Phosphate ore-phosphoric acid-gypsum process flue gas desulphurization system and process

A desulfurization system and gypsum method technology, applied in the field of phosphate rock-phosphoric acid-gypsum method flue gas desulfurization system, can solve the problems of non-conformity with circular economy, resource utilization and sustainable development strategies, etc., and achieve good desulfurization effect and production. Simple device and reliable process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

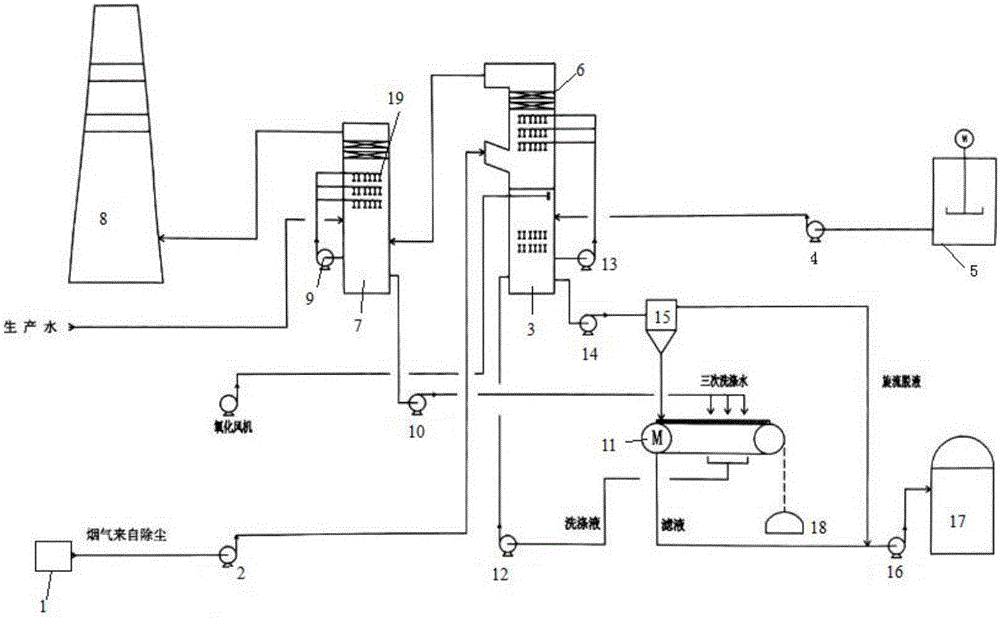

[0028] The working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] Differences from calcium desulfurization

[0030] Different from the typical calcium method flue gas desulfurization technology, the desulfurization agent used in the phosphate rock-phosphoric acid-gypsum method flue gas desulfurization is phosphate rock, and its product, process principle, process and control indicators have all changed, and the The biggest one is the desulfurization product. The final desulfurization product is no longer sulfur gypsum, but dilute phosphoric acid and fluosilicic acid, and phosphogypsum becomes waste residue. This is the essential difference between the two. The biggest differences in the process are as follows:

[0031] 1) Between the desulfurization absorption tower 3 and the chimney 8, add a defluorination absorption tower 7 made of glass fiber reinforced plastics, 3 fluorine circulating ceramic pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com