Inorganic aluminate luminescent microcrystalline glass and preparation method thereof

A glass-ceramic and aluminate technology, applied in the field of luminescent materials and lighting engineering, can solve the problems of easy aging and low stability of phosphors, and achieve the effects of stable and reliable process conditions, stable physicochemical properties, and pure luminous color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 19.52g of strontium carbonate, 10.11g of alumina, 5.95g of silicon dioxide and 0.22g of praseodymium oxide, and grind the above raw materials by ball mill or mortar to obtain uniform powder. Put the ground raw material into an alumina crucible, place it at 1600°C for 30 minutes, and keep the raw material in a molten state. Pour the molten raw material onto a stainless steel plate, quench and form it, and make glass. Heat-treat the formed glass at 1100°C for 8 hours in a hydrogen reducing atmosphere to obtain 40SrO-30Al 2 o 3 -30SiO 2 -0.2Pr 2 o 3 Microcrystalline glass.

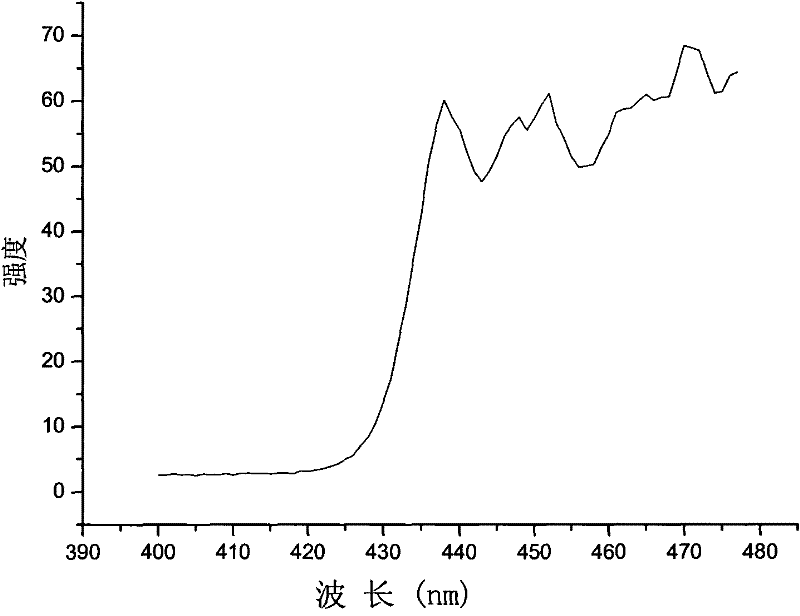

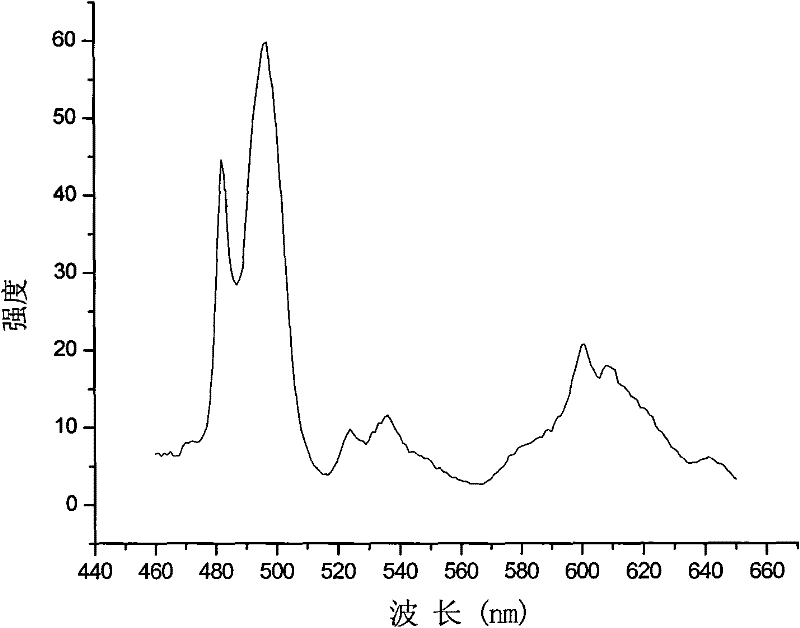

[0026] The glass-ceramics obtained in this example can be excited by visible light in the wavelength range of 430-475nm. Under the excitation of blue-violet light at 437nm, the glass-ceramic of this example shows blue-green light emission. Such as figure 1 As shown, the glass-ceramic excitation wavelength range of this embodiment is 430-475nm, such as figure 2 As shown, the emission wavel...

