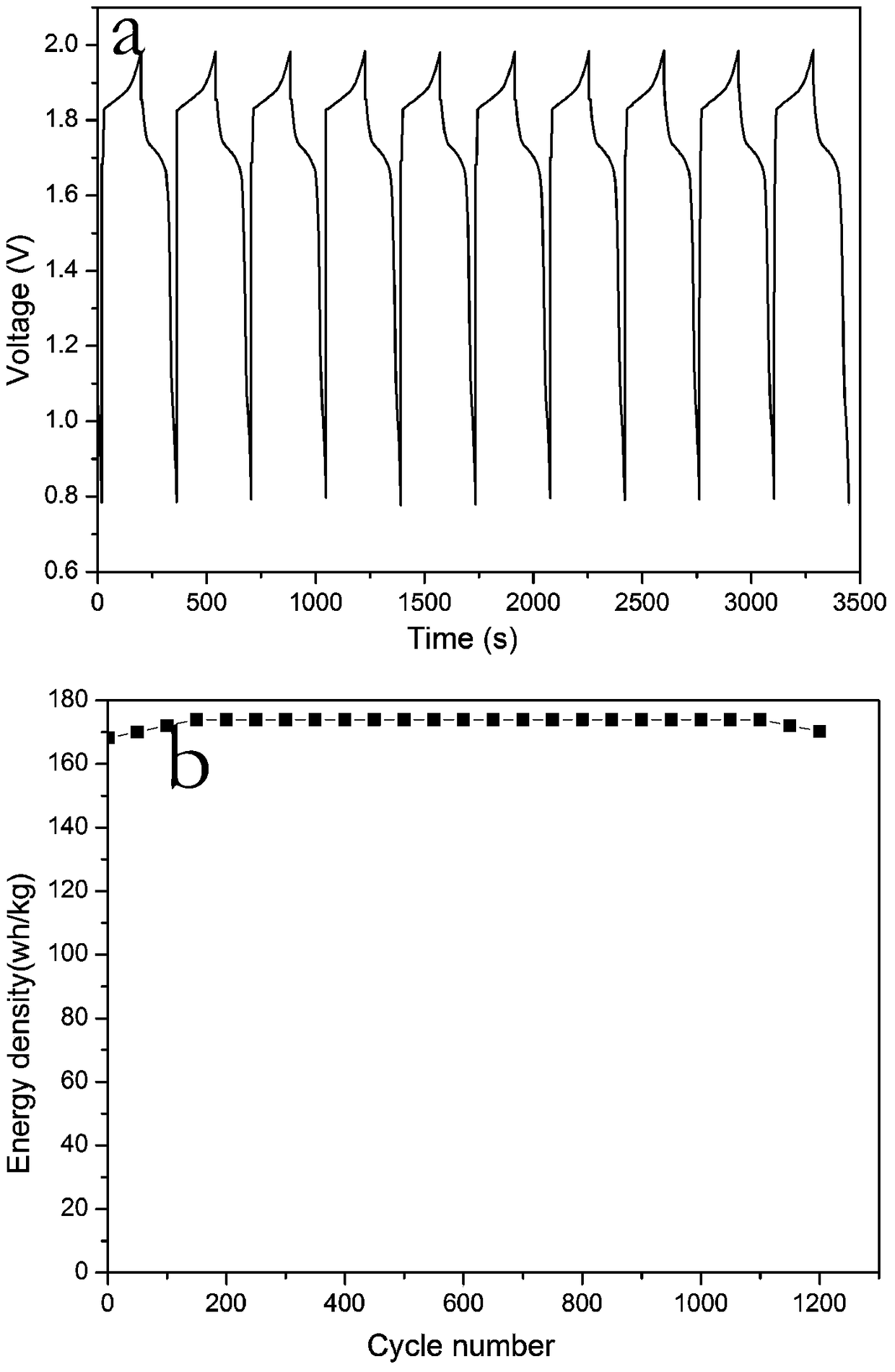

Anode material of zinc-nickel battery, as well as preparation method and application thereof

ActiveCN106848281AWide variety of sourcesLow costElectrode thermal treatmentAlkaline accumulator electrodesElectrical batteryPhysical chemistry

The invention belongs to the technical field of battery materials, and discloses an anode material of a zinc-nickel battery, as well as a preparation method and application thereof. In the anode material for a zinc-nickel battery, basic zinc carbonate is an active material, and is prepared by reacting urea or ammonium bicarbonate with zinc salt. The invention further discloses formulae of basic zinc carbonate, a conductive agent, an additive and binder in the anode material of a zinc-nickel battery. The test result for a soft NiZn battery constructed by using basic zinc carbonate as an anode active substance indicates that the integral electrochemical performance of electrodes and batteries containing the material is improved when the material is used as a battery anode material. The prepared soft battery has excellent coulombic efficiency and cycling life, the energy density of a battery is 130Wh.kg<-1>, and the circulating stability is not less than 1200 times.

Owner:JIANGSU UNIV OF TECH

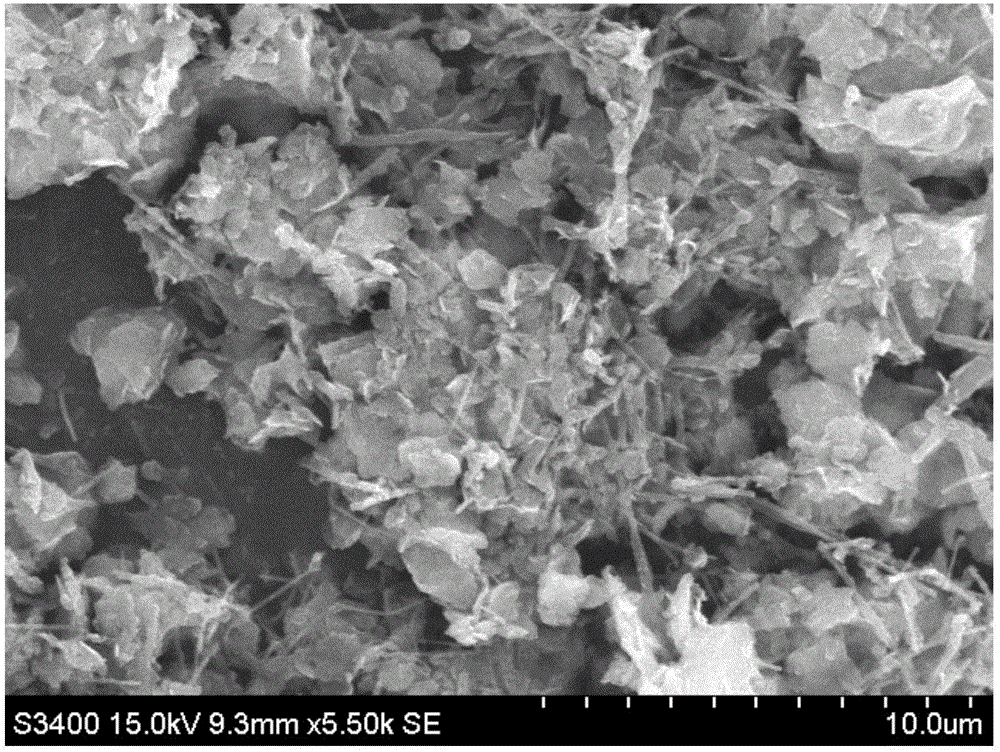

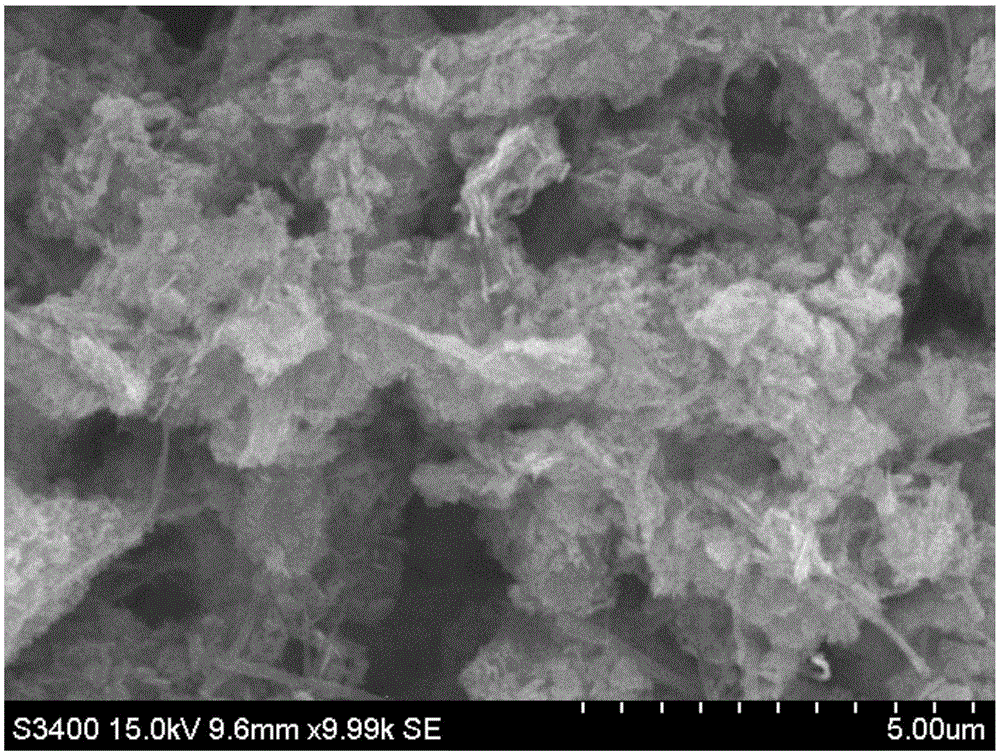

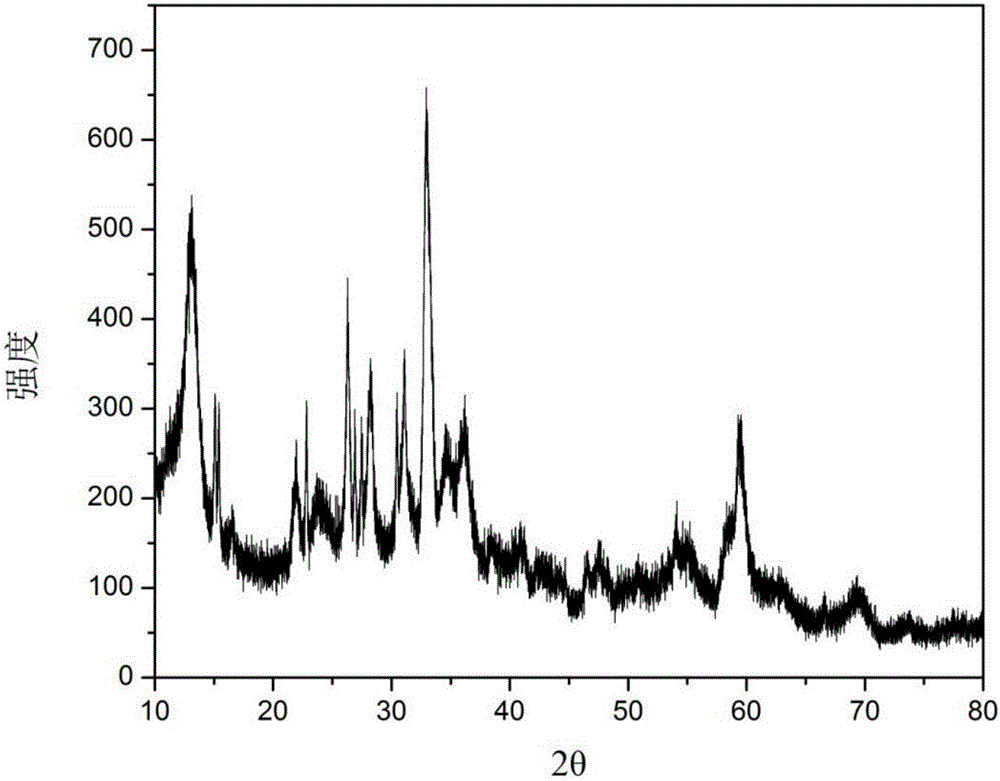

Cathode material for nickel-zinc battery and nickel-zinc battery employing cathode material

