A method for making sourdough steamed buns based on fermentation in cold storage

A technology of sour dough and fermentation method, which is applied in the field of food processing. It can solve the problems of different bread fluffiness, different appearance and taste requirements, and the production method of sour dough steamed bread cannot be simply applied, and achieve the effect of reliable process conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

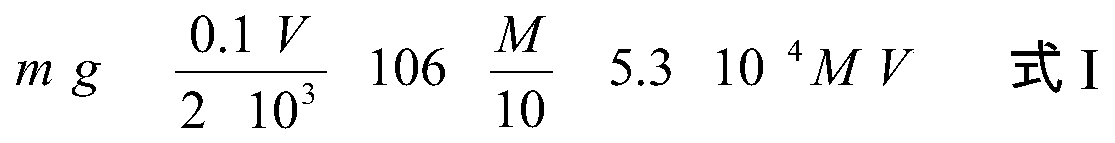

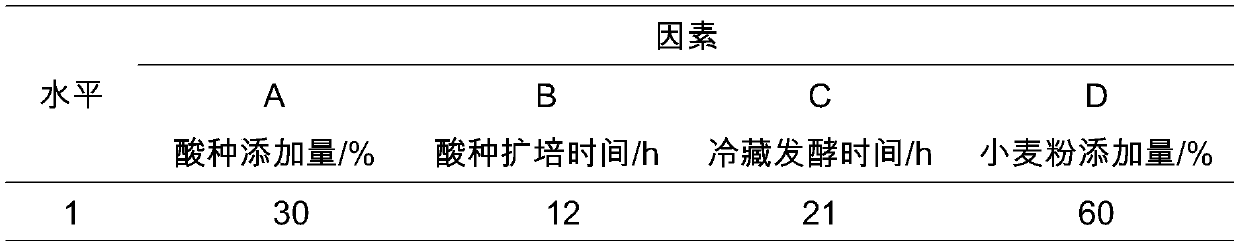

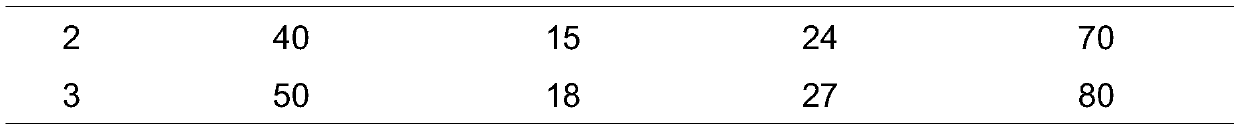

[0052] Four factors were selected: the amount of sour seed added (A), the time of sour seed expansion (B), the time of refrigerated fermentation (C), and the amount of wheat flour added to the middle seed dough (D). The specific volume of steamed bread and sensory score were used as evaluation indicators , an orthogonal experiment with four factors and three levels was carried out. Wherein, the mass percentages of the amount of the sour species accounted for the total amount of wheat flour used in sourdough steamed bread are respectively set as 30%, 40% and 50%; Set as 12h, 15h and 18h; The refrigerated fermentation time of described middle kind of dough is respectively set as 21h, 24h and 27h; Set to 60%, 70% and 80%. The total amount of wheat flour used when making a single batch (or a single combination) of sourdough steamed bread is 1000g. The factors and levels of the orthogonal test are shown in Table 1.

[0053] Table 1L 9 (4 3 ) Orthogonal test factors and levels ...

Embodiment 2

[0060] The quality evaluation of the sour dough steamed bread prepared in Example 1 was carried out, including the determination of volume, specific volume and aspect ratio, the determination of texture characteristics and sensory evaluation.

[0061] 1) Determination of volume, specific volume and aspect ratio

[0062] Referring to the AACCI 10-14.01 standard method, place the cooled steamed buns on the stand of the volumetric instrument, measure its volume and record the height, bottom diameter and other data; calculate the specific volume according to the mass of the steamed buns.

[0063] 2) Determination of texture properties

[0064] The cooled steamed buns were cut into uniform thin slices with a thickness of 15mm, and the middle three slices were taken to measure the texture properties of the steamed buns. The measurement parameters of the texture analyzer are: TPA mode; P / 36R aluminum probe; the speed before the test is 1.0mm / s, the speed of the test is 1.0mm / s, the ...

Embodiment 3

[0080] Three different wheat flour raw materials (advanced snowflake flour, steamed bread basic flour 1 and steamed bread basic flour 2, respectively produced by Hebei Heima Wheat Flour Co., Ltd., Xinxiang Sifeng Flour Co., Ltd. and COFCO Zhengzhou Haijia Food Co., Ltd.) Physicochemical properties and dough rheological properties were analyzed and determined.

[0081] Determination of physical and chemical properties of wheat flour:

[0082] Determination of moisture content, refer to GB / T 21305-2007 standard method;

[0083] Determination of ash content, refer to GB / T 5505-2008 standard method;

[0084] Determination of crude protein content, refer to GB / T 5511-2008 standard method;

[0085] Determination of wet gluten content, refer to GB / T 5506.2-2008 standard method;

[0086] For the determination of falling number, refer to the GB / T 10361-2008 standard method;

[0087] Determination of pasting properties, refer to AACC 76-21 standard method.

[0088] Determination of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com