Rare earth phosphate nano-phosphor and preparation method thereof

A technology of rare earth phosphate and nano-fluorescent powder, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of unfavorable practical application, narrow application range, and high price, and achieve stable and reliable process conditions, low cost, and particle size small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (Example 1, Rare Earth Phosphate Nano Phosphor Powder)

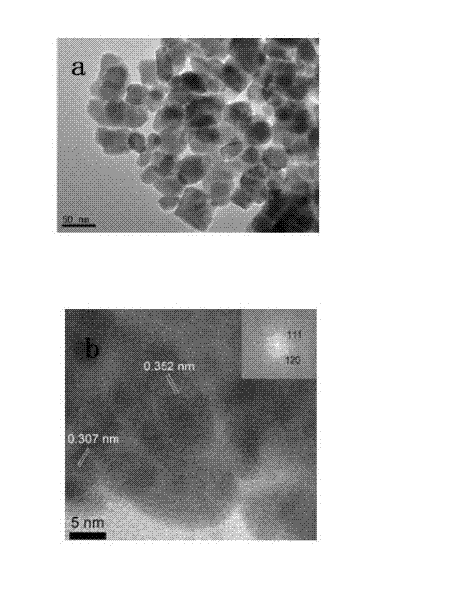

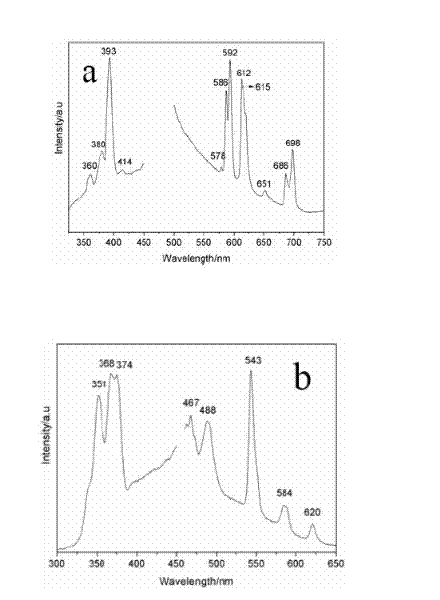

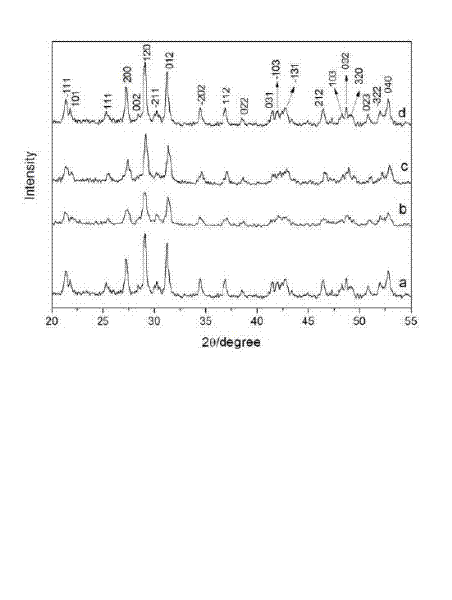

[0032]The rare earth phosphate nano-phosphor powder of this embodiment includes a structural formula of Bi (1-y) PO 4 :y Eu 3+ Nano-rare earth phosphate particles and adsorption on Bi (1-y) PO 4 :y Eu 3+ A layer of oleate ions outside the nano-rare earth phosphate particles; the particle size of the nano-rare earth phosphate particles is 40-80nm, 0.05— It is adsorbed on the surface of nano-rare earth phosphate particles, while the organic long chain at the other end of the oleate ion as a lipophilic group is far away from the surface of nano-rare earth phosphate particles; It emits red light visible to the naked eye under ultraviolet light at 254 nm.

Embodiment 2

[0033] (Example 2, Rare Earth Phosphate Nano Phosphor Powder)

[0034] The rare earth phosphate nano-phosphor powder of this embodiment includes a structural formula of Bi (1-y) PO 4 :y Tb 3+ Nano-rare earth phosphate particles and adsorption on Bi (1-y) PO 4 :y Tb 3+ A layer of oleate ions outside the nano-rare earth phosphate particles; the particle size of the nano-rare earth phosphate particles is 40-80nm, 0.05— It is adsorbed on the surface of nano-rare earth phosphate particles, while the organic long chain at the other end of the oleate ion as a lipophilic group is far away from the surface of nano-rare-earth phosphate particles; the phosphor is a white powder with a wavelength of 254 It emits green light visible to the naked eye under ultraviolet light of 1 nm.

Embodiment 3

[0035] (Example 3, Rare Earth Phosphate Nano Phosphor Powder)

[0036] The rare earth phosphate nano-phosphor powder of this embodiment includes a structural formula of Bi (1-y) PO 4 :y Sm 3+ Nano-rare earth phosphate particles and adsorption on Bi (1-y) PO 4 :y Sm 3+ A layer of oleate ions outside the nano-rare earth phosphate particles; the particle size of the nano-rare earth phosphate particles is 40-80nm, 0.05— It is adsorbed on the surface of nano-rare earth phosphate particles, while the organic long chain at the other end of the oleate ion as a lipophilic group is far away from the surface of nano-rare-earth phosphate particles; the phosphor is a white powder with a wavelength of 254 It emits a light red light visible to the naked eye under ultraviolet light of 10 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com