ActiveCN105449194AEasy to getQuick migrationCell electrodesNickel accumulatorsCarbon compositesDispersity

The invention discloses a preparation method of a cathode material for a nickel-zinc battery. The method comprises large-scale modification of a carbon material, so that the surface has an oxygen-containing group, and the carbon material has good dispersity in water or an organic solvent. The invention further discloses a preparation method of an Ni(OH)<2> / carbon composite material. The material is applied to a positive electrode and a Zn negative electrode to construct a soft package NiZn battery. A test result shows that the material improves the electric contact performance of the electrodes when used as an electrode material, so that the overall electrochemical properties of the electrodes and the battery including the material are improved.

Owner:JIANGSU UNIV OF TECH

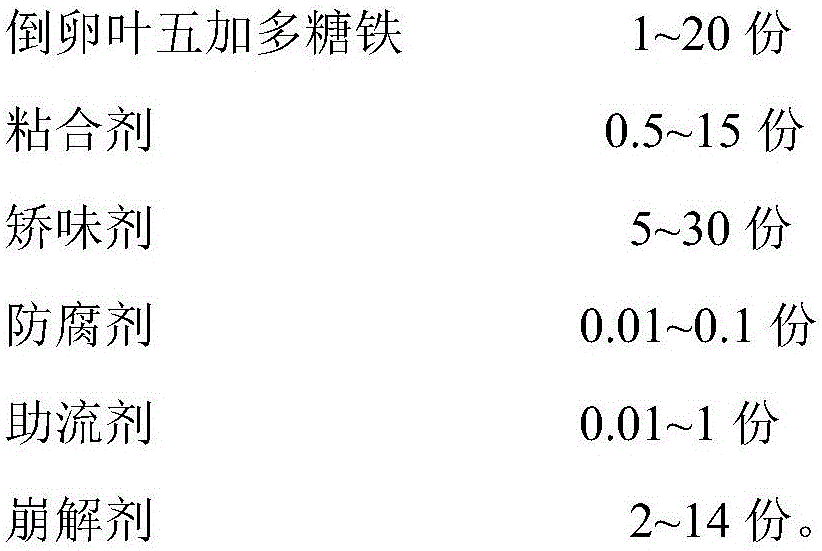

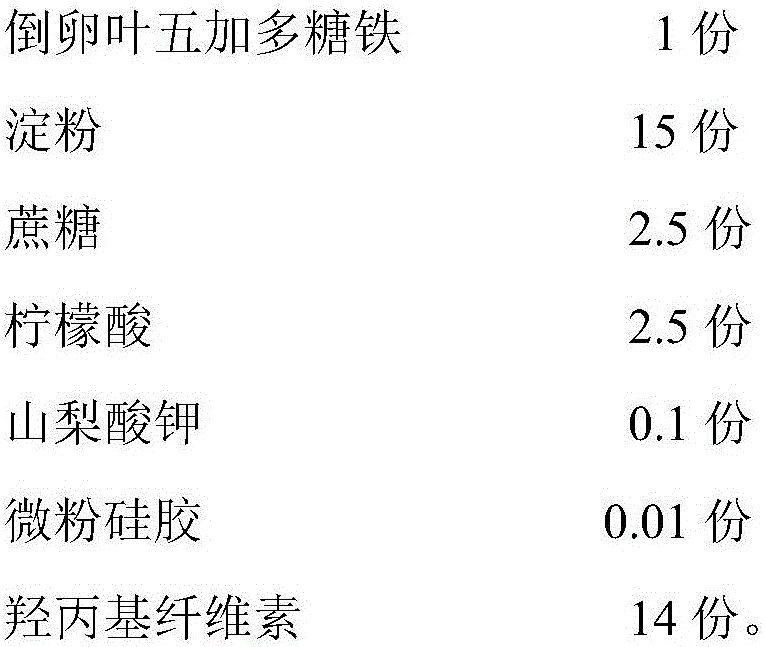

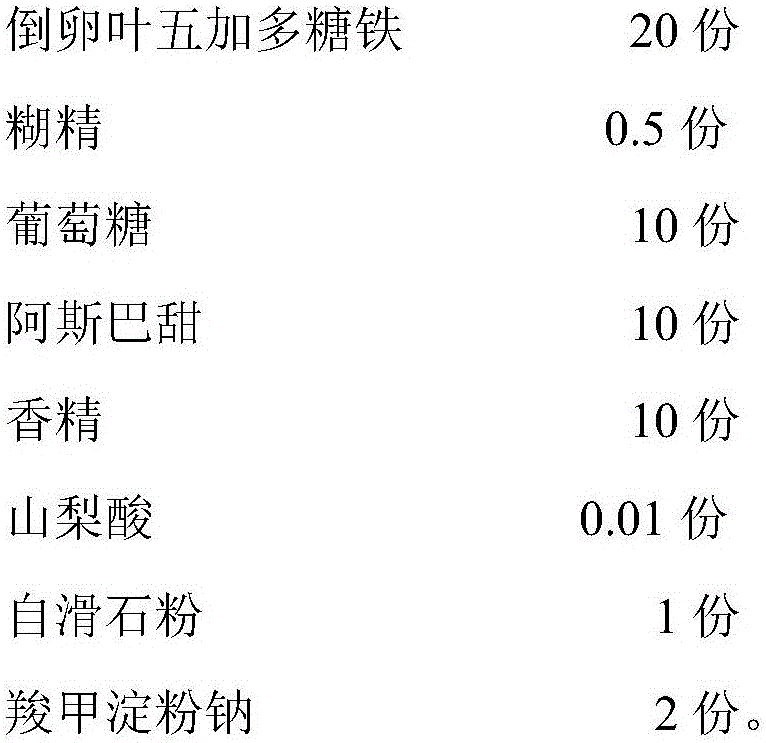

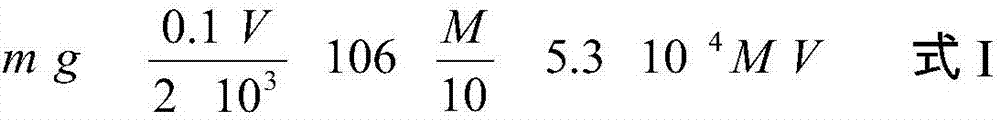

Preparation method of acanthopanax obovatus Hoo polysaccharide iron and application thereof

InactiveCN105777925AGood effect of iron supplementationReduce manufacturing costHeavy metal active ingredientsOrganic active ingredientsSide effectIron supplement

The invention discloses a preparation method of acanthopanax obovatus Hoo polysaccharide iron and application of the acanthopanax obovatus Hoo polysaccharide iron, and belongs to the technical field of pharmaceutical synthesis. The preparation of the acanthopanax obovatus Hoo polysaccharide iron particularly comprises the following steps: 1, preparing an acanthopanax obovatus Hoo polysaccharide composite membrane; 2, preparing the acanthopanax obovatus Hoo polysaccharide iron. The preparation method of the invention has less reaction steps, mild reaction conditions, good reproducibility and reliable process conditions, and further has operability and suitability for industrial production. In addition, an iron supplement preparation provided by the invention is good in iron supplementing effect, low in production cost and small in side effect on intestines and stomach.

Owner:宋逍

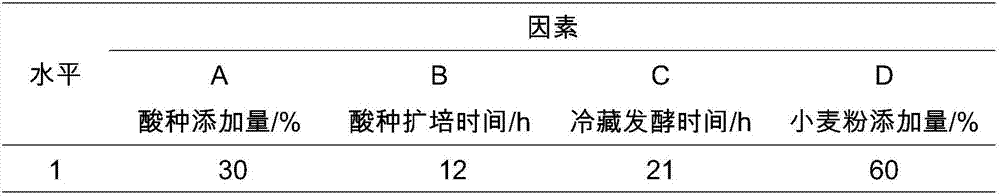

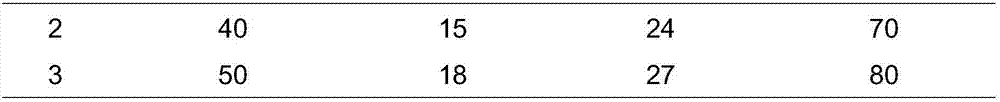

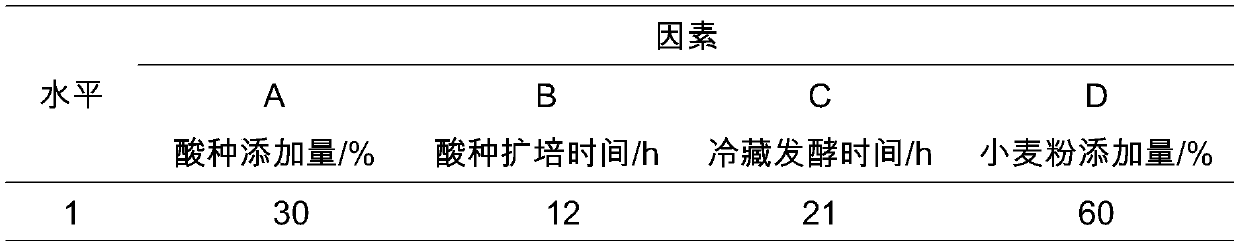

Method for making sour dough steamed bun based on refrigeration sponge-dough method

ActiveCN106889443AStable and reliable process conditionsEase of industrial productionFood scienceFood flavorRefrigeration