Embodiment 2

[0028] Weigh 17.11 g of strontium carbonate, 11.82 g of aluminum oxide, 5.97 g of silicon dioxide and 0.19 g of praseodymium oxide, and grind the above raw materials by ball mill or mortar to obtain uniform powder. Put the ground raw material into an alumina crucible, place it at 1620°C for 30 minutes, and keep the raw material in a molten state. Pour the molten raw material onto a stainless steel plate, quench and form it, and make glass. The formed glass is heat-treated at 1150°C for 10 hours in a carbon monoxide reducing atmosphere to obtain 35SrO-35Al 2 o 3 -30SiO 2 -0.175Pr 2 o 3 Microcrystalline glass.

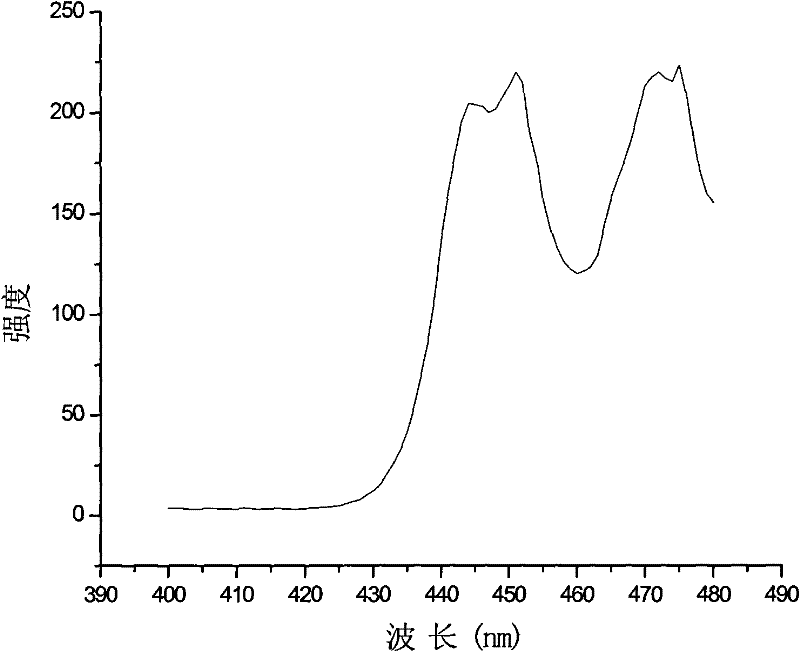

[0029] The glass-ceramics obtained in this example can be excited by visible light in the wavelength range of 430-475nm. Under the excitation of blue-violet light at 445nm, the glass-ceramics of this example presents a blue-green luminescent color. Such as image 3 As shown, the glass-ceramic excitation wavelength range of this embodiment is 430-475nm, such as Fi...

Embodiment 3

[0031] Weigh 17.07g of strontium carbonate, 11.79g of aluminum oxide, 5.95g of silicon dioxide and 0.25g of praseodymium oxide, and grind the above raw materials by ball mill or mortar to obtain uniform powder. Put the ground raw material into an alumina crucible, place it at 1600°C for 30 minutes, and keep the raw material in a molten state. Pour the molten raw material onto a stainless steel plate, quench and form it, and make glass. Put the formed glass in a hydrogen reducing atmosphere and heat treat it at 800°C for 10 hours to obtain 35SrO-35Al 2 o 3 -30SiO 2 -0.23Pr 2 o 3 Microcrystalline glass.

[0032] The glass-ceramics obtained in this embodiment can be excited by visible light in the wavelength range of 425-475nm. Under the excitation of 441nm blue-violet light, the luminescent color of the glass-ceramic of this embodiment is blue-green. Such as Figure 5 As shown, the glass-ceramic excitation wavelength range of this embodiment is 425-475nm, such as Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com