Preparation method of fluorescent carbon quantum dot

A technology of carbon quantum dots and fluorescence, applied in the field of preparation of fluorescent carbon quantum dots, to achieve the effects of easy scale-up and batch production, cheap raw materials, and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Dry the recovered coffee grounds, weigh 1g of coffee grounds and add 50ml of deionized water, mix ultrasonically for 2h, then put the mixture into a 50ml polytetrafluoroethylene reactor, and react at 170°C for 5h. Cool the reaction kettle at room temperature, filter with filter paper after cooling, centrifuge at 15,000rpm for 5min, and take the supernatant liquid to obtain a completely dispersed carbon quantum dot dispersion, which is golden yellow. After evaporation, the concentration becomes darker and the color is dark brown.

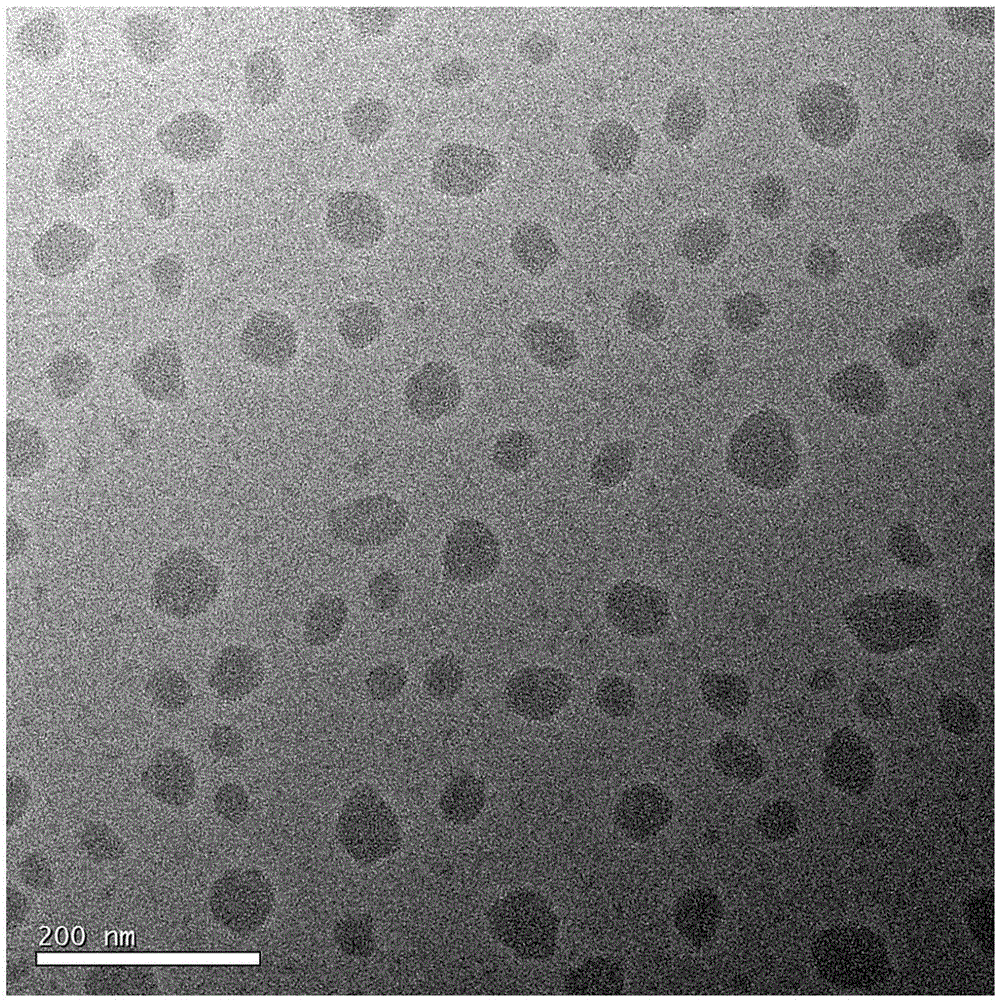

[0023] Such as figure 1 As shown in the TEM photo, the prepared carbon quantum dots are completely dispersed without agglomeration, and the shape is spherical, the particle size is 26.5-73.3nm, and the average particle size is 44.0nm.