The invention provides a method for making a sour dough steamed bun based on a refrigeration sponge-dough method. The method comprises the following steps: mixing a sour dough, water and wheat meal and fermenting a prepared a sponge dough in a refrigeration manner at the temperature of 2-6 DEG C for 21-27h, wherein the mass of the wheat meal used for preparing the sponge dough takes 50%-80% of the total weight of wheat meal of the sour dough steamed bun, and the using amount of the sour dough takes 30%-50% of the total weight of the wheat meal of the sour dough steamed bun; standing the sponge dough, tempering and mixing the sponge dough with alkali fly, water and wheat meal, so as to prepare a main dough; dividing the main dough, pressing the dough, forming and proofing, steaming the proofed dough, so as to obtain the sour dough steamed bun. The prepared steamed bun does not have pungent smell, so that the prepared sour dough steamed bun has the characteristics of abundant and heavy flavors. Meanwhile, reference bases can be provided for industrial production of the sour dough steamed bun, and industrialization and large-scale production of the sour dough steamed bun are promoted favorably.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

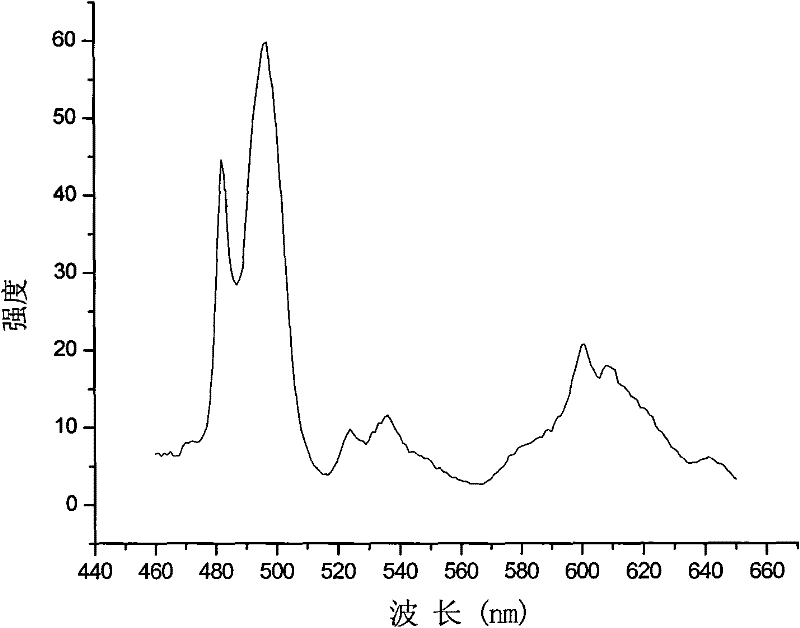

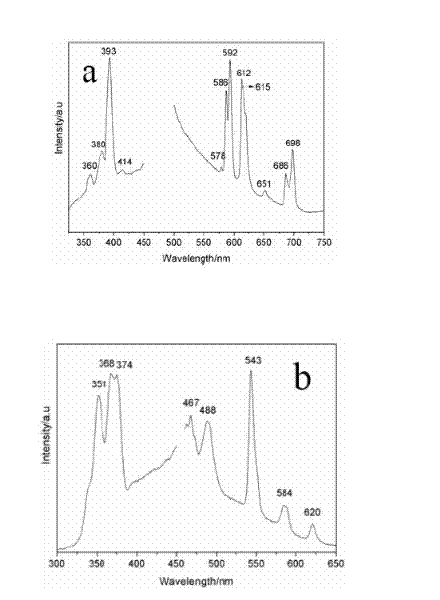

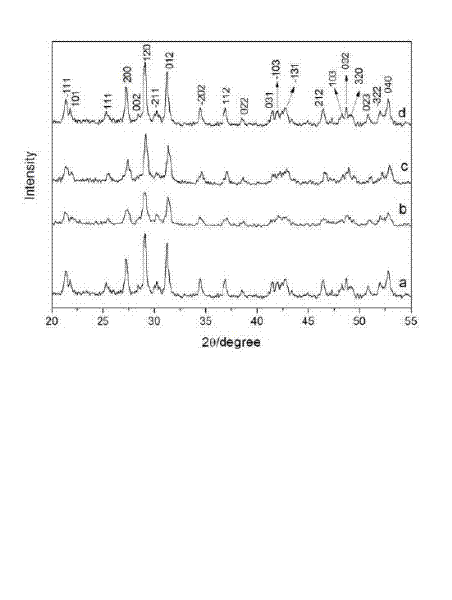

Sm3+ glass doping brilliant glass ceramics and preparation method thereof

The invention discloses a preparation method of Sm3+ glass doping brilliant glass ceramics. The Sm3+ glass doping brilliant glass ceramics consists of XZnO-YB2O3-ZSiO2-RNa2O-MAl2O3-NTiO2-QZrO2-TSm2O3, zinc oxide, boric acid, silicon dioxide, aluminum oxide, sodium carbonate, titanium dioxide, zirconium dioxide and samarium sesquioxide serve as raw materials, raw materials are melted at the temperature from 1,400 DEG C to 1,500 DEG C after being grinded and mixed, glass is produced, the annealing is conducted for 2-3 hours at the temperature from 500 DEG C to 550 DEG C, and the glass is cooled to the room temperature. The crystallization treatment is conducted, the coring is conducted for 2-2.5 hours at the temperature from 550 DEG C to 575 DEG C, the crystallization is conducted for 6-12 hours at the temperature from 720 DEG C to 740 DEG C and the zinc borosilicate brilliant glass ceramics is obtained. The method is simple in process, reliable and stable in process condition, wide in application and good in physical and chemical stability. The luminescent property of the glass ceramics is better than that of normal glass materials.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

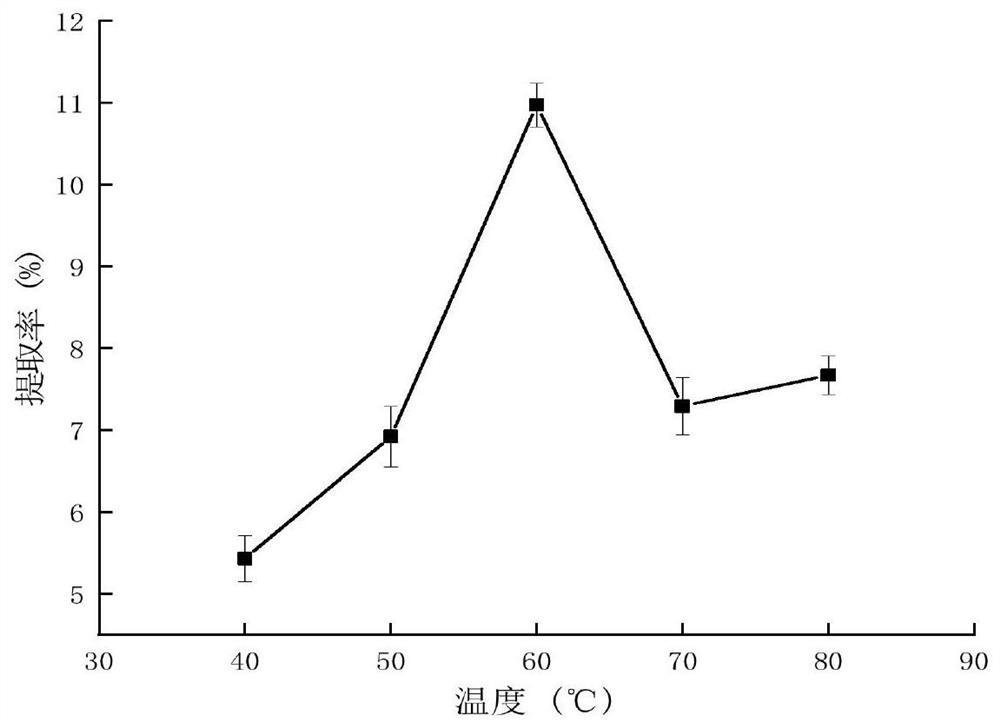

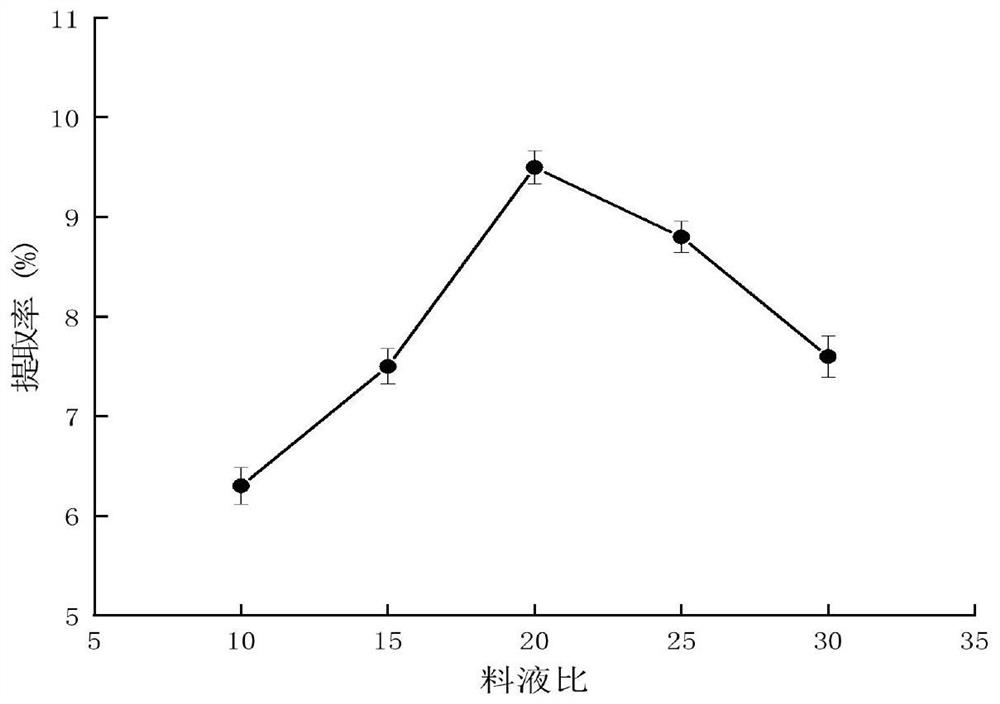

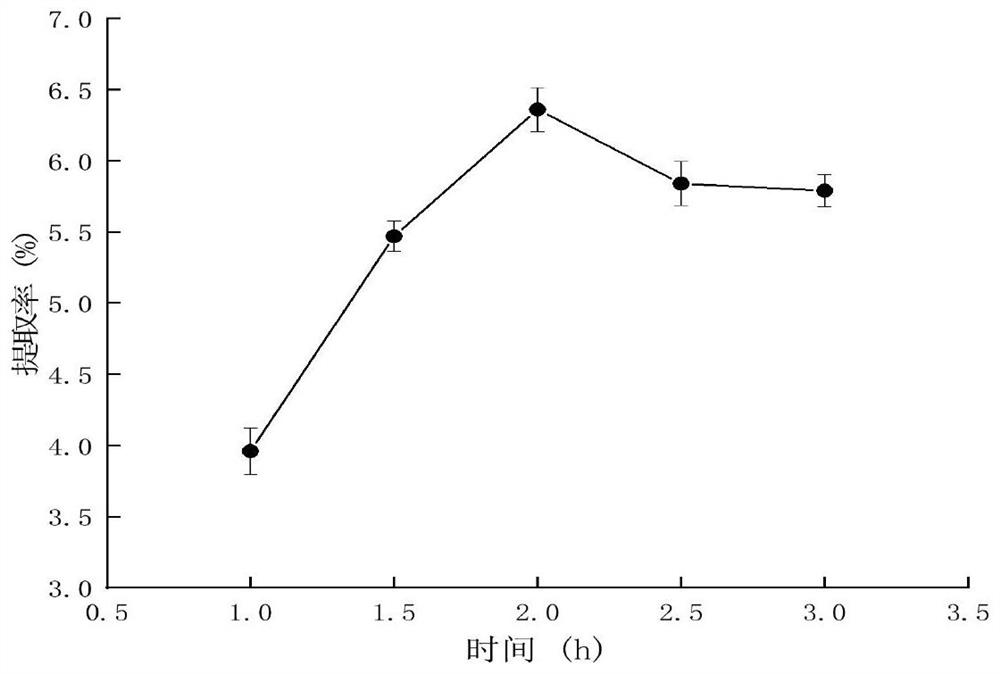

Method for optimizing sweet potato polysaccharide extraction conditions based on response surface method

