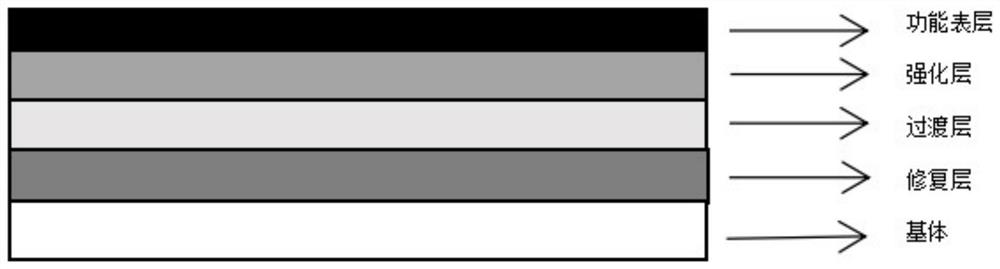

Titanium alloy surface repairing and strengthening functional coating integrated coating material and preparation method and application thereof

A technology for surface repair and coating materials, which is applied in the direction of metal material coating technology, coating, ion implantation plating, etc., can solve the problems of poor wear resistance and high temperature resistance, poor bonding force, low hardness, etc., and achieve improvement The effect of impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A coating material integrating titanium alloy surface repair and strengthening functional coating, using Ti-6Al-4V titanium alloy as the base material, is controllably prepared by vacuum arc ion deposition and magnetron sputtering composite technology, the specific steps as follows:

[0043] (1) Pre-preparation of the base material: grinding the surface of the titanium alloy to remove the oxide film on the surface of the titanium alloy;

[0044] (2) Surface cleaning of the substrate material: Ultrasonic cleaning of the titanium alloy substrate in acetone for 9 minutes, then ultrasonic cleaning in absolute ethanol for 8 minutes, and finally ultrasonic cleaning in deionized water for 10 minutes to remove surface grease and pollutants, and then blow dry. Make the surface of the original titanium alloy smooth; after drying, fix it on the workpiece rack in the vacuum chamber, and the distance between the titanium alloy workpiece and the Ti target is 30cm;

[0045] (3) Surfa...

Embodiment 2

[0053] A coating material integrating titanium alloy surface repair and strengthening functional coating, using Ti-6Al-4V titanium alloy as the base material, is controllably prepared by vacuum arc ion deposition and magnetron sputtering composite technology, the specific steps as follows:

[0054] (1) Pre-preparation of the base material: grinding the surface of the titanium alloy to remove the oxide film on the surface of the titanium alloy;

[0055] (2) Surface cleaning of the substrate material: Ultrasonic cleaning of the titanium alloy substrate in acetone for 9 minutes, then ultrasonic cleaning in absolute ethanol for 8 minutes, and finally ultrasonic cleaning in deionized water for 10 minutes to remove surface grease and pollutants, and then blow dry. Make the surface of the original titanium alloy smooth; dry it and fix it on the workpiece rack in the vacuum chamber, the distance between the titanium alloy workpiece and the Ti target is 35cm;

[0056] (3) Surface pret...

Embodiment 3

[0062] A coating material integrating titanium alloy surface repair and strengthening functional coating, using Ti-6Al-4V titanium alloy as the base material, is controllably prepared by vacuum arc ion deposition and magnetron sputtering composite technology, the specific steps as follows:

[0063] (1) Pre-preparation of the base material: grinding the surface of the titanium alloy to remove the oxide film on the surface of the titanium alloy;

[0064] (2) Surface cleaning of the substrate material: Ultrasonic cleaning of the titanium alloy substrate in acetone for 9 minutes, then ultrasonic cleaning in absolute ethanol for 8 minutes, and finally ultrasonic cleaning in deionized water for 10 minutes to remove surface grease and pollutants, and then blow dry. Make the surface of the original titanium alloy smooth; dry it and fix it on the workpiece rack in the vacuum chamber, the distance between the titanium alloy workpiece and the Ti target is 40cm;

[0065] (3) Surface pret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com