Cathode material for nickel-zinc battery and nickel-zinc battery employing cathode material

A zinc-nickel battery and cathode material technology, applied in the field of energy storage, can solve the problems of low energy density, high price, consumption of acid and oxidant, etc., achieve high energy density and power density, stable and reliable process conditions, and simple process flow easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1. (Modification of Carbon Material)

[0028] The carbon material used in this embodiment is a surface-treated carbon material. The carbon material includes carbon nanotubes, nanofibers, conductive carbon black, graphene, etc., and the surface is modified with oxygen-containing functional groups such as carboxyl groups, hydroxyl groups, and epoxy groups. The interior of the carbon material remains intact and maintains good electrical conductivity.

Embodiment 2

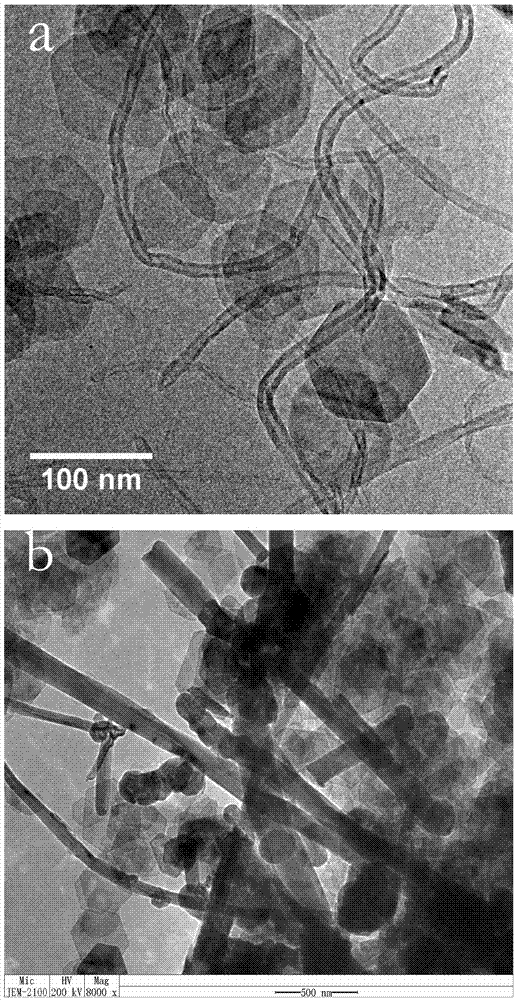

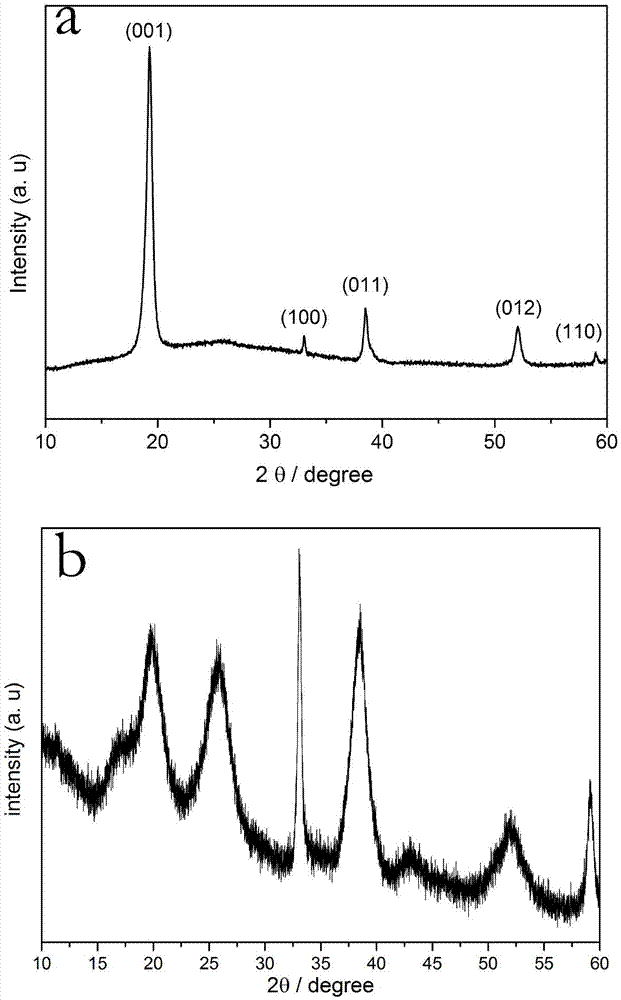

[0029] Example 2: Ni(OH) 2 / Carbon Nanotubes)