PendingCN112239509AStable and reliable process conditionsSimple extraction processColor/spectral properties measurementsSystems biologyProcess engineeringAlcohol ethyl

The invention relates to a method for optimizing sweet potato polysaccharide extraction conditions based on a response surface method. The method comprises the following steps: peeling and cutting sweet potatoes into strips, performing freezing-drying, drying, smashing and sieving; extracting sweet potato polysaccharide by a water extraction and alcohol precipitation method, and determining variable parameters of sweet potato polysaccharide extraction by a response surface method; adding petroleum ether for degreasing, and adding ethanol into the precipitate; adding water and performing extracting; performing centrifuging, performing concentrating, adding absolute ethyl alcohol, standing overnight, and performing centrifuging to prepare a crude polysaccharide solution; removing protein, performing decolorizing, performing concentrating and performing dialyzing to obtain crude sweet potato polysaccharide. Variable parameters of sweet potato polysaccharide extraction are determined by adopting a response surface method, and a four-factor three-level response surface analysis test is designed, so the optimal extraction process condition of sweet potato polysaccharide is optimized, anda reference basis is provided for comprehensive development and utilization of sweet potatoes. The actual value is very close to the theoretical predicted value. Therefore, the response surface optimization of the Design-Expert software on the sweet potato polysaccharide extraction process condition is reliable, and the method has a practical value.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

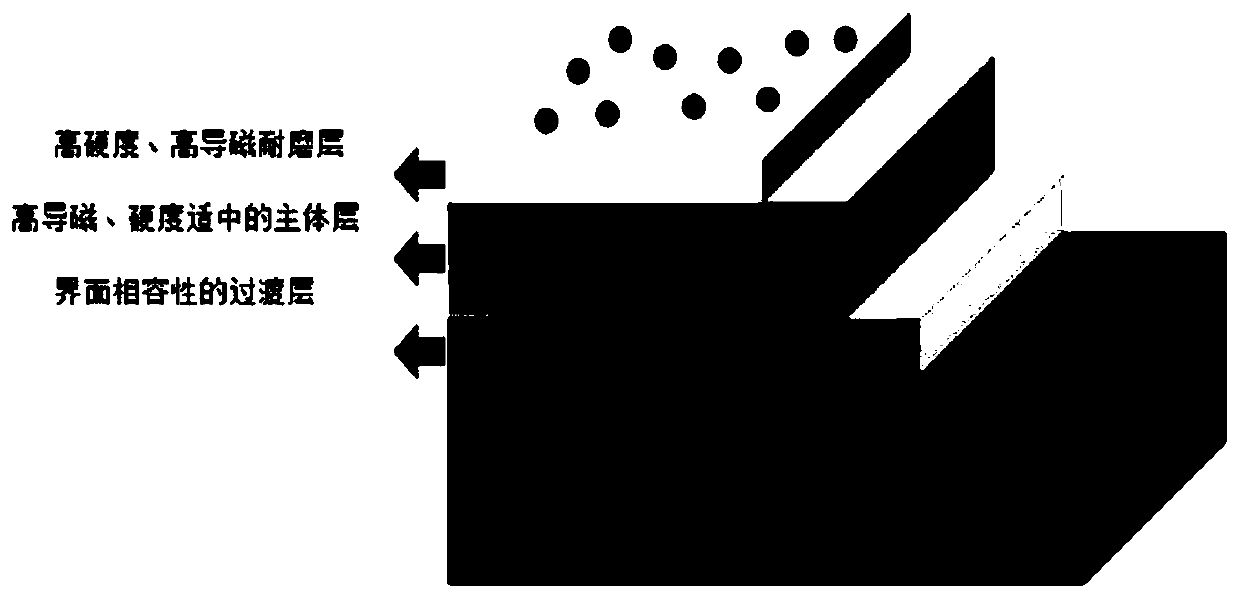

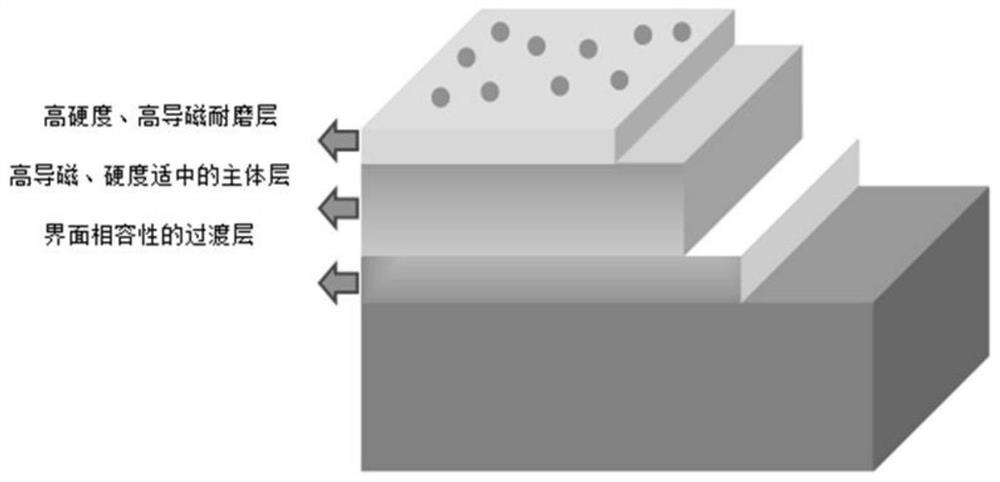

Titanium alloy surface high-magnetic-conductivity wear-resistant coating material for magnetic fluid sealing, preparation method thereof and application thereof

ActiveCN111593344AHigh hardnessImprove magnetic permeabilityEngine sealsTransportation and packagingConductive coatingHigh wear resistance

The invention belongs to the technical field of surface protection and magnetic conductive coatings, and discloses a titanium alloy surface high-magnetic-conductivity wear-resistant coating material for magnetic fluid sealing, a preparation method of the titanium alloy surface high-magnetic-conductivity wear-resistant coating material and application of the titanium alloy surface high-magnetic-conductivity wear-resistant coating material. The titanium alloy surface high-magnetic-conductivity wear-resistant coating material sequentially comprises a wear-resistant layer, a body layer and a transition layer. The transition layer is located between a substrate and the body layer. The transition layer comprises 85%-97% of iron-cobalt-vanadium alloy, 1%-5% of Si and 1%-5% of B. The body layer comprises 85-95% of iron-cobalt-vanadium alloy, 2%-5% of Si, 2%-5% of B and 1%-5% of WC. The wear-resistant layer comprises 70%-80% of iron-cobalt-vanadium alloy, 1%-5% of Si, 1%-5% of B and 10%-20% ofWC. The coating material integrates multiple functions of the high hardness, the high wear resistance and the high magnetic conductivity. A laser cladding method is adopted to manufacture the coatingmaterial, and the coating material can serve as a titanium alloy part of a magnetic fluid sealing system to be applied to the field of aerospace.

Owner:GUANGDONG UNIV OF TECH +1

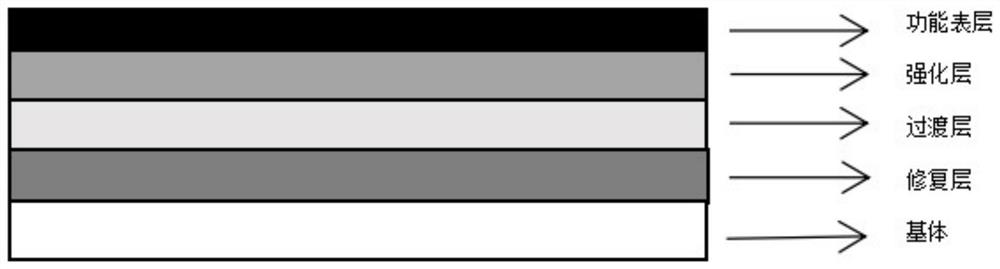

Titanium alloy surface repairing and strengthening functional coating integrated coating material and preparation method and application thereof

PendingCN114293148AImprove impact resistanceEffective combinationVacuum evaporation coatingSputtering coatingDiamond-like carbonOxidation resistant

The invention belongs to the technical field of surface modification, and discloses a titanium alloy surface repairing and strengthening functional coating integrated coating material and a preparation method and application thereof. The coating material sequentially comprises a high-hardness and self-lubricating functional surface layer, a wear-resistant, high-temperature-resistant and oxidation-resistant strengthening layer, a transition layer (moderate in hardness) and a size repair layer with strong film-substrate combination, the size repair layer is located on the surface of a substrate and is composed of Ti, the transition layer is composed of TiAl, the strengthening layer is composed of TiAlN, and the thickness of the size repair layer is larger than that of the substrate. And the functional surface layer is made of DLC (Diamond Like Carbon). The coating material has the advantages of being high in hardness, good in abrasion resistance, high temperature resistance and oxidation resistance and capable of achieving repairing and strengthening integration and multiple functions. A vacuum arc deposition and magnetron sputtering composite physical vapor deposition method is adopted for preparation, the coating material can be used for surface protection of a titanium alloy transmission part, and the coating material plays an important role in improving the reliability and stability of manufacturing equipment in China.