Embodiment 2

[0025] Dry the recovered coffee grounds, weigh 3g of coffee grounds and add 50ml of deionized water, mix ultrasonically for 2h, then put the mixture into a 50ml polytetrafluoroethylene reactor, and react at 190°C for 5h. Cool the reaction kettle at room temperature, filter with filter paper after cooling, centrifuge at 15,000 rpm for 5 minutes, and take the supernatant liquid to obtain a completely dispersed dispersion of carbon quantum dots, which is golden yellow. After evaporation, the concentration becomes darker and the color is dark brown.

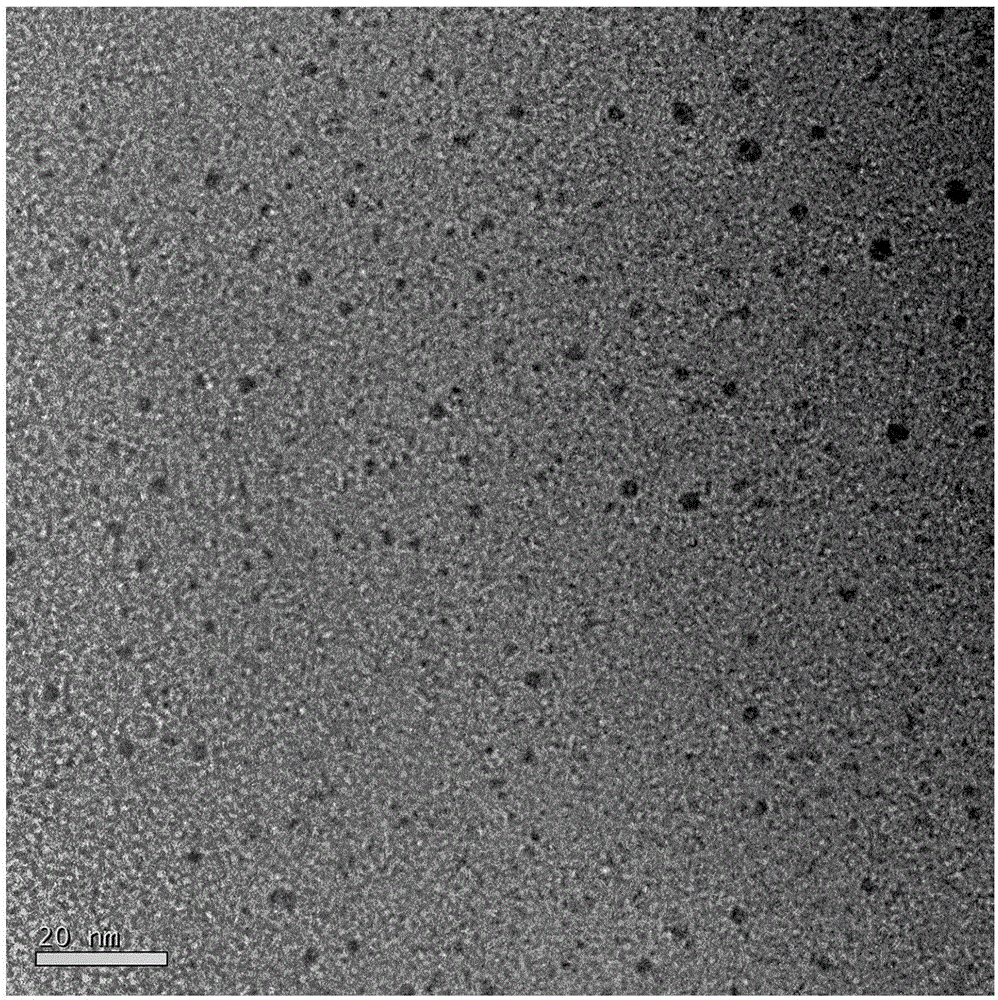

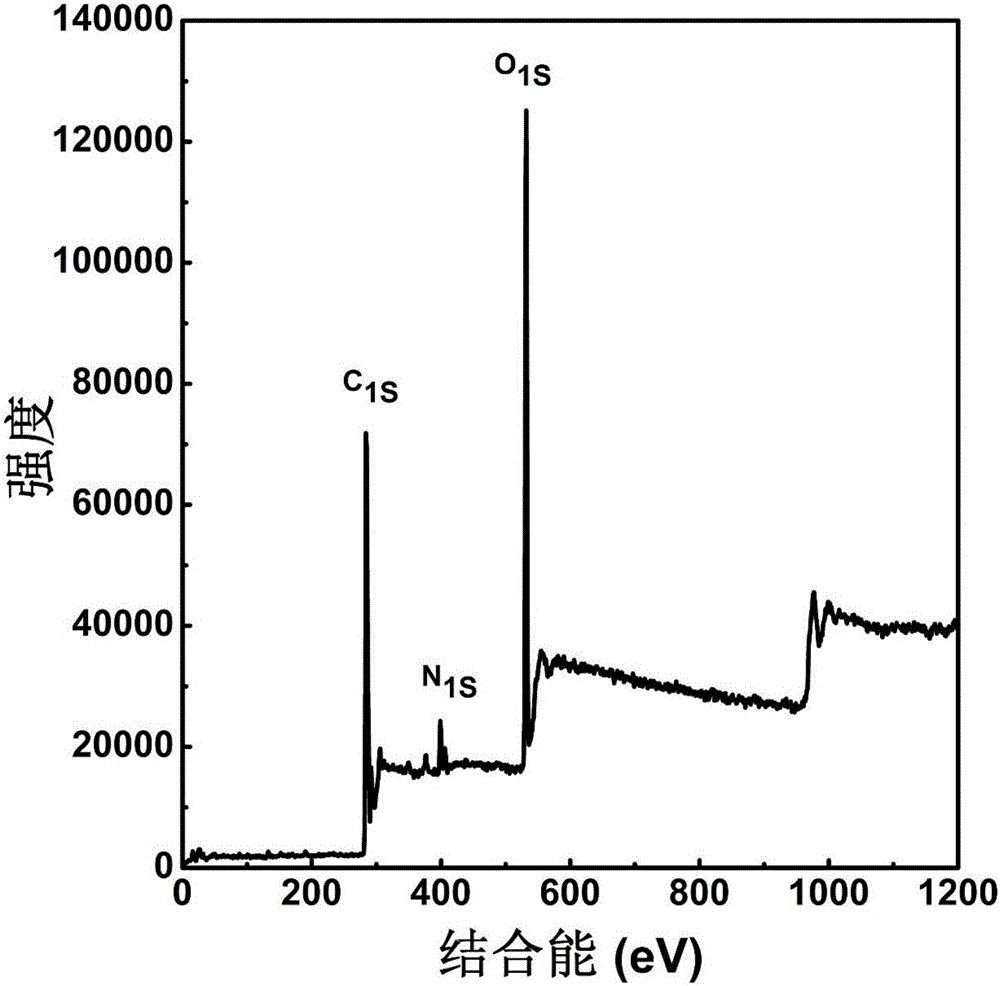

[0026] Such as figure 2 As shown in the TEM photo, the prepared carbon quantum dots are completely dispersed without agglomeration, and the shape is spherical, with a particle size of 1.1-4.4nm and an average particle size of 2.8nm. Take a certain amount of dispersion liquid of carbon quantum dots and evaporate to dryness at 80°C. Such as image 3 It is the XPS spectrum of carbon quantum dot particle powder. There are C, H, O, a...

Embodiment 3

[0028] Dry the recovered coffee grounds, weigh 3g of coffee grounds and add 50ml of deionized water, mix ultrasonically for 2h, then put the mixture into a 50ml polytetrafluoroethylene reactor, and react at 190°C for 10h. Cool the reaction kettle at room temperature, filter with filter paper after cooling, centrifuge at 15,000rpm for 5min, and take the supernatant liquid to obtain a fully dispersed carbon quantum dot dispersion, which is golden yellow. After evaporation, the concentration becomes darker and the color is dark brown.

[0029] The prepared carbon quantum dots are completely dispersed without agglomeration, the shape is spherical, the particle size is 2.2-4.6nm, and the average particle size is 3.4nm. Such as Figure 5 As shown, the prepared carbon quantum dot dispersion liquid has an obvious emission peak in the visible light band under the excitation of 650-900 nm. The emission peak is red-shifted with the increase of the excitation wavelength, which is an exc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com