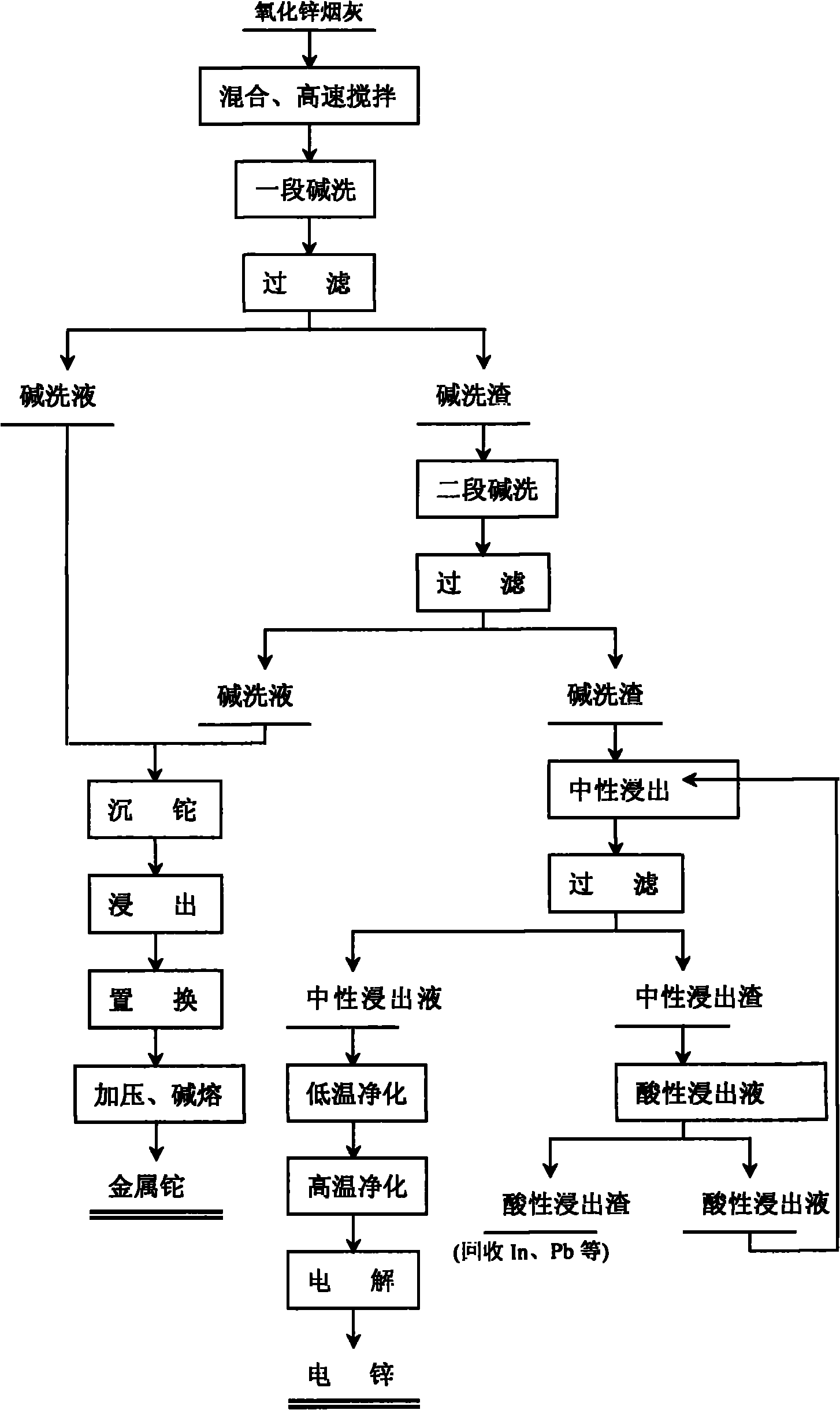

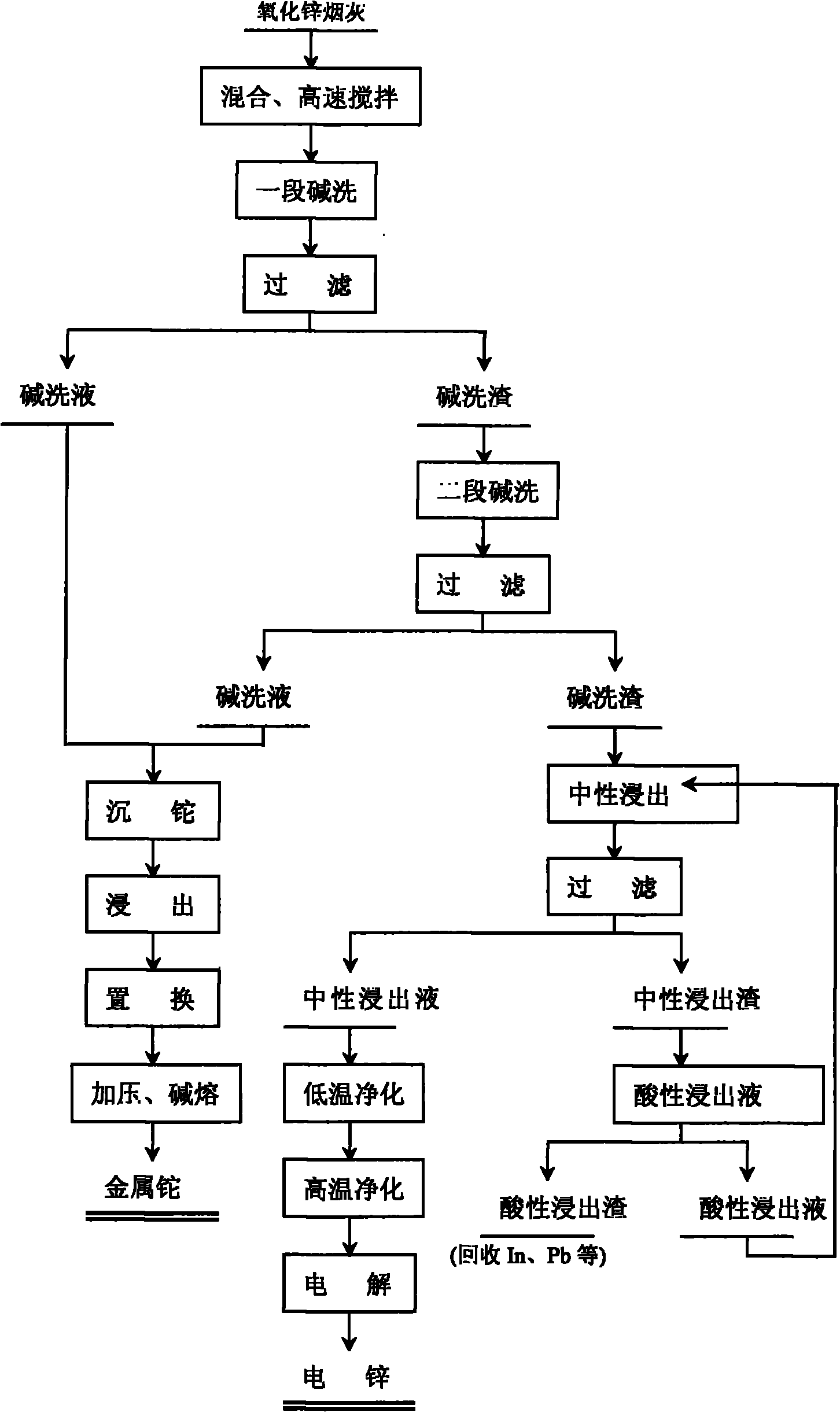

Comprehensive recovery method of zinc oxide fume dust

A recovery method and technology of zinc oxide, applied in the direction of improving process efficiency, can solve the problems of affecting zinc electrolysis, high cost, no economic feasibility of industrial application, etc., to achieve the effect of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Adopt the present invention to carry out comprehensive recovery to multi-hearth furnace zinc oxide soot, zinc oxide soot composition is following percentage by weight Zn35.87%, F2.65%, Cl5.81%, In0.0468%, Tl0.28%, Cd3. 13%, Cu0.12%, Fe1.47%, Pb15.35%, Co0.005%, Ni0.002%, As0.041%, Sb0.075%, according to the following steps:

[0056] Step 1: Calculate Na 2 CO 3 Add the total weight, and calculate according to the conventional method to make the F, Cl and Na contained in the zinc oxide soot to be treated 2 CO 3 The Na required for the reaction to form NaF and NaCl 2 CO 3 Theoretical weight; Alkali washing is carried out in two stages. In the first section of alkali washing step, the zinc oxide soot and the above-mentioned Na 2 CO 3 55% of theoretical weight in solid Na 2 CO 3 After mixing evenly, add water and stir at a high speed, the stirring speed is 600r / min, so that the zinc oxide soot is dissolved and mixed with Na 2 CO 3 reaction to generate a zinc oxide ...

Embodiment 2

[0063] Adopt the present invention to carry out comprehensive recovery to zinc oxide soot, the component of zinc oxide soot is following percentage by weight Zn35.87%, F2.65%, Cl5.81%, In0.0468%, Tl0.28%, Cd3.13 %, Cu0.12%, Fe1.47%, Pb15.35%, Co0.005%, Ni0.002%, As0.041%, Sb0.075%.