Owner:GUANGDONG UNIV OF TECH

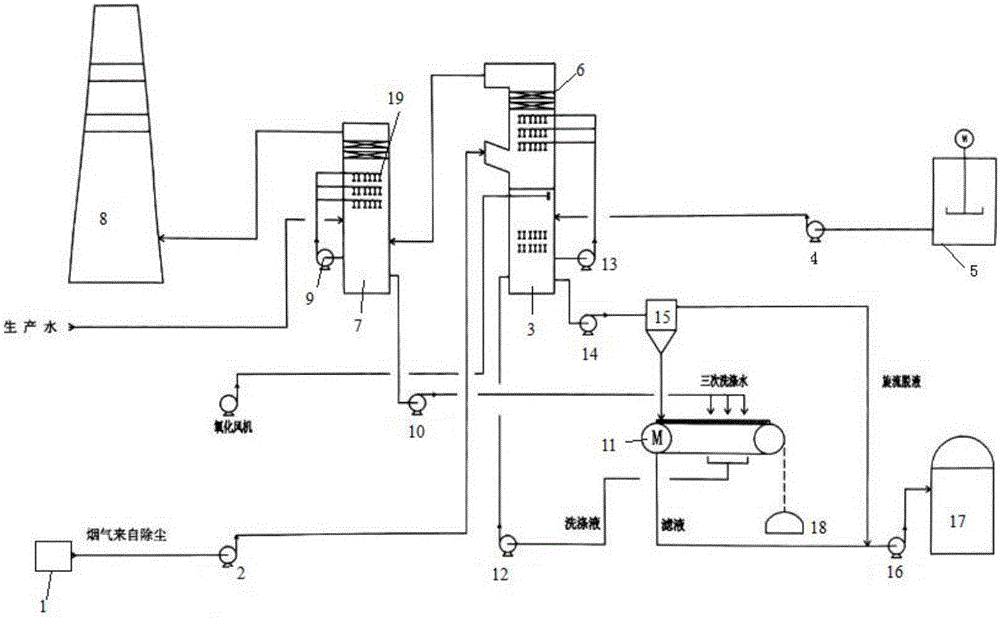

Phosphate ore-phosphoric acid-gypsum process flue gas desulphurization system and process

InactiveCN106178920AAchieve emission standardsThe reaction process is feasibleDispersed particle separationPhosphoric acidPhosphateResource utilization

The invention discloses a phosphate ore-phosphoric acid-gypsum process flue gas desulphurization system and process. Phosphate ore is crushed and ground into powder, and phosphoric ore pulp is prepared by means of a phosphate ore slurry box and is continuously conveyed and supplemented into a desulfurizing absorption tower; boiler smoke output from a boiler dust remover enters the desulfurizing absorption tower through an outlet pipeline of an induced draft fan and makes countercurrent contact with the phosphoric ore pulp from the desulfurizing absorption tower for a desulfurizing absorption reaction; desulfurized tail gas passes through a demister of the desulfurizing absorption tower, and carried liquid drops are removed; the tail gas from the top of the desulfurizing absorption tower enters a defluorination absorption tower and makes contact with a fluorine circulating liquid, a washing absorption liquid is sent by a defluorination absorption liquid tower to a belt-type vacuum filtering machine to serve as ardealite washing water and then conveyed to the desulfurizing absorption tower through a diluted phosphoric acid pump to be recycled; washed desulfurization and defluorination purified smoke passes through a cyclone demister and is discharged to the air through a chimney. The phosphate ore-phosphoric acid-gypsum process flue gas desulphurization system and process have the characteristics of meeting circular economy, resource utilization and sustainable development.

Owner:SHAANXI CARBONIFICATION ENERGY CO LTD

Method for preparing sheet silver powder with high dispersibility

ActiveCN101279369BGood dispersionMeet different performance requirementsShaking/oscillating/vibrating mixersApparent densityMetallurgy

The invention discloses a preparation method of high-dispersion flake silver powder, which is characterized in that spherical raw material silver powder with the1 to 3Mum of particle size D50 and the more than 99.95 percent of silver content is ground into the flake silver powder by adopting a grinding machine, the dispersion is then improved by ultrasonic dispersion and airflow dispersion, and the high-dispersion flake silver powder with the 3 to 25Mum of flake diameter D50 and the apparent density of 0.5 to 1.8g / cm<3> is obtained. The preparation process has simple process flow, which is applicable to the industrial mass production of flake silver powder.

Owner:JINCHUAN GROUP LIMITED

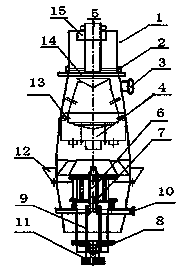

Supersonic jet gun used in jet flow homogeneous filter

InactiveCN104001424AHigh clarityImprove storage stabilitySemi-permeable membranesPhysicsChinese herbs

The invention relates to a supersonic jet gun used in a jet flow homogeneous filter, and relates to the biological engineering plant cell blasting, extraction and purification; the supersonic jet gun can reach the flow velocity above 2 M / S, the supersonic jet gun impacts a telescopic target fixedly arranged on an outlet end, the telescopic target can actively adjust the impact distance by an adjusting nut, strengthens the target cell blasting effect, and meets the requirements of extract ingredients, and compared with a usual method, the measurable content of effective components of a preparation by use of the supersonic jet gun is 10-100% higher, so that raw materials are saved, a lot of solvent is saved, the supersonic jet gun is precisely designed, easy to manufacture, and more ideal in filtering homogenizing effect, particularly brings biggest convenience and flexibility for Chinese herbal medicine development and industrial production, and provides reliable technical conditions for the production of various types of unique creative products.

Owner:北京飞潮环境工程技术有限公司 +1

Nano silver paste for chip mounting and method for preparing nano silver paste

ActiveCN102935518BNo pollution in the processLower sintering temperatureMaterial nanotechnologyReducing agentElectrolyte

The invention provides a method for preparing a nano silver paste. The method includes step A, a reducing agent and a dispersing agent are dropwise added in a silver nitrate solution and stirred; step B, the solution obtained through the step A is subjected to centrifugation to obtain nano silver particles with upper layers as mixed solutions and lower layers as sedimentation; step C, the nano silver particles separated through the step B is cleaned by deionized water and subjected to flocculation by a electrolyte solution, and nano silver particles capable of being subjected to centrifugation are re-precipitated; step D, the nano silver particles are subjected to cleaning, flocculation and centrifugation for a plurality of times to obtain a water-soluble nano silver paste; and step E, the nano silver paste is applied to a chip and a substrate surface to be interconnected, and the interconnected chip and substrate surface is heated in a hot air work bench or a stove to form a sintering joint.

Owner:深圳市先进连接科技有限公司

A method for making sourdough steamed buns based on fermentation in cold storage

The invention provides a method for making a sour dough steamed bun based on a refrigeration sponge-dough method. The method comprises the following steps: mixing a sour dough, water and wheat meal and fermenting a prepared a sponge dough in a refrigeration manner at the temperature of 2-6 DEG C for 21-27h, wherein the mass of the wheat meal used for preparing the sponge dough takes 50%-80% of the total weight of wheat meal of the sour dough steamed bun, and the using amount of the sour dough takes 30%-50% of the total weight of the wheat meal of the sour dough steamed bun; standing the sponge dough, tempering and mixing the sponge dough with alkali fly, water and wheat meal, so as to prepare a main dough; dividing the main dough, pressing the dough, forming and proofing, steaming the proofed dough, so as to obtain the sour dough steamed bun. The prepared steamed bun does not have pungent smell, so that the prepared sour dough steamed bun has the characteristics of abundant and heavy flavors. Meanwhile, reference bases can be provided for industrial production of the sour dough steamed bun, and industrialization and large-scale production of the sour dough steamed bun are promoted favorably.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

A kind of nano-silver/epoxy resin composite thermal interface material and preparation method thereof

InactiveCN106589829BNo pollution in the processImprove heat transfer efficiencyHeat-exchange elementsEpoxyHeat transfer efficiency

The invention relates to a nanosilver / epoxy resin composite thermal interface material and a preparation method thereof. The nanosilver / epoxy resin composite thermal interface material is prepared through the following method: (1) adding silver salt to a complexing agent, and performing uniform mixing so as to obtain a silver complex; and sequentially adding the silver complex, a reducing agent containing two aldehyde groups and an imidazole curing agent to epoxy resins, and performing uniform mixing so as to obtain mixed sol; and (2) pouring the mixed sol obtained in the step (1) to a mold, placing the mold in a heating box, performing heating under the constant temperature of 50-70 DEG C for 2-6h, then performing temperature rise to 90-130 DEG C, performing heating under constant temperature for 2-6h, so as to obtain the nanosilver / epoxy resin composite thermal interface material. According to the nanosilver / epoxy resin composite thermal interface material provided by the invention, the heat conductivity can reach 3.25W / mK, the interface heat-transfer efficiency is greatly improved, interface thermal resistance is effectively reduced, few defects exist and the properties are favorable.

Owner:WUHAN UNIV OF TECH +1

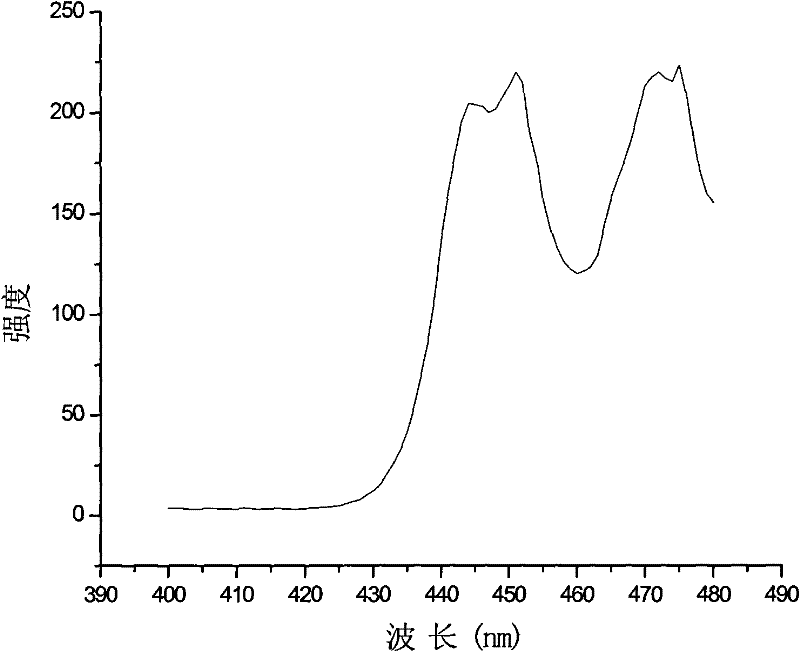

Inorganic aluminate luminescent microcrystalline glass and preparation method thereof

The invention discloses inorganic aluminate luminescent microcrystalline glass and a preparation method thereof. The inorganic aluminate luminescent microcrystalline glass is a substance shown as a chemical formula, namely, X SrO-Y Al2O3-Z SiO2-R Pr2O3, wherein X, Y, Z and R are molar fractions; X is more than or equal to 25 and less than or equal to 40; Y is more than or equal to 25 and less than or equal to 40; Z is more than or equal to 25 and less than or equal to 50; and R is more than or equal to 0.1 and less than or equal to 2. The preparation method comprises the following steps of: grinding strontium carbonate, alumina, silicon dioxide and praseodymium oxide serving as raw materials and mixing; fusing at the temperature of between 1,550 and 1,650 DEG C and molding the raw materials to obtain glass; and thermally treating the molded glass at the temperature of between 800 and 1,150 DEG C in a reducing atmosphere for 8 to 12 hours so as to obtain the inorganic aluminate luminescent microcrystalline glass. The inorganic aluminate luminescent microcrystalline glass has a relatively wide excitation spectrum in a blue light range, pure luminescent chromaticity, a stable physical property, a simple preparation method and low cost.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

