Method for preparing reducing sugar by supercritical hydrolysis of plant fibers and semi-continuous reactor thereof

A plant fiber and reaction device technology, which is applied in chemical/physical/physical-chemical stationary reactors, sugar production, monosaccharide, etc. problem, to achieve the effect of accurate monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

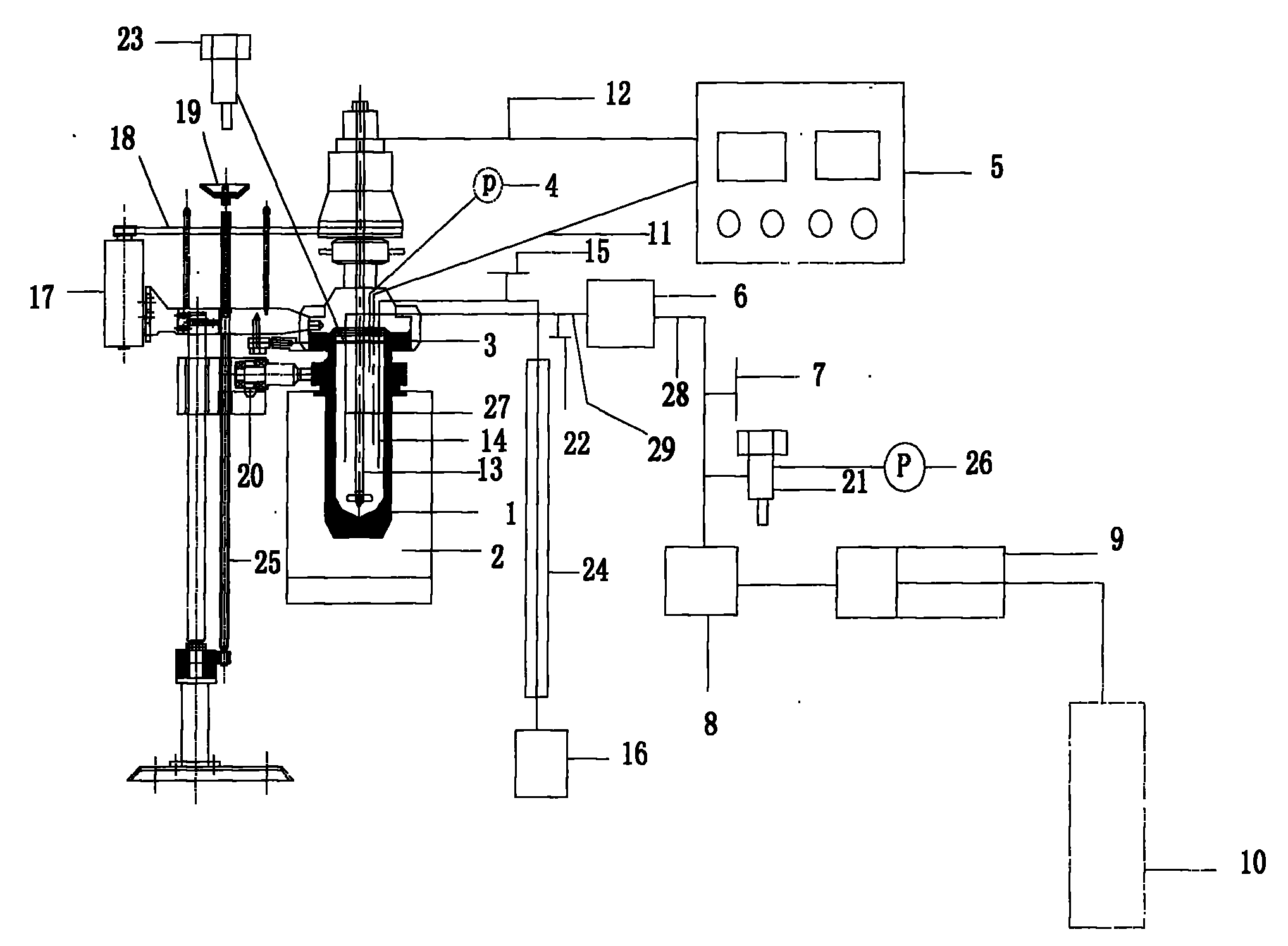

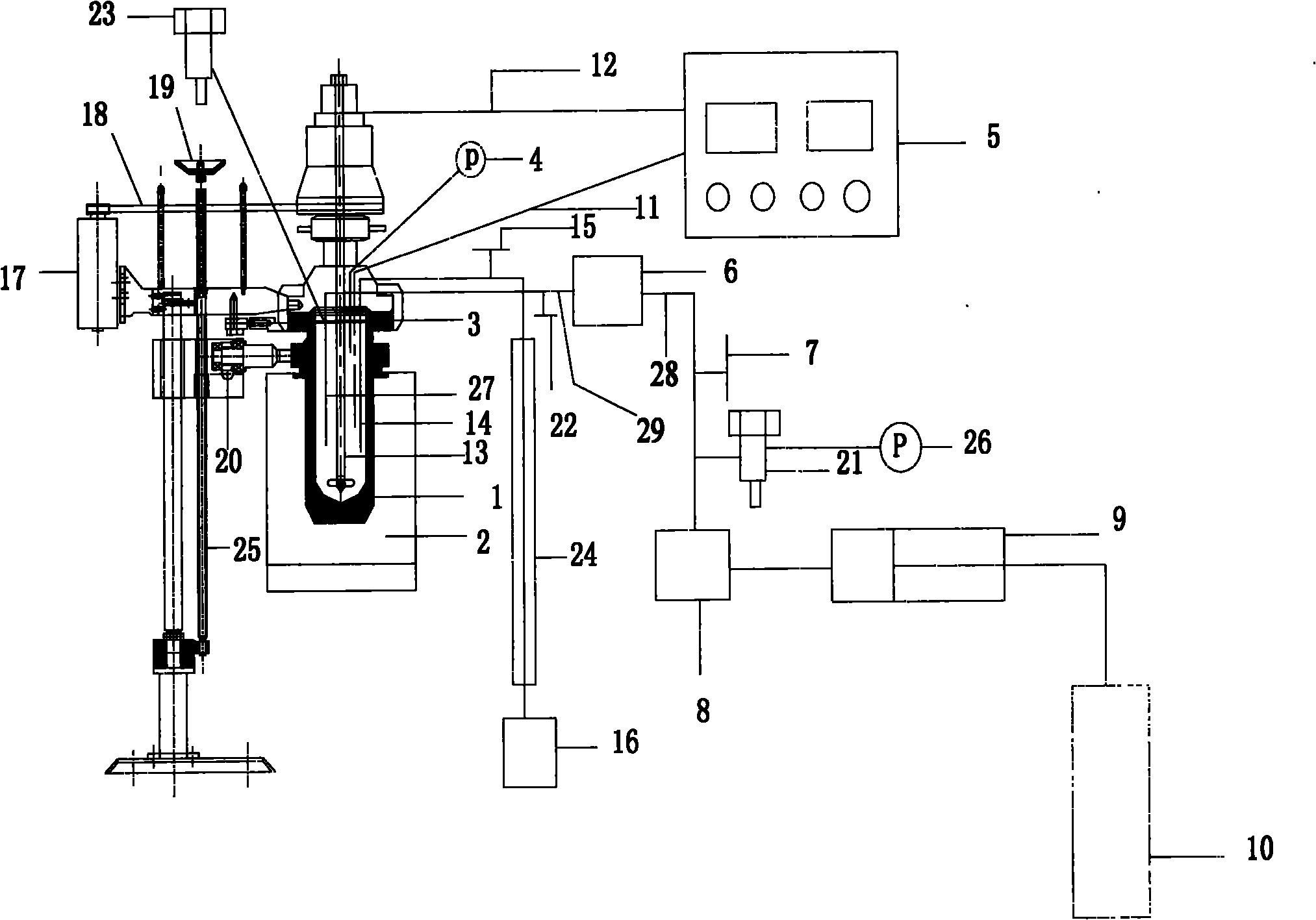

Method used

Image

Examples

Embodiment 1

[0023] Unload the 8 nuts on the cover 3 of the reactor body with a wrench, shake the lifting hand wheel 19 on the lifting screw 25 counterclockwise, the reactor body 1 will descend with the lifting screw 25, and when the reactor body 1 falls to the bottom, Add pure water more than 3 times the volume of the material into the reactor body with a measuring