[0064] Follow these steps:

[0065] Step 1: Calculate Na 2 CO 3 Add the total weight, and calculate the F, Cl and Na contained in the zinc oxide soot according to the conventional method 2 CO 3 The Na required for the reaction to form NaF and NaCl 2 CO 3 Theoretical weight; Alkali washing is carried out in two stages. In the first section of alkali washing step, the zinc oxide soot and the above-mentioned Na 2 CO 3 65% of theoretical weight in solid Na 2 CO 3 After mixing evenly, add water and stir at a high speed, the stirring speed is 700r / min, so that the zinc oxide soot is dissolved and mixed with Na 2 CO 3 reaction to generate a zinc oxide soot solution containing solid slag, and f...

Embodiment 3

[0073] Adopt the present invention to carry out comprehensive recovery to multi-hearth furnace zinc oxide soot, the component of zinc oxide soot is following percentage by weight Zn35.87%, F2.65%, Cl5.81%, In0.0468%, Tl0.28%, Cd3.13%, Cu0.12%, Fe1.47%, Pb15.35%, Co0.005%, Ni0.002%, As0.041%, Sb0.075%.

[0074] Follow these steps:

[0075] Step 1: Calculate Na 2 CO 3 Add the total weight, and calculate the F, Cl and Na contained in the zinc oxide soot according to the conventional method 2 CO 3 The Na required for the reaction to form NaF and NaCl 2 CO 3 Theoretical weight; Alkali washing is carried out in two stages. In the first section of alkali washing step, the above-mentioned Na 2 CO 3 75% of theoretical weight in solid Na 2 CO 3 After mixing evenly, add water and stir at a high speed, the stirring speed is 750r / min, so that the zinc oxide soot is dissolved and mixed with Na 2 CO 3 reaction to generate a zinc oxide soot solution containing solid slag, and filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com