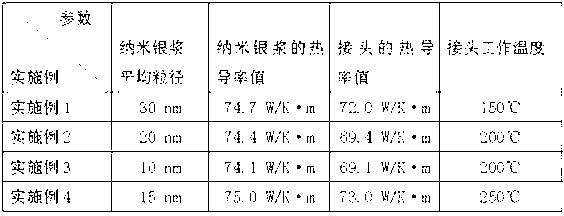

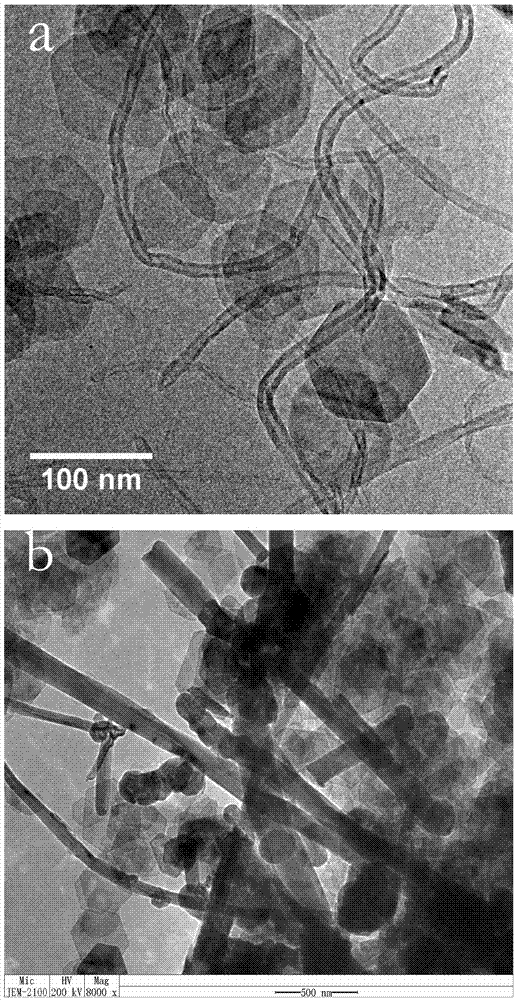

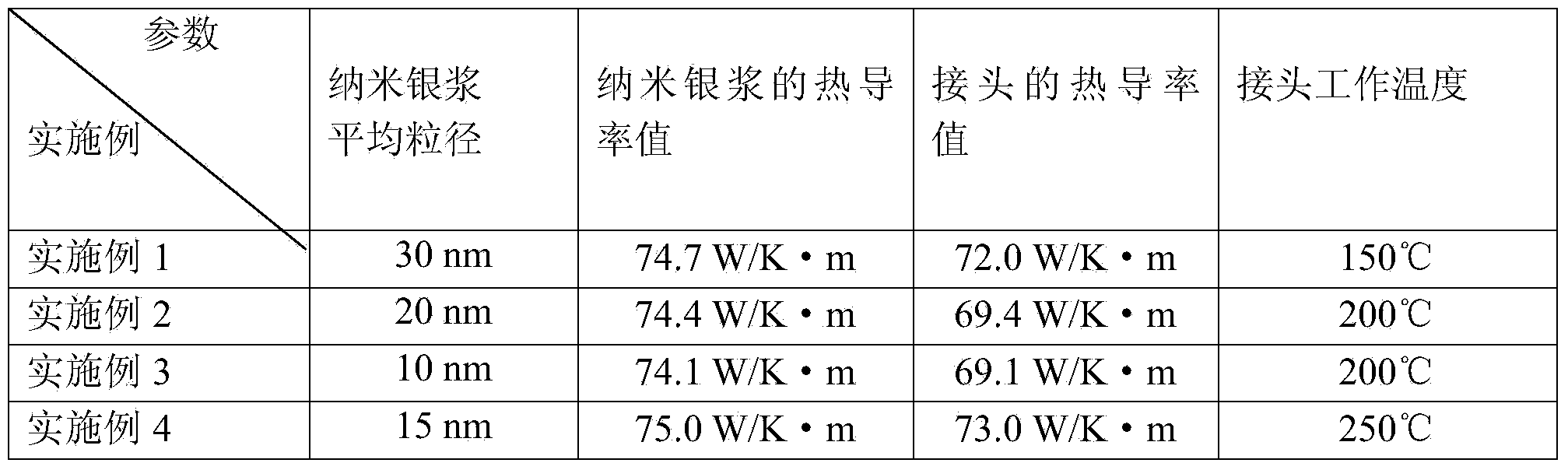

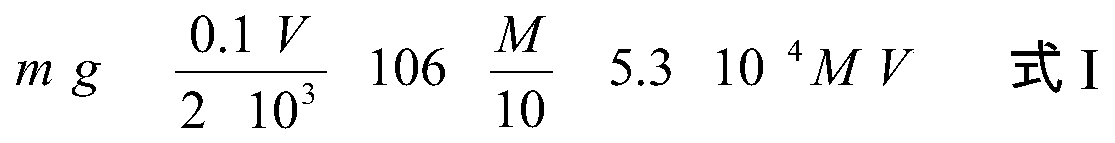

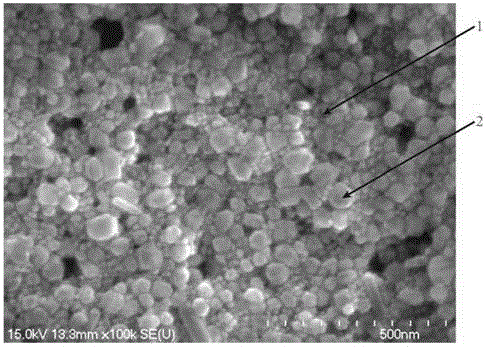

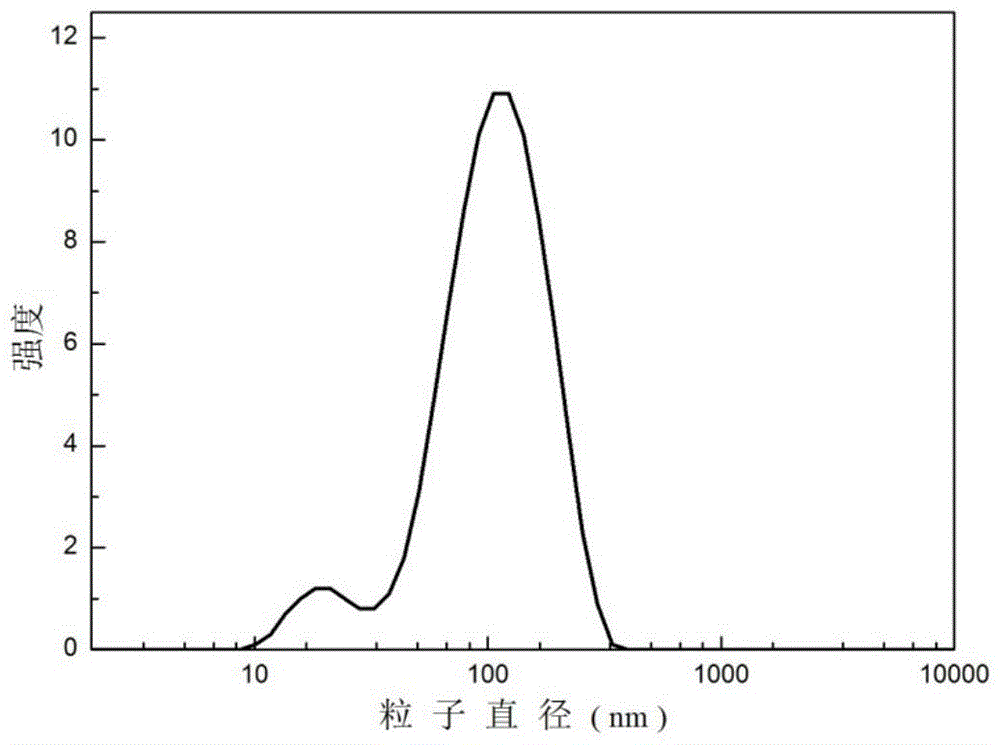

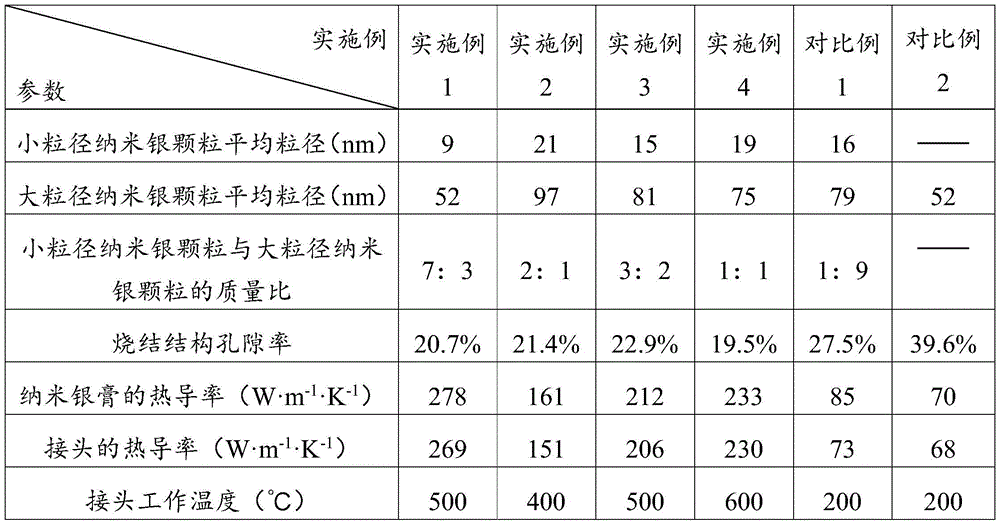

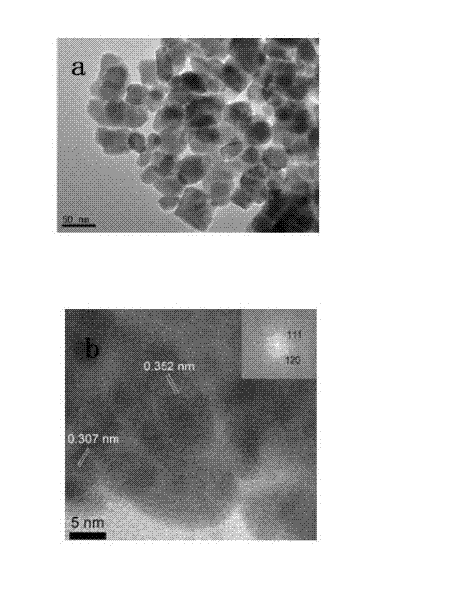

A bimodal distribution nano-silver paste used as thermal interface material and preparation method thereof

ActiveCN104668551BNo pollution in the processHigh thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesSilver pasteSilver particles

The invention provides bimodal distribution nano-silver paste serving as a thermal interface material and a preparation method of the bimodal distribution nano-silver paste. The preparation method comprises the following steps of mixing small-grain-diameter nano-silver particles with grain diameters of 5-20 nanometers, large-grain-diameter nano-silver particles with grain diameters of 30-150 nanometers and ultra-pure water according to a certain mass proportion of 4:1-1:1; mechanically stirring the mixture; ultrasonically dispersing the mixture and centrifuging the mixture; and removing an upper layer of solution so as to obtain the bimodal distribution nano-silver paste. The invention also provides a preparation method for the small-grain-diameter nano-silver particles with the grain diameters of 5-20 nanometers and the large-grain-diameter nano-silver particles with the grain diameters of 30-150 nanometers. Compared with unimodal distribution nano-silver paste and tin-lead solder, the bimodal distribution nano-silver paste which is prepared by the method has high heat conduction performance and high sintering structural stability. The preparation method is simple, preparation technological conditions are stable and reliable, the environment cannot be polluted, and the bimodal distribution nano-silver paste can be used industrially.