cylinder, then shake the lifting handwheel 19 on the lifting screw 25 clockwise, and the reactor body 1 rises with the lifting screw 25 until it reaches the level of the kettle cover. 3 When matching, put 8 nuts on the bolts of the kettle cover 3 and tighten them diagonally, open the nitrogen cylinder, the valve on the reactor body pipeline, use nitrogen to drive away the air in the kettle, and close the valve at the bottom of the storage tank 6. The spherical valve 22 is connected to the electric heating furnace 2 on the reaction kettle body 1, and the condensed water pipeline is opened to condense the rotor to avoid degaussing...

Embodiment 2

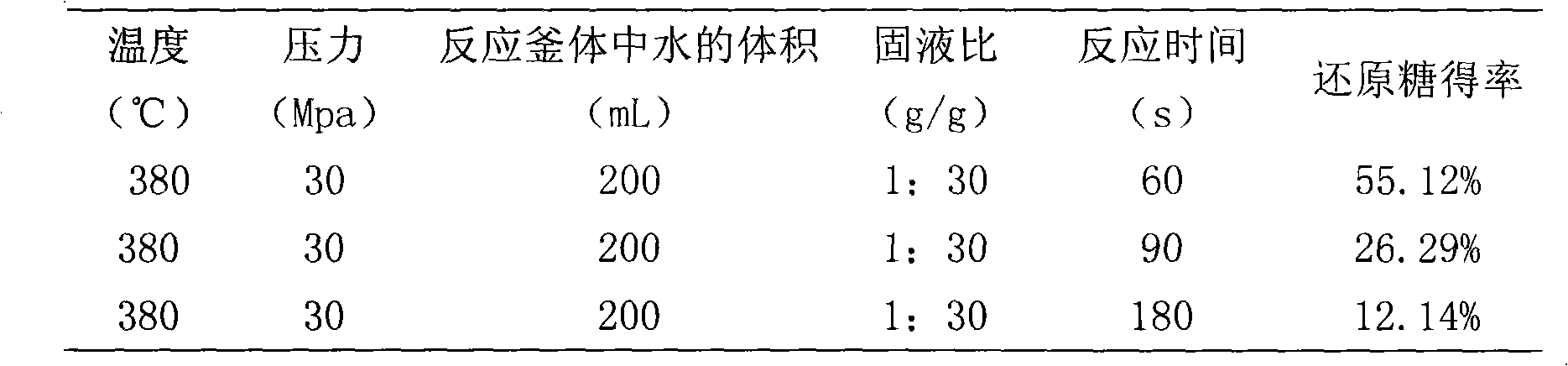

[0032] In order to illustrate that the present invention has a shorter reaction time than the batch reaction device, plant fiber waste corrugated carton (OCC) is selected as raw material, and the process conditions are: temperature 390 ° C, pressure 23-24MPa, the volume of water in the reactor body 150mL, The plant fiber slurry solid-liquid ratio (g / g) 1: 65 that adds in the storage tank, reaction time 10-90s, rotating speed 100rpm, its result is as follows table 3

[0033] Table 3: Hydrolyzed reducing sugar yield of OCC at 390°C, 23-24Mpa

[0034]

[0035]

[0036] It can be seen from Table 3 that at a temperature of 390°C, a pressure of 23Mpa, and a volume of water in the reactor body of 150mL, when the solid-liquid ratio (g / g) of the added plant fiber slurry is 1:65, the reaction time only needs 10s, and the reducing sugar yield It is 51.39%, and the traditional batch reaction device needs several minutes or even dozens of minutes for the light temperature raising pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com