Preparation method of acanthopanax obovatus Hoo polysaccharide iron and application thereof

A technology of Acanthopanax ovalifolia and polysaccharide iron, which is applied in the field of drug synthesis, can solve the problems of high daily cost, and achieve the effects of low production cost, operability, and reliable process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

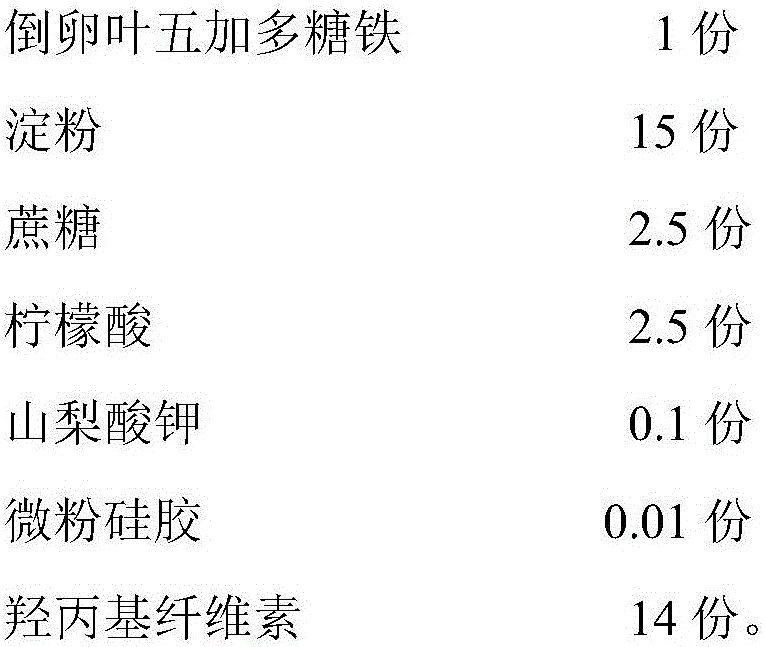

Embodiment 1

[0026] A preparation method of Acanthopanax obtusa polysaccharide iron, specifically according to the following steps:

[0027] Step 1: Extract Acanthopanax Obovatus polysaccharide: Dry the rhizome of Acanthopanax obovata at 80℃, smash it through a 60-mesh sieve, weigh 8g of the pulverized Acanthopanax obtusa rhizome, and use 12 times the volume Reflux the dehydrated ethanol for degreasing twice, 1h each time, filter, dry the filter residue, use double distilled water, according to the material-to-liquid ratio 1:14g / mL, extract once at 75℃, combine the extracts, and then press 1g The medicinal materials are concentrated into 1 mL for concentration, and Sevage reagent is added to the concentrated solution so that the volume ratio of the concentrated solution to Sevage reagent is 1:4. After being thoroughly mixed by a 2500r / min homogenizer, centrifuged, the supernatant is taken and the Sevage reagent is added. The volume ratio of the supernatant to the Sevage reagent is 1:4. The Se...

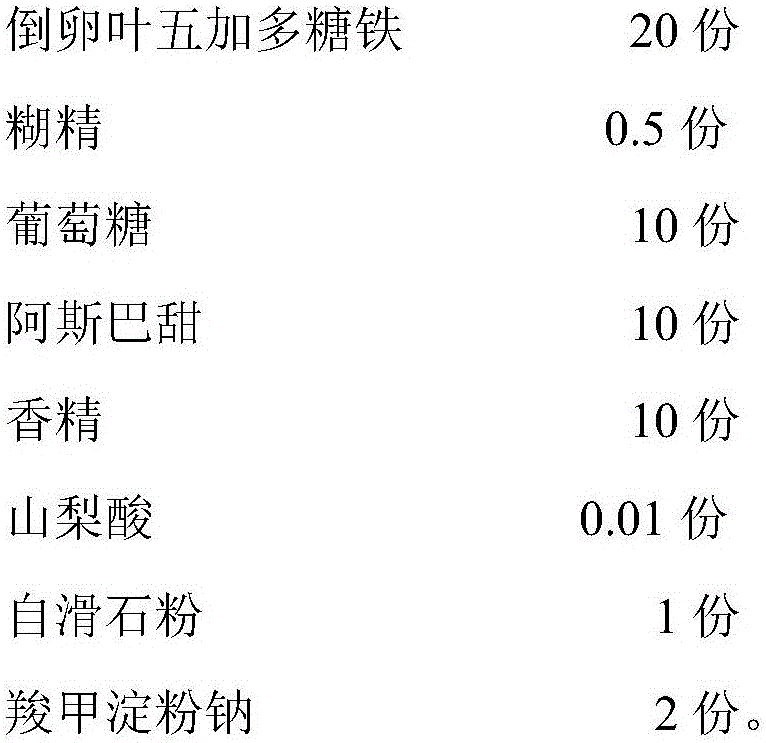

Embodiment 2

[0034] A preparation method of Acanthopanax obtusa polysaccharide iron, specifically according to the following steps:

[0035] Step 1: Extract Acanthopanax Obovata polysaccharide: Dry the rhizome of Acanthopanax obovata at 80℃, smash it through a 60-mesh sieve, weigh 10g of the smashed Acanthopanax rhizome and use 10 times the volume Reflux the absolute ethanol for 2 times, 3h each time, filter, dry the filter residue, use double distilled water, according to the material-to-liquid ratio 1:15g / mL, extract 3 times at 80℃, combine the extracts, and then press 1g The medicinal materials are concentrated into 1 mL for concentration, and the Sevage reagent is added to the concentrated solution so that the volume ratio of the concentrated solution to the Sevage reagent is 1:5. The concentrated solution is thoroughly mixed with a 3000r / min homogenizer and then centrifuged. The supernatant is taken and then the Sevage reagent is added. The volume ratio of the supernatant to the Sevage r...

Embodiment 3

[0042] A preparation method of Acanthopanax obtusa polysaccharide iron, specifically according to the following steps:

[0043] Step 1: Extract Acanthopanax Obovatus Polysaccharide: Dry the rhizome of Acanthopanax Obovata at 80℃, smash it through a 60-mesh sieve, weigh 12g of the pulverized Acanthopanax obtusa rhizome, and use 8 times the volume The absolute ethanol is refluxed for 2 times, 2h each time, filtered, and the filter residue is air-dried, then use double distilled water, according to the material-to-liquid ratio of 1:16g / mL, extract 2 times at 85℃, combine the extracts, and then press 1g. The medicinal materials are concentrated into 1 mL for concentration, and Sevage reagent is added to the concentrated solution so that the volume ratio of the concentrated solution to Sevage reagent is 1:6. After being thoroughly mixed by a 3500r / min homogenizer, centrifuged, the supernatant is taken and then Sevage reagent is added. The volume ratio of the supernatant to the Sevage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com