Owner:深圳市先进连接科技有限公司

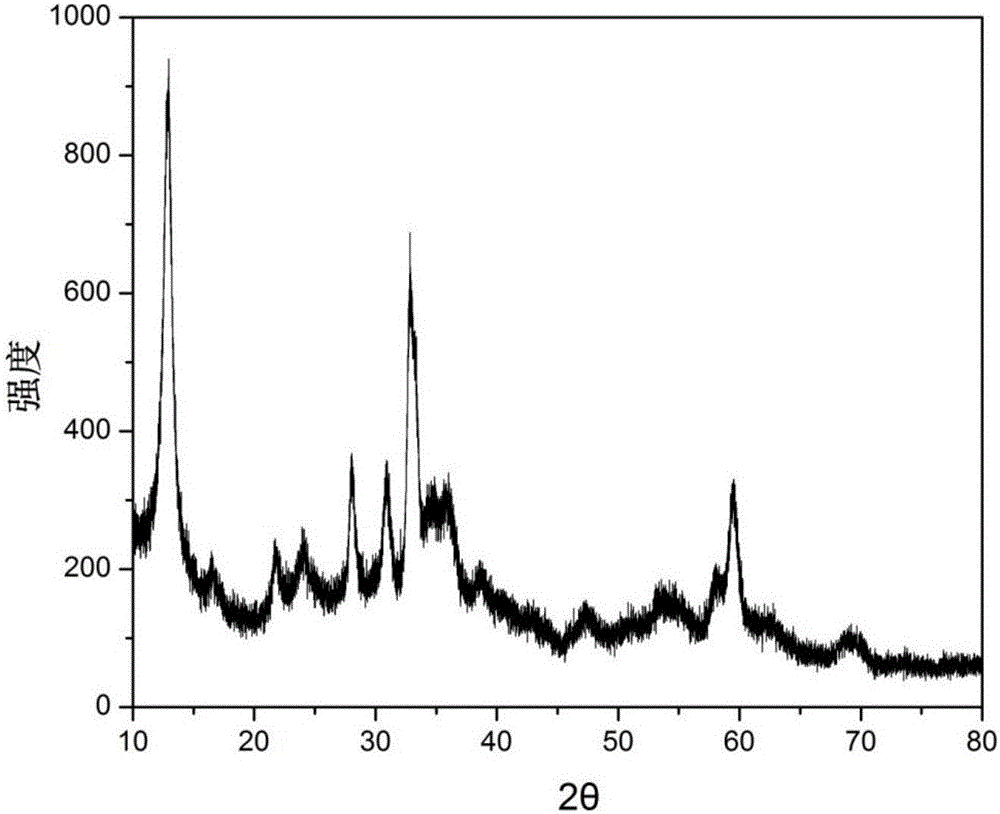

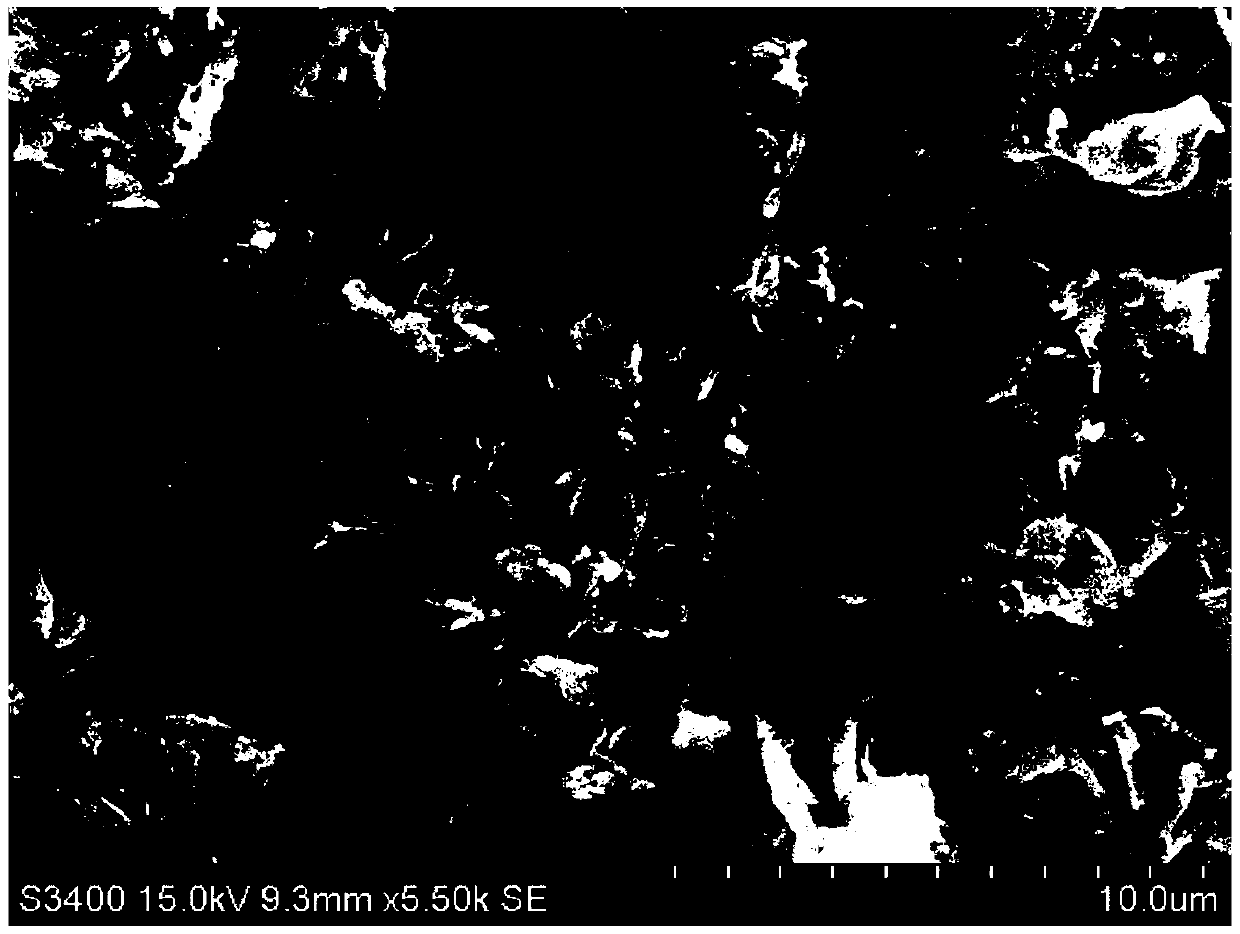

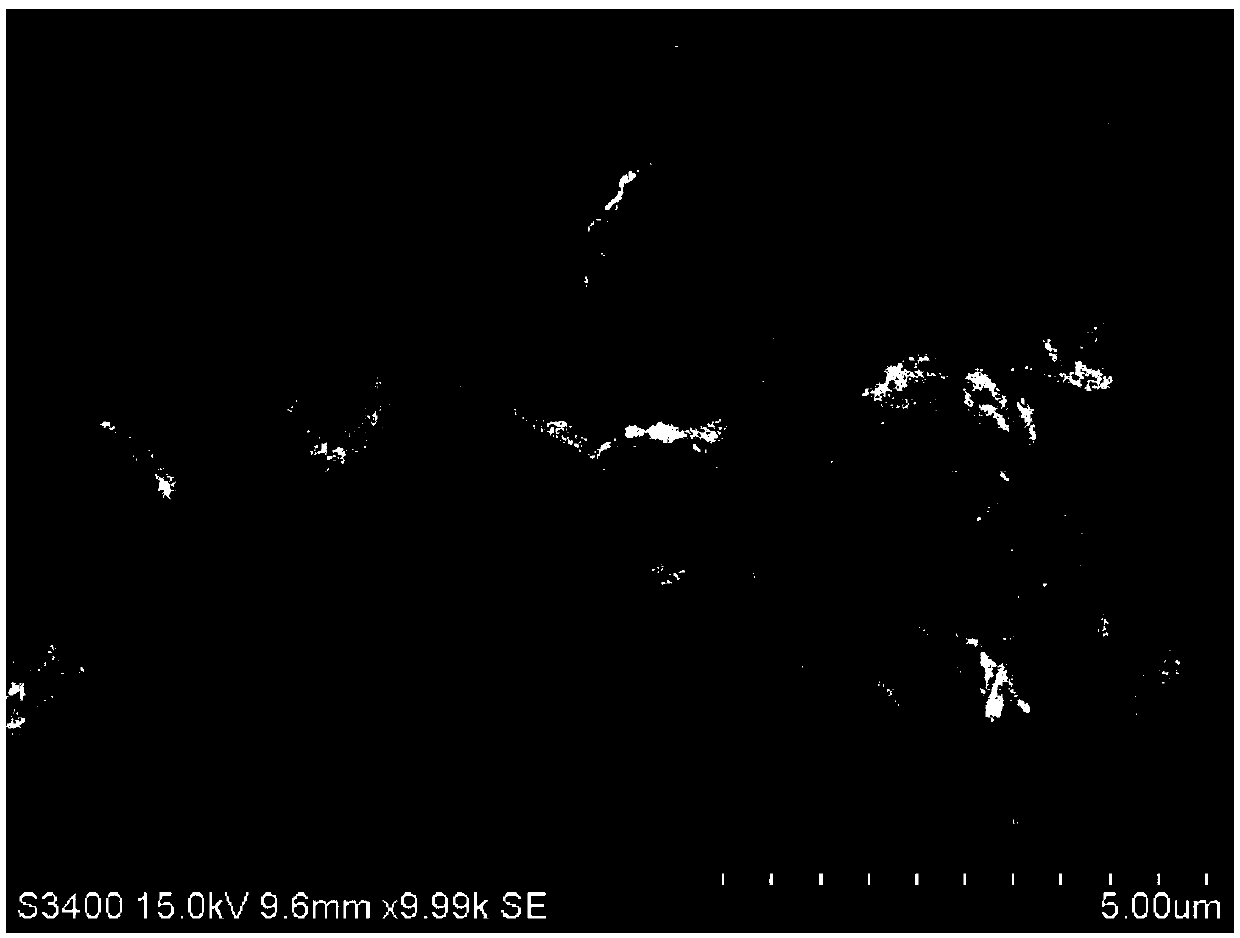

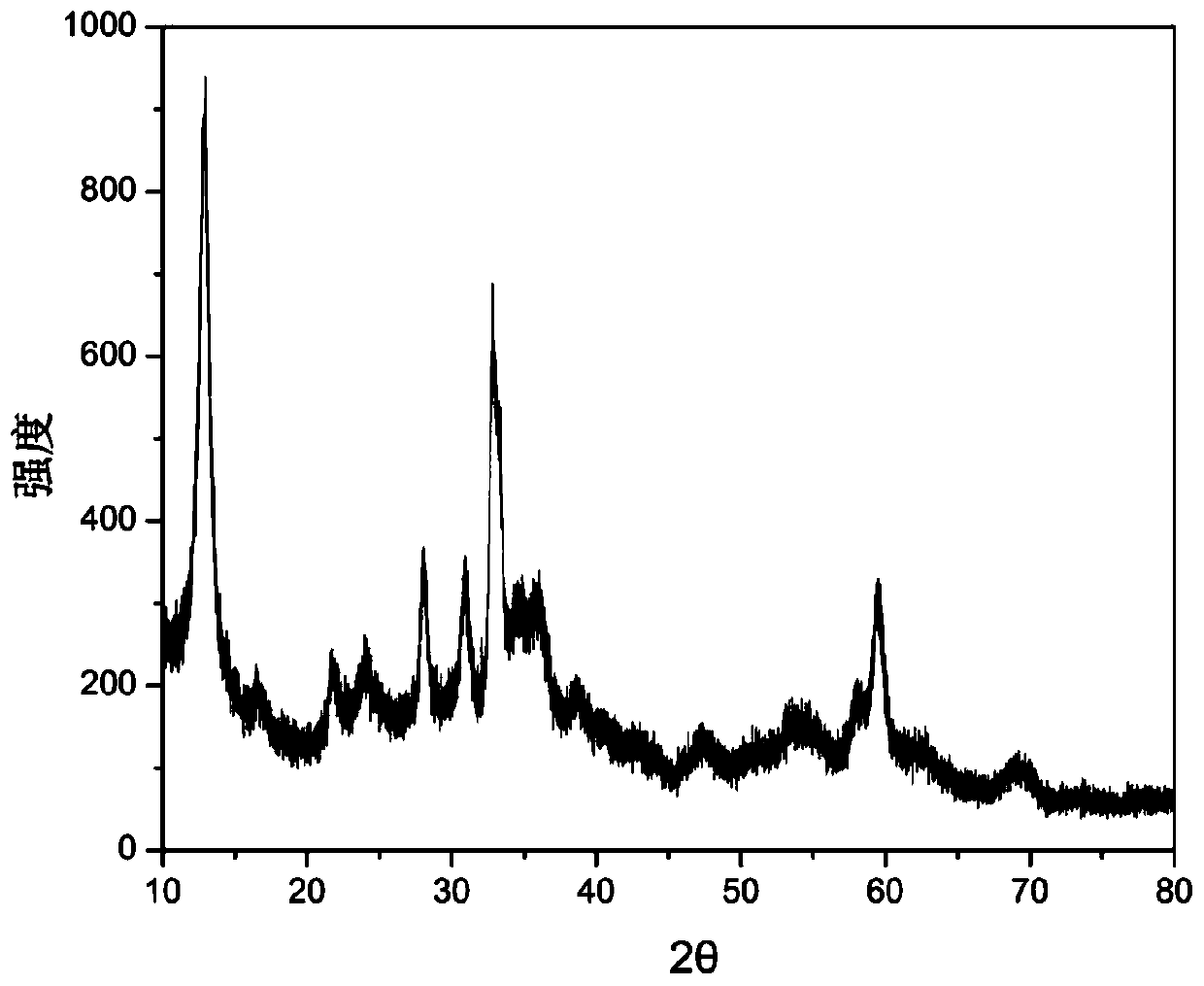

Rare earth phosphate nano-phosphor and preparation method thereof

InactiveCN101792666BEasy to getSmall particle sizeLuminescent compositionsLuminous intensityPhosphate

The invention discloses a rare earth phosphate nano-phosphor and a preparation method thereof. A synthesis method comprises the steps of taking polyphosphoric acid, nitric acid and rare earth nitrate as raw materials, taking sodium oleate as surfactant and performing hydrothermal treatment on precursors at 100 to 180 DEG C to obtain oil-soluble phosphor. According to the difference of rare earth ions contained, the phosphor emits visible red, green or light red light under the irradiation of 254nm-wavelength ultraviolet rays of a low-pressure mercury lamp. The obtained phosphor is white powder with small particle size, uniform size distribution and high luminescent intensity, and as the surfaces of phosphor particles adsorb hydrophilic groups COO- at one end of oleate ions while organic long chains at the other end of the oleate ions are oleophylic groups, the nano-phosphor has good dispersity in organic solvent and can be dispersed in the organic solvent to form transparent sol.

Owner:JIANGSU FOCUS NEW ENERGY TECH +1

Method for preparing spherical silver powder by using hydroxymethyl amino condensation product as dispersant

The invention relates to a method for preparing spherical silver powder by using a hydroxymethyl amino condensation product as a dispersant. The obtained superfine spherical silver powder can be used for preparing conductive slurry in the electronic industry. The method comprises the following steps: (1) preparing the hydroxymethyl amino condensation product serving as the dispersant by using an amine compound and formaldehyde solution; and (2) preparing mixed solution of a reducing agent and the dispersant, adjusting the pH value of the mixed solution of the reducing agent and the dispersantby using aqueous ammonia or nitric acid solution, adding silver nitrate solution into the mixed solution consisting of the reducing agent and the dispersant while stirring, and after the reaction is completed, standing, filtering, washing and drying the reaction product to obtain the superfine silver powder with different granularity from 0.5 to 3 microns.

Owner:SOUTHEAST UNIV

A kind of negative electrode material of zinc-nickel battery

ActiveCN106684362BLower internal resistanceIncrease profitCell electrodesNickel accumulatorsCarbon compositesHigh energy

Owner:JIANGSU UNIV OF TECH

Zinc-nickel battery cathode material, preparation method thereof, and zinc-nickel battery using the cathode material

ActiveCN105449194BEasy to getQuick migrationCell electrodesNickel accumulatorsDispersityCarbon composites

The invention discloses a preparation method of a cathode material for a nickel-zinc battery. The method comprises large-scale modification of a carbon material, so that the surface has an oxygen-containing group, and the carbon material has good dispersity in water or an organic solvent. The invention further discloses a preparation method of an Ni(OH)<2> / carbon composite material. The material is applied to a positive electrode and a Zn negative electrode to construct a soft package NiZn battery. A test result shows that the material improves the electric contact performance of the electrodes when used as an electrode material, so that the overall electrochemical properties of the electrodes and the battery including the material are improved.

Owner:JIANGSU UNIV OF TECH

A kind of preparation method of nano calcium hydroxide

InactiveCN104291371BHigh purityAvoid reunionMaterial nanotechnologyCalcium/strontium/barium oxides/hydroxidesCalcium hydroxideOrganic solvent