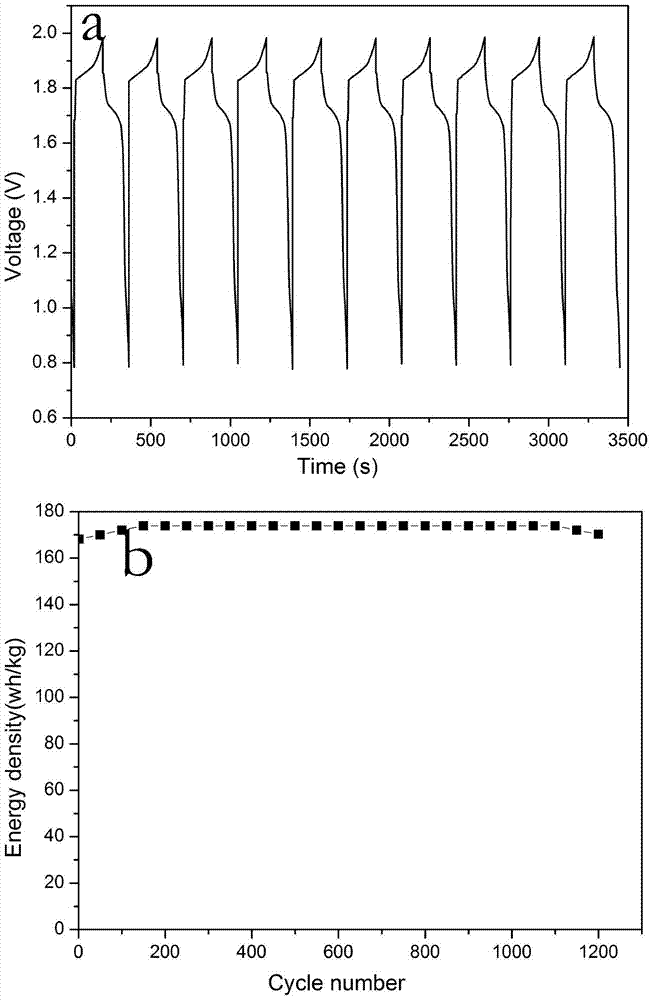

[0030] Ni(OH) of this embodiment 2 / Carbon nanotubes are composite materials, in which the carbon nanotubes are single-wall, double-wall or multi-wall carbon nanotubes. The diameter of the nanotubes is 50-200nm and the length is 100nm-5μm. The surface of the nanotubes is treated with carboxyl groups on the surface Oxygen-containing functional groups such as, hydroxyl and epoxy groups, Ni(OH) 2 Covalently bonded with carbon nanotubes, electrons can be quickly transferred through carbon nanotubes during charging and discharging. The composite material is a black powder and has high energy density and power density when assembled into NiZn batteries. When the density is 140-160Wh / Kg, the cycle stability reaches more than 900 times.

Embodiment 3

[0031] (Example 3, Ni(OH) 2 / Nano Carbon Fiber)

[0032] Ni(OH) of this embodiment 2 / Nanofibers are composite materials, where the diameter of the nanofibers is 50-200nm, and the length is 500nm-5μm. The surface of the nanofibers is treated, and the surface has oxygen-containing functional groups such as carboxyl, hydroxyl and epoxy groups, Ni(OH) 2 It is covalently bonded with carbon nanofibers, and electrons can be quickly transferred through carbon nanofibers during charging and discharging. The composite material is black powder and has high energy density and power density when assembled into NiZn batteries. When the density is 140-160Wh / Kg, the cycle stability reaches more than 900 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com