The invention provides a preparation method for nanometer calcium hydroxide. According to the preparation method, quick lime powder, organic solvent, and water are uniformly mixed according to a certain ratio, so that a suspending liquid is prepared; the suspending liquid is then placed into an ultrasound reactor for decomposition, so that calcium hydroxide particles with nanometer-scale grain size are prepared. The preparation method has the characteristics that the raw materials are cheap and can be easily obtained, the decomposition liquid can be repeatedly used, the preparation condition is mild, the preparation process is simple and convenient, and the prepared nanometer calcium hydroxide is high in purity and uniform in particle size distribution; the preparation method can satisfy different requirements for environment management, fire-resisting materials, medicine, and other special fields.

Owner:杨富巍

A titanium alloy surface high magnetic permeability and wear-resistant coating material for magnetic fluid sealing, its preparation method and application

ActiveCN111593344BHigh hardnessImprove magnetic permeabilityEngine sealsTransportation and packagingConductive coatingTitanium alloy

The invention belongs to the technical field of surface protection and magnetically conductive coating, and discloses a titanium alloy surface high magnetically conductive and wear-resistant coating material used for magnetic fluid sealing, a preparation method and application thereof. The coating material sequentially includes a wear-resistant layer, a main body layer and a transition layer, and the transition layer is located between the substrate and the main body layer; the composition of the transition layer is: 85-97% of iron-cobalt-vanadium alloy, 1-5% of Si , B 1-5%; the composition of the main body layer is: iron-cobalt-vanadium alloy 85-95%, Si 2-5%, B 2-5%, WC 1-5%; the composition of the wear-resistant layer is : Iron-cobalt-vanadium alloy 70-80%, Si 1-5%, B 1-5%, WC 10-20%. The coating material has multifunctional integration of high hardness, good wear resistance and high magnetic permeability. Prepared by laser cladding, the coating material can be used as a titanium alloy part of a magnetic fluid sealing system in the aerospace field.

Owner:GUANGDONG UNIV OF TECH +1

Zinc-nickel battery negative electrode material

ActiveCN106684362ALower internal resistanceIncrease profitCell electrodesNickel accumulatorsCarbon compositesHigh energy

The invention discloses a zinc-nickel battery negative electrode material. A basic zinc carbonate and carbon composite material is taken as a zinc-nickel battery negative electrode active substance, and a zinc-nickel battery negative electrode containing the basic zinc carbonate and carbon composite material and an Ni positive electrode are prepared to construct a soft package NiZn battery. The test result indicates that the overall electrochemical performance of the electrode and the battery containing the material is improved when the material is taken as the battery negative electrode material for use. The prepared soft package battery has the advantages of high energy density, coulombic efficiency and long cycle life.

Owner:JIANGSU UNIV OF TECH

A negative electrode material for a zinc-nickel battery and its preparation method and application

ActiveCN106848281BWide variety of sourcesLow costElectrode thermal treatmentAlkaline accumulator electrodesPhysical chemistryElectrochemistry

The invention belongs to the technical field of battery materials, and discloses a negative electrode material of a zinc-nickel battery, a preparation method and application thereof. The active material in the negative electrode material of the zinc-nickel battery of the present invention is basic zinc carbonate, and the basic zinc carbonate is prepared by reacting urea or ammonium bicarbonate with zinc salt; the invention also discloses the basic zinc carbonate in the negative material of the zinc-nickel battery Paste formulation of zinc carbonate, conductive agent, additives and binders. The test results of the soft-packed NiZn battery constructed by using the basic zinc carbonate as the negative electrode active material show that when the material is used as the negative electrode material of the battery, the overall electrochemical performance of the electrode and the battery containing the material is improved. The prepared pouch battery has good coulombic efficiency and cycle life, and the energy density of the battery is 130Wh kg ‑1 , the cycle stability is not less than 1200 times.

Owner:JIANGSU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com